Introduction: Navigating the Global Market for automotive parts and machine

The automotive parts and machine industry is a dynamic landscape, presenting significant challenges for international B2B buyers seeking to source high-quality components efficiently. In regions like Africa, South America, the Middle East, and Europe, the complexities of sourcing automotive parts can lead to delays and increased costs. This guide is designed to navigate these challenges by providing a comprehensive overview of the types of automotive parts available, their applications, and strategies for effective supplier vetting.

Buyers will find insights into various product categories, including engine components, machine tools, and remanufactured parts, tailored to meet diverse needs across multiple sectors—from passenger vehicles to heavy-duty machinery. Additionally, the guide delves into critical factors influencing cost, allowing businesses to make informed decisions that align with their budgetary constraints.

By equipping international B2B buyers with actionable knowledge, this guide empowers them to streamline their procurement processes, enhance their supply chain resilience, and ultimately improve their operational efficiency. Whether you are looking to establish new supplier relationships or optimize existing ones, the insights provided here will serve as a valuable resource in your purchasing journey.

Understanding automotive parts and machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engine Components | Includes pistons, crankshafts, and cylinder heads | Engine remanufacturing, automotive assembly | Pros: High performance, customizable options. Cons: Can be costly and require technical expertise. |

| Machine Shop Services | Precision machining, welding, and assembly | Custom part production, engine rebuilding | Pros: Tailored services, quick turnaround. Cons: Quality can vary by shop; requires thorough vetting. |

| CNC Machining | Automated precision cutting and shaping | Prototyping, small to medium batch production | Pros: High accuracy, repeatability. Cons: Initial setup costs can be high. |

| Remanufactured Parts | Reconditioned to OEM specifications | Cost-effective alternatives for end-users | Pros: Sustainable, often cheaper than new. Cons: May not always meet new part performance standards. |

| Specialty Automotive Parts | Customized or rare parts for specific applications | Restoration projects, niche markets | Pros: Unique solutions, often high quality. Cons: Longer lead times, potentially higher costs. |

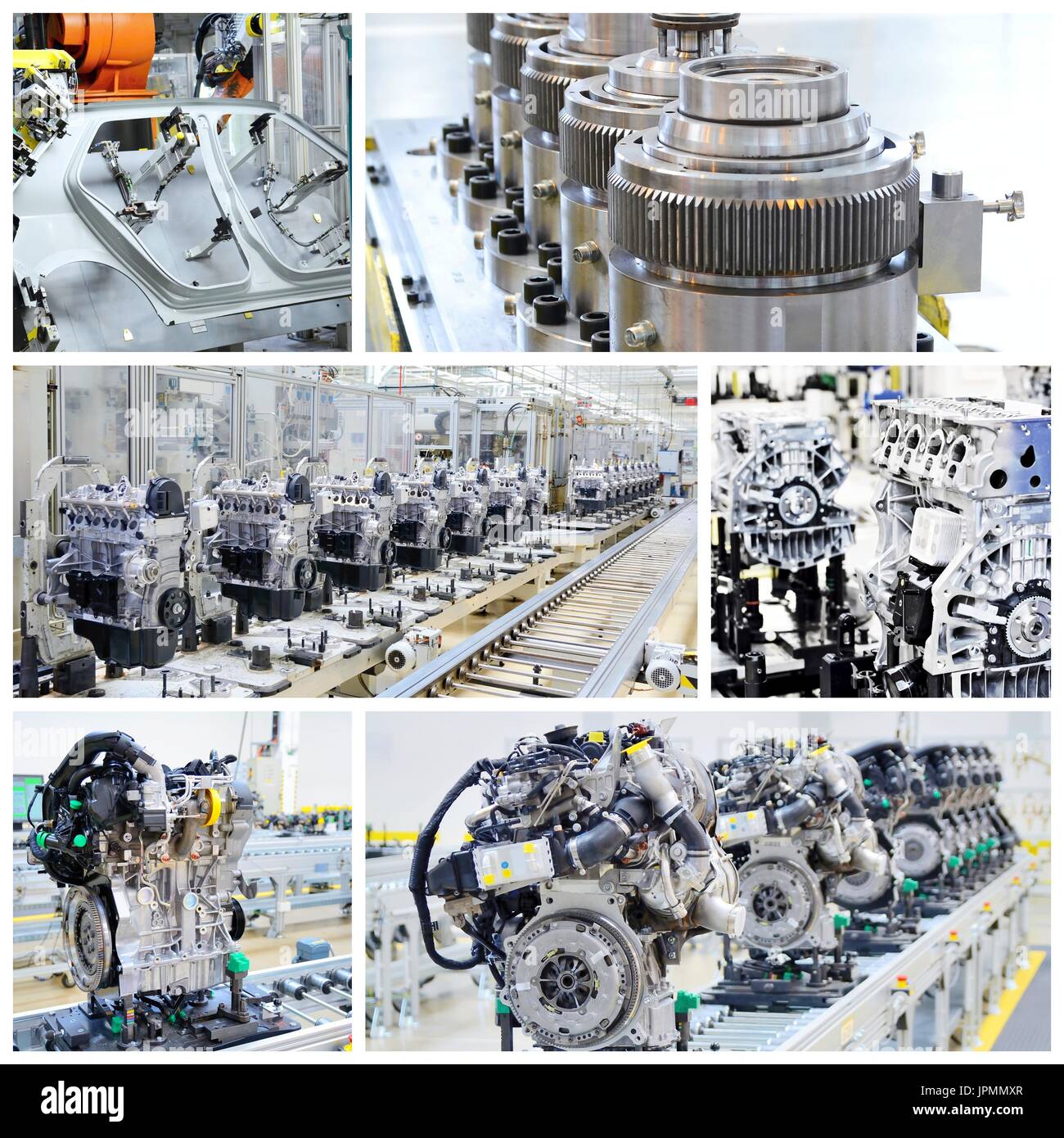

What Are Engine Components and Their Importance in B2B Transactions?

Engine components, such as pistons, crankshafts, and cylinder heads, are essential for the functionality of any automotive engine. These parts are critical for performance, efficiency, and longevity. In B2B transactions, buyers must consider compatibility with existing systems, performance specifications, and the reputation of manufacturers. Customization options are often available, providing an opportunity for businesses to enhance their offerings and meet specific client needs.

How Do Machine Shop Services Enhance Automotive Manufacturing?

Machine shop services encompass a range of processes, including precision machining, welding, and assembly. These services are vital for producing custom parts and undertaking engine rebuilding projects. B2B buyers should evaluate potential partners based on their capabilities, turnaround times, and quality assurance processes. A reliable machine shop can significantly reduce lead times and improve product quality, making them a valuable asset in the supply chain.

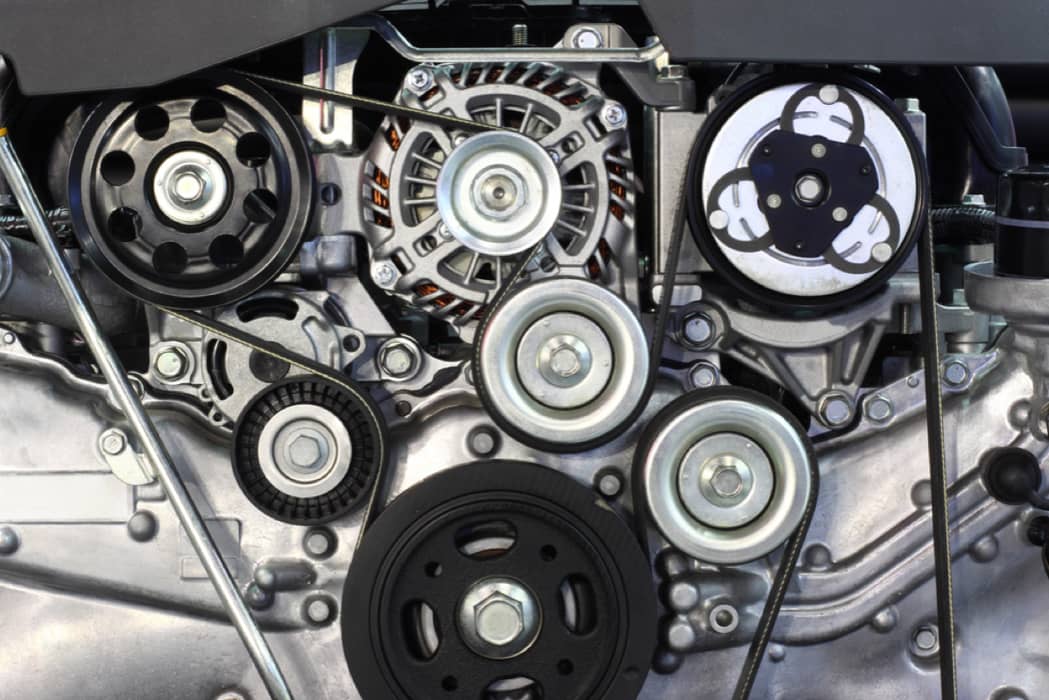

Why Is CNC Machining a Game-Changer for Automotive Parts Production?

CNC (Computer Numerical Control) machining is a highly automated process that allows for precise cutting and shaping of materials. This technology is increasingly used in automotive manufacturing for prototyping and small to medium batch production. B2B buyers benefit from the high accuracy and repeatability offered by CNC machining, which can lead to better product quality. However, initial setup costs can be a barrier, so it is crucial to assess the long-term benefits versus upfront expenses.

What Advantages Do Remanufactured Parts Offer to B2B Buyers?

Remanufactured parts are reconditioned to meet or exceed OEM specifications, making them a cost-effective alternative for businesses looking to reduce expenses without sacrificing quality. These parts can be particularly appealing in markets with budget constraints. However, buyers should be cautious and ensure that remanufactured parts come from reputable sources, as performance may vary compared to new components. Sustainability is an additional benefit, appealing to environmentally conscious businesses.

How Do Specialty Automotive Parts Cater to Niche Markets?

Specialty automotive parts are designed for specific applications or rare vehicles, making them essential for restoration projects and niche markets. These parts often require longer lead times and may come at a premium price due to their unique nature. B2B buyers should consider the quality of materials and manufacturing processes when sourcing specialty parts, as this can greatly influence the success of restoration or customization projects.

Key Industrial Applications of automotive parts and machine

| Industry/Sector | Specific Application of Automotive Parts and Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Engine Block Remanufacturing | Reduces costs and extends the lifecycle of engines | Quality assurance, local regulations, turnaround time |

| Heavy Equipment | Custom Engine Design and Assembly | Enhances performance and reliability of machinery | Customization capabilities, material sourcing, lead times |

| Transportation and Logistics | Precision CNC Machining for Components | Increases efficiency and reduces downtime | Precision standards, supplier reliability, certifications |

| Automotive Repair Services | Cylinder Head Rebuilding | Restores engine performance, reduces waste | Repair capabilities, warranty terms, service timelines |

| Agriculture Machinery | Piston and Valve Manufacturing | Improves machinery efficiency, reduces fuel costs | Durability, compatibility with existing equipment, price competitiveness |

How Are Automotive Parts and Machines Applied in Automotive Manufacturing?

In automotive manufacturing, engine block remanufacturing is a critical application that offers significant cost savings and sustainability benefits. By refurbishing existing engine blocks, manufacturers can reduce waste and extend the lifecycle of their engines. This process not only enhances operational efficiency but also aligns with eco-friendly practices, a growing concern for international buyers, particularly in regions like Europe and South America where regulations on waste are stringent. Buyers should focus on suppliers with robust quality assurance processes and an understanding of local regulations to ensure compliance and reliability.

What Role Does Custom Engine Design Play in Heavy Equipment?

Custom engine design and assembly are vital in the heavy equipment sector, where performance and reliability are paramount. By tailoring engines to specific applications, businesses can enhance the efficiency and productivity of their machinery, which is crucial in demanding environments such as construction or mining. International buyers from regions like the Middle East and Africa should consider sourcing from suppliers that offer customization capabilities and have experience with local operational conditions to ensure optimal performance.

How Does Precision CNC Machining Benefit Transportation and Logistics?

Precision CNC machining is essential for creating high-quality components in the transportation and logistics industry. This technology enhances efficiency by producing parts with tight tolerances, thereby reducing the risk of equipment failure and downtime. For international buyers, particularly in emerging markets, sourcing from suppliers that adhere to international precision standards and demonstrate reliability in delivery is crucial for maintaining operational continuity.

Why is Cylinder Head Rebuilding Important for Automotive Repair Services?

Cylinder head rebuilding is a key service in automotive repair that restores engine performance and minimizes waste by reusing existing parts. This service is particularly valuable in regions with limited access to new parts, as it provides a cost-effective solution for maintaining vehicle functionality. Buyers should evaluate repair service providers based on their capabilities, warranty terms, and turnaround times to ensure they receive timely and reliable service.

What Advantages Do Piston and Valve Manufacturing Offer in Agriculture Machinery?

In the agricultural sector, piston and valve manufacturing significantly contributes to the efficiency of machinery, directly impacting fuel consumption and operational costs. High-quality pistons and valves ensure that engines run smoothly, which is essential for the demanding tasks in farming. International buyers should prioritize sourcing from manufacturers that offer durable products compatible with a wide range of existing equipment, while also being competitive in pricing to maximize their operational budgets.

3 Common User Pain Points for ‘automotive parts and machine’ & Their Solutions

Scenario 1: Delays in Supply Chain and Product Availability

The Problem: One of the significant challenges faced by B2B buyers in the automotive parts and machine sector is the unpredictability of supply chains. International buyers, especially from regions like Africa and South America, may struggle with inconsistent product availability and long lead times. This uncertainty not only affects their operational efficiency but can also lead to costly downtime if critical components are not available when needed.

The Solution: To mitigate supply chain delays, B2B buyers should establish strong relationships with multiple suppliers across different geographic locations. This approach diversifies the sourcing strategy and reduces dependency on a single supplier. Additionally, implementing a Just-In-Time (JIT) inventory management system can help optimize stock levels and ensure that necessary parts arrive right when they are needed. Buyers should also engage in regular communication with suppliers to stay updated on inventory levels and expected delivery times. Investing in technology solutions that provide real-time tracking of shipments can further enhance visibility and allow for proactive adjustments in the procurement process.

Scenario 2: Quality Assurance Challenges in Parts Sourcing

The Problem: Another common issue for B2B buyers is the variability in the quality of automotive parts sourced from different suppliers. Inconsistent quality can lead to performance issues, increased warranty claims, and damage to reputation, particularly for businesses that rely on high-performance machinery or vehicles. Buyers may find themselves in situations where they must frequently return parts, leading to additional costs and delays.

The Solution: To ensure high-quality sourcing, buyers should implement a stringent supplier evaluation process that includes quality certifications, performance history, and customer reviews. Establishing a set of clear specifications and standards for the parts required is crucial. Buyers can also request samples or conduct pilot tests before committing to large orders. Additionally, building partnerships with reputable manufacturers known for their quality control processes can enhance trust and reliability. Regular audits and inspections of suppliers can further reinforce quality assurance and help maintain a consistent supply of high-grade parts.

Scenario 3: Technical Expertise and Support Limitations

The Problem: Many B2B buyers may encounter difficulties when it comes to understanding the technical specifications and installation requirements of complex automotive parts and machinery. This lack of technical expertise can lead to improper installation, resulting in equipment failures or suboptimal performance. Buyers might also struggle to find adequate support and resources to troubleshoot issues that arise during the use of these parts.

The Solution: To overcome this technical barrier, buyers should seek suppliers that offer comprehensive technical support and training as part of their service. Engaging with manufacturers that provide detailed documentation, installation guides, and access to customer support can significantly improve the buyer’s confidence in handling complex machinery. Additionally, organizing workshops or training sessions with suppliers can enhance the technical skills of the buyer’s workforce. Investing in technology such as augmented reality (AR) tools for virtual training can also help visualize the installation process, making it easier for teams to understand complex tasks. Finally, leveraging online forums and communities can provide additional resources and peer support to address common challenges faced in the industry.

Strategic Material Selection Guide for automotive parts and machine

What Are the Key Properties of Common Materials Used in Automotive Parts and Machines?

When selecting materials for automotive parts and machines, it’s essential to consider their properties, advantages, disadvantages, and specific applications. Here, we analyze four commonly used materials: steel, aluminum, cast iron, and composites.

How Does Steel Perform as a Material for Automotive Applications?

Steel is a versatile material known for its high tensile strength and durability. It typically has a temperature rating of up to 300°C and can withstand high pressures, making it suitable for various automotive components like frames, engine parts, and suspension systems. Steel’s corrosion resistance can be enhanced through galvanization or coatings, which is crucial in regions with high humidity or saline environments.

Pros: Steel is relatively inexpensive, widely available, and easy to fabricate. Its strength allows for thinner components without compromising structural integrity.

Cons: Steel is heavier than other materials, which can negatively impact fuel efficiency in vehicles. Additionally, it is prone to rust if not properly treated.

Impact on Application: Steel is compatible with various media, including oils and fuels, making it ideal for engine components. However, buyers must consider the environmental conditions of their markets, especially in humid regions like parts of Africa and South America, where corrosion is a concern.

What Advantages Does Aluminum Offer in Automotive Manufacturing?

Aluminum is increasingly popular in automotive manufacturing due to its lightweight properties, which enhance fuel efficiency. It can handle temperatures up to 400°C and has good corrosion resistance, especially when anodized. Aluminum is commonly used in engine blocks, transmission cases, and body panels.

Pros: The primary advantage of aluminum is its weight savings, which can lead to improved vehicle performance and fuel economy. It is also easier to machine than steel and can be recycled efficiently.

Cons: Aluminum is generally more expensive than steel and can be less durable under high-stress conditions. It may also require specialized welding techniques, increasing manufacturing complexity.

Impact on Application: Aluminum’s lightweight nature makes it suitable for performance vehicles, but international buyers should be aware of specific standards for aluminum alloys (like ASTM or DIN) that may affect their sourcing decisions.

Why is Cast Iron Still Relevant in Automotive Parts?

Cast iron is known for its excellent wear resistance and ability to dampen vibrations, making it a preferred choice for engine blocks and cylinder heads. It can withstand high temperatures and pressures, typically rated up to 500°C.

Pros: Cast iron is cost-effective and offers good machinability. Its durability makes it suitable for heavy-duty applications.

Cons: The material is heavy, which can detract from overall vehicle efficiency. It is also more brittle than steel and can crack under extreme stress.

Impact on Application: Cast iron is compatible with various automotive fluids, but international buyers must consider shipping costs due to its weight. Compliance with local standards for cast iron components is also crucial.

How Do Composites Enhance Automotive Part Performance?

Composite materials, such as carbon fiber and fiberglass, are becoming increasingly popular due to their high strength-to-weight ratios. They can withstand temperatures up to 300°C and offer excellent corrosion resistance.

Pros: Composites are lightweight and can be molded into complex shapes, allowing for innovative designs. They also provide superior fatigue resistance compared to metals.

Cons: The primary disadvantage is the high cost of production and the complexity of manufacturing processes. Repairing composite materials can also be challenging.

Impact on Application: Composites are often used in high-performance vehicles and racing applications. International buyers should be aware of the specific material standards that govern composite materials, which may vary significantly between regions.

Summary Table of Material Selection for Automotive Parts and Machines

| Material | Typical Use Case for automotive parts and machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Engine components, frames, suspension systems | High strength and durability | Heavier, prone to rust | Low |

| Aluminum | Engine blocks, transmission cases, body panels | Lightweight, enhances fuel efficiency | More expensive, less durable | Med |

| Cast Iron | Engine blocks, cylinder heads | Excellent wear resistance | Heavy, brittle under stress | Low |

| Composites | High-performance vehicles, racing applications | High strength-to-weight ratio | High cost, complex repair | High |

This guide provides a comprehensive overview of material selection considerations for automotive parts and machines, aiding international B2B buyers in making informed decisions based on their specific market needs and conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for automotive parts and machine

What Are the Key Manufacturing Processes for Automotive Parts and Machines?

The manufacturing of automotive parts and machines involves a systematic approach that ensures precision and quality. Understanding these processes is crucial for international B2B buyers looking to source reliable components. The main stages of manufacturing include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Automotive Manufacturing?

Material preparation is the foundation of the manufacturing process. It involves selecting high-quality raw materials that meet specific industry standards. This stage includes:

- Material Selection: Choosing the right metal alloys, plastics, or composites based on the part’s functional requirements.

- Cutting and Shaping: Utilizing techniques such as laser cutting or water jet cutting to create the initial shapes from raw materials.

- Surface Treatment: This may involve processes like sandblasting or chemical cleaning to enhance the material’s surface properties, ensuring better adherence during subsequent processes.

What Forming Techniques Are Commonly Used in Automotive Part Manufacturing?

Once materials are prepared, the next step is forming, which shapes the material into the desired part. This can include various techniques:

- Casting: Pouring molten metal into a mold to create complex shapes. This method is often used for engine blocks and transmission cases.

- Machining: Processes such as CNC (Computer Numerical Control) machining allow for high precision in shaping parts. Machining is vital for components requiring tight tolerances, such as cylinder heads and crankshafts.

- Stamping: Used for producing flat parts, stamping involves pressing sheets of metal into shapes using dies.

How Are Automotive Parts Assembled?

Assembly is a critical phase in the manufacturing process where individual components come together to form complete systems. This stage can be broken down into:

- Sub-assembly: Smaller components are assembled first, which are then integrated into larger systems. For instance, fuel injectors might be assembled separately before being installed in the engine assembly.

- Final Assembly: The complete assembly is put together, which may include installing electrical systems, mounting parts, and ensuring that all components fit correctly.

- Integration: This involves ensuring that various systems (like electrical, hydraulic, and mechanical) work together seamlessly.

What Finishing Processes Are Involved in Automotive Manufacturing?

Finishing processes enhance the aesthetic and functional qualities of automotive parts. This includes:

- Coating: Applying protective coatings to prevent corrosion and wear. Common coatings include powder coating and anodizing.

- Polishing and Buffing: These processes improve the surface finish, contributing to the part’s overall quality and appearance.

- Quality Inspection: Before finalizing the product, rigorous inspections are conducted to ensure that parts meet specified standards.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is paramount in automotive manufacturing, ensuring that parts meet international and industry-specific standards. For B2B buyers, understanding these standards is essential to ensure product reliability.

Which International Standards Are Relevant for Automotive Parts Manufacturing?

- ISO 9001: This global standard focuses on quality management systems, ensuring consistent quality in products and services.

- ISO/TS 16949: Specifically for the automotive sector, this standard emphasizes continuous improvement and defect prevention.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are crucial in maintaining product integrity throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This stage checks the quality of raw materials and components before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, various checks are performed to ensure ongoing compliance with quality standards.

- Final Quality Control (FQC): After assembly, the final product undergoes a comprehensive inspection to verify that it meets all specifications and standards.

What Testing Methods Are Commonly Used for Automotive Parts?

Various testing methods are employed to ensure that automotive parts meet stringent quality standards:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle testing, and X-ray inspection are used to detect internal flaws without damaging the components.

- Performance Testing: This involves subjecting parts to various conditions to ensure they perform as expected under real-world scenarios. Engine components may be tested for durability and efficiency.

- Dimensional Inspection: Using precision measurement tools, manufacturers check that parts meet specified dimensions and tolerances.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are some strategies:

- Audits: Conducting regular audits of suppliers can help assess their compliance with quality standards. Buyers should look for certifications that demonstrate adherence to ISO or industry-specific standards.

- Quality Reports: Requesting detailed quality reports can provide insights into a supplier’s performance metrics, defect rates, and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality practices and product integrity.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances based on regional standards and practices. Here are key considerations:

- Regional Compliance: Understanding local regulations and compliance requirements in target markets, such as CE marking in Europe or API standards in the Middle East.

- Cultural Differences: Recognizing that quality expectations may vary by region, it is vital to communicate clearly with suppliers about specific quality requirements.

- Logistics and Shipping: Quality control does not end at manufacturing; ensuring that products are transported in conditions that maintain their integrity is essential.

By understanding the manufacturing processes and quality assurance measures in automotive parts production, international B2B buyers can make informed decisions, ensuring they source high-quality components that meet their operational needs. This knowledge not only enhances procurement strategies but also fosters long-term partnerships with reliable suppliers across the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive parts and machine’

In the complex landscape of automotive parts and machinery procurement, having a structured approach is essential for international B2B buyers. This guide serves as a practical checklist to streamline the sourcing process, ensuring that you secure high-quality components and reliable services.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it is critical to clearly outline your technical requirements. This includes understanding the specific parts needed, their intended use, and any performance standards they must meet.

– Key Considerations:

– Identify the make and model of vehicles or machinery.

– Determine any unique modifications or customizations required.

Step 2: Conduct Market Research

Thorough market research allows you to gauge the landscape of available suppliers and products. Explore various channels, including online marketplaces, industry forums, and trade shows, to identify potential vendors.

– Useful Strategies:

– Analyze competitor sourcing strategies.

– Utilize industry reports to understand pricing trends and market demand.

Step 3: Evaluate Potential Suppliers

It’s crucial to vet suppliers thoroughly before making a commitment. Request company profiles, case studies, and references from buyers in a similar industry or region to ensure reliability.

– What to Look For:

– Supplier certifications and industry standards compliance.

– Positive customer reviews and testimonials.

Step 4: Verify Supplier Certifications

Ensure that suppliers possess the necessary certifications and quality assurance processes. This step is vital for maintaining product quality and reliability, particularly in regulated markets.

– Important Certifications:

– ISO 9001 for quality management systems.

– Specific industry certifications relevant to automotive parts.

Step 5: Request Samples and Prototypes

Before placing a large order, request samples or prototypes of the parts you intend to procure. This allows you to assess the quality and compatibility of the products with your requirements.

– Evaluation Criteria:

– Fit and finish of the parts.

– Performance tests to validate specifications.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, delivery schedules, and payment terms. Clear terms help prevent misunderstandings and ensure smooth transactions.

– Key Focus Areas:

– Understand the total cost of ownership, including shipping and tariffs.

– Discuss warranty and return policies for defective products.

Step 7: Establish a Communication Plan

Effective communication is critical throughout the sourcing process. Set up regular check-ins with your supplier to monitor order status, address any issues, and maintain a positive relationship.

– Best Practices:

– Utilize project management tools for transparency.

– Define points of contact for both parties to streamline communications.

By following this structured checklist, B2B buyers can enhance their sourcing efforts for automotive parts and machinery, ultimately leading to better procurement outcomes and stronger supplier relationships.

Comprehensive Cost and Pricing Analysis for automotive parts and machine Sourcing

What Are the Key Cost Components in Automotive Parts and Machine Sourcing?

When sourcing automotive parts and machinery, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used, such as steel, aluminum, or specialty alloys, can significantly affect pricing. For instance, high-grade materials may enhance performance but can drive costs higher.

-

Labor: Labor costs vary based on the complexity of the work and the skill level required. Skilled labor in regions with higher living costs, such as parts of Europe, may increase overall expenses compared to countries with lower wage standards.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these costs.

-

Tooling: The initial investment in tools and equipment necessary for production can be substantial, particularly for custom parts. Buyers should consider these upfront costs as part of the total expenditure.

-

Quality Control (QC): Ensuring that parts meet specific standards requires investment in quality control measures, which can add to the overall cost. Certifications like ISO can enhance product credibility but may also increase costs.

-

Logistics: Shipping and handling fees can vary widely, especially for international shipments. Factors such as distance, mode of transport, and customs duties play a crucial role in logistics costs.

-

Margin: Suppliers typically mark up prices to cover their costs and ensure profitability. Understanding typical margins in the industry can help buyers negotiate better deals.

How Do Pricing Influencers Affect Automotive Parts Procurement?

Several factors influence pricing in automotive parts sourcing:

-

Volume/MOQ: Purchasing in bulk often leads to significant discounts. Suppliers may have minimum order quantities (MOQ) that can affect pricing strategies.

-

Specifications and Customization: Custom parts typically cost more due to the additional engineering and production processes required. Clear specifications help suppliers provide accurate quotes.

-

Material Quality and Certifications: Higher quality materials and certifications can justify higher prices. Buyers should assess whether the additional cost aligns with their performance requirements.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge a premium.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the total landed cost.

What Are the Best Negotiation Strategies for B2B Buyers in the Automotive Sector?

To achieve cost efficiency, B2B buyers should consider the following tips:

-

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the total cost of ownership, including maintenance, operational costs, and potential downtime. This broader perspective can justify higher upfront costs for more reliable parts.

-

Negotiate Terms: Engage in discussions about payment terms, delivery schedules, and warranties. Flexible terms can enhance cash flow and reduce financial risks.

-

Seek Multiple Quotes: Gathering quotes from multiple suppliers can provide insights into market rates and help identify the most competitive offers.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms over time, as suppliers may offer loyalty discounts or priority service.

-

Understand Regional Pricing Nuances: International buyers should be aware of regional price variances. Factors such as local demand, labor costs, and regulatory environments can influence pricing structures.

Disclaimer on Indicative Prices

Prices for automotive parts and machinery can fluctuate based on market conditions, supplier negotiations, and regional economic factors. It is advisable for buyers to conduct thorough market research and obtain updated quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing automotive parts and machine With Other Solutions

Understanding Alternative Solutions in Automotive Parts and Machine

When considering solutions for automotive parts and machining, it’s vital for B2B buyers to evaluate various alternatives that could meet their operational needs. This analysis will focus on comparing traditional automotive parts and machining services against two viable alternatives: additive manufacturing and remanufactured parts. Each option offers unique benefits and challenges that can influence purchasing decisions.

| Comparison Aspect | Automotive Parts And Machine | Additive Manufacturing | Remanufactured Parts |

|---|---|---|---|

| Performance | High precision; reliable | Versatile; complex designs | Good quality; consistent |

| Cost | Moderate to high | Variable; can be high for complex parts | Generally lower; cost-effective |

| Ease of Implementation | Standardized processes | Requires specialized knowledge | Simple; widely accepted |

| Maintenance | Regular upkeep required | Minimal; technology-dependent | Moderate; depends on part condition |

| Best Use Case | Custom machining for engines | Prototyping; complex geometries | Replacements for worn-out parts |

What Are the Advantages and Disadvantages of Additive Manufacturing?

Additive manufacturing, or 3D printing, allows for the creation of complex parts that traditional machining methods may not easily achieve. This technology excels in rapid prototyping and offers design flexibility, enabling the production of lightweight and intricate components. However, the cost can be high, particularly for sophisticated designs or large production runs. Additionally, the need for specialized knowledge and equipment can complicate implementation for businesses that lack technical expertise.

How Do Remanufactured Parts Compare in the Automotive Industry?

Remanufactured parts provide a cost-effective solution for businesses looking to replace worn components without compromising on quality. These parts are restored to meet or exceed original specifications, making them a reliable alternative. The implementation process is straightforward, as remanufactured parts are typically compatible with existing systems. However, the performance may not always match that of new components, and maintenance requirements can vary based on the initial condition of the part being remanufactured.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate solution for automotive parts and machining depends on several factors, including performance requirements, budget constraints, and the specific application needs of the business. For projects requiring high precision and customization, traditional automotive parts and machining services may be best. Conversely, if innovation and rapid development are priorities, additive manufacturing could be advantageous. Lastly, for cost-sensitive operations where quality is still paramount, remanufactured parts offer an attractive solution. B2B buyers should assess their unique operational requirements and consider these alternatives to make an informed decision.

Essential Technical Properties and Trade Terminology for automotive parts and machine

What Are the Key Technical Properties of Automotive Parts?

Understanding the technical properties of automotive parts is vital for B2B buyers to ensure quality, performance, and compatibility. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the classification of materials based on their properties, such as strength, durability, and resistance to wear and corrosion. Common materials include aluminum alloys, steel, and cast iron. Selecting the appropriate material grade is crucial for ensuring that parts can withstand the stresses of automotive applications, thus reducing the risk of failure and enhancing longevity.

2. Tolerance

Tolerance defines the allowable deviation from a specified dimension or measurement. In automotive manufacturing, tight tolerances (e.g., ±0.001 inches) are often required to ensure proper fit and functionality. Understanding tolerances is essential for B2B buyers as it impacts the performance of components, particularly in precision-engineered parts like engine blocks and cylinder heads.

3. Surface Finish

Surface finish refers to the texture and smoothness of a component’s surface, which can significantly affect friction, wear, and adhesion. Specifications may include Ra (average roughness) values, which indicate how smooth or rough a surface is. A proper surface finish is vital for components like cylinder heads where sealing surfaces must be precise to prevent leaks.

4. Heat Treatment

Heat treatment involves processes such as annealing, quenching, and tempering to alter a material’s mechanical properties. This process can enhance hardness, strength, and ductility, which are critical for high-performance automotive applications. B2B buyers should inquire about heat treatment processes to ensure that parts meet the demands of their specific applications.

5. Weight

Weight is a crucial factor in automotive design, influencing fuel efficiency and overall vehicle performance. Lightweight materials, such as aluminum and composites, are increasingly used to reduce weight without compromising strength. Buyers must consider the weight of automotive parts to align with performance goals and regulatory requirements.

What Are Common Trade Terms in Automotive Parts Procurement?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold directly to vehicle manufacturers for use in new vehicles. OEM parts are often preferred for their guaranteed compatibility and quality, making this term vital for buyers seeking reliable components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is important for B2B buyers, as it affects inventory management and cost-efficiency. Buyers must evaluate their needs against suppliers’ MOQs to avoid excess inventory or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This term is crucial for buyers as it facilitates competitive bidding and helps in budget planning. A well-structured RFQ can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international buyers to avoid misunderstandings and ensure smooth transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. Understanding lead times helps buyers plan their procurement strategy and manage production schedules effectively. Delays in lead time can disrupt supply chains, making this a critical consideration in B2B transactions.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring the procurement of high-quality automotive parts that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the automotive parts and machine Sector

What Are the Current Market Dynamics in the Automotive Parts and Machine Sector?

The automotive parts and machine sector is witnessing transformative changes driven by globalization and technological advancements. Key market dynamics include the increasing demand for high-performance components, propelled by the rise of electric vehicles (EVs) and hybrid technologies. Buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking suppliers that can deliver innovative and reliable parts, especially as they navigate local regulatory landscapes that prioritize sustainability and emissions reductions.

Emerging trends include the integration of digital technologies in sourcing processes. B2B buyers are leveraging platforms that utilize artificial intelligence (AI) and machine learning to streamline procurement, assess supplier reliability, and predict market fluctuations. Additionally, there is a growing emphasis on just-in-time manufacturing, which allows companies to minimize inventory costs and respond more flexibly to market demands. For international buyers, this means seeking partnerships with suppliers that not only offer high-quality products but also demonstrate agility and responsiveness in their operations.

Furthermore, there is a notable shift towards regional sourcing to mitigate risks associated with global supply chain disruptions. This trend is particularly relevant for buyers from Africa and South America, where local suppliers can offer advantages such as reduced lead times and lower transportation costs. Understanding these market dynamics is essential for B2B buyers looking to establish robust supply chains in the automotive parts and machine sector.

How Does Sustainability Impact Sourcing Decisions in the Automotive Parts and Machine Sector?

Sustainability has become a cornerstone of sourcing strategies in the automotive parts and machine sector, significantly influencing buyer decisions. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to prioritize suppliers that adhere to sustainable practices. This includes the use of eco-friendly materials, energy-efficient production methods, and waste reduction strategies.

Ethical sourcing is also gaining traction, with companies increasingly focused on the social implications of their supply chains. B2B buyers are looking for suppliers who can provide transparency regarding their sourcing practices, labor conditions, and community engagement. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices are becoming essential criteria for supplier selection.

Moreover, the shift towards electric vehicles has spurred demand for components made from sustainable materials. Buyers are exploring options such as recycled metals and bioplastics, which not only reduce environmental footprints but also align with consumer preferences for greener products. As sustainability continues to reshape the automotive landscape, B2B buyers must integrate these considerations into their sourcing strategies to remain competitive and socially responsible.

What Is the Historical Context of the Automotive Parts and Machine Sector for Today’s B2B Buyers?

The automotive parts and machine sector has evolved significantly since the early days of automobile manufacturing. Initially characterized by manual production and rudimentary machining techniques, the industry has transitioned into a highly mechanized and technologically advanced field. The introduction of assembly line techniques in the early 20th century revolutionized production efficiency, enabling manufacturers to produce vehicles at unprecedented scales.

Over the decades, the sector has faced numerous challenges, including economic downturns and shifts in consumer demand. The oil crises of the 1970s prompted a reevaluation of fuel efficiency and performance, leading to innovations in engine design and materials. More recently, the push towards electric vehicles and sustainable practices has catalyzed a new wave of technological advancements and sourcing strategies.

For today’s B2B buyers, understanding this historical context is crucial. It highlights the importance of adaptability and innovation in a sector that is continuously evolving. By learning from past trends and disruptions, buyers can make informed decisions that align with current market dynamics and future growth opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of automotive parts and machine

-

1. How do I solve supply chain disruptions when sourcing automotive parts?

Supply chain disruptions can be managed by diversifying your supplier base. Consider sourcing from multiple manufacturers across different regions to mitigate risks. Establishing strong relationships with suppliers can also lead to better communication and quicker resolution of issues. Additionally, investing in inventory management software can help you forecast demand and maintain adequate stock levels, reducing the impact of delays. -

2. What is the best approach for selecting a reliable automotive parts supplier?

To select a reliable supplier, start by assessing their industry reputation and experience. Look for certifications, customer testimonials, and case studies that demonstrate their expertise. Conduct site visits if possible, and inquire about their quality assurance processes. Finally, ensure they have the capability to meet your specific needs in terms of customization and volume. -

3. What are the typical payment terms in international B2B transactions for automotive parts?

Payment terms can vary widely, but common practices include advance payment, letters of credit, or net terms (e.g., net 30, net 60). It’s crucial to negotiate terms that align with your cash flow and risk tolerance. Ensure that both parties clearly understand these terms in the contract to avoid disputes later. Consider using escrow services for larger transactions to enhance security. -

4. How can I ensure quality control in automotive parts procurement?

To ensure quality control, implement a rigorous vetting process for suppliers that includes quality certifications (ISO, TS16949) and regular audits. Request samples for testing before making bulk purchases and establish clear specifications for parts. Additionally, consider third-party inspection services to verify the quality of products before they are shipped. -

5. What customization options should I discuss with my automotive parts supplier?

When discussing customization, inquire about material specifications, dimensions, and performance characteristics tailored to your application. Explore options for branding, labeling, and packaging that align with your marketing strategy. It’s also beneficial to discuss lead times for customized parts to ensure they fit into your production schedule. -

6. What logistics considerations should I keep in mind when sourcing automotive parts internationally?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a shipping method that balances cost and speed, and ensure your supplier is familiar with the necessary documentation for customs clearance. It’s also wise to partner with a logistics provider experienced in international trade to streamline the process and avoid delays. -

7. How do minimum order quantities (MOQ) affect my sourcing strategy?

Minimum order quantities (MOQ) can significantly impact your sourcing strategy by influencing your cash flow and inventory levels. If the MOQ is higher than your immediate needs, consider negotiating with suppliers for lower MOQs or consolidating orders with other buyers. This approach can help you manage costs while ensuring you have sufficient stock to meet demand. -

8. What are the key factors to consider when evaluating shipping costs for automotive parts?

Key factors include the weight and dimensions of the parts, shipping method (air, sea, or land), distance to the destination, and any applicable tariffs or customs duties. Request detailed quotes from multiple logistics providers to compare costs. Additionally, consider the total landed cost, which encompasses shipping, insurance, and customs fees, to get a clear picture of your expenses.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Automotive Parts And Machine Manufacturers & Suppliers List

1. Yelp – Top Automotive Machine Shops in Atlanta

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: Top Automotive Machine Shops in Atlanta, GA include: 1. Brent Epps Automotive Machine Shop – 4.5 stars, known for reasonable prices and engineering expertise. 2. Hurricane Performance & Auto Machine – 5.0 stars, recognized for excellent customer service and quick resolutions to mistakes. 3. Cylinder Head Exchange – 3.0 stars, praised for same-day service and competitive pricing. 4. Suwanee Machine…

2. Automotive Parts & Machine – Engine Rebuilding Services

Domain: automachineshop.net

Registered: 2001 (24 years)

Introduction: Automotive Parts & Machine is a complete Automotive Machine Shop in Frederick, MD, owned by Dave Featherstone since 1979. They offer services for any engine, from lawnmowers to heavy-duty equipment. Key services include: Engine Rebuilding, Cylinder Head Rebuilding, Fusion Welding/Oven Welding of Cast Iron and Aluminum, Milling of heads, Turning Flywheels/Brake Drums/Rotors, Bearing press work, and…

3. Chix Engine – Custom Rebuilt Engines

Domain: chixengine.com

Registered: 2005 (20 years)

Introduction: Automotive Machine Repair Shop located in Marietta, GA. Services include: Engine Parts, Cylinder Head Repair, Custom Rebuilt Engines. In business for 40 years, providing complete automotive services for foreign and domestic vehicles. Offers custom engine work for standard engines, internal engine parts, and custom orders. Parts available include Rings, Cam Shafts, Timing Components, Oil Pumps, Gas…

4. Scott’s Auto Machine – Automotive Machine Shop Services

Domain: scottsautomachine.com

Registered: 2008 (17 years)

Introduction: Scott’s Auto Machine & Parts Company, Inc. offers complete automotive machine shop services and a full line of engine parts. Key services include: crankshaft balancing, engine block machining, cylinder head work, connecting rod services, high performance restoration, crate engine assembly, and cleaning of miscellaneous engine parts. The company is an authorized rebuilder for GM 602 and 604 sealed …

5. Atlanta Speed Shop – High-Performance Engine Building

Domain: atlantaspeedshop.com

Registered: 2004 (21 years)

Introduction: Atlanta Speed Shop specializes in high-performance engine building and machining. They offer engine packages for sale, as well as new and used parts. The shop focuses on hot rods, street cars, race cars, and late model projects. They have an average of 50 engine builds in process at most times, emphasizing quality, performance, and workmanship. In 2022, they plan to begin complete restorations of …

6. Will’s Auto Machine Shop – Automobile Machine Services

Domain: yellowpages.com

Registered: 1996 (29 years)

Introduction: This company, Will’s Auto Machine Shop – Automobile Machine Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Egge Machinery – Piston Sets

Domain: egge.com

Registered: 1995 (30 years)

Introduction: Egge Machinery Company specializes in manufacturing pistons and water pumps for domestic vehicles from the early 1900s to 1980. Key products include:

1. **Piston Sets**:

– Wisconson Industrial Piston set with pins – E1221-4: $645.39 (1922-34 Wisconson)

– Egge Piston Set with Pins – L991-8: $509.74 (1949-53 Ford 255 8cyl; Mercury 255 8cyl)

– Egge Piston Set with Pins – L2267-8: $646.21 (1…

8. Automotive Machine Shops – SBC 350 Boring Recommendations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Recommendations for automotive machine shops in the north metro Atlanta area, specifically for a SBC 350 engine that needs to be bored. Atlanta Speed Shop quoted $1500 for the service, excluding installation of bearings, rods, and pistons. Will’s shop is noted as more affordable but has a 7-week lead time. Scott’s Machine Shop in Fayetteville is mentioned for block decking, though costs and timeli…

Strategic Sourcing Conclusion and Outlook for automotive parts and machine

In the competitive landscape of automotive parts and machine sourcing, strategic partnerships are more essential than ever. By prioritizing relationships with reliable suppliers and machine shops, international B2B buyers can secure high-quality components that meet stringent manufacturing standards. The emphasis on advanced services, such as engine block remanufacturing and precision CNC machining, showcases the industry’s commitment to innovation and efficiency.

Understanding regional market dynamics in areas like Africa, South America, the Middle East, and Europe is crucial for optimizing supply chains. Buyers should leverage local knowledge and expertise to navigate complexities and enhance procurement strategies. Additionally, the rise of e-commerce platforms in these regions offers unprecedented access to a wider range of products and services, creating opportunities for cost savings and improved delivery times.

As we look ahead, the automotive parts and machine sector will continue to evolve, driven by technological advancements and shifting consumer demands. Now is the time for buyers to engage with trusted partners and explore new avenues for sourcing. Embrace the future of automotive procurement by fostering strategic alliances that can drive growth and innovation in your business.