Introduction: Navigating the Global Market for bending jig metal

Navigating the complexities of sourcing bending jig metal can pose significant challenges for B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As businesses strive to enhance their metal fabrication processes, understanding the various types of bending jigs and their applications becomes crucial. This guide delves into the nuances of bending jig metal, offering insights into the different models available, their specific uses in various industries, and the critical factors to consider when selecting a supplier.

In a global market characterized by diverse supplier standards and fluctuating costs, having a comprehensive resource at your fingertips is essential. This guide not only outlines the essential features of bending jigs but also provides strategies for vetting suppliers effectively, ensuring you make informed purchasing decisions. Key considerations such as cost analysis, quality assurance, and logistical challenges are examined, equipping buyers with the knowledge needed to navigate this competitive landscape.

Whether you are in Nigeria, Vietnam, or beyond, this guide aims to empower you to optimize your sourcing strategy for bending jig metal. By leveraging the information presented, international buyers can enhance their operational efficiency and ultimately drive business growth. Prepare to explore a wealth of actionable insights tailored to meet the demands of your specific market needs.

Understanding bending jig metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Bending Jigs | Simple design, operated by hand | Small workshops, DIY projects | Pros: Cost-effective, easy to use. Cons: Labor-intensive, limited to small-scale operations. |

| Hydraulic Bending Jigs | Powered by hydraulic systems, offers high precision | Large-scale manufacturing, metal fabrication | Pros: High efficiency, suitable for thick materials. Cons: Higher initial investment, requires maintenance. |

| Electric Bending Jigs | Automated operation with electric motors | Industrial applications, mass production | Pros: Fast production, consistent results. Cons: Higher energy consumption, may require skilled operators. |

| Universal Bending Jigs | Versatile design, accommodates various materials | General metalworking, custom fabrication | Pros: Adaptable, cost-effective for diverse tasks. Cons: May lack specialization for specific tasks. |

| Specialty Bending Jigs | Designed for specific shapes or materials | Niche applications, complex metalwork | Pros: Highly efficient for specific tasks. Cons: Limited use outside designated applications. |

What Are the Key Characteristics of Manual Bending Jigs?

Manual bending jigs are characterized by their straightforward, hand-operated design, making them ideal for small workshops and DIY projects. These jigs are typically less expensive, providing a cost-effective solution for businesses with limited budgets. However, they require significant manual effort and are best suited for low-volume production, limiting their scalability in larger operations. B2B buyers should consider their production needs and workforce capabilities when evaluating manual bending jigs.

How Do Hydraulic Bending Jigs Enhance Metal Fabrication?

Hydraulic bending jigs utilize hydraulic power to achieve high precision and efficiency, making them suitable for large-scale manufacturing and metal fabrication. These jigs can handle thicker materials and produce consistent results, which is critical in industries where precision is paramount. While they require a higher initial investment and ongoing maintenance, the productivity gains often justify the costs. Businesses focusing on high-volume production will find hydraulic jigs particularly beneficial.

What Advantages Do Electric Bending Jigs Offer?

Electric bending jigs are automated systems that provide fast and consistent production capabilities, ideal for industrial applications and mass production. They are designed to reduce labor costs and improve efficiency, making them a popular choice among large manufacturers. However, the higher energy consumption and the need for skilled operators can be downsides. B2B buyers should assess their operational scale and workforce skills when considering electric jigs.

Why Are Universal Bending Jigs a Smart Choice for General Metalworking?

Universal bending jigs are designed to accommodate a variety of materials and bending tasks, making them versatile tools in general metalworking and custom fabrication. They offer a cost-effective solution for businesses that require flexibility in their operations. However, while they can handle a range of tasks, they may not provide the same level of efficiency or precision as specialized jigs. Companies should weigh the benefits of versatility against the need for specific capabilities.

What Makes Specialty Bending Jigs Essential for Niche Applications?

Specialty bending jigs are engineered for specific shapes or materials, making them invaluable in niche applications and complex metalwork. They deliver high efficiency and precision for designated tasks, which can significantly enhance productivity in specialized industries. However, their limited use outside of specific applications can be a drawback for businesses seeking broader functionality. B2B buyers should evaluate their specific needs and the potential return on investment when considering specialty jigs.

Key Industrial Applications of bending jig metal

| Industry/Sector | Specific Application of bending jig metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Custom metal components for machinery | Enhanced precision in manufacturing, reducing waste | Quality of materials, precision specifications, and lead times |

| Automotive Manufacturing | Production of vehicle frames and body parts | Improved structural integrity and safety of vehicles | Compliance with industry standards, durability of jigs, and cost |

| Construction | Fabrication of metal structures and reinforcements | Increased efficiency in building processes | Availability of various bending angles, customization options |

| Aerospace | Creation of components for aircraft structures | High-performance standards ensuring safety and reliability | Material certifications, precision engineering, and global sourcing |

| Jewelry and Crafts | Designing intricate metal jewelry pieces | Unique designs that enhance market value | Craftsmanship quality, material sourcing, and delivery timelines |

How is Bending Jig Metal Used in Metal Fabrication?

In the metal fabrication industry, bending jig metal is crucial for producing custom components used in machinery and equipment. These jigs allow for precise bends and shapes, ensuring that parts fit together seamlessly during assembly. By utilizing bending jigs, manufacturers can significantly reduce material waste and enhance production efficiency. Buyers in this sector should consider the quality of materials used in the jigs, the precision of the bending specifications, and lead times, especially when sourcing from regions like Africa or South America, where logistics can vary.

What Role Does Bending Jig Metal Play in Automotive Manufacturing?

Bending jig metal is indispensable in automotive manufacturing, particularly for creating vehicle frames and body parts. The use of bending jigs ensures that components meet strict safety standards while maintaining structural integrity. This application is vital for producing high-quality vehicles that can withstand rigorous testing. When sourcing bending jigs, automotive manufacturers must prioritize compliance with industry standards, the durability of the jigs, and cost-effectiveness, particularly when dealing with suppliers in regions with varying manufacturing capabilities, like the Middle East.

How is Bending Jig Metal Applied in Construction?

In the construction sector, bending jig metal is used to fabricate metal structures and reinforcements, such as beams and supports. The ability to create accurate bends enhances the efficiency of building processes, allowing for quicker assembly on-site. This application is particularly beneficial in projects that require custom-sized components. Buyers in this industry should focus on the availability of various bending angles and customization options to fit specific project requirements, especially when working with suppliers across Europe or Africa.

Why is Bending Jig Metal Important in Aerospace Manufacturing?

Aerospace manufacturing relies heavily on bending jig metal for producing components that meet high-performance standards. The precision offered by these jigs is critical for ensuring the safety and reliability of aircraft structures. Aerospace manufacturers often face stringent regulations, making the quality of bending jigs paramount. When sourcing, it is essential to consider material certifications, precision engineering capabilities, and the ability to source globally, as this sector often requires suppliers with a proven track record.

How is Bending Jig Metal Used in Jewelry and Crafts?

In the jewelry and crafts industry, bending jig metal is utilized to design intricate metal pieces, allowing artisans to create unique jewelry designs. The precision and flexibility provided by these jigs enable craftsmen to produce detailed work that enhances the market value of their products. Buyers in this sector should focus on the quality of craftsmanship, material sourcing, and reliable delivery timelines to ensure their projects are completed on schedule, particularly when sourcing from countries like Vietnam or Nigeria, where local artisans may have specific needs.

3 Common User Pain Points for ‘bending jig metal’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Bends in Various Materials

The Problem: B2B buyers often face the challenge of achieving consistent bends across different materials such as steel, aluminum, and brass. Variations in material properties can lead to unpredictable results, affecting product quality and increasing waste. This inconsistency can also delay production schedules, as adjustments and rework are frequently necessary. For businesses, this not only impacts profitability but can also jeopardize client relationships when deadlines are missed.

The Solution: To overcome this issue, buyers should invest in a high-quality bending jig specifically designed to handle multiple materials. For instance, a universal metal bender with adjustable settings allows operators to tailor the bending process according to the specific material being used. Additionally, conducting material tests before large production runs can help determine the ideal settings for each type of metal. It is also advisable to maintain detailed records of bending parameters, which can be referred to for future projects. This proactive approach ensures consistency and reliability in the bending process, ultimately reducing waste and improving product quality.

Scenario 2: High Initial Costs of Bending Equipment

The Problem: Many B2B buyers are deterred by the high initial costs associated with purchasing bending jigs and related equipment. For smaller manufacturers or startups, this financial burden can be significant, leading to hesitance in adopting necessary technology. Moreover, without the right tools, companies may resort to less efficient methods, resulting in lower productivity and increased labor costs.

The Solution: One effective strategy is to explore leasing options or financing plans that spread the cost of equipment over time. Many manufacturers offer flexible payment solutions, making it easier for businesses to invest in quality bending jigs without straining their budgets. Additionally, buyers should evaluate the total cost of ownership, factoring in the long-term savings in labor and material costs that come with efficient equipment. Researching suppliers who offer bundled packages that include training and maintenance services can also provide added value, ensuring that the investment leads to higher productivity and reduced operational costs.

Scenario 3: Lack of Skilled Labor for Operating Bending Jigs

The Problem: The shortage of skilled labor capable of operating advanced bending equipment is a significant concern for many B2B buyers. As manufacturing processes become more complex, finding qualified personnel who can effectively utilize bending jigs becomes increasingly challenging. This skills gap can lead to operational inefficiencies, increased training costs, and a reliance on trial and error, which can ultimately compromise product quality.

The Solution: To address this challenge, businesses should consider investing in comprehensive training programs for their employees. Collaborating with equipment suppliers to provide on-site training can enhance the skill level of existing staff. Furthermore, implementing a mentorship system where experienced workers guide less skilled employees can foster a culture of learning and development. In addition, businesses should actively participate in local trade schools and vocational programs to help cultivate a pipeline of skilled workers. By prioritizing training and skill development, companies can mitigate the impact of labor shortages and ensure that their bending jigs are operated efficiently and effectively.

Strategic Material Selection Guide for bending jig metal

What are the Key Properties of Common Materials Used for Bending Jigs?

When selecting materials for bending jigs, it’s essential to consider their properties that directly influence performance. Here, we analyze four common materials: steel, aluminum, stainless steel, and plastic composites.

Steel: The Traditional Choice for Durability

Steel is a widely used material for bending jigs due to its high strength and durability. It can withstand significant pressure and is resistant to deformation under heavy loads. However, steel is susceptible to corrosion, particularly in humid environments, which can affect its longevity. For international buyers, understanding local climate conditions is crucial, as this may necessitate additional protective coatings or treatments.

Pros:

– High strength and durability.

– Cost-effective for large-scale production.

Cons:

– Heavier than other materials, which can complicate handling.

– Requires maintenance to prevent rust.

Aluminum: Lightweight and Versatile

Aluminum is favored for its lightweight properties, making it easier to handle and transport. It offers good corrosion resistance, which is beneficial in various environments. However, aluminum is generally less strong than steel, which may limit its application in high-stress scenarios. International buyers should consider the specific requirements of their applications, especially in industries where weight savings are critical.

Pros:

– Lightweight and easy to manipulate.

– Excellent corrosion resistance.

Cons:

– Lower strength compared to steel.

– Higher cost per unit than steel.

Stainless Steel: The Corrosion-Resistant Option

Stainless steel combines the strength of steel with enhanced corrosion resistance. This makes it ideal for bending jigs used in industries like food processing or pharmaceuticals, where hygiene is paramount. However, the higher cost and complexity of manufacturing processes can be a consideration for budget-conscious buyers. Compliance with international standards, such as ASTM or DIN, is crucial, especially for applications requiring stringent quality controls.

Pros:

– High strength and excellent corrosion resistance.

– Suitable for hygiene-sensitive applications.

Cons:

– More expensive than standard steel.

– Manufacturing can be more complex.

Plastic Composites: Innovative and Lightweight

Plastic composites are gaining traction in bending jig applications due to their lightweight nature and resistance to corrosion. They can be engineered for specific properties, such as flexibility or rigidity, depending on the application. However, their strength may not match that of metals, limiting their use in high-load situations. Buyers in regions with less access to metal fabrication may find plastic composites an attractive alternative, provided they understand the trade-offs in strength and durability.

Pros:

– Lightweight and corrosion-resistant.

– Customizable properties for specific applications.

Cons:

– Generally lower strength compared to metals.

– May not be suitable for heavy-duty applications.

Summary Table of Material Selection for Bending Jigs

| Material | Typical Use Case for bending jig metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Prone to corrosion | Low |

| Aluminum | Lightweight jigs for transport | Lightweight and easy to handle | Lower strength compared to steel | Medium |

| Stainless Steel | Food processing and hygiene-sensitive | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic Composites | Lightweight, corrosion-resistant jigs | Customizable properties | Generally lower strength | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in bending jigs. Understanding these factors will aid in making informed purchasing decisions that align with specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for bending jig metal

What Are the Main Stages of Manufacturing Bending Jig Metal?

Manufacturing bending jigs for metal involves several critical stages that ensure the final product meets the necessary specifications for strength, durability, and precision. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is selecting the right materials, typically high-strength steel or aluminum, depending on the intended application. The metal is sourced from reputable suppliers who comply with international standards. After sourcing, the material undergoes cutting to the required dimensions, often using laser cutting or shearing methods. This stage is crucial, as accurate dimensions are fundamental to the jig’s performance.

Forming Techniques Used in Bending Jig Production

Once the materials are prepared, the next step is forming, which often employs techniques such as bending, stamping, and machining. For bending jigs, hydraulic presses are commonly used to achieve precise bends without compromising the integrity of the metal. Additionally, CNC (Computer Numerical Control) machines may be employed to ensure high precision in the shaping process. The forming stage is vital for creating the specific contours needed for the jig’s functionality.

Assembly Process for Bending Jigs

After the individual components are formed, they are assembled into the final product. This stage may involve welding, riveting, or bolting parts together. Care is taken to ensure that all components fit correctly and operate smoothly. Quality checks are typically performed during assembly to identify any misalignments or defects early in the process.

Finishing Touches in Bending Jig Manufacturing

The last stage in manufacturing is finishing, which can include processes such as painting, powder coating, or galvanizing to enhance durability and corrosion resistance. This is particularly important for jigs used in environments exposed to moisture or chemicals. The finishing process not only improves the aesthetic appeal but also extends the lifespan of the product.

How Is Quality Assurance Managed in Bending Jig Metal Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing of bending jigs, ensuring that each product meets the required specifications and standards. Internationally recognized standards such as ISO 9001 are often implemented to establish a framework for quality management systems.

What Are the Relevant International Standards for Bending Jig Metal?

ISO 9001 outlines the requirements for a quality management system and emphasizes continual improvement, customer satisfaction, and the involvement of top management. Additionally, industry-specific standards such as CE marking for European markets and API standards for petroleum-related applications may apply depending on the jig’s intended use. Compliance with these standards not only enhances product quality but also builds trust with international buyers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure adherence to quality standards. These checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During the manufacturing process, operators conduct inspections to catch defects early.

- Final Quality Control (FQC): After assembly, the finished jigs undergo rigorous testing and inspection before they are shipped.

These checkpoints allow manufacturers to identify issues and rectify them promptly, reducing the likelihood of defective products reaching the customer.

What Testing Methods Are Commonly Used for Bending Jigs?

Various testing methods are employed to ensure that bending jigs meet the necessary quality and performance standards. These methods can include:

- Dimensional Inspection: Utilizing calipers and gauges to verify that the jig dimensions adhere to specifications.

- Load Testing: Applying weights to the jigs to assess their strength and durability under operational conditions.

- Visual Inspection: Inspecting for surface defects, weld integrity, and overall craftsmanship.

By implementing these testing methods, manufacturers can provide assurance to B2B buyers that their products are reliable and of high quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial to ensuring product reliability. Here are some actionable steps buyers can take:

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. Buyers may consider employing third-party audit services for an objective evaluation.

-

Request Quality Assurance Reports: Suppliers should be willing to provide documentation regarding their quality control processes, including results from IQC, IPQC, and FQC stages.

-

Seek Third-Party Inspections: Engaging third-party inspection services can help verify that the products meet the required standards before shipment. This is particularly beneficial for buyers importing goods from distant suppliers.

What Nuances Should International Buyers Consider Regarding QC and Certification?

International buyers should be aware of certain nuances related to quality control and certification that can impact their procurement processes:

-

Regional Compliance Requirements: Different regions may have specific compliance requirements that manufacturers must meet. For example, products sold in Europe may need CE certification, while those intended for the U.S. market may require compliance with ANSI standards.

-

Cultural Differences in Quality Expectations: Understanding the cultural context of suppliers can also play a role in quality expectations. Buyers should engage in open communication to clarify quality standards and expectations.

-

Logistics and Lead Times: Quality assurance processes can affect lead times. Buyers should factor in the time required for testing and certification when planning their procurement schedules.

By understanding these elements of manufacturing and quality assurance, B2B buyers can make informed decisions when sourcing bending jigs, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bending jig metal’

Introduction

Sourcing bending jig metal requires careful consideration of several factors to ensure you obtain the right materials for your metalworking needs. This guide provides a practical step-by-step checklist designed specifically for B2B buyers, focusing on essential actions that can streamline the procurement process and help you secure high-quality bending jig metal.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly define your technical specifications. This includes the type of metal, dimensions, thickness, and any specific properties required, such as tensile strength or corrosion resistance. Having precise specifications helps in communicating your needs to suppliers and ensures that you receive materials that meet your exact requirements.

- Metal Types: Consider whether you need aluminum, steel, or another metal based on your project requirements.

- Dimensional Precision: Specify tolerances and dimensions to avoid discrepancies during manufacturing.

Step 2: Identify Reputable Suppliers

Research and compile a list of potential suppliers who specialize in bending jig metal. Look for companies with a solid reputation in the industry, as well as positive reviews and testimonials from other B2B clients. A reputable supplier is more likely to provide high-quality materials and reliable service.

- Online Research: Utilize platforms like LinkedIn, industry forums, and trade shows to identify potential suppliers.

- Industry Associations: Consider suppliers who are members of recognized industry associations, as this often indicates a commitment to quality.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step helps you gauge their reliability, product quality, and customer service, which are vital for a successful partnership.

- Request Samples: If possible, ask for material samples to assess quality firsthand.

- Check Certifications: Verify that suppliers hold relevant certifications (e.g., ISO, CE) that align with industry standards.

Step 4: Assess Pricing and Payment Terms

Once you’ve shortlisted potential suppliers, compare their pricing structures and payment terms. Ensure that the pricing aligns with your budget while also considering the total cost of ownership, which includes shipping, handling, and potential customs duties.

- Bulk Discounts: Inquire about discounts for bulk orders or long-term contracts.

- Payment Flexibility: Look for suppliers offering flexible payment options that can accommodate your financial situation.

Step 5: Review Delivery and Lead Times

Understanding delivery schedules and lead times is crucial to your production planning. Ensure that the suppliers can meet your deadlines and have a proven track record of timely deliveries. Delays in sourcing can lead to significant disruptions in your operations.

- Shipping Options: Evaluate different shipping methods and their associated costs to find the most efficient solution.

- Production Capacity: Confirm the supplier’s production capacity to handle your order volume without delays.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate the terms and conditions of your purchase. This includes pricing, delivery schedules, quality assurances, and return policies. Clear and mutually agreed-upon terms can prevent disputes and ensure a smooth transaction.

- Written Agreement: Document all negotiated terms in a formal contract to protect both parties.

- Quality Guarantees: Ensure that quality standards are explicitly stated in the agreement.

Step 7: Establish a Relationship for Future Orders

After the initial order, focus on building a long-term relationship with your supplier. Open communication and feedback can enhance collaboration and facilitate better service in future transactions. A solid partnership can lead to favorable terms and priority service.

- Regular Check-Ins: Schedule periodic meetings to discuss performance and any adjustments needed in your supply chain.

- Feedback Loop: Provide feedback on quality and service to help the supplier improve and better meet your needs.

By following this checklist, B2B buyers can efficiently navigate the complexities of sourcing bending jig metal, ensuring that they partner with the right suppliers to meet their manufacturing demands.

Comprehensive Cost and Pricing Analysis for bending jig metal Sourcing

What Are the Key Cost Components in Bending Jig Metal Sourcing?

When sourcing bending jigs for metalwork, understanding the cost structure is vital for effective budgeting and decision-making. The primary cost components include:

-

Materials: The type of metal used—such as steel, aluminum, or specialty alloys—significantly influences costs. Higher-grade materials often come at a premium but can enhance durability and performance.

-

Labor: Labor costs vary by region and complexity of the manufacturing process. In countries with higher labor rates, such as those in Europe, the cost of skilled labor can substantially affect the overall pricing.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and administrative expenses. Efficient production processes can help minimize these costs.

-

Tooling: Specific jigs may require custom tooling, which can add to the upfront costs. Understanding whether the supplier has existing tooling or needs to create new molds is crucial for cost estimation.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but can increase costs. Certifications such as ISO or industry-specific standards may also add to the expense.

-

Logistics: Shipping costs, particularly for international buyers, can vary greatly based on distance, weight, and chosen shipping methods. Incoterms (International Commercial Terms) play a crucial role in defining responsibilities and costs associated with transportation.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely based on their operational efficiency, market demand, and competitive positioning.

How Do Price Influencers Affect Bending Jig Metal Costs?

Several factors can influence the pricing of bending jigs, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom designs or specific functionalities can lead to higher costs. Buyers should clearly outline their needs to avoid unexpected charges.

-

Materials and Quality: The selection of materials directly impacts pricing. High-quality materials may have higher upfront costs but can result in lower maintenance and replacement expenses over time.

-

Supplier Factors: The supplier’s reputation, experience, and location can affect pricing. Established suppliers with proven track records may charge more but offer reliability and assurance.

-

Incoterms: Choosing the right Incoterms can optimize logistics costs. For instance, “FOB” (Free On Board) might be preferable for buyers who want to control shipping, while “CIF” (Cost Insurance and Freight) can simplify the process by including shipping costs.

What Buyer Tips Can Help Optimize Bending Jig Metal Sourcing Costs?

To maximize value and minimize costs in bending jig sourcing, consider the following strategies:

-

Negotiation: Always negotiate prices with suppliers. Understanding their cost structure and demonstrating long-term purchasing potential can lead to better deals.

-

Cost-Efficiency: Assess the total cost of ownership, not just the purchase price. Consider maintenance, potential repairs, and longevity in your evaluation.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect overall costs. Engaging a local expert or freight forwarder can provide insights into these variables.

-

Supplier Comparison: Compare multiple suppliers to ensure competitive pricing. Request quotes that detail all cost components to facilitate comparison.

-

Long-Term Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and favorable terms over time.

Disclaimer

The prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and material availability. Buyers should conduct thorough research and seek quotes from multiple suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing bending jig metal With Other Solutions

Exploring Alternatives to Bending Jig Metal

When evaluating solutions for metal bending, it’s crucial to consider alternatives that can meet similar needs. Bending jig metal is a traditional method favored for its precision and reliability in metal fabrication. However, various technologies and methods can offer different advantages depending on specific operational requirements, cost constraints, and intended applications. Below, we explore a comparative analysis of bending jig metal against two viable alternatives: universal metal benders and hydraulic benders.

| Comparison Aspect | Bending Jig Metal | Universal Metal Bender | Hydraulic Bender |

|---|---|---|---|

| Performance | High precision for small to medium bends | Versatile, suitable for various materials | High power, ideal for thick metals |

| Cost | Moderate investment | Affordable, ranges from $76 to $484 | Higher upfront cost, typically $1,000+ |

| Ease of Implementation | Requires skilled labor | User-friendly for DIY and pros | Requires training for optimal use |

| Maintenance | Low maintenance | Moderate, periodic checks needed | Higher maintenance due to hydraulic systems |

| Best Use Case | Jewelry making, small metalwork | General metalwork, DIY projects | Heavy-duty industrial applications |

What are the Advantages and Disadvantages of Universal Metal Benders?

Universal metal benders are an excellent alternative for businesses looking for flexibility in their metalworking processes. These tools are designed to handle various materials, including steel, brass, and aluminum, making them suitable for a wide range of projects. They are relatively easy to use, often appealing to both professionals and hobbyists. However, while they are generally more affordable than bending jig metal setups, they may not offer the same level of precision for intricate designs, which can be a downside for specialized applications like jewelry crafting.

How Do Hydraulic Benders Compare to Bending Jig Metal?

Hydraulic benders represent a more powerful option for metal bending, particularly when dealing with thicker materials or larger production runs. Their ability to exert significant force makes them ideal for industrial applications where high throughput and efficiency are essential. However, the initial investment and operational costs can be substantially higher than bending jig metal or universal benders. Additionally, hydraulic systems require regular maintenance and operator training to ensure safety and efficiency, which could be a barrier for smaller businesses or those with limited resources.

How Can B2B Buyers Choose the Right Metal Bending Solution?

When selecting a metal bending solution, B2B buyers should assess their specific needs, including the types of materials they work with, the complexity of the projects, and their budget. For businesses focused on intricate designs and small-scale production, bending jig metal may be the best fit due to its precision. Conversely, if versatility and cost-effectiveness are more critical, universal metal benders could be the ideal choice. For those in heavy manufacturing or looking to maximize output, investing in hydraulic benders may yield the best long-term benefits despite the higher initial costs. Ultimately, understanding the operational requirements and potential return on investment will guide buyers in making the most informed decision for their metalworking needs.

Essential Technical Properties and Trade Terminology for bending jig metal

What Are the Key Technical Properties of Bending Jig Metal?

When selecting bending jig metal, understanding the technical properties is essential for ensuring optimal performance and longevity. Here are some critical specifications to consider:

-

Material Grade

The material grade refers to the composition and quality of the metal used in the bending jig. Common materials include carbon steel, stainless steel, and aluminum. Each material offers different levels of strength, corrosion resistance, and weight. For instance, stainless steel is preferred in environments prone to moisture, while carbon steel is often chosen for its strength and cost-effectiveness. Selecting the right material grade is vital for ensuring the jig meets the specific demands of the bending process. -

Tolerance

Tolerance defines the acceptable range of deviation from a specified dimension. In the context of bending jigs, tighter tolerances are critical for achieving precise bends and maintaining quality control. Poor tolerance can lead to misalignments, which affect the final product’s quality. Understanding tolerance levels helps buyers ensure that their jigs can deliver the accuracy required for their specific applications, ultimately reducing waste and rework. -

Load Capacity

This specification indicates the maximum weight the bending jig can handle without compromising its structural integrity. Load capacity is essential for B2B buyers as it determines whether a jig can accommodate the materials and thicknesses they intend to work with. Ensuring the jig has an appropriate load capacity is crucial for both safety and efficiency in production processes. -

Finish Type

The finish type describes the surface treatment applied to the metal. Common finishes include galvanized, powder-coated, or polished. Each finish offers different benefits, such as enhanced corrosion resistance or improved aesthetics. For international buyers, understanding the finish type is essential as it can influence both the longevity of the jig and its suitability for specific environmental conditions. -

Bending Radius

The bending radius is the minimum radius that a material can be bent without cracking or deforming. This property is particularly important when working with different materials and thicknesses, as each type may require specific bending techniques. Buyers should consider the bending radius to ensure compatibility with their production requirements, which can significantly impact the quality of the final product.

What Are Common Trade Terms in the Bending Jig Metal Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B space. Here are some common trade terms relevant to bending jig metal:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bending jigs, understanding OEM relationships can help buyers identify trusted sources for high-quality jigs and components that meet their specific needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For businesses, understanding MOQ is vital for budgeting and inventory management. It can also influence purchasing decisions, especially for smaller companies or those just starting. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price bids from suppliers. It is an essential step for buyers looking to compare pricing and terms across different vendors. A well-crafted RFQ can streamline the purchasing process, ensuring that all necessary specifications are communicated clearly. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, specifying who is responsible for shipping, insurance, and tariffs. Understanding these terms is crucial for international buyers to avoid misunderstandings and ensure smooth logistics. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For B2B buyers, understanding lead times is critical for planning production schedules and managing inventory levels effectively. -

Customization Options

Customization options indicate the ability to tailor products to meet specific client requirements. This can include alterations in size, shape, or material. For businesses with unique needs, understanding customization options can enhance product performance and satisfaction.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions when investing in bending jig metal, ensuring that they choose solutions that align with their operational requirements and business goals.

Navigating Market Dynamics and Sourcing Trends in the bending jig metal Sector

What Are the Current Market Dynamics and Key Trends in the Bending Jig Metal Sector?

The bending jig metal sector is experiencing significant growth driven by various global factors. As industries continue to innovate, the demand for precise and efficient metal bending solutions has surged. This trend is particularly pronounced in developing regions such as Africa and South America, where infrastructure projects are proliferating. In these markets, the need for reliable metal fabrication tools is crucial, as businesses seek to enhance productivity and reduce lead times.

Emerging B2B technologies are reshaping sourcing practices. Automation and advanced manufacturing techniques, such as CNC machining, are becoming essential in the production of bending jigs. This shift not only improves precision but also allows for custom solutions tailored to specific client needs. Additionally, the rise of e-commerce platforms has facilitated easier access to global suppliers, enabling international buyers to compare prices and quality from the comfort of their offices.

Another noteworthy trend is the increasing emphasis on product versatility. Buyers are seeking universal bending jigs that can accommodate various materials, including steel, brass, and aluminum. This adaptability is essential for businesses looking to diversify their offerings without investing heavily in multiple specialized tools.

How Is Sustainability and Ethical Sourcing Impacting the Bending Jig Metal Industry?

Sustainability has emerged as a critical consideration in the bending jig metal sector, influencing both production methods and supply chain practices. The environmental impact of metal fabrication processes, including resource depletion and waste generation, has prompted many companies to adopt greener practices. This shift is not merely a trend but a response to increasing regulatory pressures and consumer demand for sustainable products.

Ethical sourcing is equally important, as businesses strive to ensure that their supply chains are transparent and responsible. B2B buyers are increasingly prioritizing suppliers that demonstrate compliance with environmental standards and labor rights. Certifications such as ISO 14001 for environmental management and the use of recycled materials are becoming essential criteria for procurement decisions.

Moreover, companies are investing in technologies that minimize energy consumption during production and reduce emissions. This not only meets regulatory requirements but also enhances brand reputation among environmentally conscious consumers. By aligning sourcing practices with sustainability goals, businesses can differentiate themselves in a competitive market.

How Has the Bending Jig Metal Sector Evolved Over Time?

The bending jig metal sector has seen considerable evolution over the decades, transitioning from manual tools to sophisticated, automated solutions. Initially, metal bending was a labor-intensive process reliant on basic mechanical jigs. However, the introduction of digital technologies and advanced materials has revolutionized the industry.

As markets expanded and global trade increased, the demand for high-precision bending tools grew. This evolution has led to the development of versatile, high-capacity bending jigs that cater to diverse applications across various sectors, including construction, automotive, and aerospace. The current landscape reflects a blend of traditional craftsmanship and cutting-edge technology, providing B2B buyers with a wide range of options to meet their unique requirements.

In summary, understanding the dynamics of the bending jig metal market is crucial for international B2B buyers. With a focus on sustainability, technological advancements, and evolving market needs, businesses must adapt to maintain a competitive edge in this rapidly changing sector.

Frequently Asked Questions (FAQs) for B2B Buyers of bending jig metal

-

1. How do I solve issues with bending precision in metalworking?

To enhance bending precision, ensure you are using high-quality bending jigs specifically designed for the type of metal you are working with. Invest in adjustable jigs that allow for fine-tuning during the bending process. Regular maintenance of your tools and machinery is crucial; worn-out components can lead to inaccuracies. Additionally, conduct tests on scrap pieces before starting on the final product to ensure that your settings are correct and adjustments can be made as necessary. -

2. What is the best type of bending jig for aluminum?

For aluminum, a lightweight yet sturdy bending jig is ideal, as it can efficiently handle the material’s characteristics. Look for jigs that feature adjustable settings to accommodate various angles and bends, such as a universal metal bender. Ensure the jig has a strong frame, preferably made from cast iron or high-grade steel, to maintain stability during the bending process. Brands like Kaka Industrial and Stortz offer specialized options suited for aluminum, providing the balance of flexibility and strength needed for optimal results. -

3. What customization options are typically available for bending jigs?

Many suppliers offer customization options for bending jigs, including size adjustments, specific tooling for unique shapes, and modifications to accommodate different metal thicknesses. Custom jigs can be designed to meet specific project requirements, enhancing efficiency and accuracy. When discussing customization with suppliers, inquire about lead times, costs, and any additional fees that may apply. Be sure to communicate your exact needs and specifications to ensure the final product aligns with your expectations. -

4. How can I vet suppliers for bending jigs in international markets?

To vet suppliers, start by researching their reputation through reviews and testimonials from other B2B buyers. Check for certifications that validate quality and safety standards in their products. It’s also beneficial to request samples or visit their production facilities if possible. Engage in direct communication to assess their responsiveness and willingness to address your queries. Additionally, consider their experience in exporting to your region, as this can affect logistics and compliance with local regulations. -

5. What are the minimum order quantities (MOQs) for bending jigs?

Minimum order quantities can vary significantly among suppliers, often depending on the type of bending jig and the level of customization required. Standard products may have lower MOQs, while specialized or custom jigs could require larger orders to justify production costs. Before committing, discuss MOQs directly with potential suppliers and assess how they align with your purchasing needs. Negotiating MOQs may also be possible, especially for long-term partnerships or bulk orders. -

6. What payment terms should I expect when sourcing bending jigs internationally?

Payment terms vary by supplier and region but typically include options like advance payments, partial payments, or net terms (e.g., net 30 or net 60). Many international suppliers prefer secure payment methods such as letters of credit, PayPal, or bank transfers. It’s crucial to clarify payment terms upfront to avoid surprises. Additionally, ensure you understand any currency exchange implications or transaction fees that may affect the overall cost of your order. -

7. How do I ensure quality assurance (QA) for bending jigs sourced from abroad?

To ensure quality assurance, request detailed specifications and quality control processes from your supplier. Establish clear inspection criteria before shipment, which may include material quality tests and performance checks. Consider third-party inspection services to assess the products before they leave the supplier’s facility. Maintaining open communication throughout the production process can also help identify potential issues early, allowing for adjustments to be made prior to shipping. -

8. What logistics considerations should I keep in mind when importing bending jigs?

When importing bending jigs, consider factors such as shipping costs, lead times, and customs regulations in your country. Choose a reliable freight forwarder experienced in handling industrial equipment to navigate the complexities of international shipping. Ensure that your supplier provides all necessary documentation for customs clearance, including invoices and certificates of origin. Additionally, factor in potential delays due to customs processing and plan your inventory accordingly to avoid disruptions in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Bending Jig Metal Manufacturers & Suppliers List

1. Stuller – Professional Superior Bending Jig Set

Domain: stuller.com

Registered: 1996 (29 years)

Introduction: Professional Superior Bending Jig Set; Expedite available; 3 items per request; Unavailable for sizing, engraving, and other customization services; Commodity bands in 14K gold only; $25.00 fee per request.

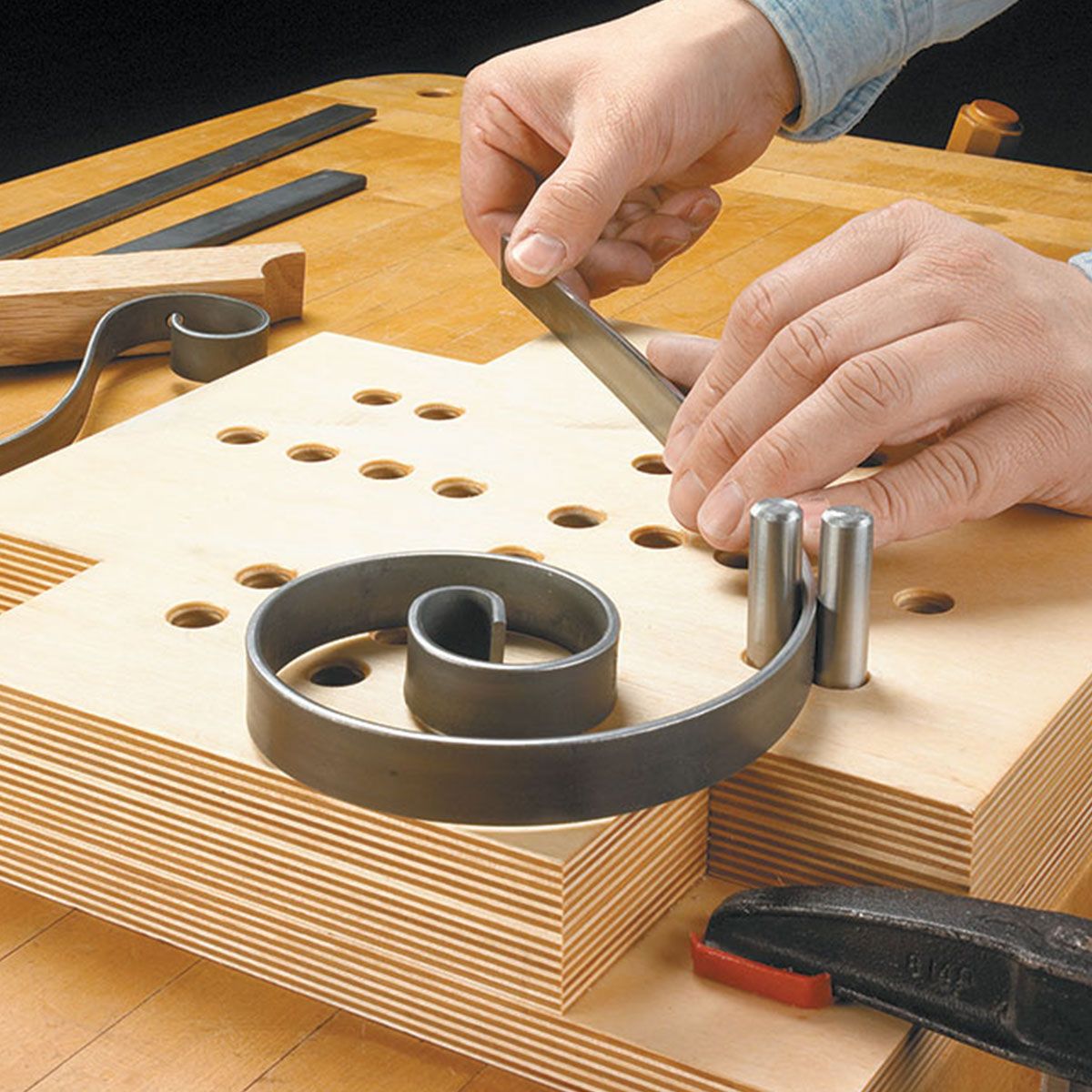

2. Ultra Jig – Bending Jig

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Bending Jig based on the Ultra Jig design; constructed from two 1/2″ x 9″ mild steel plates, flush riveted together; features thirty 1/2″ diameter holes, 1/2″ deep, spaced in 1/8″ increments from the center; each hole has a 1/4″ through hole for easy pin removal; includes a length of angle iron for clamping in a vise; seasoned with multiple coats of flax oil; dies made from round mild steel stock …

3. Kaka Industrial – Universal Metal Bender

Domain: kakaindustrial.com

Registered: 2014 (11 years)

Introduction: Universal Metal Bender products from Kaka Industrial include a variety of models suitable for DIY hobbyists and professional metalworkers. Key products include: 1. KAKA Industrial SBG-30: High precision metal bender for steel, brass, copper, and aluminum; cast-iron steel frame; priced at $460. 2. KAKA Industrial SBG-40: Heavy-duty universal bender for flat, square, and round bars; combination of s…

4. Stortz – Portable Metal Benders

Domain: stortz.com

Registered: 1997 (28 years)

Introduction: This company, Stortz – Portable Metal Benders, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Woodsmith – Scroll-Bending Jig

Domain: woodsmithplans.com

Registered: 2000 (25 years)

Introduction: Scroll-Bending Jig allows you to bend metal rods and bars into decorative shapes and useful objects. It is designed for creating hardware items such as shelf brackets, hooks, and handles. The plan includes 4 pages of step-by-step instructions, over 20 full-color photos, illustrations, and exploded views. The plan is available in Imperial units for $6.95. A shop-tested guarantee from Woodsmith maga…

6. Otto Frei – Metal Wire Bending Jig

Domain: ottofrei.com

Registered: 2000 (25 years)

Introduction: This company, Otto Frei – Metal Wire Bending Jig, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. iForge Iron – DIY Bending Jigs

Domain: iforgeiron.com

Registered: 2001 (24 years)

Introduction: Bending jig ideas discussed include using steel discs, assorted pulleys, slices of steel pipe as bending mandrels, and welding techniques with angle iron. Suggestions for DIY jigs involve using a vise for holding the workpiece, creating jigs from scrap materials, and utilizing impact sockets for bending. The conversation highlights the need for larger sizes of bending tools, with recommendations f…

8. Barts Metalwork – Ultimate Bending Machine

Domain: homemadetools.net

Registered: 2011 (14 years)

Introduction: Homemade ultimate bending machine designed by Barts Metalwork. The machine combines multiple bending tools into one compact design, making it suitable for small shops. Users have noted the need for larger diameter dies for improved functionality and have discussed the spacing of the roller for ring bending. The machine has been positively received after a year of use, with users appreciating its v…

Strategic Sourcing Conclusion and Outlook for bending jig metal

What Are the Key Takeaways for Strategic Sourcing of Bending Jigs?

In the rapidly evolving landscape of metal fabrication, strategic sourcing of bending jigs presents a significant opportunity for international B2B buyers. Understanding the diverse range of products available—from professional jig sets to universal metal benders—enables businesses to select tools that best meet their specific needs. High-quality equipment not only enhances operational efficiency but also ensures the precision required for various metalworking applications.

Additionally, the importance of supplier reliability cannot be overstated. Establishing strong relationships with reputable manufacturers can lead to better pricing, timely delivery, and access to the latest innovations in bending technology. This is particularly crucial for buyers in regions like Africa, South America, the Middle East, and Europe, where supply chain dynamics may differ.

How Can B2B Buyers Prepare for Future Trends in Metal Bending?

Looking ahead, international buyers should stay informed about emerging trends and technological advancements in the bending jig market. Investing in advanced equipment can lead to increased productivity and competitiveness. By proactively engaging with suppliers and exploring new products, businesses can position themselves for success in a competitive market.

Now is the time to act—evaluate your current metal bending needs and consider strategic sourcing as a pathway to enhance your operational capabilities.