Contents

Manufacturing Insight: Automated Cnc

Honyo Prototype: Precision Automated CNC Machining for Demanding Production Requirements

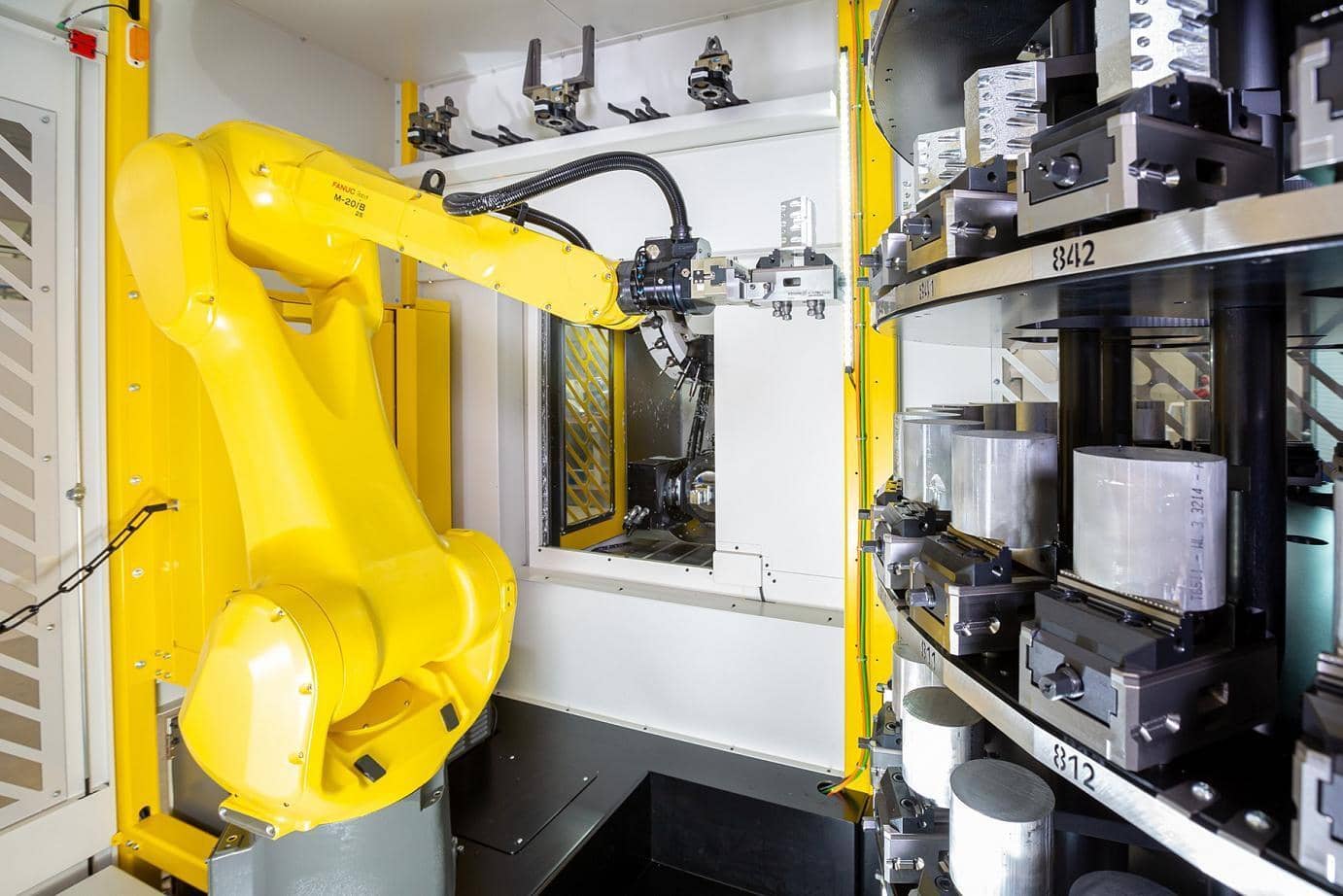

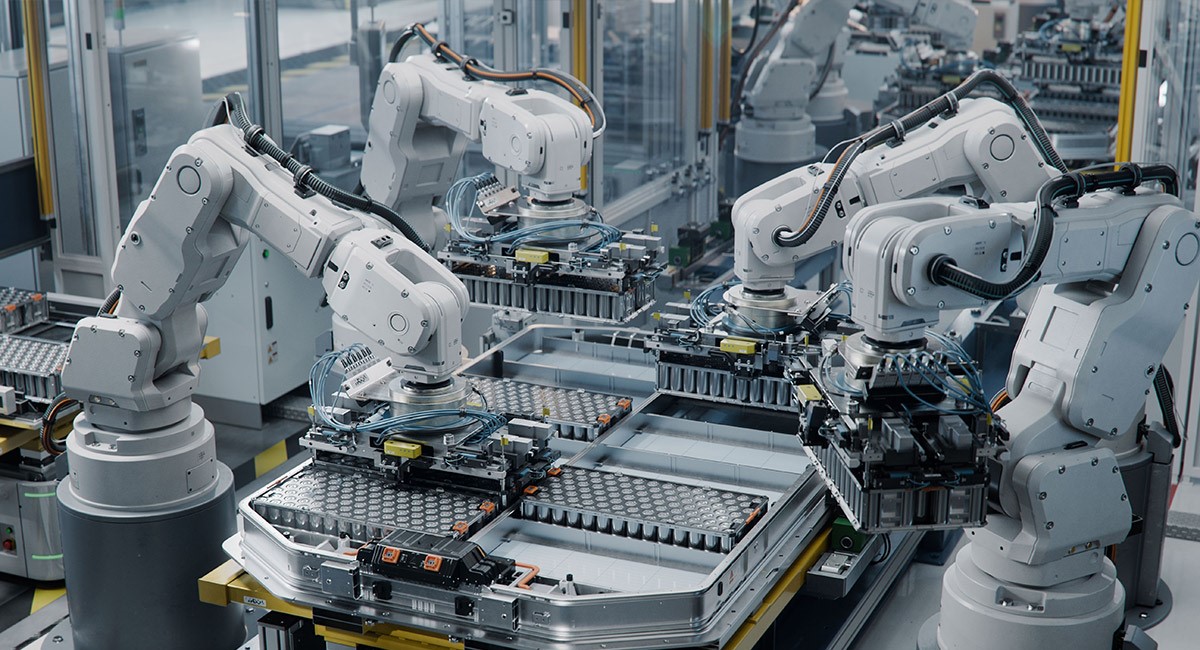

In today’s accelerated manufacturing landscape, achieving rapid time-to-market without compromising precision demands advanced automated CNC solutions. Honyo Prototype leverages state-of-the-art multi-axis CNC machining centers—integrated with robotics and in-process inspection—to deliver exceptional repeatability, reduced cycle times, and consistent part quality for complex geometries. Our automated systems excel in high-mix, low-to-medium volume production, maintaining sub-micron tolerances across aerospace components, medical devices, and industrial tooling while minimizing human intervention and associated variability.

Central to our service efficiency is Honyo’s proprietary Online Instant Quote platform, engineered for engineering teams requiring speed and transparency. Unlike generic quoting tools, our system utilizes real-time machine availability, material databases, and geometric complexity analysis to generate accurate, detailed cost and lead time estimates within minutes—eliminating traditional quoting bottlenecks. This seamless integration between digital workflow and physical production ensures your prototypes and production runs transition from CAD model to certified part with unparalleled velocity. Partner with Honyo to transform design intent into manufactured reality through intelligent automation and data-driven precision.

Technical Capabilities

Automated CNC Machining Technical Specifications

Automated CNC systems for milling and turning are engineered to deliver high precision, repeatability, and efficiency in production environments. These systems integrate advanced control software, tool management, and in-process inspection to maintain tight tolerances across a range of engineering materials including aluminum, steel, ABS, and nylon. Below are the key technical specifications focused on 3, 4, and 5-axis milling, CNC turning, and tight tolerance capabilities.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Axis Configuration | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (dual rotary) | X, Z, (C for live tooling) | A-axis rotates about X, B-axis about Y |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.003 mm | Measured per ISO 230-2 |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.002 mm | ±0.001 mm | Consistent over long runs |

| Typical Tolerance Range | ±0.010 mm | ±0.010 mm | ±0.010 mm | ±0.005 mm (diameter) | Tight tolerances achievable with process control |

| Spindle Speed (max) | 24,000 rpm | 24,000 rpm | 20,000 rpm | 6,000 rpm | High-speed spindles optional |

| Spindle Power | 15–22 kW | 15–22 kW | 15–20 kW | 10–18 kW | Depends on machine class |

| Tool Capacity (ATC) | 20–30 tools | 30–40 tools | 40–60 tools | 8–12 stations (live tools) | Automatic Tool Changer standard |

| Work Envelope (max) | 1000 x 600 x 500 mm | 800 x 600 x 500 mm | 600 x 500 x 400 mm | Ø300 mm x 500 mm length | Varies by machine model |

| Materials Compatible | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Includes both metals and engineering plastics |

| Surface Finish (typical) | Ra 0.8 µm | Ra 0.8 µm | Ra 0.4 µm | Ra 0.4–0.8 µm | Achievable with fine finishing passes |

| Coolant System | Through-spindle optional | High-pressure flood | High-pressure flood | Mist or flood coolant | Required for steel and nylon |

| Automation Interface | Compatible with pallet systems, robots, and gantry loaders | Enables lights-out manufacturing | |||

| Control System | Fanuc, Siemens, or Heidenhain | Fanuc, Siemens, or Heidenhain | Fanuc, Siemens, or Heidenhain | Fanuc or Siemens | Supports G-code and CAM integration |

Material-Specific Notes

Aluminum is readily machined at high speeds across all configurations. Steel (including stainless and alloy grades) requires rigid setups and proper tooling but is fully supported. ABS and nylon, as engineering thermoplastics, are compatible with CNC systems using sharp tooling and optimized feed rates to prevent melting or burring. Special chip management may be required for nylon due to its tendency to generate stringy swarf.

These specifications represent industrial-grade automated CNC platforms suitable for prototyping and low-to-high volume production where dimensional accuracy, surface quality, and material versatility are critical.

From CAD to Part: The Process

Honyo Prototype’s automated CNC workflow integrates digital efficiency with engineering expertise to deliver precision parts rapidly. This process minimizes manual intervention while ensuring manufacturability and quality through strategic human oversight at critical stages. Below is a detailed explanation of each phase:

CAD Upload and System Integration

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or 2D drawings via our secure customer portal. Our system automatically validates file integrity, extracts geometric data, and identifies critical features such as tolerances, surface finishes, and material specifications. Complex assemblies are segmented into individual components for parallel processing, while the platform flags incomplete submissions requiring client clarification before progression.

AI-Powered Quoting Engine

Uploaded geometry triggers our proprietary AI quoting system, which analyzes 15+ manufacturing parameters including part volume, feature complexity, machine time estimates, and material utilization. The AI cross-references real-time data from our production floor—current machine availability, operator schedules, and material stock levels—to generate a technically accurate quote within 90 seconds. Pricing dynamically adjusts for factors like batch size, secondary operations, and rush fees, with all assumptions documented in the quote report for transparency.

Engineer-Validated DFM Analysis

Following quote acceptance, our system conducts an automated Design for Manufacturability (DFM) scan identifying potential issues such as non-standard tool access, excessive tolerances, or thin wall sections. Crucially, this AI-generated report undergoes mandatory review by a certified Honyo manufacturing engineer who:

Validates or overrides AI suggestions based on shop-specific capabilities

Proposes actionable design optimizations to reduce cost without compromising function

Documents all recommendations with annotated visuals for client approval

Key DFM Checks and Actions

| Check Category | Automated Detection | Engineer Action |

|———————-|———————————————-|————————————————–|

| Geometric Feasibility | Undercuts, deep cavities, small radii | Recommends alternative toolpaths or design mods |

| Tolerance Analysis | Over-specified GD&T, conflicting tolerances | Suggests achievable alternatives per ISO 2768 |

| Material Efficiency | Suboptimal stock size, excessive waste | Adjusts billet dimensions to minimize scrap |

| Process Optimization | Unnecessary secondary ops, fixturing issues | Proposes consolidated operations or tooling mods |

Smart Production Execution

Approved designs move to production where our Manufacturing Execution System (MES) auto-generates optimized CNC programs using integrated CAM software. Each job receives a unique QR code linking to:

Real-time machine status updates visible to clients

Automated tool wear compensation via in-process probing

First-article inspection data against original CAD

All critical dimensions undergo automated CMM verification with deviations triggering instant workflow holds for engineering review. High-mix jobs leverage our flexible cell setup with pre-staged tooling to maintain 24-72 hour standard lead times.

Traceable Global Delivery

Completed parts undergo final visual and dimensional validation against AS9102 standards before packaging. Each shipment includes:

Material certification and process documentation

Digital inspection report with deviation heatmaps

Real-time logistics tracking via integrated carriers (DHL, FedEx, regional partners)

Our system auto-schedules shipments based on client-defined delivery windows, with climate-controlled options for sensitive materials. Post-delivery, clients access full production analytics through their portal for continuous improvement collaboration.

This closed-loop process reduces traditional CNC lead times by 40-60% while maintaining rigorous quality control through engineered validation points. The integration of AI speed with human expertise ensures scalability without compromising on the precision expected from a high-end prototyping partner.

Start Your Project

Looking for precision automated CNC solutions? Contact Susan Leo at [email protected] to discuss your project requirements.

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, providing high-efficiency automated CNC services for rapid prototyping and low-to-mid volume production.

Our integrated automation systems ensure consistent part quality, faster turnaround times, and reduced labor costs—ideal for industries requiring tight tolerances and repeatable accuracy.

Reach out today to optimize your manufacturing workflow with expert support from our engineering team.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.