Contents

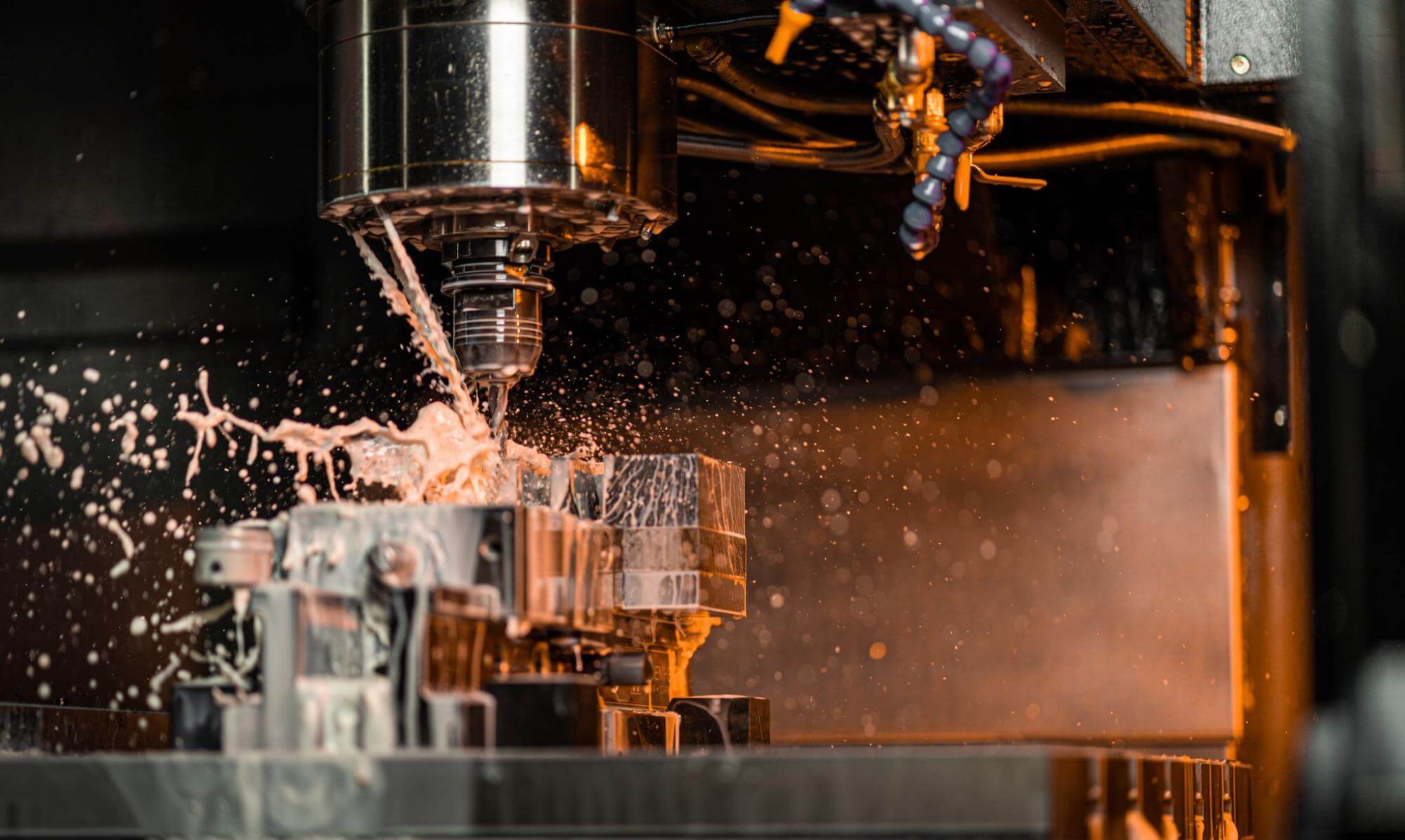

Manufacturing Insight: Background Cnc

Honyo Prototype CNC Machining Services Introduction

Honyo Prototype delivers precision CNC machining solutions engineered for rapid prototyping and low-volume production, serving industries where accuracy and material integrity are non-negotiable. Our facility operates advanced 3-axis, 4-axis, and 5-axis CNC milling and turning centers, consistently achieving tolerances down to ±0.005 mm across aerospace alloys, medical-grade polymers, titanium, and hardened steels. This capability ensures complex geometries and critical surface finishes meet stringent engineering specifications without compromising turnaround speed.

Central to our service efficiency is the Online Instant Quote platform, which provides automated, transparent pricing within minutes of uploading CAD files. Engineers and procurement teams eliminate traditional quoting delays by receiving immediate cost feedback based on real-time machine availability, material utilization, and feature complexity. This integration of digital workflow with manufacturing expertise accelerates development cycles while maintaining full traceability from design submission to shipped part.

For technical partners requiring agile, high-fidelity component fabrication, Honyo Prototype bridges the gap between concept validation and production readiness through validated processes and data-driven manufacturing execution. Submit designs to experience how our CNC services reduce time-to-prototype without sacrificing precision.

Technical Capabilities

Background CNC refers to core capabilities and technical specifications commonly associated with advanced CNC machining services, particularly in high-precision prototyping and low-to-medium volume production environments. This includes multi-axis milling (3, 4, and 5-axis), CNC turning, and the ability to maintain tight tolerances across a range of engineering-grade materials such as aluminum, steel, ABS, and nylon.

The following table outlines the technical specifications relevant to these processes and materials:

| Parameter | Specification |

|---|---|

| Machining Processes | 3-Axis Milling, 4-Axis Indexed Milling, 5-Axis Simultaneous Milling, CNC Turning |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Standard Tolerances | ±0.025 mm (±0.001 in) |

| Tight Tolerance Capability | ±0.012 mm (±0.0005 in) achievable with process control and inspection |

| Surface Finish (As Machined) | 3.2 μm (125 μin) typical; down to 0.8 μm (32 μin) with polishing or special finishing |

| Max Work Envelope (Milling) | 760 x 410 x 410 mm (30 x 16 x 16 in) – varies by machine |

| Max Work Envelope (Turning) | Ø300 mm x 600 mm (Ø12 in x 24 in) maximum part diameter and length |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Spindle Speed (Turning) | Up to 6,000 RPM (varies by chuck size and material) |

| Tooling System | ISO 30 / HSK 63 compatible; automatic tool changers (ATC) standard |

| Control System | Fanuc, Siemens, or Heidenhain based CNC controls |

| Materials – Metals | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 17-4 PH stainless), Titanium (Grade 2, 5) |

| Materials – Plastics | ABS, Nylon (6 & 66), Delrin (POM), PEEK, Polycarbonate, HDPE |

| Fixturing | Modular vises, tombstones, custom soft jaws, zero-point systems |

| In-Process Inspection | Available via touch probe systems (e.g., Renishaw) |

| Post-Processing | Deburring, anodizing (Type II & III), powder coating, passivation, bead blasting |

These specifications support high-accuracy part production across complex geometries and demanding applications in aerospace, medical, robotics, and industrial equipment sectors. Multi-axis capabilities enable single-setup machining of intricate features, while tight tolerance control ensures repeatability and part-to-part consistency across both metallic and engineering plastic substrates.

From CAD to Part: The Process

Honyo Prototype’s background CNC process integrates digital automation with expert engineering oversight to deliver rapid, high-fidelity prototypes and low-volume production parts. This workflow minimizes manual intervention while ensuring manufacturability and quality through embedded validation checkpoints. Below is the technical sequence:

CAD Upload and Initial Processing

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system automatically detects critical geometry parameters including feature tolerances, wall thicknesses, material requirements, and part complexity metrics. Geometric dimensioning and tolerancing (GD&T) annotations are parsed for downstream analysis. Non-conforming files trigger immediate client notification with specific error diagnostics.

AI-Powered Quoting Engine

Uploaded geometry feeds into our proprietary AI quoting module trained on 12+ years of CNC machining data across 8 material families. The engine calculates machine runtime using toolpath simulation algorithms, material waste factors, and fixture requirements. Real-time material pricing from certified suppliers and machine utilization rates are incorporated. Quotes include cost breakdowns for 3-axis, 4-axis, and 5-axis options with accuracy metrics (±0.05mm standard). Human validation by application engineers occurs for non-standard geometries or exotic materials, maintaining 92% first-pass quote accuracy.

Automated DFM Analysis with Expert Refinement

Every design undergoes automated Design for Manufacturability screening against our CNC rule library containing 1,850+ parameters. The system flags high-risk features such as thin walls (<0.8mm in aluminum), deep cavities (depth:width >6:1), and non-optimal hole depths. Critical verification points include:

| Verification Category | Threshold | Action |

|---|---|---|

| Minimum Wall Thickness | < Material-dependent limit | Geometry modification recommendation |

| Tool Access Clearance | < 3mm interference | Suggest alternative approach or EDM |

| Surface Finish Consistency | Ra variance >1.6μm predicted | Propose post-process polishing |

| Tolerance Stack Analysis | Cumulative error >0.1mm | Recommend datum adjustment |

DFM reports generate within 4 business hours with visual annotations. Engineers collaborate with clients via shared markup tools to resolve issues before production release.

Production Execution

Approved designs move to our digital work order system with auto-generated G-code verified through virtual machine simulation (NCSIMUL). Material procurement initiates against pre-qualified supplier stock. Machining occurs on our monitored equipment floor (Haas, DMG MORI, Makino) with real-time spindle load and vibration telemetry. In-process inspections use Renishaw probes for critical dimensions at 25%, 50%, and 100% completion milestones. All non-conformances trigger automated engineering review.

Quality-Controlled Delivery

Final inspection includes CMM validation against original CAD with full FAIR documentation. Parts undergo first-article inspection per AS9102 standards for aerospace clients. Packaging uses static-dissipative materials with humidity indicators for sensitive polymers. Shipment includes digital quality dossier with dimensional reports and material certs. Standard lead time is 5-7 business days from DFM approval, with expedited 72-hour options for qualified geometries. All deliveries include door-to-door tracking with customs documentation handled in-house for international shipments.

Start Your Project

Looking to enhance your manufacturing capabilities with precision background CNC services? Partner with Honyo Prototype for high-quality, efficient, and reliable CNC machining solutions.

Our state-of-the-art factory in Shenzhen offers advanced background CNC processing tailored to meet the demanding requirements of prototyping and low-volume production. With strict quality control, fast turnaround times, and extensive material expertise, we ensure consistent accuracy and performance for every component.

For project inquiries or to request a quote, contact Susan Leo at [email protected]. Let’s build precision together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.