Introduction: Navigating the Global Market for automatic bar machine

In an increasingly competitive hospitality landscape, sourcing an automatic bar machine that meets diverse customer expectations can be a daunting challenge for B2B buyers. These innovative machines not only enhance service efficiency but also elevate the quality of beverage offerings. This guide aims to demystify the global market for automatic bar machines, providing vital insights into the various types available, their applications across different sectors, and crucial considerations for supplier vetting.

From understanding the nuances of product features to navigating pricing structures, this comprehensive resource empowers international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia. By equipping you with knowledge about the latest technologies, operational benefits, and potential ROI, this guide enables informed purchasing decisions that align with your business goals.

Whether you are looking to streamline operations in a bustling bar, enhance guest experiences in a hotel, or improve beverage service at an event venue, our in-depth analysis will serve as your roadmap to success in the automatic bar machine market. The insights provided here will help you identify the right solutions tailored to your specific operational needs, ensuring that you remain competitive and relevant in a fast-evolving industry.

Understanding automatic bar machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Premium Cocktail Machines | High-quality ingredients, customizable strength, touchscreen interface | Restaurants, Bars, Events | Pros: Effortless cocktail creation; Cons: Higher initial investment. |

| Compact Cocktail Makers | Smaller footprint, fewer spirit reservoirs, rotary dial interface | Small Bars, Home Use | Pros: Space-efficient; Cons: Limited capacity. |

| Professional Automated Bartenders | High volume output, advanced mixing technology, integration with POS systems | High-Volume Venues, Nightclubs | Pros: Fast service; Cons: Complex installation and maintenance. |

| Capsule-Based Drink Systems | Uses pre-measured capsules for consistent quality; barcode recognition | Catering Services, Hotel Bars | Pros: No ingredient waste; Cons: Ongoing cost for capsules. |

| Multi-Function Beverage Dispensers | Versatile for cocktails, mocktails, and other beverages; customizable settings | Cafés, Event Venues | Pros: Multi-purpose use; Cons: May require staff training. |

What are the Characteristics of Premium Cocktail Machines?

Premium cocktail machines are designed to deliver high-quality drinks with minimal effort. They typically feature customizable strength settings, allowing users to select the desired potency of their cocktails. With a touchscreen interface, these machines can mix a variety of cocktails at the push of a button, making them ideal for restaurants and bars that aim to provide a premium experience without extensive bartending skills. When considering a purchase, B2B buyers should evaluate the machine’s capacity, ease of cleaning, and compatibility with various spirits.

How Do Compact Cocktail Makers Cater to Small Spaces?

Compact cocktail makers are ideal for small bars or home use, offering a space-efficient solution for crafting cocktails. These machines often have a rotary dial interface and can hold fewer spirit reservoirs, making them user-friendly for environments with limited space. For B2B buyers, it is essential to consider the volume of customers served and the types of cocktails offered, as these machines may not meet the demands of high-volume venues.

Why Choose Professional Automated Bartenders for High-Volume Venues?

Professional automated bartenders are built for high-volume environments such as nightclubs and large event spaces. They utilize advanced mixing technology and can integrate with POS systems, allowing for seamless service and quick drink preparation. While they can significantly enhance efficiency, B2B buyers should be aware of the complexities involved in installation and maintenance, as well as the higher upfront costs associated with these machines.

What are the Benefits of Capsule-Based Drink Systems?

Capsule-based drink systems provide a unique solution for businesses looking to minimize waste and ensure consistent drink quality. These machines use pre-measured capsules that contain all necessary ingredients, making them easy to operate and maintain. They are particularly suited for catering services and hotel bars where speed and consistency are crucial. However, buyers should consider the ongoing costs of purchasing capsules when evaluating their budget.

How Do Multi-Function Beverage Dispensers Enhance Service Flexibility?

Multi-function beverage dispensers are versatile machines capable of serving cocktails, mocktails, and other beverages, making them suitable for various business environments such as cafés and event venues. Their customizable settings allow for a broad range of drink options, appealing to diverse customer preferences. B2B buyers should assess the machine’s adaptability to different drink types and the potential need for staff training to maximize its capabilities.

Key Industrial Applications of automatic bar machine

| Industry/Sector | Specific Application of automatic bar machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Automated cocktail service in hotels and bars | Enhances customer experience with quick, consistent drinks | Reliability, speed of service, ease of cleaning, and maintenance |

| Event Management | On-demand cocktail preparation for events and parties | Streamlines service during high-demand periods | Portability, capacity, and variety of drink options |

| Retail and E-commerce | Integration in retail spaces for self-serve cocktails | Attracts customers and increases sales through unique offerings | Compliance with local beverage regulations, user-friendly design |

| Catering Services | Mobile bars for catering events | Offers flexibility and premium service without extensive staffing | Size, weight, and power requirements for transport |

| Corporate Offices | In-house cocktail preparation for employee engagement | Boosts morale and enhances workplace culture | Customization options, ease of use, and safety features |

How is the automatic bar machine utilized in the hospitality sector?

In the hospitality industry, automatic bar machines are revolutionizing the way drinks are served in hotels and bars. These machines allow for the rapid preparation of cocktails, enabling establishments to handle high volumes of orders efficiently. By reducing wait times and ensuring consistent quality, businesses can enhance customer satisfaction. International buyers should consider the machine’s reliability, speed, and ease of cleaning, as these factors significantly impact daily operations and customer experiences.

What role does the automatic bar machine play in event management?

For event management companies, automatic bar machines provide a seamless solution for cocktail service during large gatherings. The ability to prepare drinks on-demand allows caterers to focus on other aspects of event planning while ensuring guests receive high-quality cocktails quickly. This is particularly beneficial during peak times when demand surges. When sourcing, buyers should prioritize portability and the machine’s capacity to handle various drink options, as well as its ability to maintain efficiency under pressure.

How can retail spaces benefit from automatic bar machines?

In retail environments, automatic bar machines can be integrated into self-serve cocktail stations, attracting customers looking for a unique shopping experience. This innovative approach not only enhances foot traffic but also increases sales by offering customers the chance to try premium cocktails while they shop. Buyers in this sector should ensure that the machines comply with local beverage regulations and are user-friendly to encourage customer interaction.

What advantages do automatic bar machines offer catering services?

Catering services can leverage automatic bar machines for mobile bars at events, providing a high-end cocktail experience without the need for extensive staffing. This flexibility allows caterers to adapt to varying event sizes and types, enhancing their service offerings. When considering a purchase, buyers should evaluate the machine’s size and weight for transport, as well as its power requirements to ensure it fits within their logistical capabilities.

How do automatic bar machines enhance corporate offices?

In corporate settings, automatic bar machines can serve as an engaging feature for employee gatherings, boosting morale and fostering a positive workplace culture. By allowing employees to craft their cocktails, companies can create a relaxed atmosphere conducive to team building. Buyers should look for machines that offer customization options and are easy to operate, ensuring that all employees can enjoy the experience safely and comfortably.

3 Common User Pain Points for ‘automatic bar machine’ & Their Solutions

Scenario 1: Difficulty in Ensuring Consistency in Drink Quality

The Problem: For B2B buyers in the hospitality industry, particularly those operating bars or restaurants, maintaining consistency in drink quality is crucial. Inconsistent cocktails can lead to dissatisfied customers and tarnished brand reputation. This challenge is exacerbated when staff members have varying levels of mixology skills, resulting in drinks that differ in taste, strength, and presentation. These inconsistencies can affect customer loyalty and overall sales, posing a significant challenge for business owners.

The Solution: Investing in an automatic bar machine can help streamline drink preparation and ensure consistent quality. These machines are designed to mix cocktails using precise measurements and high-quality ingredients, eliminating human error. When selecting an automatic bar machine, it’s important to look for features such as customizable strength settings, pre-programmed recipes, and high-quality ingredient capsules. Buyers should also consider machines that can accommodate a range of spirits and cocktail types to provide versatility in offerings. Training staff on how to operate the machine effectively will further enhance consistency, allowing businesses to deliver a uniform product that meets customer expectations.

Scenario 2: High Operational Costs Due to Inefficient Processes

The Problem: Many bars and restaurants face high operational costs due to inefficient cocktail preparation processes. Traditional methods often involve extensive labor, time-consuming ingredient sourcing, and waste from over-pouring or spoilage of mixers. This inefficiency not only increases labor costs but also affects the bottom line through waste and decreased customer turnover during peak hours.

The Solution: Automatic bar machines can significantly reduce operational costs by streamlining the cocktail-making process. By automating the mixing process, these machines minimize the time required to prepare drinks, allowing bartenders to serve more customers in less time. To maximize cost efficiency, B2B buyers should consider machines with multi-spirit capabilities and a wide range of cocktail options. This versatility allows bars to reduce the number of staff needed during busy hours and minimizes the need for extensive inventory management of mixers and garnishes. Additionally, implementing a subscription model for cocktail capsules can further reduce costs by ensuring a steady supply of high-quality ingredients without the need for large upfront purchases.

Scenario 3: Challenges in Meeting Diverse Customer Preferences

The Problem: In a globalized market, bars and restaurants often cater to a diverse clientele with varying tastes and preferences. This diversity can pose a challenge for businesses that struggle to offer a wide range of cocktails without overcomplicating their menu or inventory. Meeting customer demands for unique or custom cocktails can be resource-intensive and may require specialized staff training, which can be difficult to maintain consistently.

The Solution: An automatic bar machine provides an ideal solution for addressing diverse customer preferences. These machines typically come equipped with multiple cocktail recipes and allow for customization of drink strength and flavors. B2B buyers should seek machines that offer a wide selection of cocktail capsules, including options for mocktails and signature drinks. This capability enables establishments to quickly adapt their offerings to meet changing customer demands without the need for extensive training or inventory management. Additionally, machine features such as touchscreen interfaces can make it easy for staff to experiment with new recipes, thus enhancing the customer experience while maintaining operational efficiency.

Strategic Material Selection Guide for automatic bar machine

What Materials Are Commonly Used in Automatic Bar Machines?

When selecting materials for automatic bar machines, it is crucial to consider properties that directly impact performance, durability, and compliance with international standards. Below, we analyze four common materials used in the construction of these machines: stainless steel, plastic, aluminum, and glass.

How Does Stainless Steel Perform in Automatic Bar Machines?

Stainless steel is a popular choice for automatic bar machines due to its excellent corrosion resistance and high strength. It can withstand high temperatures and pressures, making it suitable for components that may come into contact with hot liquids or steam. The key properties of stainless steel include a temperature rating of up to 800°C and resistance to oxidation.

Pros: Its durability ensures a long lifespan, which is vital for B2B buyers looking for reliable equipment. Stainless steel is also easy to clean and maintain, which is essential in food and beverage applications.

Cons: The primary drawback is its cost, as stainless steel tends to be more expensive than other materials. Additionally, the manufacturing complexity can increase due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with a wide range of liquids, including acidic juices and alcoholic beverages, making it ideal for bar machines.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel is essential. Buyers in regions like Europe may prioritize materials that meet EU regulations for food safety.

What Role Does Plastic Play in Automatic Bar Machines?

Plastic is often used in various components of automatic bar machines, especially for non-structural parts. It is lightweight, cost-effective, and can be molded into complex shapes, which is beneficial for design flexibility.

Pros: The low cost of plastic makes it an attractive option for manufacturers looking to reduce production expenses. Additionally, plastics can be engineered to be resistant to certain chemicals, enhancing their suitability for specific applications.

Cons: However, plastics generally have lower durability compared to metals and can be prone to wear and tear over time. They may also have lower temperature resistance, which can limit their use in high-heat applications.

Impact on Application: The compatibility of plastic with various liquids is essential, but it may not be suitable for all types of beverages, particularly those with high alcohol content.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with regulations such as FDA standards for food contact materials, particularly in regions with strict food safety laws.

How Does Aluminum Compare in Automatic Bar Machines?

Aluminum is another common material used in automatic bar machines, known for its lightweight properties and good corrosion resistance. It can be anodized to enhance its durability and aesthetic appeal.

Pros: Aluminum is relatively inexpensive and offers a good strength-to-weight ratio, making it easier to handle during installation and maintenance.

Cons: However, aluminum may not be as durable as stainless steel, particularly in high-stress applications. It can also be susceptible to scratching and denting.

Impact on Application: Aluminum is suitable for components that do not require high-temperature resistance, making it ideal for external parts of the machine.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum is important. Buyers should also consider the availability of aluminum in their region, as sourcing can vary.

What Advantages Does Glass Offer for Automatic Bar Machines?

Glass is often used in automatic bar machines for aesthetic components, such as display panels or containers. It is non-reactive, ensuring that it does not alter the taste of beverages.

Pros: The primary advantage of glass is its ability to provide a premium look and feel, enhancing the overall customer experience. It is also easy to clean and does not absorb odors.

Cons: The main limitation of glass is its fragility; it can break easily if not handled properly. Additionally, it is heavier than other materials, which can complicate the design and transportation of the machine.

Impact on Application: Glass is suitable for displaying beverages and ingredients but should be used cautiously in areas prone to impact.

Considerations for International Buyers: Buyers should ensure that glass components meet safety standards to prevent breakage and ensure safe handling, particularly in commercial settings.

Summary Table

| Material | Typical Use Case for automatic bar machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, mixers | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Non-structural parts, buttons | Cost-effective and lightweight | Lower durability and temperature resistance | Low |

| Aluminum | External components, frames | Lightweight and inexpensive | Less durable than stainless steel | Medium |

| Glass | Display panels, containers | Premium aesthetic and non-reactive | Fragile and heavier | Medium |

This analysis provides B2B buyers with actionable insights into material selection, ensuring that they make informed decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for automatic bar machine

What Are the Key Manufacturing Processes for Automatic Bar Machines?

The manufacturing of automatic bar machines involves several critical stages that ensure the final product meets quality standards and performs efficiently. Understanding these stages helps B2B buyers evaluate potential suppliers and the capabilities of the machines.

What Are the Main Stages of Manufacturing Automatic Bar Machines?

-

Material Preparation:

The first step involves sourcing high-quality raw materials, including metals for the frame, plastics for various components, and electronic parts for the machine’s operational systems. Suppliers often conduct rigorous checks on these materials to ensure they comply with relevant standards. -

Forming:

In this stage, raw materials undergo various forming processes such as cutting, bending, and machining. Precision is crucial here; CNC (Computer Numerical Control) machines are commonly used to achieve the exact specifications required for intricate parts like control panels and dispensing mechanisms. -

Assembly:

After forming, the components are assembled into the final product. This process may be manual or automated, depending on the scale of production. Automated assembly lines can enhance efficiency, while manual assembly allows for more detailed quality control. Each machine is typically assembled in a clean environment to prevent contamination. -

Finishing:

The final stage includes surface treatment, painting, and applying protective coatings to enhance durability and aesthetics. This step also involves testing electrical components and ensuring that all mechanical parts function seamlessly.

How Is Quality Assurance Integrated Into the Manufacturing Process?

Quality assurance is a fundamental aspect of the manufacturing process for automatic bar machines. It ensures that every unit produced adheres to both international standards and specific industry requirements.

What International Standards Apply to Automatic Bar Machines?

-

ISO 9001:

This international standard specifies requirements for a quality management system (QMS). Manufacturers aiming for ISO 9001 certification must demonstrate their ability to consistently provide products that meet customer and regulatory requirements. -

CE Marking:

For machines sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly important for B2B buyers in Europe, as it assures them of the machine’s safety and reliability. -

API Standards:

If the machine has components used in the food and beverage industry, API (American Petroleum Institute) standards may also apply. These standards ensure that materials used are suitable for food contact and safe for consumer use.

What Are the Quality Control Checkpoints Throughout the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch any issues early and ensure the final product meets all specifications.

-

Incoming Quality Control (IQC):

This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Any materials that do not meet the specified standards are rejected, preventing defects from being incorporated into the production process. -

In-Process Quality Control (IPQC):

During the manufacturing process, ongoing inspections are conducted to monitor the quality of the assembly and the functioning of the machine. This includes checking tolerances, alignment, and operational tests to ensure components fit and work together as intended. -

Final Quality Control (FQC):

Once assembly is complete, a comprehensive inspection is performed. This includes testing the machine’s functionality, durability, and safety features. Often, machines undergo performance testing to simulate real-world usage, ensuring they meet the performance criteria set by the manufacturer.

What Common Testing Methods Are Used in Quality Control?

Various testing methods are employed to verify that automatic bar machines meet quality standards:

- Functional Testing: Ensures that all operational features of the machine work correctly, including ingredient dispensing and user interface functions.

- Safety Testing: Assesses electrical safety, including short-circuit tests and insulation resistance tests to prevent hazards.

- Durability Testing: Simulates extended use to identify potential failure points and ensure long-term reliability.

- Calibration: Confirms that measuring instruments and dispensing mechanisms provide accurate readings and outputs.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, ensuring that a supplier maintains rigorous quality control is essential. Here are some actionable steps to verify these processes:

-

Supplier Audits: Conducting on-site audits allows buyers to observe the manufacturing processes, QC checkpoints, and overall operational standards. This also provides an opportunity to assess the suppliers’ adherence to international standards.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the QC processes, testing methods, and results for the machines. This documentation provides insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process and the quality of the finished product. This is particularly beneficial for buyers in regions where they may not have the capacity to conduct in-depth inspections themselves.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of certain nuances regarding quality control:

-

Regulatory Compliance: Different regions have specific regulations governing the importation and use of machinery. Buyers must ensure that suppliers comply with both local and international regulations to avoid legal complications.

-

Cultural Differences: Understanding cultural attitudes toward quality can vary significantly between regions. For instance, European buyers may prioritize extensive documentation and certification, while buyers in other regions may focus more on cost-effectiveness.

-

Supply Chain Risks: Buyers should assess potential supply chain risks, such as delays due to customs or shipping. Establishing clear communication with suppliers about lead times and contingencies can help mitigate these risks.

By comprehensively understanding the manufacturing processes and quality assurance measures for automatic bar machines, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic bar machine’

This guide is designed to assist B2B buyers in effectively sourcing automatic bar machines, ensuring that you make informed decisions that align with your business needs. The following checklist outlines essential steps to follow during the procurement process, emphasizing critical considerations for a successful purchase.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s vital to clearly outline your technical requirements. This includes understanding the machine’s capacity, the types of cocktails it can prepare, and the necessary features, such as customizable strength settings and compatibility with various spirit brands. Knowing these specifications helps narrow your options and ensures the machine meets your operational demands.

Step 2: Conduct Market Research

Engage in thorough market research to identify leading suppliers and their offerings. Look for reviews, testimonials, and case studies that reflect the experiences of other businesses with similar needs. This information will provide insights into product performance and supplier reliability, which are critical for making an informed decision.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step helps ascertain the supplier’s credibility and their capacity to deliver quality products consistently.

- Check for Industry Experience: Look for suppliers with a proven track record in the hospitality or beverage sector.

- Assess Customer Support: Ensure that the supplier offers comprehensive support services, including installation and maintenance.

Step 4: Compare Pricing and Payment Terms

Once you have a shortlist of suppliers, compare their pricing structures and payment terms. Ensure that you understand what is included in the price, such as warranty periods, delivery costs, and after-sales service. A clear understanding of financial commitments will prevent unexpected expenses down the line.

- Consider Total Cost of Ownership: Evaluate not just the initial purchase price but also maintenance and operational costs associated with the machine.

Step 5: Request Demonstrations or Samples

Whenever possible, request a demonstration of the automatic bar machine or samples of its outputs. This allows you to evaluate the product’s performance and ease of use firsthand. Observing the machine in action can provide valuable insights into its efficiency and the quality of cocktails it produces.

Step 6: Verify Compliance with Local Regulations

Ensure that the automatic bar machine complies with local health and safety regulations, especially if you are operating in regions with stringent food and beverage laws. This step is crucial to avoid legal issues and ensure the machine’s acceptance by local authorities.

- Check Certifications: Look for certifications that indicate compliance with international standards, which can enhance the machine’s credibility.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier and product, carefully review and finalize the purchase agreement. Pay close attention to the terms and conditions, including warranty provisions, return policies, and service agreements. A well-drafted contract protects your interests and ensures a smooth transaction process.

By following this checklist, B2B buyers can streamline their sourcing process for automatic bar machines, ensuring that they select a product that meets their operational needs while also aligning with budgetary constraints.

Comprehensive Cost and Pricing Analysis for automatic bar machine Sourcing

What Are the Key Cost Components for Sourcing Automatic Bar Machines?

When sourcing automatic bar machines, understanding the cost structure is vital. The primary cost components include:

-

Materials: The choice of materials directly affects the quality and durability of the machines. High-grade stainless steel and food-safe plastics are common, and their prices can vary significantly based on quality and sourcing regions.

-

Labor: Labor costs can fluctuate based on geographical location. For instance, labor in Europe may be more expensive than in South America or Africa. Skilled technicians are often needed for assembly and quality checks, impacting overall labor costs.

-

Manufacturing Overhead: This includes utilities, rent, and administrative costs associated with production facilities. Companies must factor these expenses into their pricing structures, which can vary widely depending on the production scale and location.

-

Tooling: Initial setup costs for specialized tools and molds can be high, particularly for custom designs. This upfront investment is crucial for manufacturers to produce machines that meet specific buyer requirements.

-

Quality Control (QC): Rigorous QC processes ensure that machines meet safety and operational standards. The costs associated with testing and certification (e.g., CE, ISO) should not be overlooked, as they can influence the final price.

-

Logistics: Shipping costs can escalate based on distance, shipping methods, and volume. International buyers should also consider duties and taxes that may apply when importing machines.

-

Margin: Supplier margins can vary based on market competition and the perceived value of the product. Understanding these margins can help buyers negotiate better deals.

How Do Price Influencers Impact the Cost of Automatic Bar Machines?

Several factors influence the pricing of automatic bar machines, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to leverage pricing advantages.

-

Specifications and Customization: Custom features or specific design requests can significantly increase costs. Standard models are typically less expensive, so buyers should evaluate if customizations are essential.

-

Material Quality and Certifications: Higher-quality materials and certifications can enhance the machine’s reliability but will also raise costs. Buyers should balance the need for quality against budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established manufacturers with a track record may charge more due to their perceived value and lower risk.

-

Incoterms: The terms of trade determine who is responsible for shipping costs and risks. Understanding Incoterms can help buyers avoid unexpected expenses in the supply chain.

What Tips Can Help Buyers Optimize Costs When Sourcing Automatic Bar Machines?

Buyers can adopt several strategies to enhance cost-efficiency in their sourcing process:

-

Effective Negotiation: Engaging suppliers in open discussions about pricing can yield significant savings. Highlighting potential volume purchases or long-term partnerships may convince suppliers to offer better rates.

-

Understanding Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operation, and potential repair costs over the machine’s lifespan. A lower upfront cost may lead to higher long-term expenses.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, and the Middle East should be aware of regional pricing trends, shipping costs, and import duties that could affect overall expenditure. Engaging local representatives or consultants can provide valuable insights.

-

Assessing Warranty and Support Services: A good warranty and reliable customer support can prevent future costs associated with repairs or replacements. Ensure these factors are included in the pricing discussions.

Disclaimer on Indicative Prices

Prices for automatic bar machines can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and engage directly with suppliers to obtain accurate and up-to-date pricing information tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing automatic bar machine With Other Solutions

Introduction: What Are the Alternatives to an Automatic Bar Machine?

In the fast-evolving beverage service industry, businesses are continuously seeking efficient solutions to enhance their offerings and streamline operations. The automatic bar machine represents a technological advancement that simplifies cocktail preparation, but it is essential to consider other viable alternatives that may better fit specific operational needs. This analysis compares the automatic bar machine with two notable alternatives: traditional manual bartending and automated cocktail dispensers.

Comparison Table

| Comparison Aspect | Automatic Bar Machine | Traditional Manual Bartending | Automated Cocktail Dispenser |

|---|---|---|---|

| Performance | High-quality cocktails in 30 seconds | Varies based on bartender skill | Consistent, fast dispensing |

| Cost | Initial investment around $400 | Low initial cost, but labor-intensive | Moderate investment, $200-$600 |

| Ease of Implementation | Requires minimal training | Requires skilled bartenders | Simple installation, easy to use |

| Maintenance | Regular cleaning, minimal upkeep | Ongoing training, variable costs | Regular cleaning, low upkeep |

| Best Use Case | High-volume events, bars, restaurants | Personalized service, craft cocktail bars | Fast-paced environments, events |

Detailed Breakdown of Alternatives

Traditional Manual Bartending

Manual bartending is the traditional method of cocktail preparation, where skilled bartenders mix drinks based on customer orders. This approach allows for a high degree of personalization and creativity, as bartenders can customize drinks to meet specific preferences. However, the performance can vary significantly depending on the bartender’s experience and skill level, leading to inconsistent quality. Additionally, this method can be labor-intensive, requiring ongoing training and potentially higher labor costs. While ideal for establishments that prioritize personalized service and craft cocktails, it may not be the most efficient solution for high-volume settings.

Automated Cocktail Dispenser

Automated cocktail dispensers offer a middle ground between the automatic bar machine and manual bartending. These machines are designed to dispense pre-mixed cocktails at high speed, ensuring consistency and efficiency. They typically have a lower initial investment compared to automatic bar machines and are relatively easy to install and operate. However, they may not provide the same quality of cocktails as those made by skilled bartenders or automatic machines, which can limit their appeal in establishments focusing on premium offerings. Automated dispensers are best suited for fast-paced environments such as events and parties, where speed and volume are prioritized over craft cocktail quality.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right beverage preparation solution involves assessing the specific needs and operational context of your business. If you prioritize speed, consistency, and efficiency, an automatic bar machine may be the best choice, particularly in high-volume scenarios. However, if your establishment thrives on personalized service and craft cocktails, traditional manual bartending could be more beneficial despite its labor demands. Alternatively, for environments where quick service is essential without a focus on premium quality, an automated cocktail dispenser presents a viable option. Ultimately, understanding your target market and operational goals will guide you in making the most informed decision.

Essential Technical Properties and Trade Terminology for automatic bar machine

What Are the Essential Technical Properties of an Automatic Bar Machine?

Understanding the technical specifications of an automatic bar machine is crucial for B2B buyers seeking to invest in quality equipment that meets their operational needs. Below are some key properties to consider:

-

Material Grade

– Definition: This refers to the quality of materials used in the construction of the machine, such as stainless steel, aluminum, or plastics.

– Importance: High-grade materials ensure durability, corrosion resistance, and ease of cleaning. For buyers in the hospitality industry, investing in machines made from superior materials can reduce long-term maintenance costs. -

Power Consumption

– Definition: The amount of electrical power required for the machine to operate, typically measured in watts.

– Importance: Understanding power requirements is essential for assessing operational costs and ensuring compatibility with existing electrical infrastructure. Machines with lower power consumption can lead to significant savings over time. -

Production Capacity

– Definition: The volume of drinks the machine can produce in a given time frame, often expressed in drinks per hour.

– Importance: For businesses such as bars and restaurants, knowing the production capacity helps in planning service efficiency and managing customer demand, especially during peak hours. -

Dimensions and Footprint

– Definition: The physical size of the machine, including its height, width, and depth.

– Importance: Understanding the dimensions is critical for space planning. Buyers must ensure that the machine fits within their operational areas without hindering workflow. -

User Interface

– Definition: The control panel or touchscreen that allows operators to select drinks, customize settings, and monitor performance.

– Importance: A user-friendly interface reduces training time for staff and enhances operational efficiency. Machines with intuitive controls can improve service speed and customer satisfaction. -

Cleaning and Maintenance Features

– Definition: Features that facilitate the cleaning process, such as self-cleaning functions or removable parts.

– Importance: Regular maintenance is crucial for hygiene and machine longevity. Machines that simplify cleaning processes save time and labor, making them more attractive to busy establishments.

What Are Common Trade Terminology Terms Related to Automatic Bar Machines?

Familiarity with industry jargon can streamline negotiations and enhance communication with suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can inform buyers about the quality and reliability of components used in the machine, crucial for long-term performance. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their purchases effectively, especially when considering budget constraints and inventory needs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products or services.

– Importance: Issuing an RFQ allows buyers to compare offers and negotiate better deals, ensuring that they get the best value for their investment. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers regarding the delivery of goods under sales contracts.

– Importance: Understanding Incoterms helps buyers mitigate risks related to shipping, insurance, and delivery timelines, which is particularly vital in international transactions. -

Lead Time

– Definition: The time it takes from placing an order until the product is delivered.

– Importance: Knowing the lead time is essential for inventory management and ensuring that businesses can meet customer demand without delays. -

Warranty Period

– Definition: The duration during which the manufacturer guarantees the machine will function as intended.

– Importance: A robust warranty period provides buyers with confidence in the equipment’s reliability and can influence purchasing decisions based on potential future costs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting automatic bar machines that align with their operational requirements and business goals.

Navigating Market Dynamics and Sourcing Trends in the automatic bar machine Sector

What Are the Current Market Dynamics and Key Trends in the Automatic Bar Machine Sector?

The automatic bar machine sector is witnessing significant growth, driven by increasing consumer demand for convenience and high-quality cocktails at home and in commercial establishments. The global market for automatic bar machines is expanding, particularly in regions like Africa, South America, the Middle East, and Europe. Key trends include the integration of smart technology and user-friendly interfaces, allowing for personalized drink experiences. Machines that can mix a variety of cocktails with minimal user input are becoming increasingly popular, appealing to both home users and businesses looking to streamline operations.

International B2B buyers should be aware of emerging sourcing trends, such as the rising demand for multifunctional machines that not only prepare cocktails but also offer customization options. These machines often feature advanced capabilities like barcode scanning for cocktail capsules, which can optimize inventory management and reduce waste. The trend towards on-demand service models aligns with the growing preference for personalized experiences, making it essential for suppliers to offer machines that cater to diverse consumer tastes.

Additionally, sustainability is becoming a key consideration in purchasing decisions. As more businesses prioritize eco-friendly practices, suppliers that can demonstrate sustainable sourcing of materials and ethical manufacturing processes will have a competitive edge. Understanding these market dynamics can help international buyers make informed decisions and capitalize on the growing demand for automatic bar machines.

How Can Sustainability and Ethical Sourcing Impact the Automatic Bar Machine Sector?

Sustainability and ethical sourcing are increasingly crucial in the automatic bar machine sector, as businesses and consumers alike become more environmentally conscious. The production of these machines often involves materials and processes that can have significant environmental impacts, from resource extraction to energy consumption during manufacturing. B2B buyers must consider the environmental footprint of the machines they procure, including energy efficiency ratings and the use of recyclable or biodegradable materials.

Moreover, the importance of ethical supply chains cannot be overstated. Suppliers that prioritize fair labor practices and transparency in their sourcing processes will resonate with a growing segment of buyers who value corporate social responsibility. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

For businesses looking to source automatic bar machines, it is advisable to partner with manufacturers who can provide documentation on their sustainability efforts and certifications. This not only helps in reducing the environmental impact but also enhances brand reputation and consumer trust.

What Is the Brief Evolution of Automatic Bar Machines and Their Significance for B2B Buyers?

The evolution of automatic bar machines dates back to the early 2000s, when the first models began to emerge in the consumer market. Initially designed for home use, these machines have gradually transitioned into the commercial space, driven by advancements in technology and changing consumer preferences. Early models focused on basic mixing functions but have now evolved to include smart features like touchscreen interfaces, customizable drink options, and integration with mobile apps for enhanced user experience.

Today, automatic bar machines are not only seen as novelty items but as essential tools for bars, restaurants, and event venues aiming to improve efficiency and service quality. For B2B buyers, understanding the historical context of these machines highlights the importance of investing in technology that can adapt to market trends and consumer demands. As the sector continues to innovate, staying informed about the latest advancements will be crucial for making strategic purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic bar machine

-

How do I choose the right automatic bar machine for my business needs?

When selecting an automatic bar machine, consider factors such as the volume of cocktails you expect to serve, the variety of drinks you want to offer, and the space available in your establishment. Evaluate machines that provide customizable options for drink strength and ingredient types. Look for models that can efficiently handle peak hours while ensuring consistent quality. Additionally, check for user-friendly interfaces and maintenance requirements to minimize downtime. -

What are the benefits of using an automatic bar machine in a commercial setting?

Automatic bar machines streamline cocktail preparation, reducing labor costs and improving service speed. They allow for consistent drink quality, which enhances customer satisfaction. These machines can also reduce waste by precisely measuring ingredients, thus optimizing inventory management. Furthermore, they can offer a wider range of cocktails without requiring extensive bartender training, making them ideal for businesses looking to diversify their drink menu. -

What should I consider when vetting suppliers for automatic bar machines?

When vetting suppliers, assess their reputation in the market, years of experience, and customer reviews. Request references from other businesses that have purchased similar machines. Evaluate their warranty and after-sales service options, as these are crucial for long-term satisfaction. It’s also beneficial to inquire about their production capabilities, lead times, and compliance with international standards, especially if you’re importing into regions with specific regulations. -

What is the minimum order quantity (MOQ) for automatic bar machines?

The MOQ can vary significantly between manufacturers, typically ranging from one unit for smaller suppliers to several units for larger manufacturers. Factors influencing MOQ include production capacity, customization options, and shipping logistics. Always clarify MOQ during negotiations to ensure it aligns with your budget and operational needs, especially if you are testing market demand before making a larger commitment. -

What payment terms should I expect when purchasing from international suppliers?

Payment terms can vary widely; however, common practices include a deposit (often 30-50%) upon order confirmation with the balance due before shipping. Some suppliers may offer flexible terms, such as letter of credit or payment upon delivery. It’s essential to negotiate terms that protect your interests while maintaining a good relationship with the supplier. Always ensure you have a clear understanding of any additional costs, such as shipping and customs duties. -

How can I ensure quality assurance for my automatic bar machines?

Implement a thorough quality assurance process that includes pre-shipment inspections and certifications for compliance with international standards. Request detailed product specifications and quality control protocols from your supplier. Consider establishing a trial period during which you can assess the machine’s performance in your environment. Additionally, check if the supplier offers a warranty that covers defects and operational failures. -

What logistics considerations should I be aware of when importing automatic bar machines?

When importing, consider factors such as shipping methods, freight costs, and customs clearance procedures. Understand the regulations specific to your country regarding imported goods, including tariffs and import duties. It’s also crucial to plan for potential delays in shipping and ensure your logistics partner has experience with international trade. Establish clear communication with your supplier to coordinate shipping timelines and documentation effectively. -

Are there customization options available for automatic bar machines?

Many manufacturers offer customization options, allowing you to tailor the machine’s features to suit your business needs. This may include specific branding, color choices, or additional functionalities like integrated payment systems. Discuss your requirements with potential suppliers to explore available options. Keep in mind that customization may affect lead times and costs, so factor these into your decision-making process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Automatic Bar Machine Manufacturers & Suppliers List

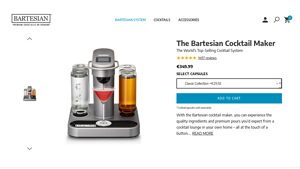

1. Bartesian – Premium Cocktail Machine

Domain: bartesian.com

Registered: 2015 (10 years)

Introduction: Bartesian Premium Cocktail Machine

– Price: $399.00

– Features:

– Mixes over 60 bar-quality cocktails on demand

– Customizable cocktail strength (mocktail, light, regular, strong)

– Touchscreen interface

– Self-cleans between cocktails

– Uses any brand of Vodka, Tequila, Whiskey, Gin, or Rum

– Requires cocktail capsules (sold separately)

– What’s in the Box:

– 1 Bartesian premium coc…

2. Smart Bar USA – Smartender® Automated Cocktail Dispensing Systems

Domain: smartbarusa.com

Registered: 2012 (13 years)

Introduction: Smartender® by Smart Bar USA® is an automated cocktail dispensing system designed to maximize profits and enhance guest experiences. Key models include Smartender 50, 34, 18 & 8 Series, Smartender GO, Smartender Self Serve, and Smartender CHILL. The systems can accommodate 50, 34, 18, or 8 distinct liquors and offer various liquor delivery options, including under/above counter or in-drawer slide-…

3. BLACK+DECKER – bev Cocktail Maker

Domain: blackanddecker.com

Registered: 1995 (30 years)

Introduction: Product Name: bev by BLACK+DECKER™ Cocktail Maker

Description: Personal bartender for mixing personalized cocktails and mocktails at the touch of a button.

Dimensions: 12 ¼” wide x 15 ½” tall x 12 ½” deep (fully assembled).

Compatible Liquor Bottle Size: Standard 750ml bottles.

Cleaning Frequency: Recommended to clean liquid lines at least once a month.

Functionality: Uses Bartesian® capsules (sol…

4. Mixo – High-Capacity Automated Cocktail Machine

Domain: mixologiq.com

Registered: 2018 (7 years)

Introduction: Mixo 20: High-capacity automated cocktail machine with a 20-bottle capacity and over 300 customizable recipes. Features built-in refrigeration for fresh ingredients, precision pouring for bar-quality consistency, and the ability to prepare up to 120 cocktails per hour in under 30 seconds. Plug-and-play setup with minimal staff training required. Offers real-time analytics for operational efficienc…

5. Hamilton Beach – Bartesian Professional Cocktail Machine

Domain: hamiltonbeachcommercial.com

Registered: 2000 (25 years)

Introduction: Bartesian Professional Cocktail Machine Model: 55306; Type: Automated cocktail machine; Features: Easy-to-use interface, customizable drink options, compatible with various cocktail capsules, built-in cleaning cycle, compact design for commercial use; Applications: Ideal for bars, restaurants, and hospitality settings; Warranty: Standard warranty included; Dimensions: Compact size suitable for lim…

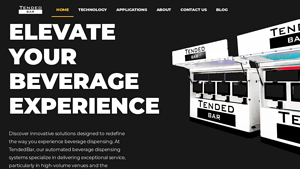

6. TendedBar – Automated Beverage Dispensing Systems

Domain: tendedbar.com

Registered: 2014 (11 years)

Introduction: TendedBar offers automated beverage dispensing systems designed for high-volume venues such as airports, hotels, convention centers, and amusement parks. Key features include: 1) Customized & Curated Menu with various liquors, mixers, wines, and beers; 2) Professional design team to create a tailored bar experience in as little as 45 days for standard 2-Screen Units; 3) Optimized beverage service …

7. RBTX – Automatic Drink Mixer

Domain: rbtx.com

Registered: 2004 (21 years)

Introduction: {“Product Name”: “Automatic Drink Mixer”, “Working Space”: “500×150 mm”, “Max Velocity”: “0.5 meters per second”, “Key Features”: {“Ease of Use”: “User-friendly touch panel with predefined cocktails”, “Accurate Dispensing”: “Air pumps ensure precise measurements and consistent taste”, “Data Integration”: “Connects to databases for tracking drink popularity and optimizing inventory”}, “Advantages”:…

8. Bartesian – Premium Cocktail Machine

Domain: seriouseats.com

Registered: 2006 (19 years)

Introduction: Bartesian 55300 Premium Cocktail Machine: Price: $399 at Amazon, $400 at Target. Features: Touchscreen for real-time support, sleek design, low profile, removable non-slip bar mat, hidden water reservoir, four glass bottles for vodka, tequila, whiskey, and gin/rum. Bev by Black + Decker Cocktail Maker: Price: $358 at Amazon, $500 at Target. Features: Allows use of uniform glass bottles or original…

9. CrownShopBoutique – Stainless Steel Cocktail Machine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Stainless Steel Cocktail Machine – Automatic Home Bar with Easy-Clean Design, Price: $701.09 (Was $737.99, 5% off), Seller: CrownShopBoutique, Feedback: 95% positive, Shipping: Save on combined shipping when purchasing multiple items.

Strategic Sourcing Conclusion and Outlook for automatic bar machine

In today’s competitive landscape, the strategic sourcing of automatic bar machines stands out as a pivotal investment for businesses aiming to enhance their beverage service efficiency and customer experience. These machines not only streamline operations but also offer consistency in quality, enabling businesses to cater to the diverse tastes of their clientele across various regions, including Africa, South America, the Middle East, and Europe.

By leveraging advanced technology, such as customizable cocktail strengths and quick mixing capabilities, companies can reduce labor costs while maximizing customer satisfaction. The potential for automating the cocktail-making process is particularly beneficial for establishments looking to innovate their service offerings, thus attracting a broader customer base.

As the market for automatic bar machines continues to evolve, international B2B buyers should remain proactive in exploring partnerships with reliable suppliers who prioritize quality and innovation. Investing in these machines not only represents a commitment to operational excellence but also positions your business for future growth.

Embrace the opportunity to elevate your beverage service—consider incorporating automatic bar machines into your operational strategy today and position your business at the forefront of this emerging trend.