Introduction: Navigating the Global Market for automotive parts & machine

In today’s interconnected economy, sourcing high-quality automotive parts and machine services can be a daunting task for international B2B buyers. The challenge lies not only in identifying reliable suppliers but also in navigating the complexities of varying standards, compliance regulations, and market dynamics across regions such as Africa, South America, the Middle East, and Europe. This guide is designed to equip you with the essential knowledge needed to confidently source automotive parts and machine services that meet your specific business needs.

This comprehensive resource covers a wide array of topics, including the types of automotive parts available, their diverse applications, and effective strategies for vetting suppliers. Additionally, we will delve into cost considerations, ensuring that you understand the financial implications of your purchasing decisions. By leveraging industry insights and best practices, this guide empowers B2B buyers to make informed choices that enhance operational efficiency and product quality.

Whether you are in Saudi Arabia seeking robust engine components or in Brazil looking for specialized machine services, this guide serves as your roadmap. With actionable insights and expert advice, you will be better prepared to navigate the global market, minimize risks, and establish partnerships that drive your business forward.

Understanding automotive parts & machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engine Rebuilding | Comprehensive overhaul of engine components | Automotive repair shops, racing teams | Pros: Extends engine life, improves performance. Cons: High cost, requires skilled labor. |

| Cylinder Head Machining | Precision resurfacing and repair of cylinder heads | Engine rebuilders, performance tuning | Pros: Enhances sealing and performance. Cons: Specialized service, may require downtime. |

| CNC Machining | Computer-controlled precision machining for parts | Custom parts manufacturing, prototyping | Pros: High precision, repeatability. Cons: Initial setup costs can be significant. |

| Fusion Welding | Specialized welding for cast iron and aluminum parts | Repair shops, custom fabrication | Pros: Durable repairs, versatile application. Cons: Requires skilled technicians, may not suit all materials. |

| Industrial Machining | Machining services for heavy-duty and industrial engines | Agriculture, construction, transportation | Pros: Tailored solutions for heavy machinery. Cons: Longer lead times for custom jobs. |

What Are the Characteristics of Engine Rebuilding Services?

Engine rebuilding involves the complete disassembly and reconditioning of an engine to restore it to optimal performance. This service is essential for automotive repair shops and racing teams looking to maximize engine lifespan and efficiency. When considering engine rebuilding, B2B buyers should evaluate the reputation of the service provider, the quality of replacement parts, and the warranty offered on the work performed.

How Does Cylinder Head Machining Enhance Engine Performance?

Cylinder head machining focuses on resurfacing and repairing cylinder heads to ensure a proper seal with the engine block. This process is crucial for maintaining engine efficiency and preventing leaks. Suitable for engine rebuilders and performance tuning specialists, buyers should consider the provider’s expertise in machining, the technology used, and the turnaround time for services to minimize vehicle downtime.

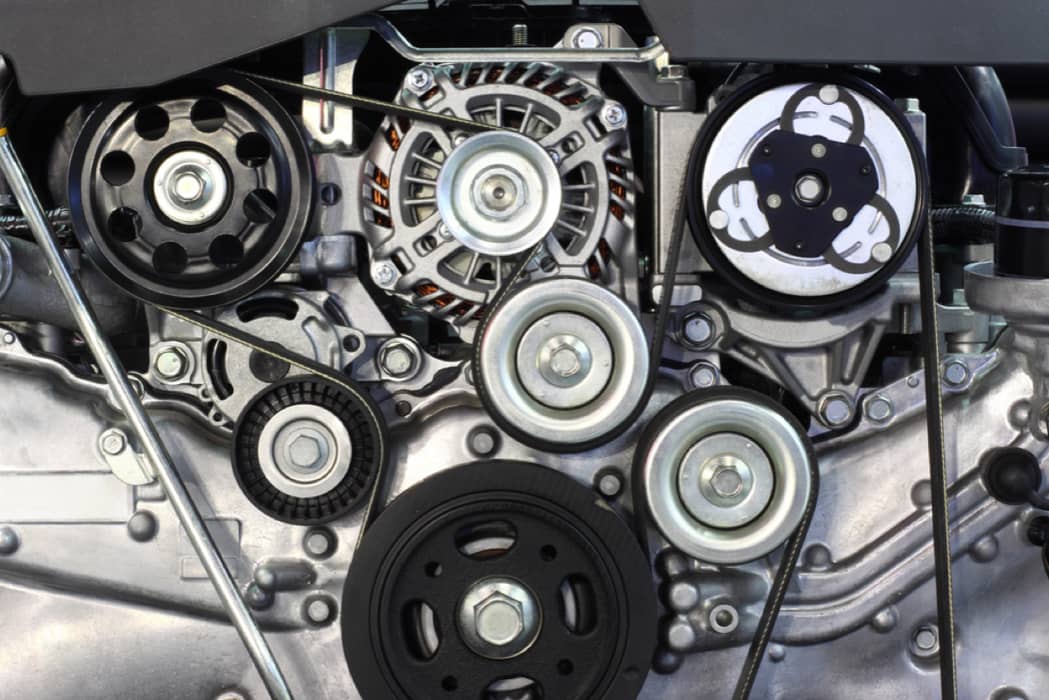

Why Choose CNC Machining for Automotive Parts?

CNC machining utilizes computer-controlled tools to create precise automotive parts, making it ideal for custom manufacturing and prototyping. This method is highly valued in industries requiring high precision, such as motorsports and specialty vehicle production. B2B buyers should assess the machine shop’s capabilities, including the range of materials they can work with and their experience in producing complex designs.

What Are the Benefits of Fusion Welding in Automotive Repair?

Fusion welding is a specialized technique used to repair cast iron and aluminum components, offering durable solutions for damaged parts. This service is frequently utilized in repair shops and custom fabrication scenarios. Buyers should consider the qualifications of the welding technicians and the types of materials they can effectively repair, as well as the potential for cost savings compared to replacing entire components.

How Does Industrial Machining Support Heavy-Duty Applications?

Industrial machining encompasses a range of machining services tailored for heavy-duty and industrial engines, commonly found in agriculture, construction, and transportation sectors. This type of service is essential for businesses looking to maintain their machinery efficiently. Buyers should evaluate the machining capabilities, lead times, and the shop’s experience in handling large-scale projects to ensure they meet their operational needs.

Key Industrial Applications of automotive parts & machine

| Industry/Sector | Specific Application of Automotive Parts & Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Precision machining for engine components | Enhanced performance and reliability of vehicles | Quality certifications, production capacity, lead time |

| Agriculture | Engine rebuilding for agricultural machinery | Increased efficiency and reduced downtime | Availability of specialized parts, service capabilities |

| Construction | Custom fabrication for heavy machinery | Improved durability and operational efficiency | Material sourcing, custom design capabilities |

| Oil & Gas | Maintenance and repair of industrial engines | Maximized uptime and compliance with safety standards | Expertise in heavy-duty applications, global logistics |

| Racing & Performance | High-performance engine parts manufacturing | Competitive edge through enhanced power and speed | R&D capabilities, precision engineering, material quality |

How is Automotive Parts & Machine Used in Automotive Manufacturing?

In automotive manufacturing, precision machining is crucial for producing high-quality engine components. Automotive parts and machine services provide essential tasks such as cylinder head resurfacing and crankshaft reconditioning, which enhance the performance and reliability of vehicles. Buyers in this sector must consider suppliers with quality certifications and proven production capacities to meet stringent automotive standards. For international buyers, understanding local regulations and ensuring timely delivery are also critical factors.

What Role Does Automotive Parts & Machine Play in Agriculture?

In the agricultural sector, engine rebuilding services for tractors and other machinery are vital for maintaining operational efficiency. Automotive parts and machine shops provide specialized services that address wear and tear, ensuring that equipment runs smoothly and reduces downtime. For B2B buyers, particularly in regions like Africa and South America, sourcing reliable parts and services that can accommodate the unique demands of agricultural machinery is essential. Additionally, understanding the local supply chain dynamics can significantly impact service reliability.

How is Custom Fabrication Used in Construction?

The construction industry often requires custom fabrication for heavy machinery to enhance durability and operational efficiency. Automotive parts and machine services can create bespoke components that meet specific project requirements, thereby extending the lifespan of the equipment. Businesses must consider material sourcing and the supplier’s ability to deliver custom designs to ensure their projects stay on schedule. For international buyers, evaluating the supplier’s experience with heavy machinery in diverse conditions is crucial.

Why is Maintenance Critical in the Oil & Gas Sector?

In the oil and gas industry, the maintenance and repair of industrial engines are paramount to maximizing uptime and ensuring compliance with safety standards. Automotive parts and machine services provide essential support through engine rebuilding and part replacement, which are vital for heavy-duty applications. Buyers should prioritize suppliers with expertise in industrial applications and robust global logistics capabilities to ensure timely repairs and parts availability, especially in remote locations.

How Does Automotive Parts & Machine Enhance Racing and Performance?

For the racing and performance sector, high-performance engine parts manufacturing is crucial for gaining a competitive edge. Automotive parts and machine services offer specialized machining that enhances engine power and speed, critical for racing applications. B2B buyers in this niche must focus on suppliers with strong R&D capabilities and a commitment to precision engineering. Material quality and the ability to meet tight deadlines are also essential to ensure optimal performance in high-stakes environments.

3 Common User Pain Points for ‘automotive parts & machine’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Auto Parts Procurement

The Problem:

B2B buyers in the automotive parts industry often face challenges in ensuring the quality and reliability of the parts they source. With numerous suppliers available, the risk of receiving subpar or counterfeit components is significant, particularly when dealing with international vendors. This issue can lead to extended downtimes, increased repair costs, and even safety concerns, as faulty parts can compromise vehicle performance.

The Solution:

To mitigate these risks, B2B buyers should implement a rigorous supplier evaluation process. Start by researching suppliers’ reputations, certifications, and industry affiliations. Look for suppliers with ISO certifications or other quality management systems in place, as these indicate adherence to international standards. Additionally, consider requesting product samples or conducting quality audits before placing large orders. Establishing long-term relationships with trusted suppliers who have demonstrated consistent quality can further enhance reliability. Utilizing third-party testing services to verify the quality of critical components before they are integrated into your supply chain can also provide an added layer of assurance.

Scenario 2: Addressing Lead Time and Delivery Reliability

The Problem:

In the automotive parts business, delays in receiving essential components can disrupt operations and impact customer satisfaction. Many B2B buyers find themselves in situations where suppliers fail to meet promised delivery dates, leading to halted projects and frustrated clients. This is particularly problematic for companies that operate in regions with logistical challenges, such as Africa and South America, where shipping times can be unpredictable.

The Solution:

To counteract this issue, buyers should prioritize suppliers who offer transparent and reliable shipping policies. Before finalizing contracts, inquire about average lead times, shipping methods, and contingency plans for potential delays. Consider diversifying your supplier base to include local vendors, which can help reduce lead times significantly. Additionally, implementing inventory management practices, such as just-in-time (JIT) inventory, can buffer against delays by ensuring that critical components are on hand when needed. Use technology to track shipments in real-time, allowing for proactive management of supply chain disruptions.

Scenario 3: Managing Technical Support and After-Sales Service

The Problem:

When purchasing automotive parts and machines, B2B buyers frequently encounter challenges related to technical support and after-sales service. Complex machinery and components often require expert knowledge for installation, operation, and maintenance. However, many suppliers provide limited or no support, leaving buyers stranded when issues arise. This lack of assistance can lead to increased downtime and higher operational costs.

The Solution:

To ensure effective post-purchase support, buyers should prioritize suppliers who offer comprehensive technical assistance and after-sales services. Before making a purchase, assess the level of technical support available, including installation guidance, troubleshooting assistance, and access to qualified technicians. Look for suppliers that provide detailed product documentation, training sessions, or even dedicated support lines. Establishing a service-level agreement (SLA) with your supplier can also ensure that you receive prompt and reliable support when needed. Additionally, investing in training for your team on the specific equipment can empower them to handle minor issues independently, reducing reliance on external support.

Strategic Material Selection Guide for automotive parts & machine

What Are the Key Properties of Aluminum in Automotive Parts?

Aluminum is widely used in automotive applications due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 600°F (315°C), making it suitable for engine components that experience high temperatures. Its low density contributes to improved fuel efficiency in vehicles. However, aluminum’s lower strength compared to steel can be a limitation in high-stress applications.

Pros and Cons of Aluminum for Automotive Parts

The primary advantage of aluminum is its lightweight characteristic, which can lead to significant fuel savings and enhanced vehicle performance. Its resistance to corrosion extends the lifespan of components, making it a preferred choice for parts exposed to harsh environments. However, aluminum can be more expensive than traditional steel and may require specialized manufacturing processes, such as welding and machining, which can increase production complexity.

Impact on Application and Considerations for International Buyers

For international B2B buyers, particularly in regions like Africa and the Middle East, compliance with local standards such as ASTM or DIN is crucial. Buyers should also consider the availability of aluminum alloys that meet specific performance requirements, as these can vary significantly by region.

How Does Steel Perform as a Material for Automotive Parts?

Steel is a staple in the automotive industry, known for its high strength and durability. It can withstand high temperatures and pressures, making it ideal for structural components and engine parts. Steel’s temperature rating can vary, but it generally performs well under extreme conditions.

Pros and Cons of Steel in Automotive Manufacturing

Steel’s primary advantage lies in its strength and cost-effectiveness, making it suitable for a wide range of applications from chassis to engine components. However, steel is heavier than alternatives like aluminum, which can negatively impact fuel efficiency. Additionally, steel is prone to corrosion if not properly treated or coated.

Impact on Application and Considerations for International Buyers

Steel components must comply with various international standards, including ISO and ASTM. Buyers in South America and Europe should be aware of the specific grades of steel that are favored in their regions, as these can influence both performance and pricing.

What Are the Benefits of Composite Materials in Automotive Applications?

Composite materials, such as carbon fiber reinforced plastics, are gaining traction in the automotive sector due to their exceptional strength-to-weight ratio. These materials can perform well under high temperatures and offer excellent corrosion resistance, making them suitable for both structural and aesthetic components.

Pros and Cons of Composites for Automotive Parts

The key advantage of composites is their lightweight nature, which can significantly enhance vehicle performance and fuel efficiency. They also allow for complex shapes and designs that are difficult to achieve with metals. However, composites can be more expensive and may require specialized manufacturing techniques, which can complicate production.

Impact on Application and Considerations for International Buyers

International buyers should consider the availability of composite materials that meet their specific needs, as well as the associated manufacturing capabilities. Compliance with standards such as ISO and local regulations is essential, especially in regions like Europe where environmental regulations are stringent.

Why Is Cast Iron Still Relevant in Automotive Manufacturing?

Cast iron is traditionally used for engine blocks and cylinder heads due to its excellent wear resistance and ability to absorb vibrations. It can withstand high temperatures, typically rated up to 1,200°F (650°C), making it suitable for high-performance applications.

Pros and Cons of Cast Iron in Automotive Parts

Cast iron’s primary advantage is its durability and ability to maintain structural integrity under stress. It is also relatively inexpensive compared to other materials. However, cast iron is heavier than alternatives like aluminum, which can affect fuel efficiency. Additionally, it is more brittle and can crack under extreme stress.

Impact on Application and Considerations for International Buyers

Buyers should be aware of the specific grades of cast iron that are most suitable for their applications, as well as compliance with international standards. In regions like Africa and South America, sourcing quality cast iron can be a challenge, so buyers must establish reliable supply chains.

| Material | Typical Use Case for automotive parts & machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine components, body panels | Lightweight, corrosion-resistant | Lower strength compared to steel | Medium |

| Steel | Chassis, structural components | High strength, cost-effective | Heavier, prone to corrosion | Low |

| Composite | Body panels, interior components | Lightweight, complex shapes | Expensive, requires specialized manufacturing | High |

| Cast Iron | Engine blocks, cylinder heads | Durable, excellent wear resistance | Heavier, brittle under extreme stress | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for automotive parts & machine

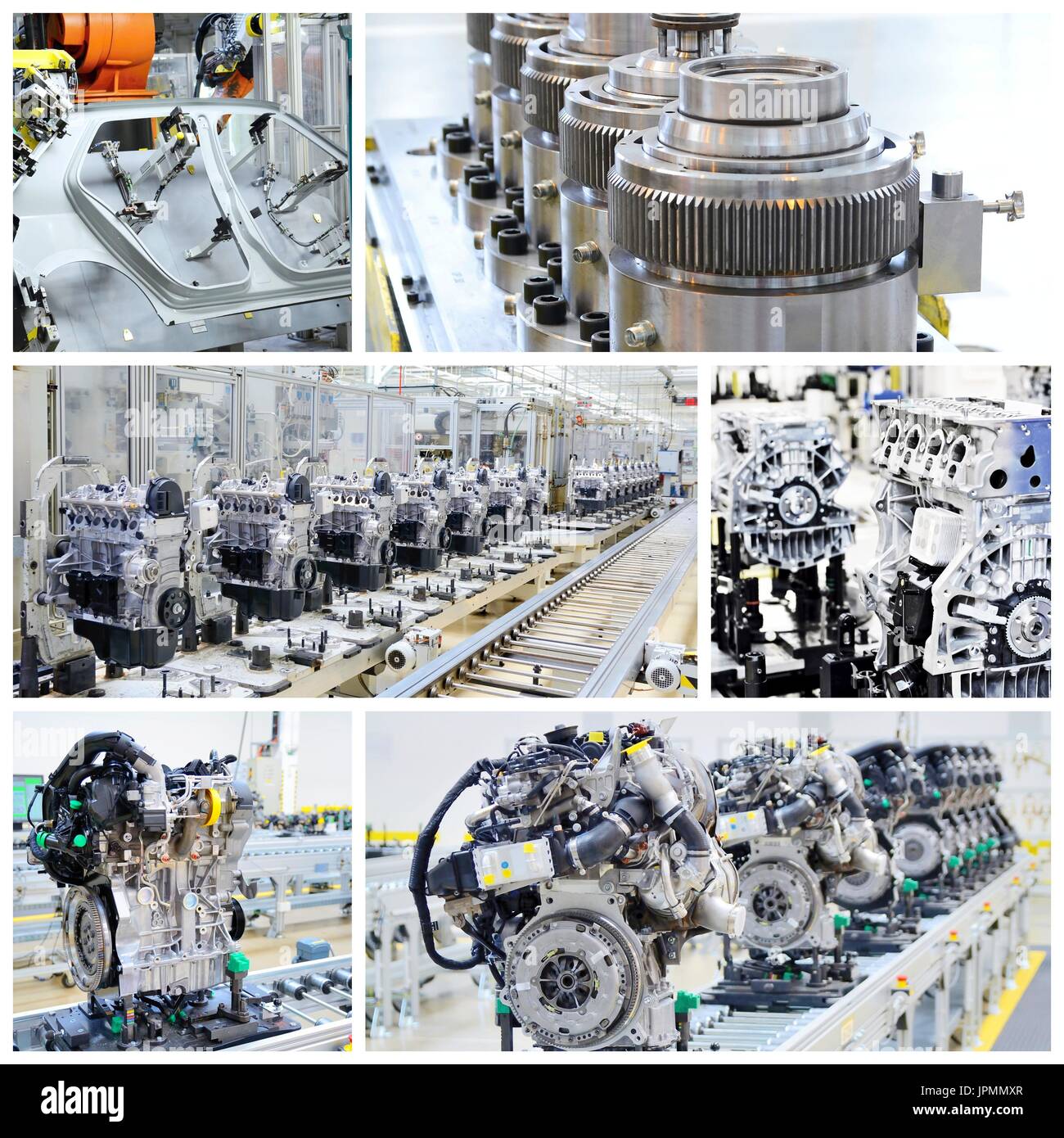

What Are the Key Stages in the Manufacturing Process for Automotive Parts?

The manufacturing process for automotive parts is intricate and involves several critical stages, each designed to ensure the final product meets the high standards required in the automotive industry. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

This initial stage involves selecting the right materials, which are typically metals, plastics, or composites, based on the specifications of the automotive part being produced. Materials undergo processes such as cutting, shearing, and cleaning to ensure they are free from contaminants that could affect quality. High-quality raw materials are essential for achieving durability and performance in automotive applications. -

Forming

During the forming stage, the prepared materials are shaped into the desired configuration using various techniques. Common methods include stamping, casting, machining, and welding. For instance, stamping is often used for metal sheets to create parts like brackets or panels, while casting is preferred for more complex shapes like engine blocks. Advanced techniques such as CNC machining provide precision that is crucial for components requiring tight tolerances. -

Assembly

Assembly involves putting together the various components to create the final part. This can be done manually or through automated processes, depending on the volume and complexity of production. For example, engine components may require precision assembly to ensure proper fit and function. Quality checks are integrated throughout this phase to identify any discrepancies early on. -

Finishing

The finishing stage enhances the appearance and performance of the automotive parts. This may involve processes like painting, plating, or applying protective coatings. Finishing not only improves aesthetics but also adds layers of protection against corrosion and wear, which is particularly important for parts exposed to harsh environments.

What Quality Control Measures Are Essential for Automotive Parts?

Quality assurance is critical in the manufacturing of automotive parts to ensure safety, reliability, and compliance with international standards. Key measures include adherence to quality standards, implementing checkpoints during production, and conducting various testing methods.

-

International Standards and Certifications

Compliance with international quality standards, such as ISO 9001, is essential for manufacturers aiming to operate in global markets. ISO 9001 outlines requirements for a quality management system (QMS), focusing on customer satisfaction and continuous improvement. Additionally, industry-specific standards like CE marking for safety in Europe or API certification for oil and gas components ensure that products meet regulatory requirements. -

Quality Control Checkpoints

Quality control checkpoints are integrated into the manufacturing process at various stages. These include:

– Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Monitors the production process to detect defects early.

– Final Quality Control (FQC): Conducts thorough inspections of finished products to verify they meet quality standards before shipment. -

Common Testing Methods

Various testing methods are employed to ensure product integrity. These include:

– Dimensional Testing: Ensures parts meet specified tolerances through tools like calipers and micrometers.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection are used to detect internal flaws without damaging the part.

– Performance Testing: Simulates real-world conditions to assess how parts perform under stress.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality assurance practices of suppliers is crucial. There are several approaches to ensure that suppliers maintain high standards.

-

Conducting Audits

Regular audits of suppliers can provide insights into their quality control processes. Buyers should consider both scheduled audits and random checks to gauge consistency in quality practices. Audits help identify potential risks and areas for improvement. -

Requesting Quality Reports

Suppliers should provide detailed quality assurance reports, including documentation of testing results, compliance certificates, and any corrective actions taken in response to identified issues. These reports serve as a valuable reference for buyers to assess the reliability of the supplier. -

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These organizations can perform inspections at various stages of production, ensuring that the supplier adheres to specified standards and protocols.

What Are the Quality Control Nuances for International Buyers?

B2B buyers in different regions may encounter unique challenges when it comes to quality assurance. Understanding these nuances is vital for successful procurement.

-

Cultural and Regulatory Differences

Buyers must be aware of the cultural and regulatory differences that may affect quality standards. For example, the EU has stringent regulations regarding automotive parts, which may differ from those in emerging markets. Familiarity with local regulations helps ensure compliance and smooth transactions. -

Language Barriers and Communication

Language differences can lead to misunderstandings regarding quality expectations. Establishing clear communication channels and utilizing multilingual staff or translation services can help mitigate these issues. -

Supply Chain Transparency

Buyers should seek suppliers who are transparent about their manufacturing processes and quality control measures. This transparency fosters trust and allows buyers to make informed decisions about supplier partnerships.

By prioritizing a thorough understanding of manufacturing processes and quality assurance practices, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers in the automotive parts and machinery sector. This approach not only safeguards their investments but also enhances their competitive advantage in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive parts & machine’

To successfully procure automotive parts and machine services, B2B buyers must navigate a complex landscape of suppliers and products. This guide provides a step-by-step checklist to ensure a systematic approach to sourcing, enabling informed decisions that align with business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. This includes understanding the type of automotive parts or machinery needed, specifications for performance, compatibility with existing systems, and any special features required.

- Key Considerations:

- Identify the engine type, size, and any unique modifications.

- Determine the quality standards and certifications applicable to your market.

Step 2: Conduct Market Research

Engage in thorough market research to identify potential suppliers. This step involves analyzing industry trends, pricing models, and competitor offerings.

- Focus Areas:

- Utilize online databases, trade shows, and industry publications to gather insights.

- Compare suppliers based on experience, reputation, and customer reviews.

Step 3: Evaluate Potential Suppliers

Before making commitments, vet potential suppliers to ensure they meet your standards. Request company profiles, case studies, and references from buyers in similar industries or regions.

- What to Look For:

- Certifications and adherence to international standards (e.g., ISO).

- Previous projects that reflect their expertise in your specific area of need.

Step 4: Request Samples or Prototypes

Obtaining samples or prototypes is crucial for assessing quality and compatibility. This step allows you to evaluate the supplier’s workmanship and determine if their products meet your specifications.

- Best Practices:

- Specify your testing criteria and the conditions under which the samples will be assessed.

- Ensure that the samples are representative of the mass production quality.

Step 5: Verify Supplier Certifications

Confirm that suppliers hold relevant industry certifications, which can indicate their commitment to quality and compliance with regulatory standards.

- Key Certifications:

- Look for ISO certifications, automotive industry standards (e.g., IATF 16949), and any local compliance certifications.

- Ask suppliers for documentation to verify their claims.

Step 6: Negotiate Terms and Pricing

Once a suitable supplier is identified, engage in negotiations to clarify terms, pricing, and delivery schedules. A transparent negotiation process fosters a good relationship and ensures that both parties have aligned expectations.

- Important Aspects:

- Discuss bulk order discounts and payment terms.

- Ensure clarity on warranty terms and after-sales support.

Step 7: Establish a Communication Protocol

Effective communication is key to a successful partnership. Establish a clear communication protocol to facilitate ongoing dialogue regarding orders, changes, and feedback.

- Recommended Actions:

- Designate points of contact on both sides for smooth information exchange.

- Utilize project management tools to track progress and address any issues promptly.

By following this checklist, B2B buyers can streamline their sourcing process for automotive parts and machinery, ensuring they select the right suppliers that meet their technical and operational needs.

Comprehensive Cost and Pricing Analysis for automotive parts & machine Sourcing

What Are the Key Cost Components in Automotive Parts and Machine Sourcing?

When sourcing automotive parts and machines, understanding the underlying cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials constitutes a significant portion of the overall pricing. The choice of materials—such as steel, aluminum, or specialized alloys—directly affects durability, performance, and pricing.

-

Labor: Labor costs encompass wages for skilled machinists and assembly workers. High expertise levels are often required for precision machining and assembly, which can vary significantly across regions.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient production processes can help lower overhead costs.

-

Tooling: Initial tooling investments can be substantial, especially for custom parts. This includes molds, dies, and specialized machinery necessary for production.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet specific standards. However, this can add to the overall cost, particularly if extensive testing is involved.

-

Logistics: Shipping costs can vary based on distance, shipping method, and the nature of the parts (e.g., size, weight). Buyers should consider the total logistics costs when evaluating suppliers.

-

Margin: Suppliers typically include a profit margin, which can fluctuate based on competition, demand, and market conditions. Understanding the market dynamics can help buyers negotiate better pricing.

How Do Price Influencers Impact Automotive Parts and Machine Costs?

Several factors can influence the pricing of automotive parts and machinery:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger volumes often leads to lower per-unit costs. Establishing a relationship with suppliers can help in negotiating favorable MOQs.

-

Specifications and Customization: Custom parts or those with specific specifications typically incur higher costs due to the additional labor and materials required. Clear communication about requirements can minimize unexpected costs.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO or TS standards) can drive up prices. However, they may also result in better performance and longevity, justifying the investment.

-

Supplier Factors: The reputation, location, and production capabilities of suppliers can significantly affect pricing. Local suppliers may offer quicker turnaround times, while overseas suppliers might provide lower prices but longer lead times.

-

Incoterms: Understanding international shipping terms is essential for B2B buyers. Incoterms can dictate who is responsible for shipping costs, insurance, and risk, impacting the total landed cost of goods.

What Tips Can Help Buyers Negotiate Better Pricing in the Automotive Parts Market?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, here are actionable tips for optimizing costs:

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, lead times, and pricing. Establishing a long-term partnership can yield better pricing and service.

-

Consider Total Cost of Ownership (TCO): Evaluate the TCO, including purchase price, maintenance, operational costs, and potential downtime. A higher initial investment may lead to lower long-term costs.

-

Understand Pricing Nuances: Be aware of local economic conditions, tariffs, and taxes that might affect pricing. These factors can vary significantly between countries and can influence your total costs.

-

Build Relationships with Suppliers: Strong supplier relationships can lead to better pricing, priority during high-demand periods, and improved service. Frequent communication and feedback can enhance these partnerships.

-

Stay Informed on Market Trends: Keeping an eye on industry trends, material costs, and technological advancements can provide leverage during negotiations and help identify cost-saving opportunities.

Disclaimer on Indicative Prices

Prices for automotive parts and machine sourcing can vary widely based on numerous factors, including market conditions, supplier capabilities, and regional economic factors. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing automotive parts & machine With Other Solutions

Understanding Alternatives in Automotive Parts & Machine Solutions

In the competitive landscape of automotive services, businesses are often faced with the challenge of selecting the right solution to meet their specific needs. While ‘automotive parts & machine’ services offer comprehensive capabilities in engine rebuilding and machine work, there are alternative solutions worth considering. This analysis provides a side-by-side comparison of automotive parts & machine services with two viable alternatives: 3D Printing for automotive parts and OEM (Original Equipment Manufacturer) parts supply.

Comparison Table

| Comparison Aspect | Automotive Parts & Machine | 3D Printing for Automotive Parts | OEM Parts Supply |

|---|---|---|---|

| Performance | High-quality, precise machining for various engine types | Variable, depends on printer quality and material used | Consistent, reliable performance as per manufacturer standards |

| Cost | Competitive, but can vary based on complexity | Potentially lower for small batches, but high setup costs | Generally higher due to brand premium, but consistent availability |

| Ease of Implementation | Requires skilled labor and specialized equipment | Requires significant initial investment and technical knowledge | Straightforward, often readily available through distributors |

| Maintenance | Regular maintenance needed for machines; skilled labor required | Limited maintenance; however, printers and materials must be managed | Minimal maintenance; OEM parts are designed for longevity |

| Best Use Case | Custom engine rebuilds, heavy machinery | Prototyping, custom parts for low-volume applications | High-volume production, standard replacements for reliability |

Pros and Cons of Each Alternative

3D Printing for Automotive Parts

3D printing technology has emerged as a viable alternative for producing automotive parts, particularly in prototyping and low-volume applications. One of its significant advantages is the ability to create complex geometries that are often impossible with traditional machining methods. However, the performance can vary widely based on the quality of the printer and the materials used. Moreover, while the initial setup costs can be high, the potential for reduced costs in small batches can be appealing. However, the technology requires technical expertise to operate and maintain, which could pose a challenge for some businesses.

OEM Parts Supply

OEM parts supply is another alternative that provides businesses with high-quality replacements directly from the original manufacturer. These parts are designed to fit perfectly and maintain the reliability of the vehicle as intended by the manufacturer. The ease of procurement through established distributors makes it a straightforward choice for businesses needing standard replacements. However, the cost can be higher due to brand premiums, and the supply may not be as flexible in terms of customization compared to machine shop services or 3D printing.

Making the Right Choice for Your B2B Needs

When evaluating the best solution for automotive parts and machine needs, B2B buyers should consider their specific requirements, such as the volume of parts needed, customization levels, and budget constraints. Automotive parts & machine services are ideal for businesses requiring precision machining and custom solutions. In contrast, 3D printing offers flexibility for low-volume or prototype parts, while OEM parts supply guarantees reliability and ease of access for standard replacements. By assessing these factors, buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for automotive parts & machine

What Are the Key Technical Properties of Automotive Parts?

Understanding the technical specifications of automotive parts is crucial for B2B buyers in the automotive industry. Here are some critical specifications that play a significant role in the selection and procurement process:

-

Material Grade: The material grade indicates the type of material used in manufacturing a part, which can affect its strength, durability, and performance. Common grades include carbon steel, stainless steel, and aluminum alloys. For buyers, knowing the material grade helps ensure that the parts can withstand the operational demands of specific vehicles or machinery.

-

Tolerance: This specification defines the permissible limit of variation in a physical dimension. Tolerance is critical for parts that must fit together precisely, such as engine components. Inaccurate tolerances can lead to poor performance or even engine failure. B2B buyers need to understand the tolerance levels required for their applications to avoid costly mistakes.

-

Surface Finish: The surface finish of a part affects its performance, longevity, and compatibility with other components. Different applications may require varying degrees of smoothness or roughness, impacting friction, wear, and fatigue. Buyers should inquire about the surface finish to ensure optimal performance in their specific applications.

-

Heat Treatment: This process enhances the mechanical properties of metals, such as hardness and strength. Parts subjected to significant stress or extreme temperatures often undergo heat treatment. For international buyers, particularly those in regions with challenging operational conditions, understanding heat treatment specifications is vital for ensuring reliability and performance.

-

Load Capacity: This specification refers to the maximum load a part can safely handle without failure. It is crucial for components such as bearings, gears, and structural parts. Buyers must assess load capacity in relation to the intended application to prevent premature wear or catastrophic failure.

What Are Common Trade Terminologies in the Automotive Parts Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the automotive parts market. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts that are used in the original assembly of vehicles. OEM parts are often preferred for their quality and compatibility. Buyers should consider whether to source OEM parts or aftermarket alternatives based on their specific needs and budget constraints.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers manage inventory levels and cost-effectiveness. It is essential for businesses, especially those in emerging markets, to negotiate favorable MOQs to optimize their supply chain efficiency.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers requesting pricing information for specific products or services. This process is critical for B2B transactions, as it helps buyers compare costs and terms across different suppliers, ensuring they get the best value.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for international transactions to prevent misunderstandings and ensure smooth logistics, especially for buyers operating across different regions like Africa, South America, the Middle East, and Europe.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the goods. Lead time is crucial for inventory management and production planning. Buyers should always clarify lead times with suppliers to align production schedules and avoid disruptions.

-

Aftermarket Parts: These are components made by manufacturers other than the original vehicle manufacturer. Aftermarket parts can offer cost savings and a wider variety of options. However, buyers should assess quality and compatibility to ensure they meet performance standards.

By understanding these essential technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the automotive parts & machine Sector

What are the Current Market Dynamics and Key Trends in the Automotive Parts & Machine Sector?

The automotive parts and machine sector is experiencing significant transformations driven by globalization, technological advancements, and evolving consumer preferences. Key trends include the rise of digital supply chain solutions and automation, which enhance efficiency and reduce operational costs. B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, are increasingly leveraging e-commerce platforms for sourcing parts, allowing for quicker decision-making and access to a broader range of products. The integration of Industry 4.0 technologies, such as IoT and AI, is reshaping production processes and enabling predictive maintenance, which is particularly beneficial for buyers focusing on long-term asset management.

Moreover, sustainability is becoming a pivotal consideration, as international regulations and consumer expectations shift towards eco-friendly practices. This trend is evident in the increasing demand for suppliers who can provide high-quality recycled materials and components that meet stringent environmental standards. The rise of electric vehicles (EVs) also presents new opportunities for parts suppliers to innovate and adapt their offerings, catering to the growing market of EV components. For international B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with both current market demands and future trends.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Automotive Parts & Machine Sector?

Sustainability and ethical sourcing have become paramount in the automotive parts and machine sector, particularly as global awareness of environmental issues rises. Buyers are increasingly focused on minimizing their environmental impact, which influences their sourcing decisions. An emphasis on ethical supply chains ensures that parts are produced under fair labor conditions, promoting corporate social responsibility and enhancing brand reputation.

The environmental impact of automotive manufacturing is substantial, with the production of parts often contributing to significant waste and emissions. Therefore, sourcing from suppliers who prioritize green certifications—such as ISO 14001 for environmental management or those utilizing recycled materials—can help B2B buyers align their operations with sustainability goals. Additionally, many manufacturers are adopting circular economy principles, which promote the reuse and recycling of materials, further reducing waste.

Investing in sustainable practices not only meets regulatory demands but also appeals to a growing segment of environmentally-conscious consumers. B2B buyers who prioritize sustainability can differentiate themselves in the marketplace, fostering long-term partnerships with suppliers that share similar values and goals.

What is the Historical Evolution of the Automotive Parts & Machine Sector and Its Relevance to B2B Buyers?

The automotive parts and machine sector has evolved significantly since the early 20th century, transitioning from manual craftsmanship to highly automated production processes. The introduction of assembly line manufacturing revolutionized the industry, allowing for mass production and standardization of automotive components. Over the decades, advances in technology, such as CNC machining and robotics, have further enhanced production efficiency and precision.

In recent years, the sector has witnessed a shift towards globalization, with supply chains extending across continents. This evolution has enabled B2B buyers to access a diverse range of suppliers and products, fostering competition and innovation. Understanding this historical context is essential for today’s buyers, as it informs their purchasing strategies and helps them navigate the complexities of modern supply chains.

As the sector continues to adapt to new technologies and market demands, B2B buyers must remain agile, leveraging historical insights to make strategic decisions that align with current and future trends. This historical perspective not only aids in identifying reliable suppliers but also in anticipating market shifts that could impact sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of automotive parts & machine

-

How do I solve sourcing challenges for automotive parts internationally?

Sourcing automotive parts internationally requires thorough research and understanding of local markets. Start by identifying potential suppliers through trade directories, industry exhibitions, and online platforms. Verify their credentials by checking references, certifications, and customer feedback. Establish a clear communication channel to discuss your specific needs, including quality standards and compliance regulations. Utilize sample orders to assess product quality before committing to larger purchases. Finally, consider leveraging local agents who can navigate regional complexities and facilitate smoother transactions. -

What is the best method for vetting suppliers of automotive parts?

The best method for vetting suppliers involves a multi-step approach. Begin by reviewing their business history, certifications, and customer reviews to gauge reliability. Request product samples to evaluate quality firsthand. Conduct factory visits or virtual tours to inspect production processes and compliance with industry standards. Additionally, assess their financial stability through credit checks or third-party reports. Establishing clear communication and negotiating terms upfront will also help identify trustworthy suppliers who meet your specific requirements. -

What customization options are available for automotive parts?

Customization options for automotive parts vary widely based on supplier capabilities. Common customization includes modifications in dimensions, materials, and finishes to meet specific performance standards. Some suppliers also offer tailored solutions for high-performance or specialty applications, such as racing engines or heavy-duty machinery. Engage in detailed discussions with suppliers about your requirements and request prototype parts to evaluate functionality. Be sure to confirm their ability to deliver consistent quality for customized orders. -

What is the typical minimum order quantity (MOQ) for automotive parts?

Minimum order quantities (MOQs) for automotive parts can vary significantly depending on the supplier and the specific parts in question. Generally, MOQs can range from as low as 50 units to several thousand. Factors influencing MOQs include production costs, part complexity, and the supplier’s manufacturing capacity. When negotiating with suppliers, clarify your needs and explore options for smaller initial orders or tiered pricing based on order volume. This can help establish a relationship while minimizing upfront risk. -

What are the common payment terms when sourcing automotive parts internationally?

Common payment terms for international sourcing of automotive parts include options like advance payment, letter of credit, and payment upon delivery. Many suppliers may require a deposit upfront, typically 30% to 50%, with the balance due before shipment or upon receipt. It’s essential to negotiate terms that provide adequate protection for both parties, particularly in terms of quality assurance and delivery timelines. Ensure that you understand any currency exchange implications and fees associated with international transactions. -

How do I ensure quality assurance for automotive parts sourced internationally?

To ensure quality assurance when sourcing automotive parts internationally, implement a robust quality management system. Begin by establishing clear specifications and standards for the parts required. Conduct pre-shipment inspections through third-party agencies to assess quality before goods leave the supplier’s premises. Maintain ongoing communication with suppliers to address any quality issues promptly. Additionally, consider sourcing from suppliers who offer warranties or guarantees on their products to protect your investment. -

What logistics considerations should I keep in mind when importing automotive parts?

When importing automotive parts, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose between air freight for speed or ocean freight for cost-effectiveness based on your urgency and budget. Understand the import duties and taxes applicable to your region, as these can significantly affect total costs. Collaborate with reliable freight forwarders familiar with automotive parts to navigate the complexities of international shipping, including documentation and compliance with local regulations. -

How can I build long-term relationships with suppliers of automotive parts?

Building long-term relationships with suppliers of automotive parts involves consistent communication, transparency, and mutual trust. Regularly engage with suppliers to discuss performance, feedback, and market trends. Consider signing long-term contracts to secure favorable terms and pricing. Additionally, support suppliers by providing timely payments and constructive feedback on product quality. By investing in these relationships, you can foster loyalty and collaboration that benefits both parties in the long run.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Automotive Parts & Machine Manufacturers & Suppliers List

1. Automotive Parts & Machine – Engine Services

Domain: automachineshop.net

Registered: 2001 (24 years)

Introduction: Automotive Parts & Machine is a complete Automotive Machine Shop in Frederick, MD, owned by Dave Featherstone since 1979. They offer services for any engine, including small lawnmowers, motorcycles, off-road heavy-duty equipment, and stationary engines. The shop has 80 years of cumulative experience and provides high-quality service. Services include milling of heads, turning flywheels, brake drum…

2. Facebook – Automotive Machine Shop

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Automotive Machine Shop, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Yelp – Automotive Parts & Machine

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Automotive Parts & Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Automotive Machine Inc. – Engine Rebuilding Services

Domain: automotivemachinemt.com

Registered: 2012 (13 years)

Introduction: Automotive Machine Inc. offers a variety of services and products including: 1. Engine rebuilding services, with over 38 years of experience. 2. A well-stocked Parts Department focused on professional and DIY engine repair mechanics, featuring internal engine components. 3. An Automotive Paint section with Sherwin Williams products, including custom paint mixing to match existing colors or create …

5. Texon Motor Center – Machine Shop Services

Domain: texonmotorcenter.com

Registered: 2006 (19 years)

Introduction: Machine Shop Services: Clean & Mag Block $85, Grind Shaft $150, Polish Shaft $60, Resize Rod $15/each, Press Rod $10/each, Install Cam Bearings $50 LS/HEMI $100, Install Freeze Plugs $50, Balance Rotating Assembly $275, Surface Head (gas) $50/each, Pressure Test Head $50/each, Align Hone Block $175, Shot Blast Head $45/each, Shot Blast Block $100/each, Sleeve Cylinder $140/each, Surface Flywheel $…

6. JAMSI Online – Automotive Engine Parts

Domain: jamsionline.com

Registered: 2018 (7 years)

Introduction: JAMSI Online offers a wide range of automotive engine parts categorized by engine family, including AMC/JEEP, BUICK, CADILLAC, CHEVROLET, and CHRYSLER. Key product categories include: Air and Fuel Intake Manifolds, Camshafts and Valvetrain, Engine Bearings, Engine Covers, Oil Pumps, Pistons and Piston Rings, Gaskets and Seals, and various components for engines, blocks, and drivetrain. Specific pr…

7. Automotive Machine & Supply Inc. – Precision Machining & Quality Parts

Domain: automotivemachine.com

Registered: 1996 (29 years)

Introduction: Automotive Machine & Supply Inc. provides precision machine work, quality parts, and technical support for professional and DIY customers. They serve three markets: auto and truck parts & machine shop service (including high performance & racing engines), motorcycle and ATV machine shop service (parts for Harley, Yamaha, Honda, & Suzuki), and industrial machining (prototype & design services). The…

Strategic Sourcing Conclusion and Outlook for automotive parts & machine

In the rapidly evolving landscape of automotive parts and machinery, strategic sourcing emerges as a crucial driver of competitive advantage for international B2B buyers. By prioritizing quality suppliers and leveraging global networks, businesses can enhance operational efficiency, reduce costs, and ensure timely access to essential components. The insights gathered from industry leaders reveal that investing in strong supplier relationships fosters innovation and adaptability—key components for navigating market volatility.

As buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize their supply chains, it is imperative to embrace a forward-thinking approach. Engaging with suppliers who understand local market dynamics and can provide tailored solutions will not only streamline procurement processes but also enhance product quality and performance.

Looking ahead, the automotive parts and machine sector is poised for significant growth driven by technological advancements and increasing demand for sustainable practices. International buyers should actively seek partnerships that align with these trends, ensuring their businesses remain at the forefront of industry developments. Now is the time to take decisive action—invest in strategic sourcing to secure your place in the future of automotive innovation.