Introduction: Navigating the Global Market for axis auto parts

In an increasingly interconnected world, sourcing quality axis auto parts can pose significant challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The complexities of navigating diverse suppliers, varying quality standards, and fluctuating prices can make the procurement process daunting. This guide aims to demystify the global market for axis auto parts, equipping buyers with essential insights into types of parts available, their applications, supplier vetting strategies, and cost considerations.

With a focus on empowering businesses to make informed purchasing decisions, this comprehensive resource delves into the nuances of sourcing used engines and transmissions that meet rigorous quality standards. It highlights the importance of selecting certified suppliers who offer hassle-free shipping, returns, and warranties, ensuring peace of mind with every transaction. By examining the competitive landscape, including successful case studies from regions like Vietnam and Brazil, this guide serves as a critical tool for buyers seeking to optimize their supply chains and enhance operational efficiency.

Whether you are a seasoned buyer or new to the auto parts market, understanding these dynamics will help you navigate the complexities of sourcing axis auto parts effectively. With the right knowledge and resources, you can forge strong partnerships that drive your business forward in the global automotive industry.

Understanding axis auto parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Used Engines | Quality-tested, certified low-mileage engines from various makes | Automotive repair shops, dealers | Pros: Cost-effective; Cons: Limited availability for specific models. |

| Used Transmissions | Certified pre-owned transmissions, compatible with diverse vehicles | Vehicle repair and restoration | Pros: Affordable; Cons: Risk of wear depending on usage history. |

| Carbon Fiber Parts | Lightweight, durable components designed for performance upgrades | Tuning shops, aftermarket retailers | Pros: Enhances vehicle performance; Cons: Higher price point. |

| OEM Replacement Parts | Genuine parts ensuring compatibility and reliability | Dealerships, fleet maintenance | Pros: Reliable quality; Cons: Higher cost compared to aftermarket. |

| Aftermarket Accessories | Customizable parts for aesthetic and performance enhancement | Custom shops, individual consumers | Pros: Wide variety; Cons: Quality can vary significantly. |

What are the Characteristics of Used Engines in Axis Auto Parts?

Used engines are a popular choice for businesses looking to manage costs effectively. Axis Auto Parts offers a wide range of quality-tested and certified engines from various manufacturers, ensuring that buyers receive reliable components that have undergone rigorous inspections. These engines are particularly suitable for automotive repair shops and dealers seeking affordable solutions for their customers. When purchasing used engines, B2B buyers should consider the engine’s mileage, compatibility with specific vehicle models, and warranty options to ensure a satisfactory investment.

How Do Used Transmissions Serve B2B Needs?

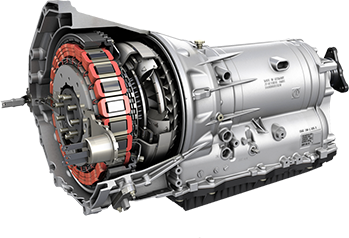

Used transmissions are crucial for businesses involved in vehicle repair and restoration. Axis Auto Parts provides a selection of certified pre-owned transmissions that are compatible with numerous makes and models. This variety allows repair shops to offer cost-effective solutions to their clients without compromising on quality. B2B buyers should evaluate the transmission’s condition, warranty coverage, and the availability of specific types to meet their operational requirements effectively.

What Advantages Do Carbon Fiber Parts Offer to Businesses?

Carbon fiber parts are increasingly sought after for their lightweight and durable nature, making them ideal for performance upgrades. Axis Auto Parts specializes in high-quality carbon fiber components that cater to tuning shops and aftermarket retailers. These parts can enhance vehicle performance significantly, attracting buyers looking to boost their offerings. However, B2B buyers must weigh the benefits against the typically higher price point and ensure they are sourcing from reputable suppliers to guarantee product quality.

Why Choose OEM Replacement Parts for B2B Transactions?

OEM replacement parts are essential for businesses that prioritize reliability and compatibility. Axis Auto Parts provides genuine parts that ensure a perfect fit and maintain the integrity of the vehicle. This is particularly important for dealerships and fleet maintenance operations where reliability is paramount. While the cost of OEM parts can be higher than aftermarket alternatives, the assurance of quality and performance often justifies the investment, making them a preferred choice for many B2B buyers.

How Do Aftermarket Accessories Fit into the B2B Landscape?

Aftermarket accessories offer a vast array of customizable options for businesses looking to enhance vehicle aesthetics and performance. Axis Auto Parts provides a diverse selection of these parts, catering to custom shops and individual consumers. While the variety is a significant advantage, B2B buyers should be cautious about quality, as it can vary widely among manufacturers. Conducting thorough research and sourcing from established suppliers can help mitigate risks associated with aftermarket parts.

Key Industrial Applications of axis auto parts

| Industry/Sector | Specific Application of axis auto parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Sourcing used engines and transmissions | Cost-effective solutions for vehicle repairs | Quality certification, warranty, and compatibility checks |

| Fleet Management | Replacement parts for commercial vehicle fleets | Reducing downtime and maintenance costs | Bulk purchasing options, delivery timelines, and warranties |

| Automotive Manufacturing | Parts for assembly lines and production | Enhancing production efficiency and product quality | Supplier reliability, certifications, and lead times |

| Export and Import Businesses | Reselling used auto parts in local markets | Access to affordable parts for growing markets | Compliance with local regulations and shipping logistics |

| Custom Automotive Modifications | High-performance parts for tuning and upgrades | Improved vehicle performance and customization options | Availability of specific models and aftermarket support |

How Are Axis Auto Parts Used in the Automotive Repair Industry?

In the automotive repair sector, Axis Auto Parts provides a reliable source for used engines and transmissions. These components are often more cost-effective than new parts, enabling repair shops to offer competitive pricing to their customers. Businesses benefit from the quality assurance provided by Axis, ensuring that parts are tested and certified. International buyers, particularly from regions like Africa and South America, should prioritize compatibility checks and warranty options to mitigate risks associated with sourcing used parts.

What Role Does Axis Auto Parts Play in Fleet Management?

Fleet management companies frequently turn to Axis Auto Parts for sourcing replacement parts for their commercial vehicle fleets. The availability of quality used parts allows these businesses to minimize downtime and control maintenance costs effectively. By maintaining a well-stocked inventory of critical components, fleet operators can ensure quick repairs and continuous operation. When sourcing for fleets, buyers should consider bulk purchasing options and the reliability of delivery timelines to maintain operational efficiency.

How Do Automotive Manufacturers Utilize Axis Auto Parts?

Automotive manufacturers often require various parts for assembly lines and production processes. Axis Auto Parts can supply these manufacturers with quality-tested components, enhancing production efficiency and product quality. By sourcing from a trusted supplier, manufacturers can streamline their operations while maintaining high standards. Key considerations for these buyers include supplier reliability and the availability of necessary certifications to meet industry standards.

How Are Export and Import Businesses Leveraging Axis Auto Parts?

Export and import businesses benefit from the accessibility of affordable used auto parts offered by Axis Auto Parts. This allows them to cater to local markets in emerging economies, where cost-effective vehicle repairs are in high demand. These businesses must navigate compliance with local regulations and ensure efficient shipping logistics to succeed in their operations. Understanding the regional market dynamics is crucial for maximizing profitability in this sector.

What Are the Advantages of Custom Automotive Modifications with Axis Auto Parts?

For businesses focused on custom automotive modifications, Axis Auto Parts provides high-performance parts that enhance vehicle tuning and upgrades. This allows for improved performance and unique customization options that appeal to automotive enthusiasts. Buyers in this niche should ensure the availability of specific models and aftermarket support to meet the diverse needs of their clientele. Collaborating with a supplier that understands the customization market can significantly enhance the value offered to customers.

3 Common User Pain Points for ‘axis auto parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Parts Quickly

The Problem: B2B buyers often face challenges in sourcing quality auto parts quickly, particularly when operating in regions with limited access to reliable suppliers. This can lead to delayed repairs and increased costs, negatively impacting their business operations. For instance, a dealership in Brazil may require a specific used transmission for a popular vehicle model, but local suppliers might not have the inventory or the assurance of quality that the buyer needs. This situation can cause frustration and a potential loss of business opportunities.

The Solution: To mitigate this issue, B2B buyers should leverage Axis Auto Parts’ extensive network and expertise. Buyers can start by using the online platform to search for the specific parts they need. Axis Auto Parts offers a broad range of tested and certified used engines and transmissions, ensuring quality and reliability. Additionally, buyers can contact Axis directly at their dedicated support line to discuss their specific requirements. This personal engagement can expedite the sourcing process and help buyers find the exact match for their needs. By establishing a relationship with Axis Auto Parts, businesses can benefit from priority service and insights into upcoming inventory, ensuring they can secure the necessary parts quickly.

Scenario 2: Concerns About Warranty and Return Policies

The Problem: When purchasing used auto parts, B2B buyers often worry about warranty coverage and return policies, especially in international transactions. For example, a repair shop in the Middle East might be hesitant to purchase a used engine without clear and robust warranty assurances, fearing that any issues post-installation could lead to significant losses and reputational damage.

The Solution: Axis Auto Parts addresses these concerns by providing a comprehensive warranty policy that includes a standard 30-day warranty, with an option for an additional 90 days. Buyers should take the time to review these policies thoroughly before making a purchase. It is advisable to document any concerns regarding specific parts during the inquiry phase and ensure that these are addressed in writing. Additionally, buyers should inquire about the hassle-free return process, which allows for returns of unsuitable parts within the specified timeframe. This proactive approach not only safeguards the buyer’s investment but also fosters trust in the supplier, making it easier to conduct future transactions.

Scenario 3: Navigating Complex Parts Compatibility Issues

The Problem: One of the most common pain points for B2B buyers in the auto parts industry is navigating the complexities of parts compatibility. For instance, a distributor in Africa might struggle to determine whether a used transmission is compatible with a specific model due to varying specifications across different markets. This uncertainty can lead to costly mistakes, such as purchasing parts that cannot be installed, resulting in delays and additional shipping costs for returns.

The Solution: To overcome compatibility challenges, B2B buyers should utilize Axis Auto Parts’ knowledgeable customer service team. Buyers are encouraged to provide detailed information about the vehicle’s make, model, and year when inquiring about parts. Axis Auto Parts has a history of assisting clients in finding the right parts by leveraging their extensive database and experienced staff. Furthermore, buyers should consider using the “Ask for a Quote” feature on the Axis Auto Parts website, which allows them to clarify any compatibility concerns before finalizing their order. By taking these steps, buyers can ensure that they are purchasing the correct parts, thereby minimizing the risk of returns and ensuring smoother operations.

Strategic Material Selection Guide for axis auto parts

What Are the Key Materials Used in Axis Auto Parts?

When selecting auto parts, the choice of materials is critical to ensuring performance, durability, and cost-effectiveness. Below, we analyze four common materials used in axis auto parts, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Aluminum Benefit Axis Auto Parts?

Aluminum is widely used in the manufacturing of auto parts due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating up to 600°F (315°C) and can withstand moderate pressure, making it suitable for various applications, including engine components and transmission housings.

Pros: Aluminum parts are durable and lightweight, which enhances fuel efficiency in vehicles. They are also relatively easy to manufacture and can be extruded or cast into complex shapes.

Cons: While aluminum is resistant to corrosion, it can be prone to fatigue under high-stress conditions. Additionally, the cost of aluminum can be higher than steel, impacting overall production costs.

Impact on Application: Aluminum’s compatibility with various media, including oils and coolants, makes it a versatile choice for many automotive applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, as aluminum parts may need specific certifications. Common standards include ASTM and ISO, which are recognized globally.

What Are the Advantages of Using Steel in Auto Parts?

Steel is another prevalent material in the auto parts industry, known for its strength and durability. With a high-temperature rating (up to 1,500°F or 815°C) and excellent pressure resistance, steel is ideal for components that experience significant stress, such as frames and axles.

Pros: Steel parts are robust and can withstand high loads, making them suitable for heavy-duty applications. They are also cost-effective compared to other materials.

Cons: Steel is heavier than aluminum, which can negatively impact vehicle efficiency. Additionally, it is susceptible to corrosion if not properly treated or coated.

Impact on Application: Steel’s strength makes it suitable for applications that require high structural integrity, such as chassis and suspension components.

Considerations for International Buyers: Buyers should be aware of the corrosion resistance standards applicable in their regions. Compliance with local regulations, such as DIN in Europe or JIS in Japan, is crucial for ensuring product reliability.

How Does Plastic Enhance the Performance of Auto Parts?

Plastics, particularly engineered polymers, are increasingly used in auto parts due to their lightweight nature and versatility. They can withstand temperatures ranging from -40°F to 250°F (-40°C to 121°C) and are often used in interior components and non-structural applications.

Pros: Plastics are lightweight, reducing vehicle weight and improving fuel efficiency. They can be molded into complex shapes, allowing for innovative designs.

Cons: Plastic parts may not offer the same level of durability as metals and can be prone to wear and tear over time. Their temperature and pressure ratings are also lower than those of metals.

Impact on Application: Plastics are suitable for applications that do not require high strength, such as dashboards and trim pieces. However, they may not be suitable for high-stress components.

Considerations for International Buyers: Buyers should consider the environmental impact of plastic materials and ensure compliance with recycling and disposal regulations in their respective countries.

What Role Does Composite Material Play in Axis Auto Parts?

Composite materials, which combine two or more different materials, are gaining traction in the automotive industry. They can offer unique properties, such as high strength-to-weight ratios and excellent corrosion resistance.

Pros: Composites are lightweight and can significantly improve fuel efficiency. They also provide superior resistance to environmental factors, making them ideal for exterior parts.

Cons: The manufacturing process for composites can be complex and costly, which may affect the overall price of the final product.

Impact on Application: Composites are particularly suitable for applications requiring both strength and weight reduction, such as body panels and structural components.

Considerations for International Buyers: Buyers should ensure that composite materials meet local manufacturing standards and certifications, as these can vary significantly across regions.

Summary Table of Material Selection for Axis Auto Parts

| Material | Typical Use Case for axis auto parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine components, transmission housings | Lightweight, corrosion-resistant | Prone to fatigue under stress | Medium |

| Steel | Chassis, axles | High strength, cost-effective | Heavier, susceptible to corrosion | Low |

| Plastic | Interior components, trim pieces | Lightweight, versatile | Lower durability, temperature limits | Low |

| Composite | Body panels, structural components | High strength-to-weight ratio | Complex manufacturing process | High |

This guide provides a comprehensive overview of the strategic material selection for axis auto parts, assisting international B2B buyers in making informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for axis auto parts

What Are the Key Manufacturing Processes for Axis Auto Parts?

Axis Auto Parts employs a systematic approach to manufacturing that ensures both efficiency and quality. The process can be divided into several key stages: material preparation, forming, assembly, and finishing. Each stage is designed to optimize production while adhering to strict quality standards.

Material Preparation: The foundation of high-quality auto parts lies in the selection of materials. Axis Auto Parts sources components from reliable suppliers, ensuring that they meet the required specifications. Materials undergo rigorous inspections before they are approved for use, which helps eliminate defects early in the production process.

Forming Techniques: Depending on the type of part being produced, various forming techniques are utilized, including stamping, casting, and machining. For example, used engines and transmissions may require specific casting methods that cater to their design intricacies. Advanced machinery and technology are employed to ensure precision and consistency in forming, which is critical for the performance of the parts.

Assembly Procedures: The assembly stage is crucial for integrating different components into a complete unit. Axis Auto Parts follows standardized assembly procedures that allow for systematic integration of parts, reducing the risk of errors. Skilled technicians are involved in this stage, often employing both automated and manual assembly methods to ensure that each part functions correctly within its system.

Finishing Touches: After assembly, parts undergo finishing processes that may include surface treatments, painting, or coating. These processes not only enhance the aesthetic appeal of the parts but also contribute to their durability and resistance to wear. Axis Auto Parts ensures that all finishing techniques comply with industry standards, which is essential for maintaining quality.

How Does Axis Auto Parts Ensure Quality Assurance in Manufacturing?

Quality assurance is a vital aspect of Axis Auto Parts’ manufacturing processes, with a strong emphasis on compliance with international standards such as ISO 9001. This certification indicates that the company adheres to quality management principles that enhance customer satisfaction and continuous improvement.

International Standards Compliance: Axis Auto Parts is committed to meeting various international standards, including CE marking for products sold in Europe and API standards for automotive components. Compliance with these standards not only demonstrates the quality of the products but also builds trust among B2B buyers in different regions, including Africa, South America, the Middle East, and Europe.

Quality Control Checkpoints: The quality control process at Axis Auto Parts includes several critical checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC). Each checkpoint serves a specific purpose:

-

IQC: This initial step involves inspecting raw materials and components before they enter the production line. By verifying the quality of incoming materials, Axis Auto Parts reduces the risk of defects in the final product.

-

IPQC: Throughout the manufacturing process, regular inspections are conducted to ensure that production is on track and that any deviations from quality standards are addressed promptly. This proactive approach helps identify issues before they escalate.

-

FQC: The final quality control stage involves comprehensive testing of the completed parts. This may include functional tests, dimensional checks, and visual inspections to ensure that each product meets the specified standards.

What Testing Methods Are Commonly Used in Quality Assurance?

Axis Auto Parts employs a range of testing methods to ensure that their products perform reliably. Common testing methods include:

-

Functional Testing: This involves operating the part under its intended conditions to confirm that it performs as expected. For example, used transmissions may be tested for smooth shifting and overall functionality.

-

Dimensional Inspection: Precision is critical in manufacturing, especially for auto parts. Dimensional inspection involves using tools like calipers and gauges to measure the physical dimensions of parts, ensuring they meet the required specifications.

-

Material Testing: This includes tests to assess the mechanical properties of materials, such as tensile strength and hardness. These tests help ensure that the materials used in manufacturing can withstand the stresses they will encounter in use.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of Axis Auto Parts:

-

Audits and Inspections: Conducting site audits can provide buyers with firsthand insight into the manufacturing processes and quality control measures in place. This allows for a thorough evaluation of the supplier’s capabilities.

-

Requesting Quality Reports: Suppliers like Axis Auto Parts should be willing to provide documentation detailing their quality control processes, inspection results, and compliance certifications. Reviewing these reports can help buyers assess the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control practices. These agencies can conduct inspections at various stages of production and provide detailed reports.

What Are the Unique Quality Control Considerations for International Buyers?

When sourcing auto parts from Axis Auto Parts, international buyers must consider several nuances related to quality control:

-

Compliance with Local Regulations: Different regions have specific regulations regarding automotive parts. Buyers should ensure that the products they import comply with local standards to avoid legal issues.

-

Cultural and Language Barriers: Communication is key when dealing with international suppliers. Buyers should ensure that they have a clear understanding of the supplier’s quality assurance processes and that any language barriers are addressed.

-

Logistics and Shipping Considerations: International shipping can introduce additional risks to product quality. Buyers should discuss packaging and handling procedures with suppliers to ensure that parts arrive in optimal condition.

By understanding the manufacturing processes and quality assurance practices at Axis Auto Parts, international B2B buyers can make informed decisions that lead to successful partnerships and high-quality automotive parts.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘axis auto parts’

When sourcing auto parts, particularly from a supplier like Axis Auto Parts, it’s essential to follow a structured approach to ensure that you are making informed decisions. This guide outlines key steps to help international B2B buyers effectively procure quality auto parts, minimizing risks and maximizing value.

Step 1: Identify Your Needs and Specifications

Before initiating the sourcing process, clearly define what parts you require. This includes specifying the type of part (e.g., engines, transmissions), make, model, and year of the vehicle. Having precise specifications ensures you find the right products and helps in communicating effectively with suppliers.

- Consider compatibility: Ensure the parts are compatible with the vehicles you service.

- Assess volume requirements: Determine how many units you need to facilitate pricing negotiations.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers, focusing on their market reputation and product offerings. Look for companies with a strong track record in providing high-quality used parts, such as Axis Auto Parts, which has been operational for over a decade.

- Review supplier websites: Check for certifications, product range, and customer testimonials.

- Engage with industry forums: Gather insights from other businesses that have sourced from these suppliers.

Step 3: Evaluate Supplier Certifications

It is vital to verify that the suppliers have the necessary certifications and quality assurance processes in place. This step is crucial for ensuring that the parts you receive meet industry standards.

- Request documentation: Ask for quality control certifications and testing results.

- Look for warranty offerings: Ensure that the supplier provides warranties on their products, which indicates confidence in their quality.

Step 4: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request quotes for the parts you need. This allows you to compare pricing, which is essential for budgeting and financial planning.

- Be specific in your requests: Include detailed specifications in your quote requests to get accurate pricing.

- Consider total cost of ownership: Factor in shipping, taxes, and potential duties when comparing prices.

Step 5: Assess Shipping and Delivery Options

Understand the shipping methods and delivery times that suppliers offer. Reliable and timely delivery is essential for maintaining your inventory and fulfilling customer demands.

- Inquire about shipping partners: Check if they use reputable carriers for international shipments.

- Evaluate return policies: Ensure the supplier has a hassle-free return policy in case the parts do not meet your expectations.

Step 6: Establish Clear Communication Channels

Effective communication is key to successful sourcing. Establish clear channels with your chosen supplier to facilitate ongoing dialogue.

- Set expectations upfront: Discuss timelines, payment terms, and support during the order process.

- Use multiple communication methods: Ensure you have access to email, phone, and possibly instant messaging for quick queries.

Step 7: Finalize the Order and Monitor Performance

Once you have selected a supplier, finalize your order and keep track of the delivery process. After receiving the parts, assess their quality to ensure they meet your specifications.

- Conduct a thorough inspection: Check parts against your specifications upon arrival.

- Provide feedback: Share your experiences with the supplier, which can help improve future transactions.

By following this structured checklist, B2B buyers can confidently navigate the sourcing process for auto parts from Axis Auto Parts or similar suppliers, ensuring quality products and efficient procurement practices.

Comprehensive Cost and Pricing Analysis for axis auto parts Sourcing

What Are the Key Cost Components for Sourcing Axis Auto Parts?

When sourcing auto parts from Axis Auto Parts, it’s essential to understand the primary cost components that contribute to the overall pricing structure. Key factors include:

-

Materials: The cost of materials significantly affects pricing. Axis Auto Parts sources used engines and transmissions that are tested and certified, which can vary in price based on the make, model, and condition. High-quality parts may come at a premium, but they often result in lower failure rates and better performance.

-

Labor: Labor costs encompass the workforce involved in the disassembly, inspection, and reassembly of parts. Skilled technicians are necessary for quality assurance, which adds to the overall labor cost.

-

Manufacturing Overhead: This includes expenses related to maintaining facilities, utilities, and equipment used in the processing of auto parts. Efficient operations can help mitigate these costs, ultimately benefiting the buyer through more competitive pricing.

-

Tooling: Investment in specialized tooling for the refurbishment of parts can influence pricing. While it may seem like a minor cost, the need for specific tools to ensure quality and compatibility can add to the overall expense.

-

Quality Control (QC): The cost of implementing a robust quality control system cannot be overlooked. Axis Auto Parts emphasizes certified parts, which means rigorous testing and inspection processes are in place to ensure reliability.

-

Logistics: Shipping costs, including handling, packaging, and transportation, play a crucial role in the final price. Axis Auto Parts offers free shipping, but buyers should consider potential customs duties and tariffs when importing parts internationally.

-

Margin: The profit margin is an essential factor in pricing strategy. Understanding how much markup is applied to the cost of sourcing can help buyers gauge whether they are receiving a fair price.

What Influences Pricing for Axis Auto Parts?

Several factors can influence pricing when sourcing from Axis Auto Parts, particularly for international buyers:

-

Volume/MOQ: Buyers looking to purchase in bulk may benefit from lower per-unit costs. Negotiating minimum order quantities (MOQ) can lead to significant savings.

-

Specifications and Customization: Custom parts or specific requirements can increase costs. Buyers should clearly communicate their needs to receive accurate quotes.

-

Materials and Quality Certifications: Parts that come with certifications or are made from higher-grade materials typically command higher prices. It’s crucial to assess whether the added cost justifies the benefits.

-

Supplier Factors: The reliability and reputation of suppliers impact pricing. Established suppliers may charge a premium due to their track record of quality and service.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is vital for international transactions. These terms dictate shipping responsibilities and costs, which can significantly affect total expenses.

What Tips Can Help Buyers Optimize Costs When Sourcing Axis Auto Parts?

International B2B buyers should consider the following tips to optimize their sourcing strategy:

-

Negotiation: Engage in discussions with suppliers to negotiate pricing, especially for larger orders. Establishing a good relationship can lead to better terms and pricing in the long run.

-

Cost-Efficiency: Assess the total cost of ownership rather than just upfront costs. This includes considering shipping, duties, and potential maintenance costs associated with the parts.

-

Pricing Nuances for International Buyers: Be mindful of exchange rates and additional fees when importing parts. Understanding local regulations and tariffs can help avoid unexpected expenses.

-

Request Quotes: Don’t hesitate to ask for quotes from multiple suppliers to compare prices and services. This practice can reveal competitive pricing and better service offerings.

-

Stay Informed: Keep abreast of market trends and pricing changes in the auto parts industry. Knowledge of supply chain dynamics can empower buyers to make informed decisions.

Disclaimer

The prices listed in this analysis are indicative and subject to change based on market conditions, availability, and specific buyer requirements. Always consult with Axis Auto Parts directly for the most accurate and current pricing information.

Alternatives Analysis: Comparing axis auto parts With Other Solutions

Understanding Alternatives in the Auto Parts Industry

When considering auto parts procurement, B2B buyers often evaluate multiple solutions to ensure they select the most suitable option for their needs. This section compares Axis Auto Parts with other viable alternatives, focusing on key aspects such as performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Axis Auto Parts | Alternative 1: OEM Parts | Alternative 2: Aftermarket Parts |

|---|---|---|---|

| Performance | Certified used engines and transmissions; tested quality | New parts with guaranteed performance | Varies; may lack consistent quality |

| Cost | Competitive pricing with free shipping | Higher cost due to brand value | Generally lower cost than OEM |

| Ease of Implementation | Simple online ordering; hassle-free returns | Installation may require professional help | Often DIY-friendly; varying complexity |

| Maintenance | Minimal; parts come with warranty | Regular maintenance needed for new parts | May require frequent replacements |

| Best Use Case | Budget-conscious buyers needing reliable used parts | Businesses wanting long-term reliability | Customers seeking value and customization |

Evaluating OEM Parts as an Alternative

Original Equipment Manufacturer (OEM) parts are new components made by the car manufacturer. They offer guaranteed performance and reliability, making them an attractive option for businesses looking to maintain high standards. However, the downside is the higher cost associated with these parts, which may not be feasible for budget-conscious buyers. Moreover, the installation often requires professional assistance, adding to the overall expense.

Exploring Aftermarket Parts as Another Option

Aftermarket parts are produced by third-party manufacturers and are typically less expensive than both OEM and used parts. They can offer a variety of options, including customizations that may not be available through OEM. However, the quality of aftermarket parts can vary significantly. Some may not meet the same performance standards, leading to potential reliability issues. Additionally, while some aftermarket parts are easy to install, others may require specialized knowledge or tools, complicating the installation process.

Conclusion: Choosing the Right Auto Parts Solution

Selecting the right solution for auto parts procurement involves evaluating your specific needs, budget constraints, and the importance of reliability. Axis Auto Parts stands out for its quality assurance and competitive pricing for used parts, making it ideal for businesses looking for reliable solutions without breaking the bank. On the other hand, OEM parts are best for those prioritizing performance and warranty, while aftermarket parts may appeal to those seeking customization and lower costs. By weighing these factors, B2B buyers can make informed decisions that align with their operational goals and financial capabilities.

Essential Technical Properties and Trade Terminology for axis auto parts

What Are the Key Technical Properties of Axis Auto Parts?

In the B2B auto parts sector, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that buyers should consider:

-

Material Grade

The material grade of auto parts, such as engines and transmissions, directly impacts their durability and performance. Common materials include cast iron, aluminum, and high-strength steel. Knowing the material grade helps buyers assess the longevity and suitability of the parts for specific vehicle applications, which can influence maintenance costs and overall vehicle performance. -

Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. For instance, precise tolerances are vital for engine components to ensure proper fit and function. Understanding tolerance levels helps buyers evaluate the quality of parts and predict how they will perform in real-world conditions, thus minimizing the risk of malfunctions. -

Mileage Rating

This specification indicates the expected life span of used engines and transmissions, typically measured in miles. Parts with lower mileage ratings are often preferred for their reliability and performance. Buyers should consider mileage ratings when selecting parts to ensure they are investing in components that will meet their operational needs without frequent replacements. -

Certification and Testing Standards

Parts that are tested and certified by industry professionals ensure they meet specific quality and safety standards. Certifications can include ISO or OEM standards. Understanding these standards is essential for B2B buyers, as it guarantees that the parts will perform reliably under various conditions, reducing the risk of failures that could lead to costly downtime. -

Compatibility Information

This refers to the specifications detailing which makes and models a part is suitable for. Compatibility information is critical for ensuring that the purchased parts will fit seamlessly into the intended vehicles. Buyers must confirm compatibility to avoid costly returns and replacements.

What Are Common Trade Terms Used in the Axis Auto Parts Industry?

Familiarity with industry jargon is vital for effective communication and negotiation in the auto parts market. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

OEM parts are made by the original manufacturer of the vehicle and are typically considered of higher quality. Understanding OEM specifications helps buyers determine whether to purchase OEM parts or aftermarket alternatives, impacting the vehicle’s performance and resale value. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. It is essential for buyers to know the MOQ, as it affects inventory management and cost efficiency. Buyers should negotiate MOQs that align with their business needs to avoid overstocking or underordering. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products. This term is crucial for buyers looking to compare prices and terms from multiple vendors. A well-structured RFQ can lead to better pricing and terms, benefiting the buyer’s bottom line. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for buyers engaged in cross-border trade, as it clarifies liability and ensures smoother transactions. -

Warranty and Return Policy

Understanding the warranty and return policies associated with auto parts is vital for mitigating risk. A clear return policy allows buyers to return unsuitable parts, while a robust warranty provides assurance of quality. Buyers should always clarify these terms before completing a purchase to ensure peace of mind.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing axis auto parts, ultimately enhancing their operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the axis auto parts Sector

What Are the Key Market Drivers and Trends in the Axis Auto Parts Sector?

The axis auto parts sector is shaped by various global drivers that influence sourcing and purchasing behaviors for international B2B buyers. One primary driver is the increasing demand for quality used auto parts, particularly in emerging markets such as Africa, South America, and Southeast Asia. These regions are witnessing a surge in vehicle ownership, leading to a corresponding rise in the need for affordable, reliable auto parts. Additionally, advancements in technology, such as online marketplaces and inventory management systems, are transforming how buyers source auto parts. These technologies enable buyers to compare prices, verify quality, and streamline procurement processes.

Emerging trends also indicate a growing focus on transparency and traceability in the supply chain. B2B buyers are increasingly seeking suppliers who can provide detailed information about the origin and quality of their parts. The integration of digital platforms for real-time inventory tracking and order management is becoming standard practice. For instance, online tools that allow buyers to request quotes and receive instant confirmations can significantly enhance the purchasing experience.

Furthermore, the shift toward electric and hybrid vehicles is influencing the types of auto parts in demand. B2B buyers are beginning to look for parts compatible with these new technologies, including specialized components and high-efficiency engines. This transition necessitates that suppliers adapt their offerings to stay relevant in a rapidly changing marketplace.

How Is Sustainability and Ethical Sourcing Impacting the Axis Auto Parts Industry?

Sustainability and ethical sourcing are becoming increasingly significant in the axis auto parts sector. International B2B buyers are more aware of the environmental impact of their purchases and are prioritizing suppliers who adhere to sustainable practices. This includes the responsible sourcing of materials, waste reduction, and energy-efficient manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are looking for suppliers that can demonstrate compliance with environmental regulations and industry standards. Certifications such as ISO 14001 for environmental management and the use of recycled materials are valuable indicators of a supplier’s commitment to sustainability. For instance, suppliers that offer “green” parts—those manufactured using eco-friendly processes—are likely to appeal to environmentally conscious buyers.

Moreover, as consumers demand greater corporate social responsibility, B2B buyers are increasingly scrutinizing the practices of their suppliers. This includes examining labor practices and ensuring that workers are treated fairly throughout the supply chain. Companies that prioritize ethical sourcing can enhance their reputation and build stronger relationships with buyers who value corporate responsibility.

How Has the Axis Auto Parts Sector Evolved Over Time?

The axis auto parts sector has undergone significant evolution over the past two decades, primarily driven by technological advancements and changing consumer preferences. Initially focused on traditional brick-and-mortar sales, the industry has embraced e-commerce, making it easier for international buyers to access a wide range of products. Online platforms have revolutionized the way parts are sourced, allowing for greater price competition and improved customer service.

As automotive technology has advanced, the demand for specialized parts has also increased. The rise of electric and hybrid vehicles has prompted suppliers to diversify their offerings to meet the needs of a new generation of vehicles. This evolution has not only expanded the product range but has also emphasized the importance of quality assurance and certification, ensuring that parts meet stringent performance standards.

In summary, the axis auto parts sector continues to adapt to market demands and technological innovations, positioning itself as a critical player in the global automotive supply chain. B2B buyers can leverage these developments to enhance their procurement strategies and secure high-quality parts that meet both performance and sustainability criteria.

Frequently Asked Questions (FAQs) for B2B Buyers of axis auto parts

-

How do I ensure the quality of used auto parts when sourcing internationally?

To ensure the quality of used auto parts, request detailed information about the parts’ history, including mileage and any prior repairs. Verify the supplier’s quality assurance processes, such as certifications and testing procedures. It’s beneficial to ask for samples or references from previous clients. Additionally, consider conducting a site visit if feasible, or utilize third-party inspection services to validate the condition of the parts before finalizing your order. -

What are the best practices for negotiating payment terms with auto parts suppliers?

When negotiating payment terms, start by discussing your company’s purchasing volume and payment history to establish credibility. Request flexible terms such as net 30 or 60 days to manage cash flow effectively. Consider negotiating discounts for early payments or bulk orders. Ensure that all terms are documented clearly in your contract to avoid misunderstandings. It’s also advisable to use secure payment methods that protect both parties, such as escrow services for larger transactions. -

What are the common minimum order quantities (MOQs) for auto parts, and how can I manage them?

MOQs for auto parts can vary significantly based on the supplier and the type of parts. Typically, established suppliers may have MOQs ranging from 10 to 100 units. To manage MOQs effectively, consider pooling orders with other businesses or negotiating lower MOQs based on your purchasing history. If you consistently order from the same supplier, express your intent to build a long-term relationship, which may encourage them to offer more favorable terms. -

How can I vet a new supplier for auto parts to ensure reliability?

To vet a new supplier, start by researching their business history, customer reviews, and any industry certifications. Request references from other international buyers who have sourced parts from them. Assess their communication responsiveness and willingness to provide detailed information. Additionally, check their logistics capabilities, including shipping times and methods, to ensure they can meet your delivery requirements. A thorough vetting process minimizes risks associated with international sourcing. -

What logistics considerations should I keep in mind when importing auto parts?

When importing auto parts, consider shipping methods, costs, and transit times. Choose between air freight for speed or ocean freight for cost-effectiveness, depending on your urgency. Be aware of customs regulations and tariffs in your country to avoid unexpected fees. Ensure that your supplier provides all necessary documentation, such as invoices and packing lists, to facilitate smooth customs clearance. Establish a reliable logistics partner to handle the complexities of international shipping. -

Can I customize auto parts to meet specific requirements for my market?

Yes, many suppliers, including Axis Auto Parts, offer customization options for auto parts. When discussing your needs, provide detailed specifications regarding the modifications required, such as dimensions, materials, or branding. Be prepared to meet any minimum order quantities associated with custom orders. Discuss lead times for production and ensure that the supplier has the capability to deliver on your customization requirements. This approach can help you differentiate your offerings in the market. -

What warranties or guarantees should I expect when sourcing used auto parts?

Reputable suppliers typically offer warranties on used auto parts, which can range from 30 days to several years. Inquire about the specific terms of the warranty, including what it covers (e.g., defects, performance issues) and the process for returns or replacements. A solid warranty indicates the supplier’s confidence in their product quality. Ensure that these terms are clearly outlined in your purchase agreement to protect your investment. -

How do I handle returns and refunds for auto parts sourced internationally?

To handle returns and refunds effectively, understand the supplier’s return policy before placing an order. Confirm the timeframe for returns, conditions under which parts can be returned, and any associated costs. Document all communications regarding returns and keep records of your purchases. If issues arise, communicate promptly with the supplier to resolve them. Establishing a clear returns process in advance can save time and resources in the event of unsatisfactory parts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Axis Auto Parts Manufacturers & Suppliers List

1. Axis Auto Parts – Engines & Transmissions

Domain: axisautoparts.com

Registered: 2024 (1 years)

Introduction: Engines, Transmissions, Parts for various makes and models from 1900 to 2024 including brands like AMC, Acura, Audi, BMW, Cadillac, Chevrolet, Chrysler, Dodge, Ford, GMC, Honda, Hyundai, Jeep, Kia, Lexus, Mazda, Mercedes-Benz, Nissan, Subaru, Toyota, Volkswagen, and more.

2. Instagram – High-Quality Used Engines & Transmissions

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: This company, Instagram – High-Quality Used Engines & Transmissions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Axis Parts – NISSAN FAIRLADY Z Accessories

Domain: axisparts.jp

Registered: 2021 (4 years)

Introduction: NISSAN FAIRLADY Z【Type:RZ34】

– Toray ultrasuede specifications Center small meter hood 3pieces/us016【for RHD&LHD】

– Regular price: $1,031.00

– Drycarbon shift panel cover for AT model/st947-870【for RHD&LHD】

– Regular price: $328.00

– Toray ultrasuede specifications meter hood cover/st869b【for RHD&LHD】

– Regular price: $436.00

– Drycarbon meter hood cover/st869【for RHD&LHD】

– Regular price:…

4. AXIS Auto – Euro Car Repair

Domain: axisauto.co

Registered: 2022 (3 years)

Introduction: AXIS Auto specializes in Euro car repair in Houston, TX, but services all makes and models. They offer professional service with a focus on customer care, utilizing OEM parts and proper tools. Their services include diagnostics to efficiently identify car issues, and they cater to performance vehicles, whether for weekend cruising or dedicated racing. They operate by appointment only.

5. 86Worx – Carbon Front Bumper Garnish

Domain: 86worx.com

Registered: 2013 (12 years)

Introduction: [{‘name’: ‘Carbon Front Bumper Garnish’, ‘price’: 374.99}, {‘name’: ‘Carbon Meter Inner Hood Cover’, ‘price’: 234.99}, {‘name’: ‘Carbon Navigation Panel Cover’, ‘price’: 214.99}, {‘name’: ‘Carbon Switch Panel Cover’, ‘price’: 174.99}, {‘name’: ‘Carbon Push Start Cover’, ‘price’: 49.99}, {‘name’: ‘Console Vent Cover’, ‘price’: 169.99}, {‘name’: ‘Carbon Dash Vent Covers’, ‘price’: 124.99}, {‘name’: …

6. Facebook – Auto Parts Dealer

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Auto Parts Dealer, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for axis auto parts

As international markets continue to expand, Axis Auto Parts stands out as a reliable partner for sourcing high-quality used engines and transmissions. With over a decade of experience, the company guarantees quality assurance through rigorous testing and certification processes. This dedication not only enhances customer confidence but also ensures that B2B buyers receive products that meet their specific needs, regardless of geographical location. The extensive network of auto part yards and resellers across the United States allows for hassle-free delivery, making Axis Auto Parts an ideal choice for businesses in Africa, South America, the Middle East, and Europe.

Strategic sourcing is vital for international buyers looking to optimize costs while maintaining quality. By leveraging Axis Auto Parts’ comprehensive inventory and competitive pricing, businesses can secure essential components that enhance operational efficiency. Moreover, the commitment to customer satisfaction through hassle-free returns and extended warranties provides an added layer of security for B2B transactions.

Looking ahead, as the demand for reliable auto parts continues to rise, now is the opportune time for international buyers to engage with Axis Auto Parts. Explore the extensive inventory and request a quote today to ensure your business remains competitive in the evolving automotive landscape.