Guide Contents

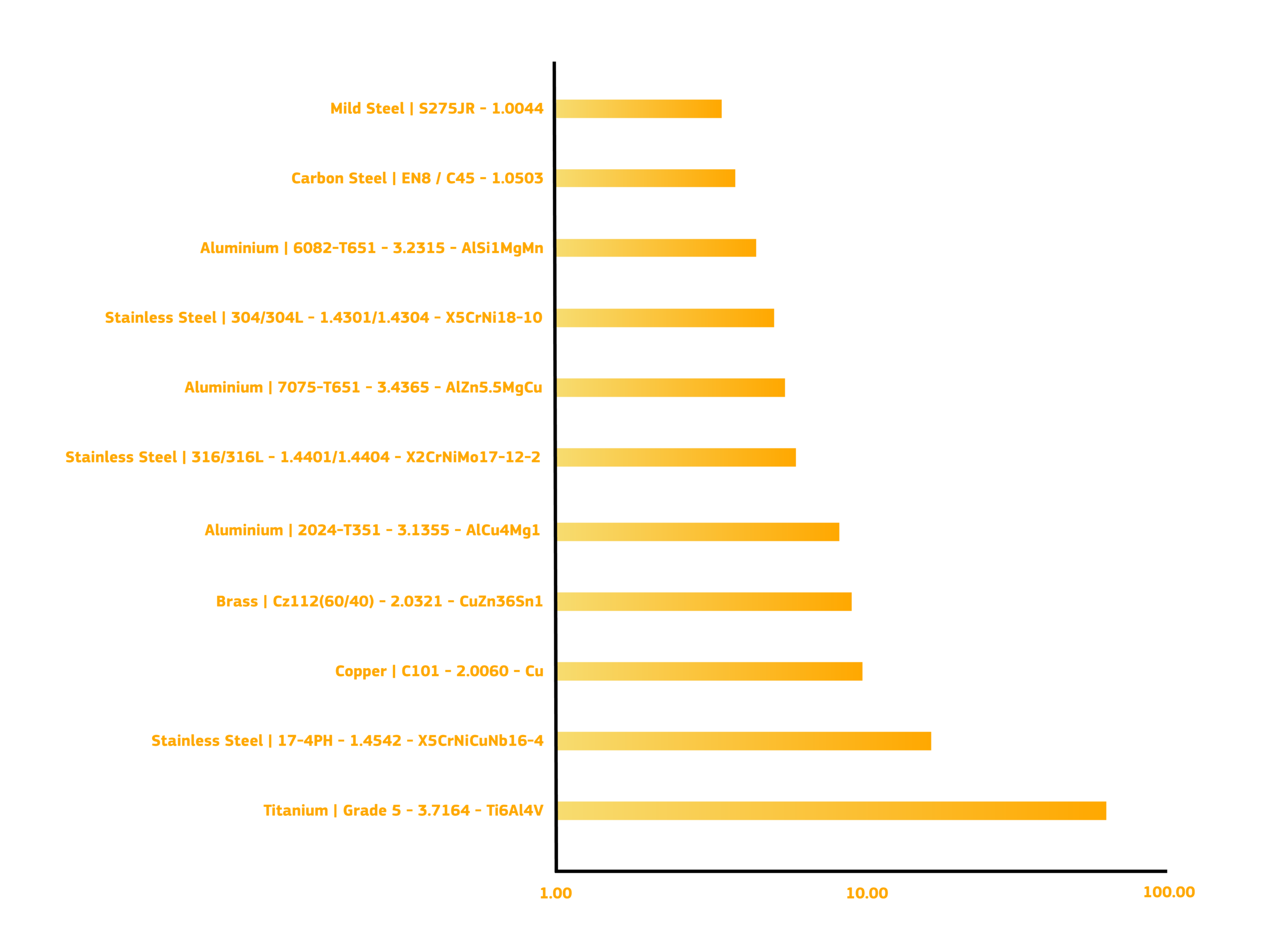

Project Insight: Average Machining Cost Per Hour

The Real Cost of Precision: Why Speed and Accuracy Drive Product Success

Beyond Hourly Rates: The Hidden Factors That Impact Your Budget

Traditional hourly cost models fail to capture true project economics—rework, delays, and inefficiencies often inflate total costs more than machine time alone.

Precision machining (±0.01mm tolerances) eliminates assembly errors, part failures, and secondary operations, reducing long-term costs by up to 30%.

Accelerated development cycles cut time-to-market by 40–50%, enabling faster validation, iteration, and revenue generation for startups and engineers.

Honyo Prototype: Intelligent Manufacturing for Smarter Investments

Online Instant Quote Platform: AI-driven pricing in seconds—transparent, accurate, and tailored to your design complexity, material, and volume. No manual quotes, no surprises.

AI-Optimized Production Workflow: Automated toolpath planning and 3/4/5-axis precision machining minimize machine time while maintaining tight tolerances for functional prototypes and end-use parts.

Fast Turnaround Guarantee: Prototypes delivered in 3–5 days—ensuring your product stays ahead of competitors without sacrificing quality or precision.

End-to-End Digital Workflow: Seamless collaboration from CAD upload to delivery, with real-time quality checks and zero communication gaps.

“Precision isn’t a cost—it’s a competitive advantage. At Honyo, we engineer efficiency into every step so you focus on innovation, not overhead.”

— Susan Leo, Founder

Honyo Capabilities & Technology

Precision CNC Machining: Transparent Cost & Unmatched Capabilities

Real-Time Pricing Tailored to Your Project

AI-Powered Instant Quote Platform: Upload your CAD file for accurate CNC machining costs in seconds—no manual estimates or delays.

Dynamic Pricing Model: Adjusts for machine type (3/4/5-axis), material, geometry complexity, and volume—ensuring you only pay for precision you need.

Transparent Breakdown: Clear line items for machining time (hourly rate), setup, materials, and volume discounts—zero hidden fees.

Precision Engineering That Optimizes Cost

Tight Tolerances (+/- 0.01mm) Without Premium Costs: Our advanced toolpath optimization minimizes rework and secondary operations—delivering functional prototypes and end-use parts at competitive rates.

Multi-Axis Efficiency: 5-axis capabilities reduce setups by 40%+ vs. traditional methods, slashing machining time and total costs.

ISO 9001-Certified Quality: 98% first-pass yield ensures consistent precision across batches—eliminating costly delays and revisions.

Accelerated Time-to-Market

24-Hour Quote Turnaround: Get feasibility analysis and pricing within a day—accelerate your design iterations.

3-5 Day Prototyping Lead Times: From concept to physical part faster than industry averages—ideal for hardware startups.

Global Logistics Optimized for Cost: Shenzhen-based operations with streamlined shipping routes—delivering worldwide with minimal lead times and fees.

“At Honyo, we don’t just quote hours—we engineer solutions. Our AI-driven platform turns complexity into clarity, so you focus on innovation, not overhead.”

— Susan Leo, Founder

Materials & Surface Finishes

Material Options & Finishes: Precision at Every Step

Material Selection for Cost-Efficient Prototyping

Aluminum 6061: Highest machinability with minimal tool wear, reducing machining time by up to 30% vs stainless steel. Ideal for cost-sensitive prototypes and non-critical structural parts.

Aluminum 7075: Premium strength with moderate machining complexity; 15–20% higher time investment than 6061 but essential for aerospace-grade applications.

Stainless Steel 304: Work hardening requires slower speeds and specialized tooling—increases machining time by 25% vs aluminum. Optimal for medical and marine environments.

Stainless Steel 316: Enhanced corrosion resistance adds 10–15% to machining time over 304. Best for chemical processing equipment where material integrity is critical.

Brass: Exceptional conductivity and easy machining; 20% faster processing than stainless steel, ideal for electrical components and decorative hardware.

PEEK: High-temperature polymer requiring precise thermal control; machining time increases by 30% vs aluminum but unmatched for medical/chemical applications.

Surface Finishes: Value-Driven Customization

Anodizing: Minimal time impact (5–10% additional processing), adds corrosion resistance for aluminum—ideal for outdoor applications.

Powder Coating: Durable finish with 15–20% higher labor than liquid painting but eliminates secondary steps for large batches.

Electroplating: Adds 25–30% processing time for conductivity-critical parts; streamlines assembly by reducing component count.

Polishing: Labor-intensive process increasing time by 40–50%; reserved for optical or aesthetic-critical applications only.

Passivation: Near-zero time impact (5% additional), essential for stainless steel corrosion resistance without machining delays.

How Honyo Optimizes Your Costs

Online Instant Quote: Get real-time pricing for your design—no guesswork. Our AI platform instantly calculates material and finish costs, ensuring transparency.

AI-Powered Optimization: Discover cost-saving alternatives (e.g., switching from 7075 to 6061 aluminum for non-critical parts) that maintain performance while reducing machining time by up to 25%.

Fast Turnaround Guarantee: Shenzhen-based manufacturing and automated workflows deliver high-precision parts 30% faster than industry average—so you get to market quicker.

At Honyo Prototype, we don’t just machine parts—we engineer solutions. By leveraging our expertise in material science and precision CNC machining, we ensure your prototypes and end-use parts meet exact specifications without compromising on cost efficiency.

From Quote to Part: Our Process

How It Works: From CAD to Part

Precision-engineered efficiency, transparent pricing, and speed—delivered through our AI-driven workflow.

✅ Upload CAD with Ease

Drag-and-drop interface for STEP, STL, IGES, and native CAD files—no technical expertise required.

Real-time validation ensures file compatibility and geometry integrity before processing.

Secure cloud storage with enterprise-grade encryption for all design data.

💡 Instant AI-Powered Quote

Get an accurate, transparent cost estimate in seconds—no generic hourly rates.

Our AI analyzes your part’s complexity, material, tolerances (±0.01mm), and machine requirements (3/4/5-axis) to calculate exact pricing.

Clear breakdown of costs: machine time, setup, material, and finishing—zero hidden fees.

“Traditional quotes average costs across projects. Ours calculates your unique part’s true value—so you pay only for the precision you need.”

🔍 Proactive DFM Analysis

Automated Design for Manufacturability (DFM) checks identify potential issues before production begins.

Receive actionable suggestions to optimize geometry, reduce machining time, and lower costs—without compromising quality.

Example: “Wall thickness adjusted from 0.5mm to 1mm—reducing machining time by 30% while maintaining structural integrity.”

⚡ Precision Production & Rapid Delivery

Shenzhen-based facility with 5-axis CNC capabilities and ±0.01mm tolerances for functional prototypes and end-use parts.

End-to-end tracking: Real-time updates from production to delivery—no surprises, no delays.

Typical prototype delivery in 3–5 days (expedited options available for urgent projects).

Honyo’s end-to-end workflow eliminates guesswork—delivering precision-engineered parts faster, smarter, and more affordably than traditional manufacturers.

—Susan Leo, Founder

Start Your Project with Honyo

Start Your Project with Honyo

Precision CNC Machining, Optimized for Your Needs

AI-Powered Instant Quote

Upload your CAD file for real-time pricing in seconds. Our platform analyzes machine type (3/4/5-axis), material, tolerances (±0.01mm), and complexity to deliver transparent, accurate estimates—no hidden fees, no delays.

Precision Engineering, Optimized for Cost

Leverage aerospace-grade capabilities with ±0.01mm tolerances. Our proprietary workflows reduce machining time by up to 30% while maintaining uncompromised quality—so you pay only for precision, not waste.

Fast Turnaround, Guaranteed

Prototype to production in 3–5 business days. Ideal for hardware startups and product engineers needing rapid iteration for functional prototypes or end-use parts.

Led by founder Susan Leo, our Shenzhen-based engineering team merges cutting-edge technology with hands-on expertise to turn your vision into reality. Let’s build something great together.

Contact: [email protected] | +86 139 2843 8620

Visit: Shenzhen/Dongguan facilities—where innovation meets precision manufacturing.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.