Contents

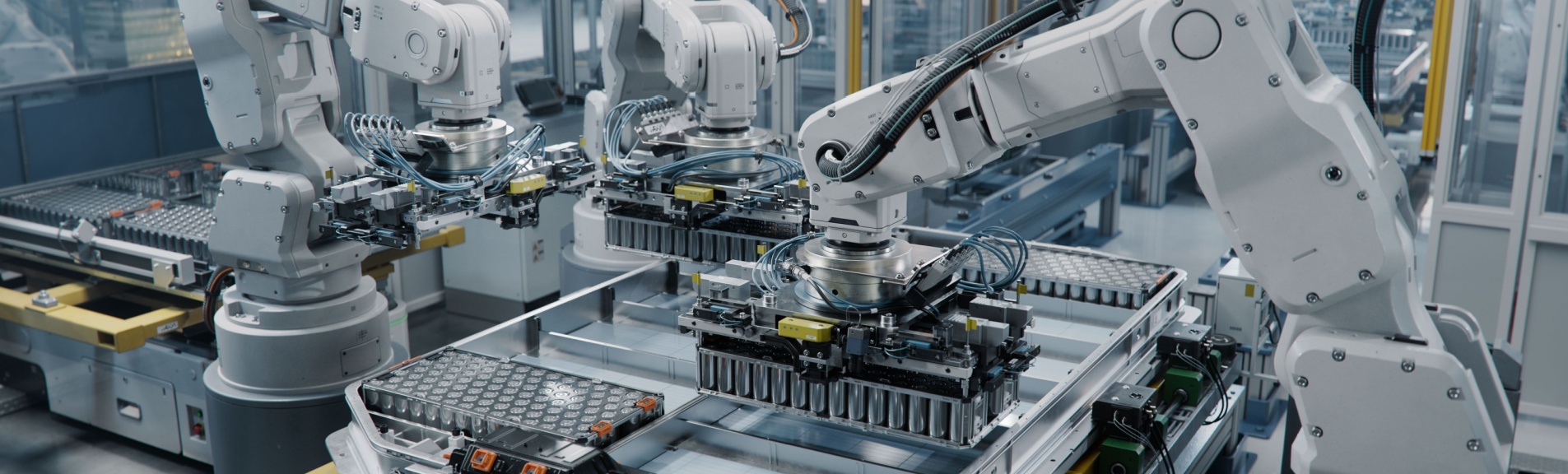

Manufacturing Insight: Automotive Precision Machining

Precision Machining for Automotive Innovation: Engineered at Honyo Prototype

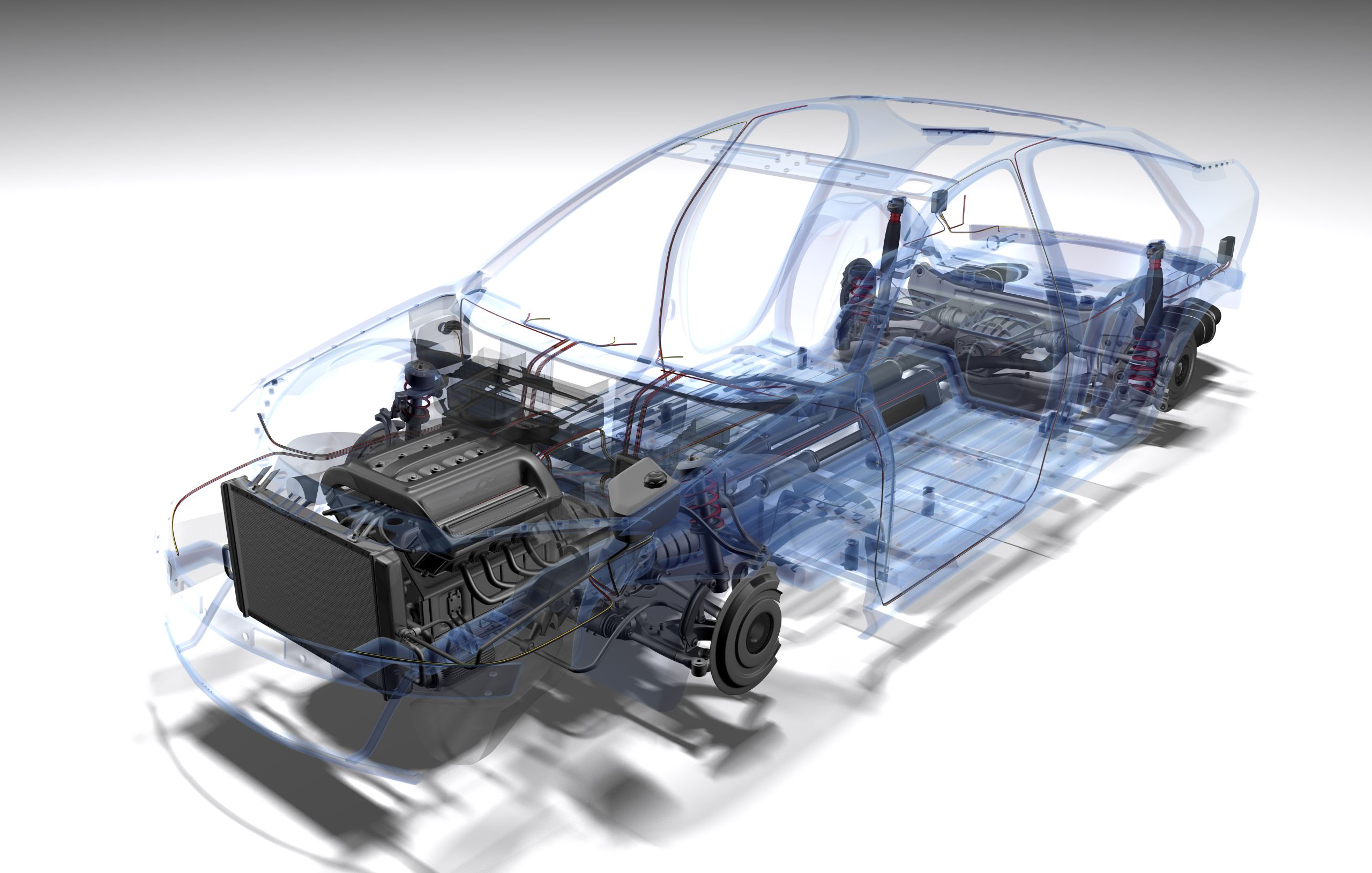

The automotive industry demands uncompromising precision, material integrity, and rapid iteration to meet evolving performance, safety, and electrification standards. At Honyo Prototype, we specialize in high-accuracy CNC machining services engineered specifically for automotive component development and low-volume production. Our advanced 3-, 4-, and 5-axis milling and turning centers consistently achieve micron-level tolerances (±0.005mm) across complex geometries, critical for transmission systems, engine components, EV powertrain elements, and sensor housings. We machine mission-critical materials including aerospace-grade aluminum alloys, hardened steels, titanium, and high-temperature composites, adhering to stringent AS9100 and IATF 16949 quality protocols to ensure every part meets OEM validation requirements.

Our technical team collaborates directly with automotive engineers to optimize designs for manufacturability, reducing lead times without sacrificing precision. This proactive approach minimizes costly redesigns and accelerates time-to-test for prototypes and pilot runs. To further streamline your development workflow, Honyo Prototype offers an Online Instant Quote platform. Upload your CAD file, specify materials and tolerances, and receive a detailed production-ready quotation in under 60 seconds—enabling faster decision-making and project initiation.

Partner with Honyo Prototype to transform automotive concepts into validated, high-performance components with the speed and technical rigor your engineering team requires.

| Key Automotive Capabilities | Technical Specifications |

|---|---|

| Tolerance Range | ±0.005mm to ±0.025mm (feature-dependent) |

| Materials Processed | Aluminum 6061/7075, 4140/4340 Steel, Ti-6Al-4V, Inconel 718, PEEK |

| Max Work Envelope | 1,200 x 600 x 500mm (5-axis) |

| Surface Finish | Ra 0.4μm to Ra 1.6μm (as-machined) |

| Certifications | IATF 16949, AS9100D, ISO 9001 |

Technical Capabilities

Automotive precision machining involves the production of complex, high-accuracy components used in powertrain systems, suspension, sensors, and engine management. At Honyo Prototype, we specialize in multi-axis CNC machining to meet the stringent requirements of automotive OEMs and Tier 1 suppliers. Our capabilities include 3, 4, and 5-axis milling as well as precision turning, enabling us to produce intricate geometries with consistent repeatability and tight tolerances.

We routinely work with a range of engineering-grade materials including aluminum alloys (e.g., 6061, 7075), carbon and stainless steels (e.g., 4140, 17-4PH), and high-performance thermoplastics such as ABS and Nylon — selected based on mechanical, thermal, and environmental performance needs.

The following table outlines the key technical specifications for our automotive precision machining services:

| Parameter | Specification |

|---|---|

| Machining Types | 3-Axis Milling, 4-Axis Indexing Milling, 5-Axis Simultaneous Milling, CNC Turning |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; down to ±0.002 mm (±0.00008″) for critical features |

| Surface Finish | As-machined: Ra 3.2 µm (125 µin); Optional polishing to Ra 0.4 µm (16 µin) |

| Max Work Envelope | Milling: 1000 x 600 x 500 mm (39.4 x 23.6 x 19.7 in); Turning: Ø300 mm x 500 mm |

| Positioning Accuracy | ±0.003 mm (±0.0001″) |

| Repeatability | ±0.002 mm (±0.00008″) |

| Materials | Aluminum (6061-T6, 7075-T6), Steel (4140, 1018, 17-4PH), ABS, Nylon (6, 66) |

| Secondary Operations | Deburring, precision cleaning, anodizing (Type II & III), passivation, laser marking |

| Inspection Equipment | CMM (Coordinate Measuring Machine), optical comparators, micrometers, calipers, bore gauges |

| Compliance Standards | ISO 9001:2015, IATF 16949 (automotive-specific QMS), PPAP documentation available |

Our 5-axis machining centers allow for single-setup completion of complex parts, reducing lead time and improving geometric accuracy. Turning operations are optimized for shafts, fittings, and rotational components requiring tight concentricity and surface integrity. All processes are supported by robust process planning, in-process inspection, and full traceability per automotive industry requirements.

From CAD to Part: The Process

Honyo Prototype Automotive Precision Machining Workflow

Our automotive precision machining process integrates advanced digital tools with stringent manufacturing protocols to deliver components meeting AS9100 and IATF 16949 standards. The workflow begins with secure CAD data ingestion and concludes with certified delivery.

CAD Data Upload & Validation

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid) via our encrypted portal. Our system performs immediate geometry validation, checking for manifold errors, unit consistency, and automotive-specific requirements like surface finish callouts per ISO 1302. Version control is enforced, with metadata logging including material specifications and critical-to-quality (CTQ) features identified per client annotations.

AI-Powered Quoting Engine

Uploaded geometry feeds our proprietary AI quoting system, which analyzes 120+ parameters including feature complexity, tolerance density (e.g., ±0.005mm positional tolerances), and material machinability (e.g., 7075-T6 aluminum vs. 4140 steel). The engine cross-references real-time machine availability, tooling costs, and historical scrap rates for similar automotive components (e.g., transmission housings, sensor mounts). Quotes include tolerance feasibility flags and estimated setup hours within 90 minutes, with explicit callouts for features requiring specialized processes like micromachining or 5-axis contouring.

Automotive-Optimized DFM Analysis

Engineers conduct a dual-path DFM review:

1. AI-Driven Preliminary Scan: Identifies high-risk features (e.g., thin walls <0.5mm, deep pockets with aspect ratios >10:1) and suggests near-net-shape adjustments to reduce machining time.

2. Human-Led Critical Review: Focuses on automotive-specific failure modes. This includes GD&T validation against functional assembly requirements, thermal distortion modeling for powertrain components, and material certification traceability (e.g., AMS 4928 for titanium alloys). We provide actionable feedback through annotated 3D markups and tolerance stack-up simulations.

Key DFM outputs include:

| DFM Parameter | Automotive Standard Requirement | Honyo Action Threshold |

|---|---|---|

| Surface Roughness | Ra 0.8µm (sealing surfaces) | Auto-flag if Ra >1.2µm |

| Positional Tolerance | ±0.02mm (bracket interfaces) | Require CMM pre-check |

| Material Certification | Full EN 10204 3.1 traceability | Mandatory CoA review |

Precision Production Execution

Machining occurs in climate-controlled cells (±0.5°C stability) using certified equipment (e.g., DMG MORI CTX beta 1250, Makino A81). Processes include:

High-speed milling with coolant-through spindles for aluminum housings (avoids built-up edge)

Wire EDM for fuel injector nozzles requiring ±2µm accuracy

In-process probing for first-article validation of datum structures

All automotive lots undergo 100% critical dimension verification via Zeiss CONTURA CMMs, with data linked to material heat numbers. Statistical process control (SPC) monitors tool wear in real-time, halting production if CpK falls below 1.67.

Certified Delivery & Documentation

Components ship with full AS9102-compliant first-article inspection reports (FAIR), including raw material certs, process flow diagrams, and CMM heat maps. For safety-critical parts (e.g., brake caliper prototypes), we provide PPAP Level 3 documentation with MSA studies. Parts are packaged in ESD-safe, humidity-controlled containers meeting ISTA 3A standards, with serialized tracking from machine load to client dock. Typical lead time from CAD upload to delivery is 7-12 business days for complex assemblies, with expedited options for urgent automotive development cycles.

This integrated approach reduces prototype-to-production transition time by 35% versus industry benchmarks while maintaining zero non-conformances on dimensional requirements for Tier 1 automotive clients in the past 18 months.

Start Your Project

For high-precision automotive machining solutions, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers tight-tolerance components with consistent quality and fast turnaround. Partner with Honyo Prototype for reliable, scalable production tailored to the demands of the automotive industry.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.