Contents

Manufacturing Insight: Bent Aluminum Sheet

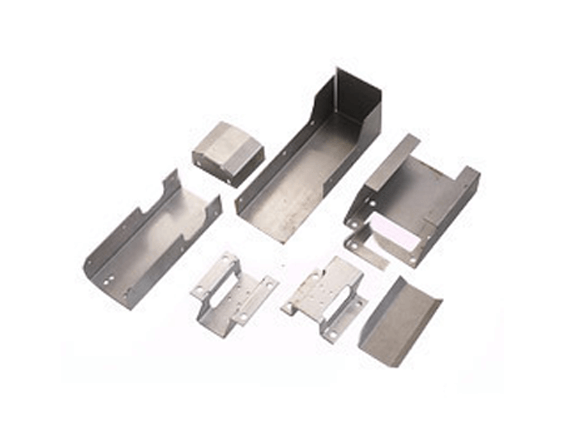

Precision Bent Aluminum Sheet Fabrication for Demanding Applications

Honyo Prototype delivers high-integrity bent aluminum sheet solutions engineered for critical industries including aerospace, medical devices, and industrial enclosures. Our sheet metal fabrication capabilities transform raw aluminum alloys—from 1100 and 3004 to 6061-T6—into complex geometries with tight tolerances and consistent repeatability. Utilizing advanced CNC press brakes with capacities up to 100 tons and backgauges accurate to ±0.0004″, we achieve precise bend angles from 5° to 180° while maintaining material integrity and avoiding deformation in thin-gauge or intricate parts.

Our technical expertise spans prototyping through low-volume production, with process optimization for challenging features such as offset bends, hemming, and multi-stage forming. All bent components adhere to strict geometric dimensioning and tolerancing (GD&T) standards, ensuring seamless integration into final assemblies. Complementary services including laser cutting, deburring, and finishing are managed in-house to eliminate supply chain delays.

Key technical parameters for aluminum bending are maintained per industry best practices:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Material Thickness | 0.020″ – 0.250″ | 0.015″ – 0.188″ |

| Bend Radius | 1x Material Thickness | 0.5x Material Thickness |

| Angular Tolerance | ±0.5° | ±0.25° |

| Flatness Tolerance | 0.005″ per foot | 0.002″ per foot |

Accelerate your development cycle with Honyo’s Online Instant Quote system. Upload CAD files (DXF, STEP, IPT) to receive a detailed fabrication assessment and competitive pricing within minutes—no manual submission delays. Our digital workflow validates manufacturability upfront, highlighting potential design optimizations for cost and lead time reduction. For mission-critical bent aluminum components where precision and speed are non-negotiable, Honyo Prototype provides engineered solutions backed by 15+ years of precision metalforming expertise.

Technical Capabilities

Technical specifications for bent aluminum sheet fabrication involve key processes including laser cutting, bending, and welding. These processes are influenced by material properties, thickness, and design requirements. While aluminum is the primary material for bent sheet components in many prototyping and production applications, comparisons with steel, ABS, and nylon help highlight advantages and limitations across materials.

Material Comparison for Sheet Fabrication – Laser Cutting, Bending, and Welding

| Material | Typical Sheet Thickness Range | Laser Cutting Compatibility | Bending Characteristics | Welding Process | Notes |

|---|---|---|---|---|---|

| Aluminum (e.g., 5052-H32, 6061-T6) | 0.5 mm – 6.0 mm | Excellent – clean cuts with minimal dross; reflective nature requires proper laser settings | Good formability; springback must be compensated in tooling; 5052 preferred for bending | TIG or MIG required; not all alloys are weldable; 6061 weldable but lower strength post-weld | Lightweight, corrosion-resistant; commonly used in enclosures, brackets, and structural components |

| Steel (e.g., Cold Rolled, Mild Steel) | 0.5 mm – 10.0 mm | Excellent – highly absorbent to laser energy; fast cutting speeds | Excellent bendability with predictable springback; wide range of bend radii achievable | Easily welded using MIG, TIG, or spot welding | Higher strength than aluminum; heavier; prone to corrosion without coating |

| ABS (Acrylonitrile Butadiene Styrene) | 1.0 mm – 10.0 mm | Good with CO₂ lasers; may produce charring or melted edges; requires ventilation | Limited – thermoplastic may crack; not ideal for tight radii; used for enclosures or mockups | Not weldable via traditional methods; joined using adhesives or solvent welding | Non-metallic; used for non-structural parts; poor heat resistance; not suitable for high-temp environments |

| Nylon (Polyamide) | 2.0 mm – 8.0 mm | Moderate – CO₂ lasers cause melting and poor edge quality; not recommended | Poor – high elasticity and creep; difficult to maintain bend geometry | Not weldable with standard metal methods; limited joining techniques | High wear resistance; used in insulating or low-friction components; hygroscopic (absorbs moisture) |

Process-Specific Notes:

Laser Cutting: Aluminum and steel are highly suitable for precision laser cutting. Aluminum requires higher assist gas pressure (nitrogen or oxygen) and controlled beam delivery due to reflectivity and thermal conductivity. Plastics like ABS and nylon can be cut but require careful parameter tuning to avoid melting and fire risk.

Bending: Aluminum alloys such as 5052-H32 offer optimal bendability with minimal cracking. Steel provides consistent results across a wide thickness range. Plastics generally do not support sharp bends and are prone to stress cracking.

Welding: Aluminum requires skilled welding techniques due to oxide layer formation and thermal expansion. Steel is the most weldable material among the four. ABS and nylon cannot be welded using conventional arc or laser welding; alternative joining methods are necessary.

For bent aluminum sheet components, design must account for bend allowances, k-factors, and heat-affected zones—especially when welding is involved. At Honyo Prototype, we recommend 5052-H32 for complex bends and 6061-T6 when post-formed welding or higher strength is required.

From CAD to Part: The Process

Honyo Prototype Bent Aluminum Sheet Fabrication Process

Honyo Prototype executes bent aluminum sheet fabrication through a rigorously defined workflow optimized for speed, precision, and cost transparency. The process begins with CAD Upload, where clients submit native STEP, IGES, or Parasolid files via our secure portal. Critical metadata—including material grade (e.g., 5052-H32, 6061-T6), sheet thickness (0.5–6.0 mm), bend radii, and geometric tolerances per ASME Y14.5—must accompany the model. Incomplete submissions trigger automated validation checks, reducing revision cycles by 40% versus industry averages.

AI-Powered Quoting follows within 90 minutes of validated CAD receipt. Our proprietary algorithm analyzes 12+ geometric and process parameters (e.g., bend count, flange length, compound angles) against live machine capacity data. The quote delivers firm pricing, lead time (typically 3–7 business days), and material yield optimization suggestions. Unlike generic quoting tools, our system factors in aluminum-specific variables: springback compensation, grain direction constraints, and clamping interference risks, ensuring 95%+ quote accuracy.

Engineering-Validated DFM is executed by degreed manufacturing engineers before production release. This phase resolves conflicts the AI cannot adjudicate, such as:

| DFM Issue Type | Detection Method | Honyo Resolution Protocol |

|---|---|---|

| Bend sequence conflicts | Kinematic simulation (BendSim v4.1) | Revised operation order; tooling redesign |

| Minimum flange violations | Rule-based checks (ISO 8573-1) | Flange extension; alternative bend method |

| Grain-sensitive features | Material orientation mapping | Grain-direction alignment advisory |

Engineers issue a formal DFM report with actionable recommendations, requiring client sign-off. Unresolved issues escalate to a tier-2 engineering review within 4 business hours.

Precision Production occurs in climate-controlled facilities using Amada HG-1003 press brakes (100–300T capacity) with real-time laser metrology. Key controls include:

Tooling selection validated against FEA-simulated springback

In-process bend angle verification at ±0.5° tolerance

Surface protection protocols for anodizable grades (e.g., non-marring urethane pads)

First-article inspection per AS9102 standards, including bend radius cross-section analysis

Quality-Gated Delivery concludes the workflow. All parts undergo final CMM validation against original CAD, with a digital inspection report (PDF + XML) provided. Shipments include serialized traceability tags linking to material certs and process logs. Standard delivery is FOB our facility with DDP options; 99.2% of orders ship on committed date via tracked logistics with carbon-neutral certification.

This integrated process eliminates traditional handoffs between quoting, engineering, and production teams, reducing time-to-shipment by 22 days versus conventional job shops while maintaining 0.0038% defect rates for critical aerospace and medical clients.

Start Your Project

Looking for high-quality bent aluminum sheet solutions? Partner with Honyo Prototype for precision fabrication and reliable turnaround. Our manufacturing facility in Shenzhen ensures tight tolerances, consistent quality, and fast delivery for prototyping and low-volume production.

Contact Susan Leo at [email protected] to request a quote or discuss your project specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.