Contents

Manufacturing Insight: Auto Sheet Metal Fabrication

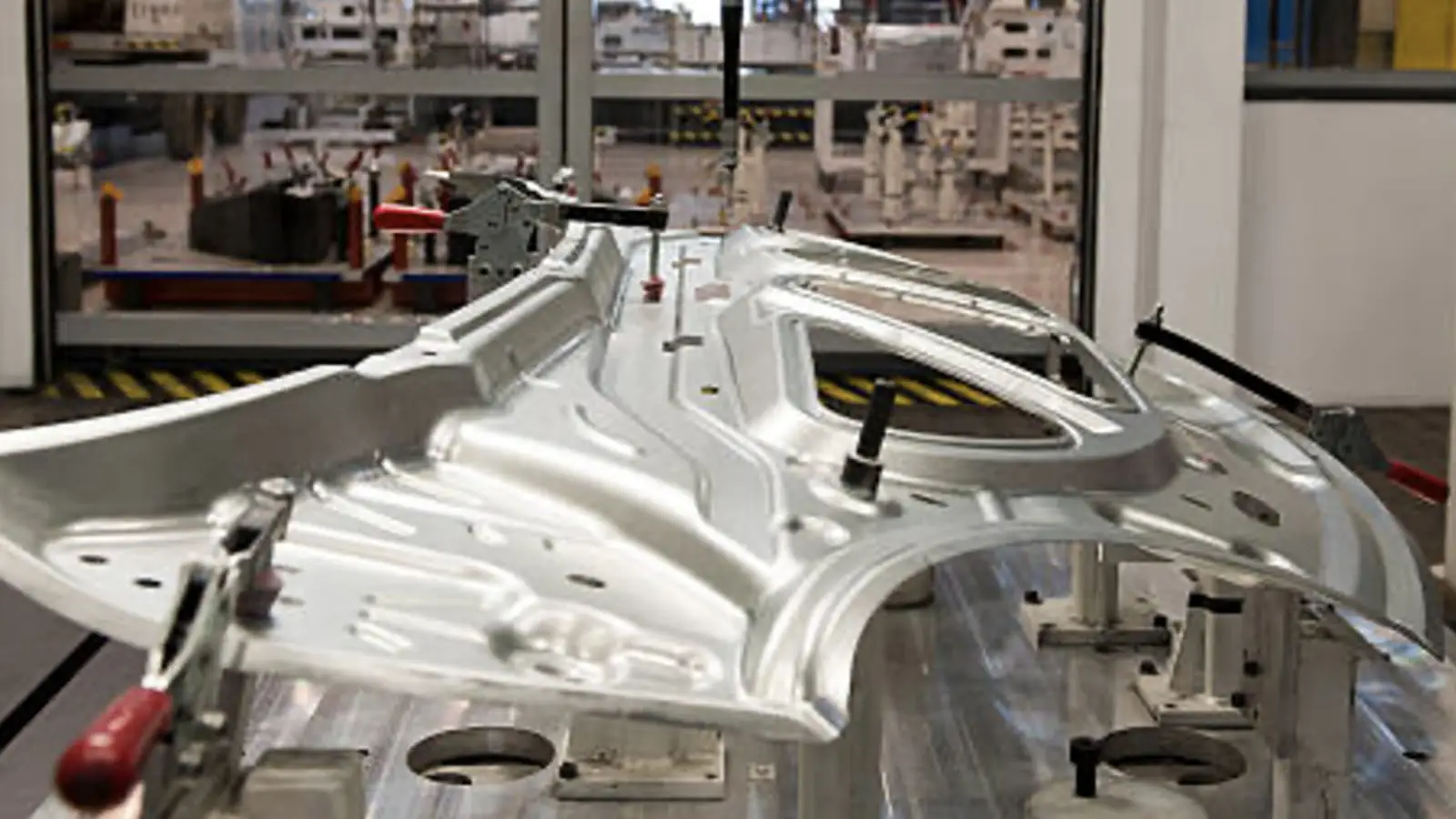

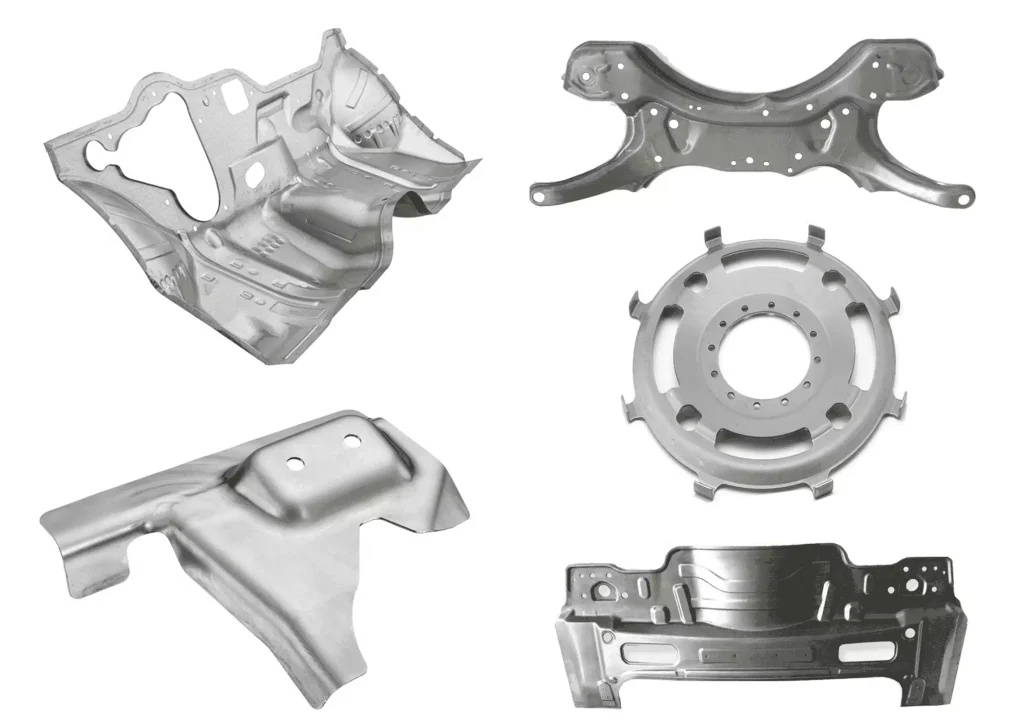

Honyo Sheet Metal Fabrication delivers precision-engineered components specifically engineered for demanding automotive applications. As a trusted partner to Tier 1 suppliers and OEMs, we specialize in transforming complex sheet metal designs into high-integrity parts, from intricate brackets and brackets to structural housings and chassis components. Our integrated manufacturing cell combines advanced laser cutting, precision CNC punching, accurate bending, and comprehensive secondary operations under stringent ISO 9001:2015 quality management. This ensures every part meets the exacting dimensional tolerances, material specifications, and surface finish requirements critical for automotive assembly and performance.

We understand the automotive sector’s relentless pressure for speed-to-market and flawless quality. Honyo’s process excellence is built on state-of-the-art Amada and Bystronic equipment, coupled with deep material science expertise across automotive-grade steels, aluminum alloys, and specialty metals. Our engineering team collaborates closely with clients during DFM analysis to optimize designs for manufacturability, cost-efficiency, and structural integrity right from the prototyping phase through low-volume production. This proactive approach minimizes delays and costly revisions downstream.

Honyo Sheet Metal Fabrication Capabilities Summary

| Process | Key Specifications | Automotive Relevance |

|———————–|———————————————|————————————|

| Laser Cutting | Up to 1″ thick, ±0.005″ tolerance | Complex bracket profiles, flanges |

| CNC Punching | High-speed nests, multiple hit configurations | Ventilation panels, mounting plates |

| Precision Bending | Up to 20′ bed length, ±1° angular tolerance | Structural frames, chassis supports |

| Secondary Operations | Welding (TIG/MIG), tapping, hardware insertion | Complete sub-assemblies |

Accelerate your automotive development cycle with Honyo’s Online Instant Quote system. Upload your STEP, DWG, or DXF files directly to our platform and receive a detailed, transparent cost analysis and lead time estimate within minutes – not days. This immediate visibility into manufacturability and pricing empowers your engineering and procurement teams to make faster, data-driven decisions without waiting for manual RFQ processing. Experience the efficiency of Honyo’s precision sheet metal fabrication, designed to meet the automotive industry’s highest standards while streamlining your path from concept to production.

Technical Capabilities

Auto sheet metal fabrication involves the automated processing of sheet materials through laser cutting, bending, and welding operations to produce precision components efficiently and consistently. Below are the technical specifications relevant to each process, including compatible materials such as Aluminum, Steel, ABS, and Nylon.

| Process | Technology Type | Thickness Range | Tolerance | Power/Force Requirements | Material Compatibility | Notes |

|---|---|---|---|---|---|---|

| Laser Cutting | Fiber Laser / CO₂ Laser | 0.5 mm – 25 mm | ±0.1 mm | 1 kW – 6 kW (fiber) | Aluminum, Steel, ABS (limited), Nylon (limited, not recommended for standard cutting) | ABS and Nylon are thermoplastics; prone to melting and edge degradation. Use only with controlled parameters and ventilation. |

| Bending | CNC Press Brake (Automated) | 0.8 mm – 12 mm | ±0.2° angular, ±0.1 mm linear | 30 – 300 tons (depending on bed length and material) | Aluminum, Steel (cold-rolled, stainless, galvanized) | ABS and Nylon are generally not suitable for CNC bending due to low stiffness and memory retention. |

| Welding | Robotic MIG/TIG or Laser Welding | 0.6 mm – 15 mm | ±0.5 mm joint alignment | 150 – 300 A (MIG/TIG), 1–4 kW (laser) | Aluminum, Steel (including stainless) | ABS and Nylon cannot be welded using arc or laser methods; use ultrasonic or hot-plate welding for thermoplastics if needed. |

Material Notes:

Aluminum and Steel are primary candidates for automated sheet metal fabrication due to their formability, strength, and weldability. Aluminum grades such as 5052, 6061, and 7075 are commonly used in laser cutting and bending. Steel variants like mild steel, stainless steel (304, 316), and galvanized steel are ideal for all three processes.

ABS and Nylon, while machinable, are not typically processed in standard sheet metal lines. They require specialized handling and are more suited for plastic fabrication techniques such as CNC routing, 3D printing, or thermoforming. Their use in laser cutting is limited due to toxic fumes and poor edge quality, and they are incompatible with high-temperature welding and high-force bending.

From CAD to Part: The Process

Honyo Prototype Auto Sheet Metal Fabrication Workflow

Honyo Prototype delivers rapid, high-precision sheet metal fabrication through a tightly integrated digital workflow designed for engineering efficiency and manufacturing excellence. The process begins with secure CAD file submission via our client portal, supporting native formats including STEP, IGES, DWG, and native CAD system files. All uploads undergo AES-256 encryption with automated version control to ensure design integrity and intellectual property protection throughout the workflow.

AI-Powered Quoting Engine

Upon CAD validation, our proprietary AI engine performs multi-parameter analysis, evaluating geometric complexity, material utilization, fabrication sequence, and secondary operations. This system cross-references real-time material pricing, machine availability, and historical production data to generate a comprehensive quote within 15 minutes. The output includes cost breakdowns by operation, material waste metrics, and lead time projections—all validated against our ISO 9001-certified production database to eliminate estimation errors common in legacy quoting systems.

Engineer-Validated DFM Analysis

Every job enters our Digital DFM (Design for Manufacturability) phase where AI-identified constraints undergo rigorous review by certified manufacturing engineers. This hybrid approach combines algorithmic speed with human expertise to resolve issues like minimum bend radii, hole-to-edge spacing, and feature interference. Clients receive an interactive DFM report within 2 business hours, highlighting actionable recommendations with 3D visualizations. Crucially, Honyo’s engineers implement tactical adjustments—such as nest optimization or process sequencing—without requiring client redesign iterations, maintaining the original functional intent while ensuring producibility.

Hybrid Production Execution

Approved designs move to production on our automated cell lines featuring Amada CNC turret presses, Bystronic laser cutters, and Trumpf bending centers. Our MES (Manufacturing Execution System) dynamically allocates jobs based on real-time machine status, material stock, and technician certifications. All critical dimensions undergo in-process CMM verification at defined checkpoints, with statistical process control data logged to the client’s digital twin. Secondary operations including welding, finishing, and assembly occur in climate-controlled clean zones to meet AS9100 aerospace or ISO 13485 medical requirements when specified.

Guaranteed Delivery Framework

Final inspection data is compiled into a cloud-accessible quality dossier including first-article inspection reports and material traceability certificates. Parts ship via our bonded logistics network with real-time GPS tracking and climate-controlled packaging. Honyo guarantees on-time delivery through our capacity-reservation model, where committed machine hours are pre-allocated for prototype runs.

Process Performance Metrics

| Process Phase | Key Activities | Typical Duration | Quality Control Point |

|———————|———————————————|——————|————————————-|

| CAD Upload | Format validation, encryption, version lock | < 15 minutes | File integrity verification |

| AI Quote | Cost modeling, material optimization | < 15 minutes | Database consistency check |

| DFM | Constraint resolution, process planning | 2-4 business hours | Engineer sign-off on recommendations |

| Production | Cutting, forming, secondary operations | 3-5 business days | In-process CMM + SPC monitoring |

| Delivery | Final inspection, packaging, shipment | 1 business day | Client-accessible quality dossier |

This workflow reduces time-to-part by 65% compared to traditional vendors while maintaining first-pass yield rates above 99.2%. The integration of AI-driven logistics with human engineering oversight ensures scalability from one-off prototypes to low-volume production without compromising precision or accountability. Clients receive full digital thread visibility from CAD submission through delivery, enabling seamless iteration for next-generation designs.

Start Your Project

Looking for precision auto sheet metal fabrication? Partner with Honyo Prototype for high-quality, scalable manufacturing solutions tailored to the automotive industry. Our Shenzhen-based factory combines advanced technology with strict quality control to deliver consistent, reliable results.

Contact Susan Leo today at [email protected] to discuss your project requirements and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.