Contents

Manufacturing Insight: Automotive Cnc Machines

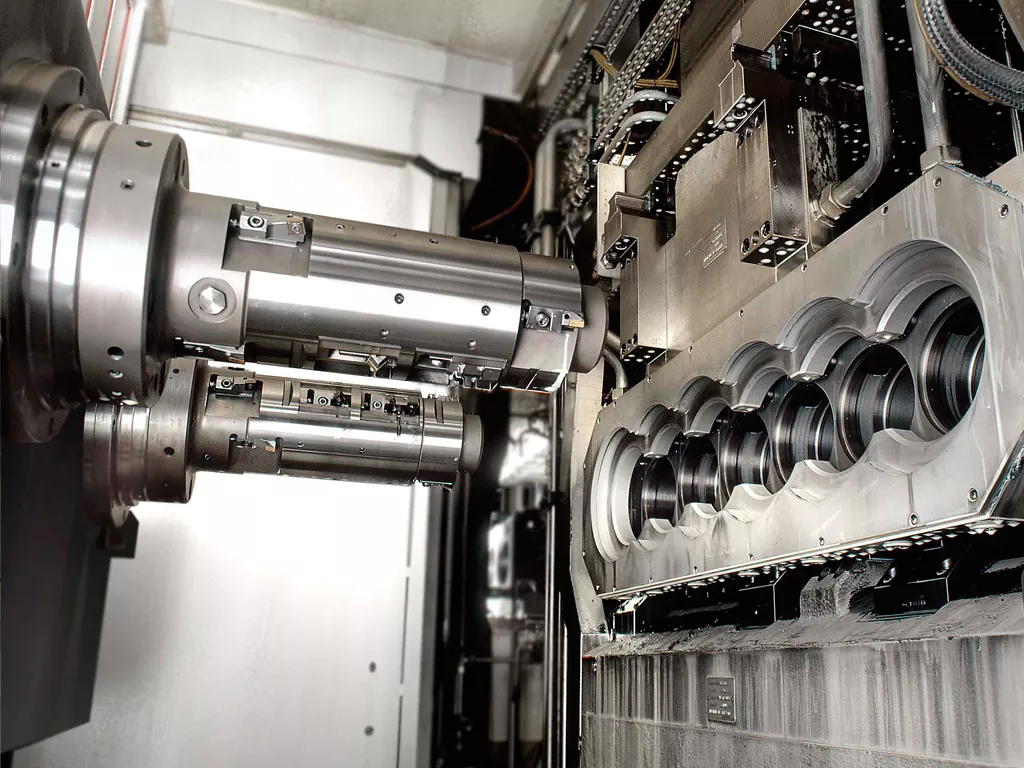

Precision CNC Machining for Demanding Automotive Applications

Honyo Prototype delivers mission-critical CNC machining services engineered specifically for the automotive sector’s stringent performance and reliability requirements. Our advanced multi-axis CNC milling and turning centers consistently achieve micron-level tolerances on complex components—from engine management systems and transmission subassemblies to sensor housings and structural prototypes—ensuring optimal fit, function, and material integrity under extreme operational conditions. We specialize in processing challenging automotive-grade alloys including 7075-T6 aluminum, 4140 steel, and high-temperature plastics, with rigorous in-process inspection protocols to validate geometric accuracy and surface finishes per ISO 2768 or custom OEM specifications.

Leveraging ISO 9001-certified processes and decades of tier-1 supplier experience, Honyo transforms CAD models into production-ready parts with accelerated turnaround times, directly supporting rapid prototyping, low-volume production, and bridge manufacturing initiatives. Our technical team collaborates closely with automotive engineers to optimize designs for manufacturability, reducing assembly complexity while maintaining critical feature tolerances. Streamline your sourcing workflow with Honyo’s Online Instant Quote platform, providing real-time pricing and lead time visibility for CNC-machined automotive components within minutes—no manual RFQ delays. Accelerate your development cycle with precision manufacturing engineered for the road ahead.

Technical Capabilities

Automotive CNC Machines – Technical Specifications Overview

Automotive CNC machines are engineered for high-precision component manufacturing, supporting complex geometries and tight tolerances required in powertrain, chassis, and safety-critical systems. These machines include 3-axis, 4-axis, and 5-axis milling centers, as well as CNC turning centers, capable of processing a range of materials including aluminum alloys, steel (carbon and stainless), ABS, and nylon. Below is a detailed comparison of typical technical specifications relevant to automotive applications.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B/C (dual rotary) | X, Z, (C-axis optional) |

| Typical Spindle Speed | 8,000 – 15,000 RPM | 10,000 – 18,000 RPM | 12,000 – 24,000 RPM | 3,000 – 8,000 RPM |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm |

| Tight Tolerance Capability | ±0.01 mm (standard), down to ±0.005 mm with process control | ±0.01 mm, ±0.005 mm with advanced tooling | ±0.005 mm, down to ±0.002 mm with thermal compensation | ±0.01 mm (diameter), ±0.005 mm with in-process gauging |

| Common Tooling Interface | ISO 30 / BT 30 | ISO 40 / BT 40 | HSK-A63 / HSK-A100 | ISO 50 / Capto C6 |

| Max Work Envelope (mm) | 700 x 400 x 400 | 800 x 500 x 500 | 1,000 x 800 x 600 | Ø300 x 500 (diameter x length) |

| Materials Processed | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Surface Finish (Ra) | 0.8 – 3.2 µm (milled) | 0.8 – 1.6 µm (with finish pass) | 0.4 – 1.6 µm (high-speed finish) | 0.8 – 2.0 µm (turned) |

| Coolant System | Flood, High-Pressure (20–70 bar) | High-Pressure + Through-Spindle | High-Pressure + Mist | Flood or Minimal Quantity Lubrication (MQL) |

| Control System | Fanuc, Siemens, Heidenhain | Fanuc, Siemens, Mitsubishi | Heidenhain, Siemens 840D | Fanuc 32i, Siemens 840D |

| Typical Automotive Applications | Brackets, housings, jigs | Multi-face components, impellers | Cylinder heads, transmission cases, suspension arms | Shafts, pins, bushings, connectors |

Material Notes:

Aluminum Alloys (e.g., 6061, 7075): Most common in automotive due to lightweight and machinability; 5-axis milling enables complex intake manifolds and structural parts.

Steel (e.g., 4140, 1045): Used for high-strength components; requires rigid machines and optimized toolpaths; turning centers preferred for shafts and gears.

ABS & Nylon (Engineering Plastics): Used for prototypes and non-structural parts; require reduced cutting forces and chip removal control to prevent melting or deformation.

These machines are typically integrated with automated tool changers (ATC), probing systems, and environmental enclosures to maintain thermal stability—critical for holding tight tolerances in high-volume or prototype automotive production.

From CAD to Part: The Process

Honyo Prototype Automotive CNC Manufacturing Process Overview

Honyo Prototype delivers precision automotive components through a rigorously defined workflow designed for quality, speed, and compliance with sector-specific standards such as IATF 16949. The process begins with secure CAD data ingestion and concludes with traceable delivery, integrating AI-driven efficiency with engineering oversight at critical stages.

CAD Upload and Data Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like CATIA V5, NX, or SolidWorks) via our encrypted portal. Our system performs immediate validation checks for geometric integrity, unit consistency, and file completeness. Automotive-specific metadata—such as material specification (e.g., 6061-T6 aluminum, 4140 steel per AMS 6349), surface finish requirements (e.g., Ra 0.8 µm), and critical GD&T callouts per ASME Y14.5—is extracted for downstream processing. Invalid or ambiguous data triggers automated alerts to the client within 2 hours.

AI-Powered Quoting with Engineering Verification

Uploaded CAD data feeds our proprietary AI quoting engine, which analyzes part geometry, material, tolerances, and finishing requirements against real-time machine availability, tooling costs, and labor rates. The AI generates a preliminary quote within 4 business hours, including estimated lead time and cost drivers. Crucially, all AI outputs undergo mandatory review by a dedicated automotive manufacturing engineer. This human-in-the-loop step validates feasibility against automotive production constraints (e.g., avoiding thin-wall sections prone to chatter in transmission housings) and adjusts for secondary operations like heat treatment or anodizing. Clients receive a technically vetted quote with clear rationale for any deviations from initial AI estimates.

Automotive-Optimized DFM Analysis

Upon quote acceptance, our engineering team conducts a comprehensive Design for Manufacturability (DFM) review focused on automotive production realities. This includes:

Evaluating tolerance stack-ups for safety-critical components (e.g., brake caliper brackets)

Identifying features requiring specialized tooling (e.g., deep cavities needing long-reach end mills)

Recommending cost-saving modifications without compromising functional performance (e.g., substituting tight tolerances with statistical process control where permissible per PPAP)

Flagging potential assembly interference issues using digital twin simulation

The DFM report, delivered within 72 hours, includes annotated CAD visuals and actionable alternatives. Client approval is required before proceeding, ensuring alignment with their engineering intent.

Precision CNC Production Execution

Production leverages our automotive-dedicated CNC cell featuring Makino 3-axis vertical mills, DMG MORI 5-axis multitasking centers, and Hardinge turning centers—all calibrated to ISO 2768-mK standards. Key practices include:

Material certification traceability from mill certificate to final part

In-process CMM verification at defined hold points (e.g., after roughing, before finishing)

Real-time tool wear monitoring with automatic offset compensation

Dedicated clean-room environment for components requiring zero particulate contamination (e.g., fuel system parts)

All processes adhere to documented work instructions compliant with VDA 6.3 process audits. First-article inspection reports (FAIR) per PPAP Level 3 are generated for client approval prior to full production release.

Quality-Controlled Delivery and Documentation

Finished parts undergo final validation against the approved DFM and CAD model using Zeiss CONTURA CMMs and optical comparators. Automotive-specific documentation packages include:

Dimensional reports with SPC data (Cp/Cpk values)

Material test reports (MTRs) with heat lot traceability

Surface roughness certification

Non-conformance reports (if applicable) with 8D root-cause analysis

Parts are packaged per VDA 19.2 cleanliness standards using anti-corrosion VCI paper and serialized containers. Delivery includes full digital traceability via our client portal, with physical shipment via climate-controlled logistics partners meeting automotive JIT/JIS requirements. Typical lead times vary by complexity as shown below:

| Part Complexity | Typical Lead Time | Max Tolerance Capability | Common Automotive Applications |

|---|---|---|---|

| Low (brackets, covers) | 5-7 business days | ±0.05 mm | Interior trim mounts, sensor brackets |

| Medium (housings, adapters) | 8-12 business days | ±0.025 mm | Transmission pump bodies, valve manifolds |

| High (safety-critical, multi-axis) | 12-18 business days | ±0.005 mm | Suspension knuckles, brake caliper bodies |

This integrated workflow ensures Honyo Prototype consistently delivers automotive CNC components that meet functional, regulatory, and timeline requirements while minimizing total program risk for our clients. All processes are auditable under IATF 16949 frameworks, providing the documentation rigor demanded by Tier 1 suppliers and OEMs.

Start Your Project

For precision automotive CNC machining solutions, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers high-accuracy components tailored to automotive industry demands. From prototyping to full-scale production, we ensure tight tolerances, fast turnaround, and consistent quality. Reach out today to discuss your project requirements and discover how our CNC machining services can support your automotive engineering goals.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.