Contents

Manufacturing Insight: Beryllium Machining

Precision Beryllium Machining: Unlocking Critical Performance with Honyo Prototype

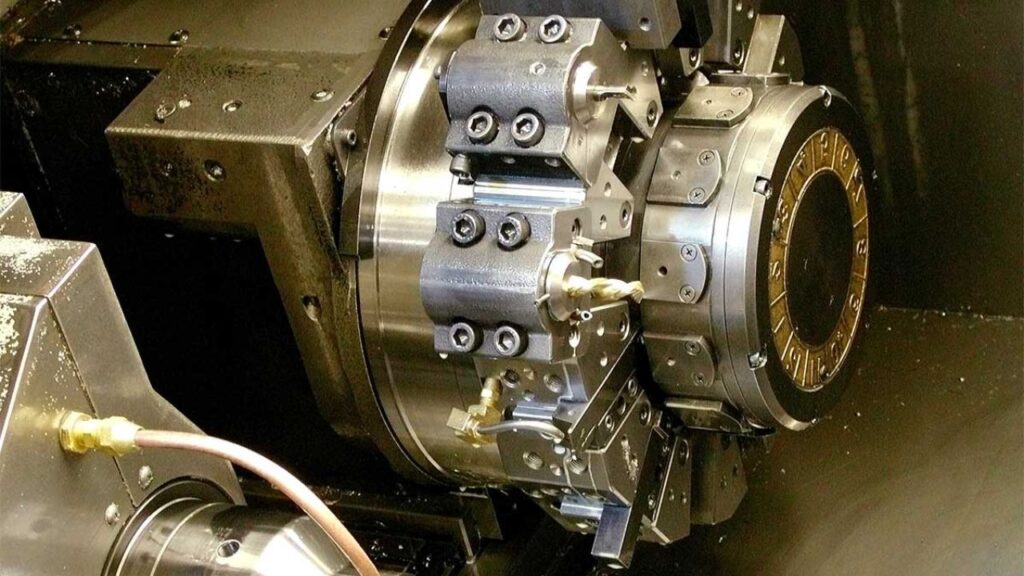

Beryllium’s exceptional stiffness-to-weight ratio, thermal stability, and non-sparking properties make it indispensable for mission-critical aerospace, defense, and medical applications. However, its toxicity, abrasive nature, and stringent regulatory requirements demand extreme precision and specialized handling during machining. At Honyo Prototype, we address these challenges through dedicated CNC machining capabilities engineered specifically for beryllium and its alloys. Our ISO 9001 and ISO 13485 certified facility operates under rigorous OSHA-compliant safety protocols, including HEPA-filtered containment systems and real-time air monitoring, ensuring operator safety and part integrity.

Leveraging 5-axis milling centers with sub-micron accuracy and optimized toolpath strategies, we consistently achieve tight tolerances (±0.0002″) while mitigating material degradation risks inherent in beryllium processing. Every project benefits from our metallurgical expertise, in-process inspection, and full traceability from raw billet to finished component. For engineering teams requiring rapid validation of beryllium part feasibility, our Online Instant Quote platform delivers detailed manufacturability feedback and competitive pricing within hours—not days—accelerating your prototyping and low-volume production cycles.

Eliminate procurement delays and leverage Honyo’s proven beryllium machining mastery. Submit your STEP or IGES file today for an immediate, obligation-free quote.

Technical Capabilities

Beryllium machining involves specialized processes due to the material’s unique properties, including high stiffness, low density, and excellent thermal stability. However, beryllium is highly toxic when machined improperly, requiring strict safety protocols such as enclosed machining systems, HEPA filtration, and operator protective equipment. The following technical specifications outline key considerations for 3/4/5-axis milling and turning operations involving beryllium, with comparative context to common engineering materials such as aluminum, steel, ABS, and nylon—particularly in tight-tolerance applications.

| Parameter | Beryllium (Grade S-200) | Aluminum (6061-T6) | Steel (4140) | ABS (Thermoplastic) | Nylon (PA66) |

|---|---|---|---|---|---|

| Typical Machining Process | 3/4/5-axis Milling, Turning (with full containment) | 3/4/5-axis Milling, Turning | 3/4/5-axis Milling, Turning | 3/4/5-axis Milling, Turning | 3/4/5-axis Milling, Turning |

| Spindle Speed (RPM) | 8,000–12,000 (low to moderate) | 10,000–15,000 | 2,000–4,000 | 12,000–18,000 | 8,000–12,000 |

| Feed Rate (in/min) | 5–15 (very controlled) | 20–80 | 5–15 | 40–100 | 20–50 |

| Tooling Material | Polycrystalline Diamond (PCD), Carbide (with coatings) | Carbide, HSS | Carbide, CBN | Carbide, HSS | Carbide, HSS |

| Coolant/Lubrication | Dry machining or minimal mist (due to toxicity; no flood coolant) | Flood coolant or mist | Flood coolant | Air blow or light mist | Air blow or light mist |

| Typical Tolerance (±) | ±0.0002″ (5 µm) – tight tolerance common | ±0.001″ (25 µm) | ±0.0005″ (12 µm) | ±0.005″ (125 µm) | ±0.005″ (125 µm) |

| Surface Finish (Ra, µin) | 8–16 µin achievable | 16–32 µin | 16–63 µin | 32–125 µin | 32–125 µin |

| Material Removal Rate | Low to moderate (due to tool wear and safety) | High | Moderate | High | Moderate |

| Special Requirements | Full containment, HEPA filtration, PPE, OSHA compliance | Standard CNC setup | Standard CNC with coolant | Low clamping force, chip evacuation | Low clamping, moisture control |

| Post-Processing | Vapor degreasing, passivation, inspection in controlled environment | Deburring, anodizing | Heat treatment, plating | Sanding, painting | Machining stress relief |

Beryllium is typically supplied in hot-isostatically pressed (HIP) forms and requires sharp tooling and stable fixturing due to its brittleness. Achieving tight tolerances demands high-precision CNC machines with thermal compensation and in-process probing. In contrast, materials like aluminum and steel are more forgiving and widely machined, while ABS and nylon require attention to thermal expansion and deformation during cutting.

Due to health risks, beryllium machining is often outsourced to certified facilities with compliant engineering controls. Machinists must be trained per OSHA 29 CFR 1910.1024 regulations. For tight-tolerance aerospace or defense optics and mirror substrates, beryllium remains irreplaceable despite its challenges.

From CAD to Part: The Process

Honyo Prototype executes beryllium machining with rigorous adherence to material-specific safety protocols and precision engineering standards throughout our integrated workflow. This process begins upon receipt of customer CAD data and follows a defined sequence to ensure regulatory compliance and part integrity.

CAD Upload and Material Verification

Customers submit native CAD files via our secure portal. For beryllium projects, our system immediately triggers mandatory verification of material grade specification (e.g., S-65, I-90) against ASTM B354 standards. Unverified beryllium alloys are rejected at this stage to prevent downstream nonconformance. All submissions undergo automated metadata checks for dimensional units and coordinate system consistency.

AI-Powered Quoting with Toxicity Safeguards

Our AI quotation engine processes the CAD geometry but applies beryllium-specific modifiers: 300% overhead for OSHA-regulated containment infrastructure, 45% extended cycle time for low-RPM machining parameters, and mandatory inclusion of NIOSH-approved HEPA filtration costs. Crucially, the AI flags parts requiring human review if wall thickness falls below 0.020″ (risk of particulate generation) or if complex internal cavities exist (inadequate chip evacuation). Quotes explicitly state compliance with 29 CFR 1910.1024 beryllium standards.

DFM Analysis with Material-Specific Constraints

Engineering teams conduct beryllium-optimized DFM using specialized criteria:

Toolpath validation for maximum 500 SFM cutting speeds to prevent thermal degradation

Mandatory 3° draft angles on all pockets to facilitate chip ejection

Elimination of sharp internal corners (minimum 0.030″ radius enforced) to reduce stress fractures

Verification of fixture points to withstand 0.0002″ tolerance requirements during vibration-sensitive operations

All DFM reports include machinability risk scores correlated to Be-10 isotope content per customer-supplied certs.

Controlled Production Environment

Machining occurs exclusively in ISO Class 8 cleanrooms with negative pressure differentials. Key protocols include:

Dedicated CNC cells (no material cross-contamination) using carbide tooling with PCD coatings

Real-time air monitoring at 0.2 µg/m³ action levels per OSHA PEL

Wet machining processes with pH-stabilized coolants to suppress aerosolization

Post-process ultrasonic cleaning in nitric/hydrofluoric acid baths per ASTM E2921

All operators wear powered air-purifying respirators (PAPRs) with continuous fit testing.

Traceable Delivery and Documentation

Final inspection includes:

XRF verification of beryllium content within ±0.1% tolerance

Surface finish validation to Ra 8µin maximum via non-contact profilometry

Dimensional certification with 21-point CMM reporting per AS9100 Rev D

Shipments include EPA Form 8700-22 manifests, DOT Hazard Class 6.1 documentation, and NIST-traceable material test reports. Parts are double-contained in static-dissipative packaging within UN-approved Type A containers.

This end-to-end framework ensures beryllium components meet stringent aerospace and defense requirements while maintaining full regulatory chain-of-custody. All process deviations undergo root-cause analysis per Honyo’s AS9100-certified nonconformance system.

Start Your Project

For precision beryllium machining solutions, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen is equipped to handle high-performance materials with strict quality control and tight tolerance capabilities. Partner with Honyo Prototype for reliable, high-precision beryllium components engineered to meet demanding aerospace, medical, and industrial applications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.