Introduction: Navigating the Global Market for bakelite sheet

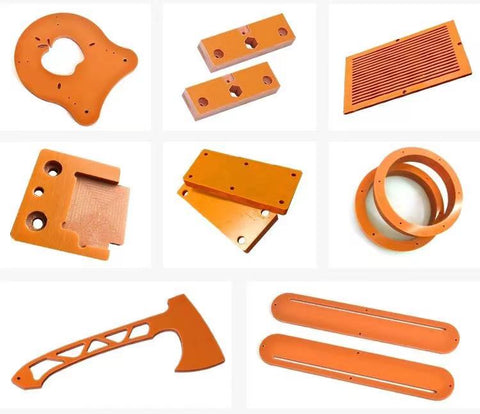

In the ever-evolving landscape of global manufacturing, sourcing high-quality Bakelite sheets presents a unique challenge for international B2B buyers. Whether you’re in Nigeria, Vietnam, or Brazil, navigating the complexities of material specifications, supplier reliability, and cost-effectiveness is crucial for making informed purchasing decisions. Bakelite sheets, known for their exceptional electrical insulation, mechanical strength, and heat resistance, are integral to various industries, including automotive, electrical, and furniture manufacturing.

This comprehensive guide delves into the multifaceted world of Bakelite sheets, covering everything from the different types available—such as paper-reinforced, fabric-reinforced, and glass-reinforced—to their diverse applications across multiple sectors. Additionally, we will provide valuable insights on vetting suppliers, understanding pricing structures, and the logistics of sourcing these materials from different regions.

By equipping you with the knowledge needed to assess quality, performance, and supplier capabilities, this guide empowers you to make strategic decisions that align with your business objectives. Whether you are exploring new materials for innovative projects or seeking reliable suppliers for ongoing production needs, understanding the global market for Bakelite sheets will enhance your competitive edge in the marketplace.

Understanding bakelite sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Paper Reinforced Bakelite | Made from layers of paper impregnated with resin | Electrical insulators, circuit boards, switchgear | Pros: Good electrical insulation, low moisture absorption. Cons: Limited mechanical strength compared to fabric or glass reinforced types. |

| Fabric Reinforced Bakelite | Features layers of fabric, enhancing strength and durability | Mechanical components, gears, bearings | Pros: High mechanical strength, excellent wear resistance. Cons: May absorb moisture if not properly sealed. |

| Glass Reinforced Bakelite | Incorporates glass fibers for enhanced thermal stability | High-temperature applications, chemical equipment, laminates | Pros: Superior thermal and chemical resistance. Cons: Heavier and potentially more expensive than other types. |

| Colored Bakelite Sheet | Available in various colors and patterns | Decorative applications, furniture, design elements | Pros: Aesthetic versatility, appealing for consumer-facing products. Cons: Color options may limit industrial applications. |

| Custom Bakelite Sheet | Tailored specifications based on buyer needs | Specialized mechanical parts, custom electrical components | Pros: Meets specific requirements, optimized performance. Cons: Longer lead times and potentially higher costs. |

What Are the Key Characteristics of Paper Reinforced Bakelite Sheets?

Paper reinforced Bakelite sheets are constructed from layers of paper that are impregnated with Bakelite resin. This type offers excellent electrical insulation properties, making it ideal for applications such as electrical insulators and circuit boards. When considering this option, buyers should evaluate the moisture absorption characteristics and mechanical strength, as while it excels in electrical applications, it may not be suitable for high-stress mechanical environments.

How Does Fabric Reinforced Bakelite Differ in Performance?

Fabric reinforced Bakelite sheets utilize layers of fabric within the resin matrix, significantly enhancing their mechanical strength and wear resistance. This variation is particularly suitable for mechanical components like gears and bearings, where durability and precision are essential. Buyers should consider the potential for moisture absorption, which can impact performance, and ensure that the material is properly sealed if used in humid environments.

What Advantages Do Glass Reinforced Bakelite Sheets Offer?

Glass reinforced Bakelite sheets are designed with glass fibers that provide exceptional thermal stability and chemical resistance. These sheets are ideal for high-temperature applications, such as in chemical processing equipment and laminates. When purchasing, buyers should note that while this type offers superior performance, it can be heavier and more expensive than alternatives, which may affect project budgets and logistics.

Why Choose Colored Bakelite Sheets for Decorative Uses?

Colored Bakelite sheets are available in a variety of hues and patterns, making them suitable for decorative applications, including furniture and design elements. Their aesthetic appeal can enhance consumer-facing products, yet buyers must weigh the pros and cons regarding industrial applications, as the color options might limit their use in certain sectors.

What Are the Benefits of Custom Bakelite Sheets?

Custom Bakelite sheets can be tailored to meet specific requirements of B2B buyers, allowing for optimized performance in specialized applications. This option is particularly valuable for companies needing unique mechanical parts or custom electrical components. However, buyers should prepare for potentially longer lead times and higher costs associated with custom orders, making it essential to plan accordingly for project timelines and budgets.

Key Industrial Applications of bakelite sheet

| Industry/Sector | Specific Application of Bakelite Sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Manufacturing | Insulators and Switchboards | High dielectric strength ensures safety and reliability in electrical systems. | Ensure compliance with international safety standards and certifications. |

| Automotive | Brake Pads and Insulation Components | Excellent heat resistance and durability enhance vehicle safety and performance. | Source from suppliers with experience in automotive-grade materials. |

| Mechanical Engineering | Gears and Bearings | Low friction and wear resistance increase operational efficiency and longevity. | Verify machinability and precision tolerances for custom parts. |

| Furniture Design | Tabletops and Cabinet Accents | Aesthetic appeal combined with durability enhances product value and customer satisfaction. | Look for customizable options to meet specific design requirements. |

| Chemical Processing | Equipment Liners and Chemical Containers | High chemical resistance prolongs equipment life and reduces maintenance costs. | Confirm compatibility with specific chemicals to prevent degradation. |

How is Bakelite Sheet Used in Electrical Manufacturing?

In the electrical manufacturing sector, Bakelite sheets serve as insulators and components for switchboards. Their high dielectric strength prevents electrical leakage and potential fires, making them indispensable in ensuring safety and reliability. International buyers must seek suppliers that adhere to stringent safety standards and have relevant certifications, particularly in regions with strict regulatory environments.

What Role Does Bakelite Sheet Play in Automotive Applications?

Bakelite sheets are utilized in the automotive industry for brake pads and insulation components. Their exceptional heat resistance and durability contribute to vehicle safety and performance, particularly in high-stress environments like racing. When sourcing, businesses should prioritize suppliers experienced in automotive-grade materials to ensure compliance with industry standards and quality assurance.

Why are Bakelite Sheets Essential in Mechanical Engineering?

In mechanical engineering, Bakelite sheets are crafted into gears and bearings due to their low friction and wear resistance. These properties enhance operational efficiency and extend the lifespan of machinery. B2B buyers should verify the machinability of the sheets and the precision tolerances required for their specific applications, ensuring that they meet their operational needs.

How are Bakelite Sheets Applied in Furniture Design?

Bakelite sheets are increasingly popular in furniture design, particularly for tabletops and cabinet accents. Their aesthetic appeal, coupled with durability, enhances product value and customer satisfaction. Buyers should look for suppliers offering customizable options to align with specific design requirements, ensuring that the final product meets both functional and aesthetic expectations.

What Advantages Do Bakelite Sheets Offer in Chemical Processing?

In the chemical processing sector, Bakelite sheets are used for equipment liners and chemical containers. Their high chemical resistance helps to prolong the life of equipment and reduce maintenance costs. When sourcing Bakelite sheets for these applications, it is crucial to confirm compatibility with specific chemicals to prevent material degradation, ensuring long-term performance and reliability.

3 Common User Pain Points for ‘bakelite sheet’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Bakelite Sheets

The Problem: One of the primary challenges B2B buyers face is sourcing high-quality Bakelite sheets that meet specific industry standards. In markets such as Africa and South America, the availability of reliable suppliers can be limited, leading to concerns over the quality and consistency of materials. Buyers often find themselves overwhelmed by numerous suppliers, each offering different grades and specifications, making it difficult to determine which products will best suit their applications.

The Solution: To effectively source high-quality Bakelite sheets, buyers should start by conducting thorough research on potential suppliers. Look for manufacturers who provide detailed product specifications, certifications, and samples. Establishing relationships with suppliers who specialize in Bakelite products can also enhance confidence in material quality. Additionally, consider utilizing online platforms that aggregate supplier reviews and ratings. Once a supplier is chosen, clearly communicate your specific requirements, including thickness, color, and reinforcement type, to ensure the delivered sheets meet your exact needs.

Scenario 2: Managing Technical Specifications and Compliance

The Problem: B2B buyers often struggle with understanding the technical specifications required for Bakelite sheets, especially when compliance with industry standards is necessary. In industries such as electronics or automotive, specifications like dielectric strength, thermal stability, and chemical resistance are critical. Misunderstanding these parameters can lead to costly production delays or product failures.

The Solution: To navigate technical specifications effectively, it’s essential for buyers to engage with technical experts or engineers during the selection process. Create a checklist of the necessary properties that Bakelite sheets must possess based on your application’s requirements. Collaborating with suppliers who offer technical support can also provide insights into material performance. Additionally, request documentation that demonstrates compliance with relevant industry standards. This proactive approach ensures that you select Bakelite sheets that not only meet technical specifications but also align with regulatory requirements, minimizing risks in the production process.

Scenario 3: Challenges with Machining and Fabrication

The Problem: Another common pain point is the difficulty in machining and fabricating Bakelite sheets to fit specific design requirements. Buyers often encounter issues with machining that lead to poor finishes, increased waste, or even damage to the sheets. This challenge can be particularly frustrating for manufacturers who require precision components for their products.

The Solution: To optimize machining processes for Bakelite sheets, buyers should invest in proper training for their machining teams. Understanding the unique properties of Bakelite, such as its hardness and brittleness, is crucial for selecting the right tools and techniques. It is advisable to use carbide tools designed for plastics and to maintain lower speeds to prevent overheating, which can lead to chipping. Additionally, consider pre-cutting the sheets into manageable sizes before machining to reduce waste. Implementing best practices for handling and machining Bakelite will not only enhance the quality of the final product but also improve efficiency in production. Seeking guidance from suppliers on machining parameters can also provide valuable insights tailored to specific applications.

Strategic Material Selection Guide for bakelite sheet

What Are the Key Properties of Different Bakelite Sheet Materials?

When selecting Bakelite sheets for various applications, understanding the specific properties of different materials is crucial. Here, we analyze three common types of Bakelite sheets: paper-reinforced, fabric-reinforced, and glass-reinforced Bakelite sheets. Each material offers unique characteristics that can influence performance and suitability for specific applications.

What Are the Properties and Applications of Paper-Reinforced Bakelite Sheets?

Paper-reinforced Bakelite sheets are made from layers of paper impregnated with Bakelite resin. This type of sheet is known for its excellent electrical insulation properties and low moisture absorption. With a temperature rating of up to 120°C, it is suitable for applications like electrical insulators, switchboards, and circuit boards.

Pros:

– Cost-effective due to lower raw material expenses.

– Lightweight and easy to machine, making it suitable for high-volume production.

– Good dielectric properties enhance performance in electrical applications.

Cons:

– Limited thermal stability compared to other reinforced types, which may restrict its use in high-temperature environments.

– Vulnerable to moisture over prolonged exposure, potentially affecting performance.

Impact on Application:

Ideal for electrical components, paper-reinforced Bakelite sheets excel in environments where moisture is controlled. However, buyers should ensure compatibility with their specific electrical and environmental conditions.

How Do Fabric-Reinforced Bakelite Sheets Perform?

Fabric-reinforced Bakelite sheets utilize layers of fabric impregnated with Bakelite resin, providing enhanced mechanical strength and wear resistance. They can withstand temperatures up to 150°C, making them suitable for mechanical parts, gears, and bearings.

Pros:

– High mechanical strength allows for precision in applications requiring durability.

– Excellent wear resistance extends the lifespan of components.

– Versatile for machining into complex shapes.

Cons:

– Higher cost compared to paper-reinforced options due to the complexity of manufacturing.

– May require specialized machining tools, increasing production costs.

Impact on Application:

Fabric-reinforced sheets are ideal for applications demanding high mechanical performance. Buyers should consider the increased investment against the long-term benefits of durability and reduced maintenance.

What Are the Advantages of Glass-Reinforced Bakelite Sheets?

Glass-reinforced Bakelite sheets are made from layers of glass fiber impregnated with Bakelite resin, providing superior thermal stability and chemical resistance. They can endure temperatures up to 200°C and are often used in high-temperature applications, chemical equipment, and laminates.

Pros:

– Exceptional thermal stability and chemical resistance make them suitable for harsh environments.

– High strength-to-weight ratio enhances performance in demanding applications.

– Reduced water absorption increases longevity in humid conditions.

Cons:

– Generally the most expensive option, which may deter cost-sensitive buyers.

– More complex manufacturing process can lead to longer lead times.

Impact on Application:

Glass-reinforced Bakelite sheets are ideal for industries such as automotive and chemical processing, where high performance is non-negotiable. International buyers should ensure compliance with relevant standards, such as ASTM or DIN, to guarantee quality and safety.

Summary Table of Bakelite Sheet Materials

| Material | Typical Use Case for Bakelite Sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Paper-Reinforced Bakelite | Electrical insulators, circuit boards | Cost-effective and easy to machine | Limited thermal stability | Low |

| Fabric-Reinforced Bakelite | Mechanical parts, gears, bearings | High mechanical strength and wear resistance | Higher cost and specialized machining required | Medium |

| Glass-Reinforced Bakelite | High-temperature applications, chemical equipment | Exceptional thermal stability and chemical resistance | Most expensive with longer lead times | High |

This strategic material selection guide provides a comprehensive overview of Bakelite sheet options, helping international B2B buyers make informed decisions based on application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bakelite sheet

What Are the Key Stages in the Manufacturing Process of Bakelite Sheets?

The manufacturing process of Bakelite sheets involves several critical stages that ensure the final product meets the stringent requirements of various industries. Understanding these stages can help B2B buyers assess the capabilities and quality of potential suppliers.

Material Preparation: How Is Bakelite Resin Made?

The first step in manufacturing Bakelite sheets is the creation of Bakelite resin, a thermosetting polymer derived from phenol and formaldehyde. These two organic compounds undergo a condensation reaction in a controlled environment, typically within a reactor subjected to heat and pressure. This process results in a complex molecular structure known as phenol formaldehyde resin. Depending on the desired properties of the final product, manufacturers may modify the resin by incorporating fillers or catalysts.

Forming: What Techniques Are Used to Create Bakelite Sheets?

Once the resin is prepared, the next stage involves forming the Bakelite sheets. This process typically involves stacking layers of reinforcing materials such as paper, fabric, or glass fiber, which are then impregnated with the Bakelite resin. These layered materials are placed in a hydraulic press, where they are subjected to heat and pressure. The combination of heat and pressure activates the curing process, solidifying the resin and binding the layers into a rigid sheet. The thickness of Bakelite sheets can vary, ranging from 0.5 mm to 50 mm, depending on the application.

Assembly: How Are Bakelite Sheets Processed for Specific Applications?

Following the curing process, the Bakelite sheets are trimmed and cut to specific sizes and shapes based on the intended application. This stage may involve CNC machining, which allows for precise cutting, drilling, and milling of the sheets. The versatility of Bakelite sheets makes them suitable for a wide array of applications, including electrical insulators, mechanical parts, and automotive components.

Finishing: What Quality Enhancements Are Implemented?

In the finishing stage, Bakelite sheets may undergo additional treatments such as polishing or surface coating to enhance their aesthetic appeal and durability. This step is crucial for applications where visual quality and surface integrity are paramount, such as in furniture or decorative items.

What Quality Assurance Practices Are Essential for Bakelite Sheet Manufacturing?

Quality assurance is a vital aspect of Bakelite sheet manufacturing, ensuring that the final products meet international standards and customer specifications. Here, we explore the quality control practices that B2B buyers should be aware of.

Which International Standards Should Be Considered?

B2B buyers should look for suppliers that adhere to recognized international quality standards such as ISO 9001. This standard ensures that organizations consistently meet customer requirements and enhance satisfaction through effective quality management systems. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications may be relevant, depending on the intended use of the Bakelite sheets.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control during the manufacturing of Bakelite sheets typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials, including the phenol and formaldehyde used to create the resin, as well as the reinforcing materials. Suppliers must ensure that all materials comply with specified standards before production begins.

-

In-Process Quality Control (IPQC): During the curing and forming stages, regular inspections are conducted to monitor the process parameters such as temperature and pressure. This helps to identify any deviations from the standard operating procedures, allowing for immediate corrective action.

-

Final Quality Control (FQC): Once the Bakelite sheets are manufactured, they undergo final inspections to ensure they meet dimensional and performance specifications. This may include mechanical testing, electrical insulation testing, and visual inspections for surface defects.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential to mitigate risks. Here are some strategies to ensure supplier compliance with quality standards:

What Audits and Reports Should Buyers Request?

Buyers should request detailed quality management system documentation, including internal audit reports and certifications. Conducting on-site audits can also provide firsthand insight into the manufacturing processes and quality control measures implemented by the supplier.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can offer an objective assessment of the supplier’s quality control practices. These inspections can be particularly valuable in verifying compliance with international standards and assessing the reliability of the manufacturing process.

What Are the Nuances of Quality Control for International B2B Transactions?

Navigating quality control in international transactions can present unique challenges. Buyers should be aware of the following nuances:

-

Regulatory Compliance: Different countries have varying regulations regarding materials and manufacturing processes. Understanding these regulations is crucial for ensuring that the Bakelite sheets comply with local laws in the buyer’s market.

-

Cultural Differences: Expectations regarding quality and communication can differ across regions. Establishing clear communication channels and setting mutual expectations can help bridge these gaps.

-

Logistical Considerations: The transportation of Bakelite sheets can be affected by international shipping regulations. Ensuring that the supplier adheres to proper packaging and labeling standards is vital to prevent damage during transit.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for Bakelite sheets equips B2B buyers with the knowledge needed to make informed purchasing decisions. By focusing on quality standards, verification strategies, and the nuances of international transactions, buyers can establish successful partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bakelite sheet’

This guide serves as a practical checklist for B2B buyers looking to procure Bakelite sheets, ensuring that you make informed decisions that meet your business needs. By following these steps, you can effectively navigate the sourcing process and select a reliable supplier that provides high-quality materials.

Step 1: Define Your Technical Specifications

Establishing your technical specifications is crucial for ensuring that the Bakelite sheets meet your application requirements. Consider factors such as thickness, reinforcement type (paper, fabric, or glass), and desired mechanical properties. Clearly defining these parameters will help you communicate effectively with suppliers and avoid purchasing unsuitable products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of Bakelite sheets. Look for companies with a strong track record in the industry and positive customer reviews. Utilize platforms like trade directories, industry forums, and LinkedIn to gather information and shortlist potential suppliers.

Step 3: Evaluate Supplier Certifications and Quality Assurance

Before engaging with suppliers, verify their certifications and quality assurance processes. Certifications such as ISO 9001 indicate adherence to international quality management standards. Additionally, inquire about their quality control measures, including testing procedures for Bakelite sheets, to ensure you receive materials that meet your specifications.

Step 4: Request Samples for Testing

Once you have narrowed down your options, request samples of Bakelite sheets from your shortlisted suppliers. Testing these samples for mechanical strength, heat resistance, and electrical insulation properties is essential to confirm that they meet your requirements. This step will help you make an informed decision based on tangible evidence rather than relying solely on supplier claims.

Step 5: Assess Pricing and Payment Terms

Compare pricing from different suppliers while considering the quality of the materials offered. Look for transparency in pricing structures and any additional costs related to shipping, handling, or customizations. Additionally, negotiate favorable payment terms that align with your cash flow needs, ensuring you have flexibility in your procurement process.

Step 6: Check Delivery Times and Logistics

Understanding the delivery times and logistics involved in sourcing Bakelite sheets is vital for planning your production schedules. Inquire about the suppliers’ lead times and shipping options to avoid delays. Also, ensure that they have reliable logistics partners to facilitate timely and safe delivery of your materials.

Step 7: Establish a Long-Term Relationship

Once you have selected a supplier, focus on building a long-term partnership. Open lines of communication can lead to better pricing, priority service, and tailored solutions for your business. Regularly assess supplier performance to ensure they continue to meet your evolving needs.

By following this checklist, you can streamline your procurement process for Bakelite sheets and ensure that you are making sound purchasing decisions that align with your operational goals.

Comprehensive Cost and Pricing Analysis for bakelite sheet Sourcing

Understanding the cost structure and pricing dynamics of Bakelite sheet sourcing is crucial for international B2B buyers looking to optimize their procurement processes. This section breaks down the key cost components, price influencers, and offers actionable tips for effective negotiation and decision-making.

What Are the Key Cost Components in Bakelite Sheet Sourcing?

The cost structure for Bakelite sheets generally comprises several essential components:

-

Materials: The primary cost driver is the raw material—phenol formaldehyde resin. Variations in the resin’s quality and the type of reinforcement (paper, fabric, or glass) can significantly impact material costs. Higher quality materials often lead to increased durability and performance, justifying a premium price.

-

Labor: Labor costs are incurred during the manufacturing process, which includes the handling of raw materials, curing, cutting, and finishing the sheets. Skilled labor is essential for ensuring quality, especially when precision machining is involved.

-

Manufacturing Overhead: This includes utilities, maintenance of machinery, and factory costs. Efficient manufacturing processes can help minimize overhead, thus reducing the overall cost per unit.

-

Tooling: Custom tooling may be required for specific applications or designs, which can add to the upfront costs. However, these costs can be amortized over larger production runs.

-

Quality Control (QC): Implementing stringent QC measures is crucial to ensure that the products meet specifications. This can involve testing for electrical insulation, mechanical strength, and thermal resistance, which adds to the overall cost.

-

Logistics: Shipping and handling costs are particularly significant for international buyers. The choice of Incoterms can influence these expenses, affecting the total landed cost.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. This margin can vary significantly based on market conditions and supplier competition.

How Do Price Influencers Affect Bakelite Sheet Costs?

Several factors can influence the pricing of Bakelite sheets:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs to determine the most cost-effective order size.

-

Specifications and Customization: Custom specifications can lead to higher costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Material Quality and Certifications: Premium materials and certifications (e.g., ISO standards) can drive up costs but provide assurance of quality and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more, but they often provide better quality and service.

-

Incoterms: The choice of Incoterms affects who bears the shipping costs and risks. Understanding the implications of terms like FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) can lead to cost savings.

What Are Some Effective Buyer Tips for Sourcing Bakelite Sheets?

-

Negotiate with Suppliers: Leverage your purchasing power by negotiating better terms, especially if you are placing large orders. Suppliers may be willing to offer discounts for bulk purchases or long-term contracts.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as durability, maintenance, and potential replacement costs over time.

-

Understand Pricing Nuances for International Markets: Different regions may have varying pricing structures due to local market conditions, tariffs, and shipping costs. For buyers in Africa, South America, the Middle East, and Europe, it’s crucial to research local suppliers and market trends.

-

Request Detailed Quotes: When sourcing Bakelite sheets, ask for itemized quotes that break down costs by component. This transparency can help identify areas for potential savings.

-

Consider Alternative Suppliers: Explore multiple suppliers to compare pricing and quality. This competitive approach can lead to better deals and improved product options.

Disclaimer

Prices for Bakelite sheets can fluctuate based on market conditions, material availability, and supplier pricing strategies. It is advisable for buyers to conduct thorough market research and obtain multiple quotes before making purchasing decisions.

Alternatives Analysis: Comparing bakelite sheet With Other Solutions

Introduction: Understanding Alternatives to Bakelite Sheets

In the evolving landscape of materials used for industrial applications, Bakelite sheets stand out due to their robust properties and historical significance. However, various alternatives exist that may better suit specific applications or budget constraints. This analysis will compare Bakelite sheets with two prominent alternatives: epoxy resin sheets and polycarbonate sheets, providing insights that can aid international B2B buyers in making informed decisions.

Comparison Table

| Comparison Aspect | Bakelite Sheet | Epoxy Resin Sheet | Polycarbonate Sheet |

|---|---|---|---|

| Performance | High mechanical strength, excellent electrical insulation, heat and flame resistant | Strong adhesion, excellent chemical resistance, good electrical insulation | High impact resistance, lightweight, good thermal insulation |

| Cost | Moderate | Moderate to high | Moderate |

| Ease of Implementation | Requires specialized machining | Easy to mold and cut | Easy to work with, can be thermoformed |

| Maintenance | Low maintenance, durable | Moderate, may require periodic checks | Low maintenance, durable |

| Best Use Case | Electrical insulation, automotive parts | Aerospace, marine, and industrial applications | Safety glasses, glazing, and protective equipment |

Detailed Breakdown of Alternatives

Epoxy Resin Sheets

Epoxy resin sheets offer several advantages, particularly in applications requiring strong adhesive properties and chemical resistance. They are often used in industries such as aerospace and marine, where durability and performance under stress are critical. However, the curing process can be time-consuming, and while they provide excellent electrical insulation, they may not match the heat resistance of Bakelite sheets. For applications where high-temperature resistance is not a primary concern, epoxy resin sheets can be a viable alternative.

Polycarbonate Sheets

Polycarbonate sheets are known for their exceptional impact resistance and lightweight nature, making them ideal for applications requiring safety and durability, such as in protective equipment and glazing. They are easy to work with and can be thermoformed, which allows for greater versatility in design. However, polycarbonate does not provide the same level of heat resistance or electrical insulation as Bakelite sheets. It may also be more susceptible to scratching unless treated with a protective coating. Nevertheless, for applications prioritizing safety and ease of use, polycarbonate sheets present a strong alternative.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate material for your application depends on various factors, including performance requirements, budget, and ease of implementation. Bakelite sheets excel in high-temperature, electrical insulation applications, while epoxy resin sheets may be preferred for their chemical resistance and adhesion capabilities. Polycarbonate sheets, on the other hand, shine in safety applications due to their impact resistance and lightweight nature. B2B buyers should assess their specific needs against the properties and advantages of each material to make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for bakelite sheet

What Are the Key Technical Properties of Bakelite Sheets Important for B2B Buyers?

When considering Bakelite sheets for industrial applications, understanding their technical properties is crucial. Here are some of the most critical specifications:

1. Material Grade

Bakelite sheets come in various grades, primarily differentiated by the type of reinforcement used. Common grades include paper-reinforced, fabric-reinforced, and glass-reinforced Bakelite. Each grade offers unique properties tailored for specific applications, such as electrical insulation or mechanical strength. Selecting the right grade ensures optimal performance in the intended application, reducing the risk of failure and enhancing product reliability.

2. Thickness Tolerance

Thickness tolerance is a vital specification that indicates the allowable deviation from the specified thickness of the Bakelite sheet. Standard thickness ranges from 0.5 mm to 50 mm, with tighter tolerances often required for precision applications. Understanding thickness tolerance helps B2B buyers ensure that the material will fit seamlessly into their designs, especially in applications like electrical insulation and mechanical components.

3. Thermal Stability

Bakelite sheets exhibit high thermal stability, maintaining their mechanical properties at elevated temperatures up to 250°C. This characteristic is essential for applications in high-heat environments, such as automotive parts and electrical insulators. B2B buyers should assess thermal stability to avoid premature material failure and ensure long-term performance.

4. Dielectric Strength

Dielectric strength refers to a material’s ability to resist electric breakdown. Bakelite sheets have excellent dielectric properties, making them suitable for electrical applications where insulation is critical. This property is particularly important for industries such as electronics and telecommunications, where safety and performance are paramount.

5. Chemical Resistance

Bakelite sheets demonstrate good resistance to various chemicals, including acids, alkalis, and solvents. This property is vital for applications involving exposure to harsh substances, such as chemical processing equipment. Understanding chemical resistance can help B2B buyers select Bakelite sheets that will withstand their specific operational environments.

What Trade Terminology Should B2B Buyers of Bakelite Sheets Be Familiar With?

Navigating the procurement process for Bakelite sheets involves understanding key industry terminology. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products for other brands under the latter’s label. In the context of Bakelite sheets, knowing if a supplier is an OEM can help buyers understand the quality and reliability of the products they are purchasing, as OEMs typically adhere to strict manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of product that a supplier is willing to sell. Understanding the MOQ is essential for B2B buyers to manage inventory effectively and minimize costs. A high MOQ might be a barrier for smaller businesses or those requiring low-volume production runs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers should prepare detailed RFQs to ensure they receive accurate quotes for Bakelite sheets, including specifications, quantities, and delivery timelines.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and delivery responsibilities when sourcing Bakelite sheets from global suppliers.

5. CNC Machining

CNC (Computer Numerical Control) machining refers to the automated process of cutting and shaping materials using computer-controlled tools. For Bakelite sheets, CNC machining allows for precise fabrication of components, ensuring that parts meet exact specifications required for various applications.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions when sourcing Bakelite sheets, ensuring they meet their specific operational needs while optimizing cost and efficiency.

Navigating Market Dynamics and Sourcing Trends in the bakelite sheet Sector

What Are the Current Market Trends Affecting Bakelite Sheet Sourcing?

The bakelite sheet market is witnessing a resurgence driven by various global factors. A growing demand for durable and heat-resistant materials in industries such as electronics, automotive, and construction is propelling market growth. The ongoing shift towards retro design aesthetics in consumer products has also revived interest in bakelite, particularly in regions like Europe and North America, where vintage styles are in vogue. Additionally, the increasing focus on sustainability and the circular economy is prompting manufacturers to explore eco-friendly alternatives, leading to innovations in bakelite production processes.

Emerging technologies, such as advanced CNC machining and additive manufacturing, are reshaping how bakelite sheets are produced and customized. These technologies enhance precision, reduce waste, and allow for the creation of complex geometries, making bakelite sheets more appealing to B2B buyers seeking tailored solutions. Moreover, the rise of e-commerce platforms is simplifying the procurement process for international buyers, particularly in Africa, South America, and the Middle East, where access to quality materials may have been limited.

As international trade dynamics evolve, buyers should stay informed about tariffs and regulations impacting bakelite imports in their regions. Understanding local market conditions and consumer preferences will be essential for navigating the complexities of sourcing bakelite sheets effectively.

How Is Sustainability Shaping Bakelite Sheet Sourcing?

Sustainability is becoming a critical factor in the sourcing of bakelite sheets, as businesses are increasingly held accountable for their environmental impact. Traditional bakelite production involves the use of phenol and formaldehyde, which can raise concerns regarding toxicity and pollution. As a result, manufacturers are under pressure to adopt greener practices, such as implementing closed-loop systems and utilizing renewable energy sources in their production processes.

Ethical sourcing is paramount for B2B buyers aiming to build a responsible supply chain. This includes vetting suppliers for compliance with environmental regulations and social responsibility standards. Certifications such as ISO 14001 for environmental management and Cradle to Cradle for sustainable product design can help buyers identify reputable suppliers committed to minimizing their ecological footprint.

Furthermore, exploring alternative materials that provide similar performance characteristics to bakelite but with a reduced environmental impact is becoming a viable option. Innovations in bioplastics and recycled materials may offer sustainable alternatives that align with the evolving values of consumers and businesses alike.

What Historical Factors Influence Today’s Bakelite Sheet Market?

The historical significance of bakelite as the first synthetic plastic has paved the way for its enduring relevance in modern manufacturing. Invented in 1907 by Leo Baekeland, bakelite revolutionized the plastics industry by offering a durable, heat-resistant alternative to natural materials. Its application in electrical insulation, automotive parts, and consumer goods laid the foundation for the extensive use of synthetic materials in various sectors today.

While modern plastics have largely supplanted bakelite in many applications, its unique properties and nostalgic appeal continue to resonate with buyers, particularly in niche markets. The ongoing revival of retro aesthetics in product design has spurred renewed interest in bakelite sheets, making them a sought-after material for both functional and decorative purposes. Understanding this historical context can provide B2B buyers with valuable insights into current market dynamics and consumer trends, enabling more informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of bakelite sheet

-

How do I identify high-quality bakelite sheets for my business needs?

To identify high-quality bakelite sheets, focus on suppliers that provide detailed product specifications, including mechanical strength, thermal resistance, and chemical stability. Request samples to evaluate the material’s physical properties and ensure it meets your requirements. Additionally, check for industry certifications and compliance with international standards, such as ISO or ASTM, which indicate the quality and reliability of the products. Engage in discussions with suppliers about their manufacturing processes to gauge their expertise and commitment to quality. -

What are the key properties of bakelite sheets that make them suitable for industrial applications?

Bakelite sheets are prized for their high mechanical strength, heat resistance (up to 250°C), and excellent electrical insulation properties. They exhibit low flammability and self-extinguishing characteristics, making them ideal for electrical components and mechanical parts. Their chemical resistance ensures durability in harsh environments. Furthermore, bakelite sheets can be easily machined, allowing for customization in various applications, from automotive parts to electrical insulators, enhancing their versatility across industries. -

What customization options are available for bakelite sheets?

Many suppliers offer customization options for bakelite sheets, including varying thicknesses (from 0.5 mm to 50 mm), reinforcement types (paper, fabric, or glass), and color choices. You can also request specific dimensions or shapes tailored to your project’s requirements. Additionally, suppliers may provide CNC machining services to create precision components. Communicating your exact needs during the inquiry process will help ensure you receive a product that meets your specifications. -

What minimum order quantities (MOQs) should I expect when purchasing bakelite sheets?

Minimum order quantities for bakelite sheets can vary significantly based on the supplier and the specific product type. Generally, MOQs may range from 50 to 500 sheets, depending on customization and manufacturing processes. For smaller businesses or specific projects, some suppliers may offer flexibility or allow smaller orders at a higher price per unit. It is advisable to discuss your needs upfront with potential suppliers to find a mutually agreeable MOQ that aligns with your project requirements. -

What payment terms should I consider when sourcing bakelite sheets internationally?

When sourcing bakelite sheets internationally, common payment terms include advance payment, letters of credit, or payment upon delivery. Discussing payment terms upfront with suppliers is crucial to avoid misunderstandings. Consider using escrow services for large orders to ensure both parties fulfill their obligations. Additionally, inquire about currency options and any potential fees associated with international transactions, as these can impact your overall cost. -

How do I vet potential bakelite sheet suppliers effectively?

To vet potential bakelite sheet suppliers, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients. Verify their certifications, quality control processes, and compliance with international standards. Conduct interviews to assess their responsiveness and willingness to address your concerns. Visiting their manufacturing facilities, if possible, can provide valuable insights into their production capabilities and commitment to quality. -

What are the best practices for shipping bakelite sheets internationally?

When shipping bakelite sheets internationally, ensure proper packaging to prevent damage during transit. Use sturdy boxes or pallets and protective materials to cushion the sheets. Choose a reliable logistics partner with experience in handling industrial materials. Discuss shipping terms (e.g., FOB, CIF) and delivery timelines upfront to avoid delays. Additionally, familiarize yourself with customs regulations in your destination country to ensure smooth clearance and compliance with import requirements. -

What quality assurance measures should I expect from bakelite sheet suppliers?

Reputable bakelite sheet suppliers should have robust quality assurance measures in place, including regular testing of raw materials and finished products. Look for suppliers who conduct mechanical and electrical property tests, as well as thermal and chemical resistance evaluations. Certifications like ISO 9001 indicate adherence to quality management standards. Request documentation of quality tests and inspection reports for your orders to ensure that the products meet your specifications and industry standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Bakelite Sheet Manufacturers & Suppliers List

1. Bee Plastic – Bakelite Innovation

Domain: beeplastic.com

Registered: 2023 (2 years)

Introduction: Bakelite is a fully synthetic plastic invented by Leo Baekeland in 1907. It has revolutionized product manufacturing across various industries including electronics, appliances, and automobiles.

2. Professional Plastics – Bakelite

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: Bakelite is a thermosetting plastic that is known for its excellent electrical insulation properties, high mechanical strength, and resistance to heat and chemicals. It is commonly used in applications such as electrical components, automotive parts, and household items. Bakelite is available in various forms, including sheets, rods, and tubes, and can be machined to precise specifications. It is …

3. Bakelite – Sheets in Various Sizes and Colors

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Bakelite Sheet available in various sizes and thicknesses, primarily made of phenolic resin. Products include options such as Black Bakelite, Red Bakelite, and Orange Bakelite sheets. Prices range from approximately $1.29 to $1,500+, with many items available for ‘Buy It Now’ and some accepting offers. Shipping options include free international shipping and local pickup within 25 miles. Condition…

4. Bakelite Sheets – High-Quality Laminated Phenolic Solutions

Domain: bakelitesheets.com

Registered: 2012 (13 years)

Introduction: Bakelite Sheet, also known as Hylam sheet, Tufnol sheet, Norplex Sheet, Micarta Sheet, Synthetic Resin Bonded Paper Base Sheet (SRBP), Phenolic Sheet, Fabric Sheet, Laminated Sheet, Synthetic Resin Bonded Fabric base Sheet (SRBF). Made from cellulose paper or fabric cloth impregnated with synthetic resin (Phenolic Resin) under heat and pressure, transforming into thermosetting industrial laminates…

5. Swift Supplies – Fabric Reinforced Bakelite Sheets

Domain: swiftsupplies.com.au

Introduction: Fabric Reinforced Bakelite Sheets are an economical grade of tough, strong electrical insulation for lower temperature (Class A / 125°C) applications. Made from synthetic resin reinforced with layers of cotton fabric, they offer good electrical properties and excellent mechanical strength. Available in various standard sizes, custom sizes can also be ordered. The sheets can withstand temperatures …

6. Quandaplastic – Ketonolic® Phenolic Bakelite Sheet

Domain: quandaplastic.com

Registered: 2009 (16 years)

Introduction: Ketonolic® Phenolic Bakelite Sheet

7. HPS EXIM – Hylam / Bakelite Sheet

Domain: hpsexim.com

Registered: 2010 (15 years)

Introduction: {“Product Name”: “Hylam / Bakelite Sheet”, “Manufacturer”: “HPS EXIM PVT. LTD.”, “Color”: [“Red”, “Brown”], “Thickness”: “0.5-80mm”, “Size”: “1220mm x 1220mm (customizable)”, “Heat Resistance Rating”: “Class E”, “Description”: “Bakelite sheets are manufactured using multiple layers of kraft paper treated with phenolic resin. These laminates serve as insulation material and are classified based on …

8. HandsOnTec – Brown Bakelite Sheet

Domain: handsontec.com

Registered: 2006 (19 years)

Introduction: {“Product Name”: “Brown Bakelite Sheet”, “Dimensions”: “19x200x250 mm”, “Price”: “$19.50”, “Pack Size”: “1-piece/lot”, “Color”: “Brown”, “Thickness”: “19 mm”, “Area”: “200×250 mm”, “Heat Resistance (Martens Test)”: “min. 125°C”, “Impact Strength”: “24.5 KJ/m²”, “Bond Strength”: “min. 5,390 N”, “Density”: “1.45 g/cm³”, “Flexural Strength”: “min. 103 MPa”, “Tensile Strength”: “min. 63.8 MPa”, “Elect…

9. JHD Material – Bakelite Sheet

Domain: blog.jhd-material.com

Registered: 2021 (4 years)

Introduction: Bakelite sheet, also known as phenolic sheet or Bakelite board, is a thermosetting plastic invented by Leo Baekeland in 1907. It is composed of phenol-formaldehyde resin, known for its excellent electrical insulation properties, heat resistance, and mechanical strength. The manufacturing process involves the compression molding of phenol-formaldehyde resins, with variations including paper-based, …

10. Hony Plastic – Bakelite Insulation Sheet

Domain: honyplastic.com

Registered: 2020 (5 years)

Introduction: Bakelite Insulation Sheet, also known as phenolic resin laminate, is made from cotton cloth impregnated with phenolic resin through drying and hot pressing. It has excellent mechanical properties, high resistance to pressure, vibrations, and friction, making it suitable for general industrial applications. The product is available in various models, including HP2061 and HONY-Bakelite, with a minim…

Strategic Sourcing Conclusion and Outlook for bakelite sheet

In conclusion, the strategic sourcing of Bakelite sheets offers significant advantages for businesses across various sectors, especially those in electrical, automotive, and mechanical industries. The unique properties of Bakelite, such as high heat resistance, excellent electrical insulation, and mechanical strength, make it an ideal choice for applications ranging from electrical insulators to durable furniture components. By understanding the diverse grades and types of Bakelite sheets available, B2B buyers can make informed purchasing decisions that align with their specific project requirements.

As the demand for innovative and sustainable materials continues to rise, leveraging strategic sourcing practices will be crucial for maintaining competitive advantage. Establishing relationships with reliable suppliers, ensuring quality control, and exploring cost-effective options can enhance procurement strategies and drive operational efficiency.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to explore the potential of Bakelite sheets as part of their material sourcing strategy. By embracing this timeless material, businesses can not only meet current demands but also innovate for future applications. Engage with suppliers today to unlock the diverse possibilities of Bakelite sheets and elevate your production capabilities.