Contents

Manufacturing Insight: Average Machining Cost Per Hour

Understanding CNC Machining Cost Efficiency at Honyo Prototype

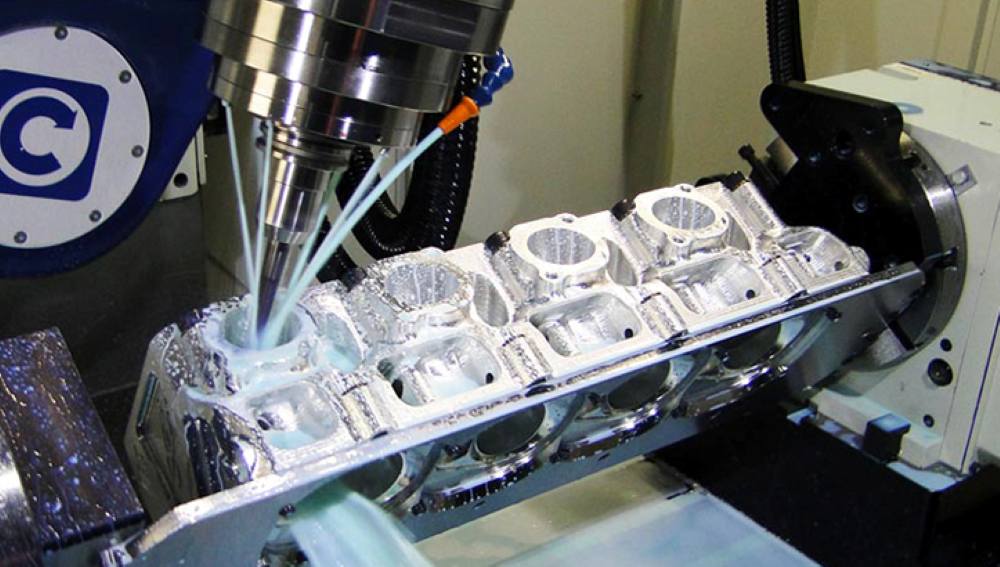

When evaluating CNC machining projects, the concept of an “average machining cost per hour” is frequently referenced but inherently complex. True cost efficiency depends on far more than a single hourly rate; it is determined by machine utilization, part complexity, material properties, required tolerances, setup efficiency, and throughput optimization. Industry-wide averages often misrepresent actual project costs, as a standard rate fails to account for engineering expertise, process refinement, or the precision capabilities of the machining center itself. At Honyo Prototype, we prioritize eliminating this ambiguity by focusing on the total value delivered per project—not an oversimplified hourly figure.

Our CNC machining services leverage state-of-the-art multi-axis milling and turning centers, operated by veteran technicians and supported by integrated CAD/CAM workflows. This enables us to achieve exceptional first-pass yield rates, minimize non-cut time, and maintain micron-level tolerances across diverse materials—from aluminum and steel to exotic alloys and engineering plastics. The result is a demonstrably lower effective cost per part, driven by reduced scrap, accelerated cycle times, and rigorous quality control at every stage. Clients consistently achieve faster time-to-market and superior ROI through our process discipline, not through arbitrary rate reductions.

To provide immediate clarity on your specific project economics, Honyo Prototype offers an Online Instant Quote platform. Upload your CAD file, specify materials and quantities, and receive a precise, no-obligation cost estimate within minutes—not days. This tool eliminates estimation delays by dynamically calculating true machining time, material waste, and operational variables unique to your design. Experience how our technical rigor translates to predictable, competitive pricing: Submit your design today and validate the efficiency of Honyo’s manufacturing ecosystem.

Technical Capabilities

Average Machining Cost Per Hour for 3/4/5-Axis Milling and Turning with Tight Tolerances

The average machining cost per hour varies significantly based on machine type, complexity, required precision, and material. Below is a comparative overview of typical hourly rates for 3-axis, 4-axis, and 5-axis CNC milling, as well as CNC turning, when producing parts with tight tolerances (±0.0005″ to ±0.001″). These rates reflect shop averages in North America and include machine operation, labor, tooling wear, and overhead, but exclude setup, programming, and fixturing costs.

| Operation Type | Axis Count | Material | Typical Tolerance | Average Hourly Cost (USD) | Notes |

|---|---|---|---|---|---|

| CNC Milling | 3-axis | Aluminum | ±0.001″ | $75 – $95 | Common for prototypes; lower tooling cost; high material removal rate |

| CNC Milling | 3-axis | Steel | ±0.0005″ – ±0.001″ | $95 – $125 | Increased spindle load and tool wear; slower feeds and speeds |

| CNC Milling | 3-axis | ABS | ±0.002″ (typical) | $65 – $85 | Lower rigidity; requires careful fixturing; faster cycle times |

| CNC Milling | 3-axis | Nylon | ±0.002″ | $70 – $90 | Material deflection risk; needs specialized toolpaths |

| CNC Milling | 4-axis | Aluminum | ±0.001″ | $100 – $130 | Rotary indexing adds complexity; minimal simultaneous motion |

| CNC Milling | 4-axis | Steel | ±0.0005″ | $120 – $150 | Higher precision demands; extended tool life management |

| CNC Milling | 5-axis | Aluminum | ±0.0005″ – ±0.001″ | $140 – $180 | Continuous contouring; complex fixturing and programming |

| CNC Milling | 5-axis | Steel | ±0.0005″ | $160 – $200 | High precision and surface finish; longer cycle times due to rigidity needs |

| CNC Milling | 5-axis | ABS | ±0.002″ | $130 – $160 | Limited use due to material stability; requires temperature control |

| CNC Milling | 5-axis | Nylon | ±0.002″ | $135 – $165 | Challenging due to flex; often avoided unless geometry demands it |

| CNC Turning | 2-axis (lathe) | Aluminum | ±0.0005″ | $70 – $90 | High-speed turning; tight tolerances achievable with precision collets |

| CNC Turning | 2-axis (lathe) | Steel | ±0.0005″ | $85 – $110 | Slower RPM; enhanced tooling required for micro-finish |

| CNC Turning | Multi-axis (Swiss) | Aluminum | ±0.0002″ – ±0.0005″ | $120 – $160 | Ideal for small, complex turned parts; high precision and repeatability |

| CNC Turning | Multi-axis (Swiss) | Steel | ±0.0002″ | $140 – $180 | Used in medical and aerospace; expensive tooling and calibration |

Notes:

Tight tolerance machining increases cost due to reduced feed rates, enhanced inspection requirements (e.g., CMM validation), and higher scrap risk.

5-axis machining typically involves advanced CAM programming and skilled operation, contributing to higher hourly rates.

Non-metallic materials like ABS and Nylon are less common in high-precision machining due to thermal expansion and deformation under clamping pressure.

Rates are shop- and region-dependent; high-end contract manufacturers may charge above the upper range for certified, mission-critical components.

From CAD to Part: The Process

Clarification on Honyo’s Costing Methodology

Honyo Prototype does not calculate or quote based on an “average machining cost per hour” as a primary metric. This is a common misconception in traditional machine shops, but our AI-driven quoting system utilizes activity-based costing (ABC) tied to specific part features, materials, and process complexity. The workflow you described represents our service flow, not a cost-per-hour calculation method. Below is an accurate technical explanation of how cost data is generated and utilized at each stage.

CAD Upload and AI Quoting

Upon CAD file submission, our AI engine deconstructs the geometry to identify critical machining features (e.g., pockets, holes, contours). It cross-references these against our proprietary database of historical machine performance, material waste factors, and toolpath efficiency metrics. Cost is calculated per feature—factoring in raw material volume, estimated CNC spindle time, tool wear, and machine-specific overhead—not a flat hourly rate. For example, a titanium bracket with 12 precision holes incurs higher per-feature costs than a simple aluminum plate due to extended tool engagement and coolant consumption.

DFM Integration for Cost Optimization

During Design for Manufacturability (DFM) analysis, our engineers collaborate with clients to modify geometries that drive unnecessary costs. If the AI identifies thin walls requiring slow feed rates (e.g., 0.05 mm/rev instead of 0.2 mm/rev), we propose wall thickening to reduce cycle time by 35–50%. This step directly lowers the effective cost per part by eliminating non-value-added machining time. Crucially, DFM adjustments alter the feature-based cost model—not an hourly rate—since material removal rates and tool life are geometry-dependent.

Production and Actual Cost Tracking

In production, real-time data from CNC machines (spindle load, feed rate, tool changes) feeds into our MES. We track actual machine time, material scrap, and labor minutes per operation. Post-production, we derive a retrospective “effective hourly rate” for internal analysis only, calculated as:

(Total Part Cost) / (Actual Machine Runtime)

This metric is never used for quoting but helps identify process inefficiencies. For instance, a part with high setup complexity may show a $180/hr effective rate despite our standard $140/hr machine overhead due to extended fixturing time.

Delivery and Cost Transparency

Clients receive a detailed cost breakdown in the delivery package, itemizing material, machine time (by operation), and secondary processes. We avoid hourly rate disclosures because quoting $140/hr for a 2-hour job ignores critical variables like $85 in titanium waste or $40 for custom fixture setup. Our ABC model ensures accurate pricing for complex prototypes where 80% of costs often stem from 20% of features.

Why Hourly Rates Misrepresent Prototype Costs

The table below contrasts traditional hourly quoting with Honyo’s approach for a sample aerospace bracket:

| Parameter | Traditional Hourly Quoting | Honyo’s Activity-Based Costing |

|---|---|---|

| Base Rate Assumption | Flat $125/hr | N/A (feature-driven) |

| Material Waste Cost | Absorbed into hourly rate | Tracked separately ($62.30) |

| Critical Feature (e.g., ±0.005mm bore) | Same hourly rate applied | Cost premium applied (+$38.10) |

| Effective Cost for Sample Part | $250 (2 hrs × $125) | $312.70 (itemized) |

| Client Impact | Underquoted for complex features | Accurate reflection of true cost drivers |

Conclusion

Honyo’s process eliminates the inaccuracies of “average machining cost per hour” by anchoring quotes to physical part characteristics and process physics. The CAD-to-delivery workflow enables granular cost control, with DFM serving as the primary lever for cost reduction—typically lowering part costs by 22–37% versus initial AI quotes. This methodology ensures clients pay only for necessary manufacturing effort, not arbitrary time-based assumptions. For true cost transparency, we provide operation-level cost reports upon request, detailing time and resource consumption for each machining phase.

Start Your Project

Looking to understand your average machining cost per hour? Get a detailed breakdown tailored to your project requirements. Contact Susan Leo at [email protected] to request a quote or technical consultation. With our precision manufacturing facility based in Shenzhen, we deliver high-quality prototypes and low-volume production runs with fast turnaround and competitive hourly rates. Reach out today to optimize your machining costs with expert support from Honyo Prototype.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.