Contents

Manufacturing Insight: Average Cost Of A Cnc Machine

Understanding CNC Machine Costs and Strategic Sourcing

Determining the average cost of a CNC machine requires careful consideration of variables such as machine type, axis configuration, brand, and intended application. Entry-level 3-axis mills may start around $50,000, while high-precision 5-axis systems or specialized machinery can exceed $500,000, with full industrial setups often surpassing $1 million when accounting for tooling, software, and facility requirements. These figures represent significant capital expenditure and ongoing operational overhead, including maintenance, skilled labor, and floor space—factors that directly impact a manufacturer’s total cost of ownership.

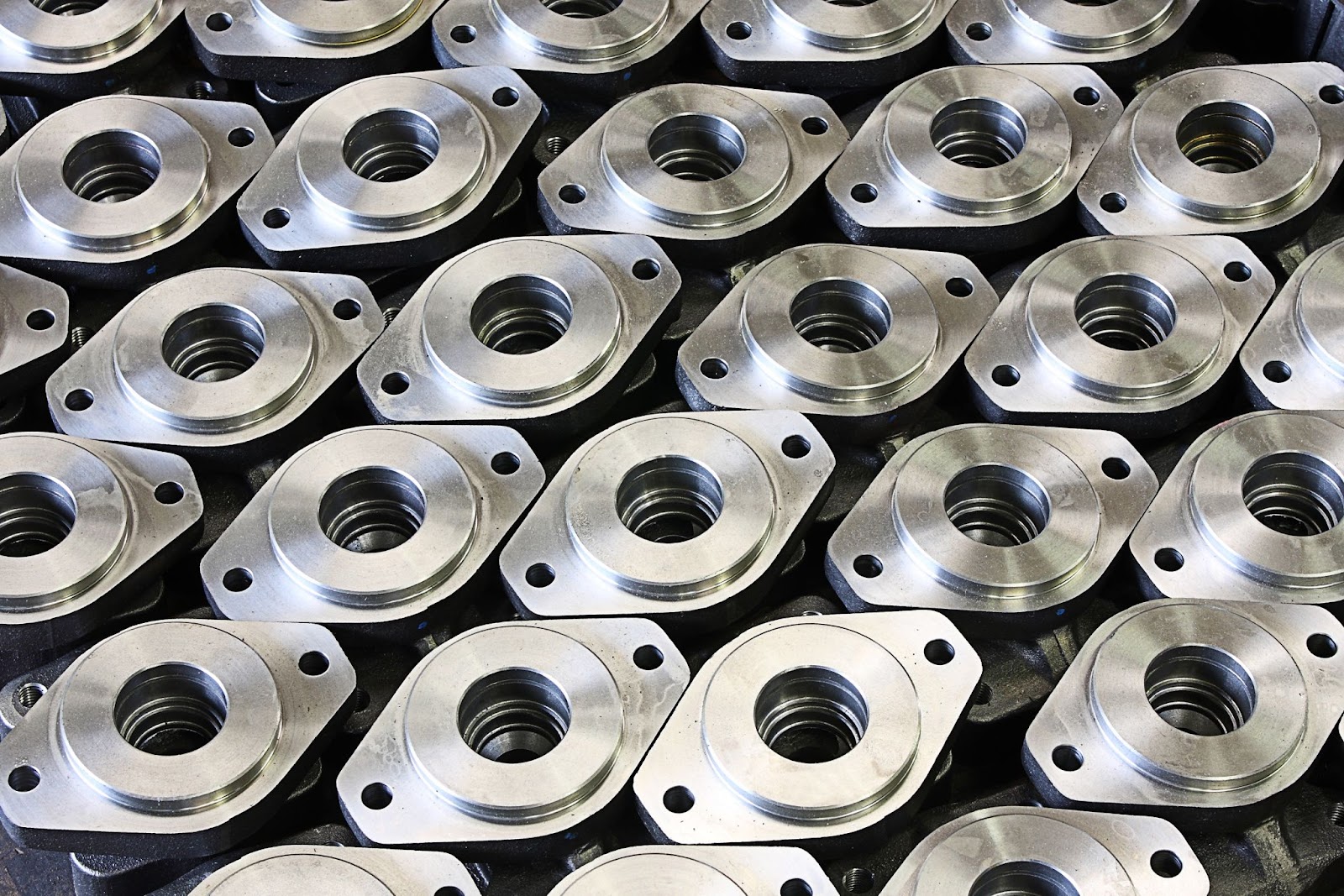

At Honyo Prototype, we eliminate these barriers by providing end-to-end CNC machining services without the burden of capital investment. Our advanced facility houses a diversified fleet of CNC equipment, from precision 3-axis mills to complex multi-axis systems, all operated by certified engineers with deep expertise in aerospace, medical, and automotive applications. Clients leverage our infrastructure to achieve tight tolerances, rapid turnaround, and rigorous quality control while converting fixed costs into predictable project-based pricing.

Central to our value proposition is the Online Instant Quote platform, which delivers transparent, real-time cost estimates within minutes. By uploading CAD files and specifying material, quantity, and finish requirements, engineering teams gain immediate visibility into pricing and lead times—accelerating procurement cycles and enabling data-driven sourcing decisions. This tool reflects our commitment to operational efficiency, allowing clients to focus on innovation rather than machinery management.

For precision CNC solutions that prioritize cost efficiency and speed, utilize our Online Instant Quote system or contact our engineering team to discuss your project specifications.

Technical Capabilities

The term “average cost of a CNC machine” varies significantly based on machine type, axis configuration, precision capabilities, and intended application. Below is a technical summary of average costs for CNC machines commonly used in precision manufacturing environments, focusing on 3-axis, 4-axis, and 5-axis milling, as well as CNC turning centers. These systems are selected for their ability to achieve tight tolerances (±0.0005″ to ±0.005″) across common engineering materials such as aluminum, steel, ABS, and nylon.

| Machine Type | Axis Configuration | Typical Applications | Material Compatibility | Precision (Tight Tolerance) | Average Cost Range (USD) | Notes |

|---|---|---|---|---|---|---|

| CNC Milling Center | 3-Axis | Prototyping, basic machining, mold components | Aluminum, Steel, ABS, Nylon | ±0.001″ | $30,000 – $70,000 | Entry-level for precision work; limited complex geometry capability |

| CNC Milling Center | 4-Axis | Complex contours, indexed parts, light 3D features | Aluminum, Steel, ABS, Nylon | ±0.0008″ | $60,000 – $120,000 | Rotary axis (A-axis) enables multi-sided machining without re-fixturing |

| CNC Milling Center | 5-Axis | Aerospace, medical, high-complexity parts | Aluminum, Steel, ABS, Nylon, High-temp plastics | ±0.0005″ | $150,000 – $500,000+ | Simultaneous multi-axis motion; optimal for tight tolerance toolpaths |

| CNC Turning Center | 2-Axis (Turning) | Shaft components, pins, threaded parts | Aluminum, Steel, ABS, Nylon | ±0.0005″ – ±0.001″ | $50,000 – $100,000 | High repeatability; often paired with live tooling for mill-turn work |

| CNC Mill-Turn Center | Multi-Axis (Y, B, C) | High-mix precision components, medical devices | Aluminum, Steel, ABS, Nylon, PEEK | ±0.0005″ | $200,000 – $600,000+ | Combines turning and milling; ideal for complex, tight-tolerance parts |

Material Notes

Aluminum and ABS are easier to machine and place lower demands on tooling and machine rigidity, making them suitable for lower-cost platforms. Steel and nylon require higher spindle power, rigidity, and thermal stability, especially when holding tight tolerances. 5-axis and mill-turn systems are preferred for high-precision steel components and complex nylon parts (e.g., functional prototypes).

Precision Considerations

Achieving tight tolerances consistently requires high-quality spindle systems (±5 µm runout or better), thermal compensation, rigid machine structures (cast iron or polymer concrete), and advanced control systems (e.g., Fanuc, Siemens, or Heidenhain). Machines in the higher cost ranges typically include these features as standard.

From CAD to Part: The Process

Honyo Prototype calculates the actual cost per CNC-machined part—not an abstract “average cost of a CNC machine”—through a structured, data-driven workflow. This process eliminates guesswork by integrating engineering analysis with real-time production economics. Below is the technical breakdown of how each phase contributes to accurate cost determination.

Upload CAD

The process begins with validated CAD file submission (STEP, IGES, or native formats). Our system performs automated geometry analysis to extract critical cost drivers: part volume, material type, feature complexity (e.g., cavities, thin walls), and initial tolerance requirements. Material selection is confirmed here, as it directly impacts 25–40% of total part cost. Files failing basic manufacturability checks (e.g., unprocessable radii, unsupported overhangs) trigger immediate client feedback to prevent downstream rework costs.

AI Quote Generation

Honyo’s proprietary AI engine analyzes the CAD-derived parameters against a database of 500,000+ historical production runs. It calculates a preliminary cost estimate using weighted variables:

| Cost Factor | Weighting | Data Source |

|---|---|---|

| Raw Material Volume | 30% | Live supplier pricing + scrap rate algorithms |

| Machine Time | 45% | Dynamic hourly rates (3-axis: $75–$120; 5-axis: $130–$200) |

| Tooling Complexity | 15% | Feature-based toolpath simulation |

| Setup Frequency | 10% | Fixture/repositioning time algorithms |

This quote includes a confidence score (typically 85–95% for standard geometries) and flags high-risk assumptions for DFM review.

DFM Analysis

Engineers conduct a rigorous Design for Manufacturability assessment, focusing on cost-optimization levers:

Tolerance Rationalization: Over-specified tolerances (e.g., ±0.001″ vs. achievable ±0.005″) are revised, reducing machining time by 15–30%.

Setup Consolidation: Features reoriented to minimize machine repositioning, directly lowering labor and machine-hour costs.

Material Efficiency: Nesting optimization for multi-part runs cuts raw material waste by 12–25%.

Process Selection: Recommending milling vs. turning or hybrid processes based on feature geometry.

DFM revisions typically reduce the initial AI quote by 18–22% while maintaining functional requirements. The final quote reflects these engineering adjustments.

Production Execution

Cost accuracy is validated during manufacturing through:

Real-time machine monitoring tracking actual cycle times against AI estimates.

Material usage reconciliation (scrap rates logged per batch).

Labor cost allocation based on certified operator skill levels.

Discrepancies >5% from the DFM-adjusted quote trigger root-cause analysis—e.g., unexpected tool wear from material inclusions. This data continuously retrains the AI model.

Delivery & Cost Validation

Final cost reconciliation occurs post-shipment, incorporating:

Actual machine hours consumed (vs. estimated)

Verified material consumption (including secondary operations)

Logistics expenses (e.g., expedited shipping)

A detailed cost breakdown report is provided, showing variance analysis against the DFM-confirmed quote. Historical data from this phase feeds continuous improvement of the AI engine’s accuracy.

Why This Eliminates “Averages”

Honyo rejects generic “average cost” metrics because CNC part costs are inherently project-specific. Our workflow delivers actionable, part-specific cost transparency by:

1. Quantifying cost drivers at the geometry level (not machine type).

2. Using DFM to eliminate non-value-added expenses before production.

3. Validating estimates against real-world production data.

This approach ensures clients pay only for necessary operations, with typical quote-to-actual cost variance held below 7% for qualified designs. For true cost predictability, we recommend engaging early in the design phase to leverage DFM insights.

Start Your Project

Looking to understand the average cost of a CNC machine for your next manufacturing project? Get accurate, up-to-date pricing tailored to your specifications and production needs.

Contact Susan Leo at [email protected] for a detailed breakdown and expert guidance. With our state-of-the-art factory located in Shenzhen, we deliver high-quality CNC machining solutions with fast turnaround and competitive pricing.

Let us help you make an informed investment—reach out today to request a quote or schedule a consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.