Introduction: Navigating the Global Market for auto parts and machine

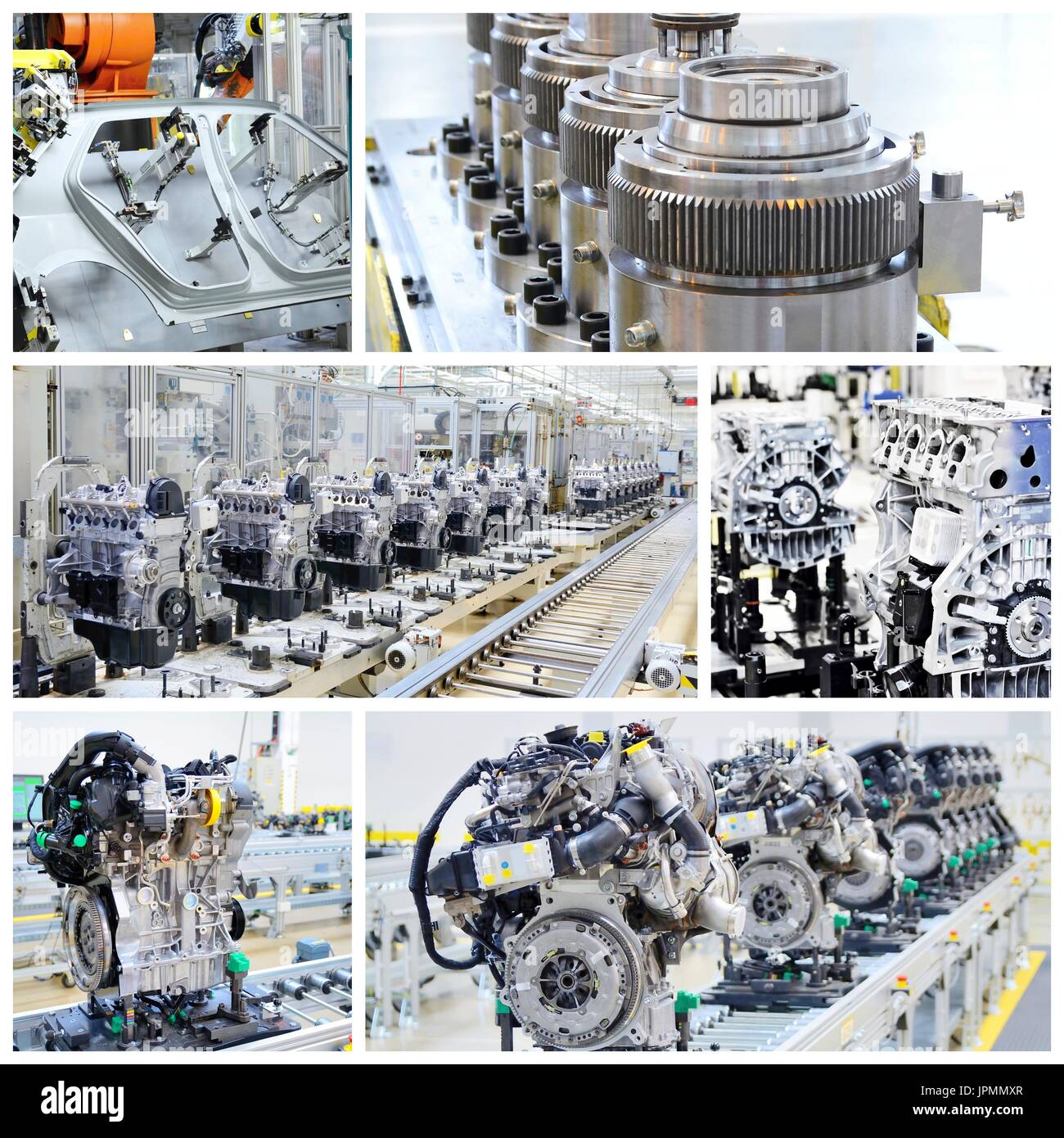

Navigating the global market for auto parts and machine services presents a unique set of challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Sourcing reliable and high-quality auto parts is not merely about finding the lowest price; it involves understanding regional supply chains, compliance with local regulations, and the intricacies of logistics. This guide aims to equip international buyers with the knowledge needed to make informed purchasing decisions, covering essential aspects such as types of auto parts, applications across various industries, supplier vetting processes, and cost considerations.

In today’s fast-paced automotive market, the demand for precision-engineered components is rising. Buyers must be adept at evaluating the capabilities of machine shops, ensuring they can meet specific requirements for both standard and custom parts. This guide provides a comprehensive overview of the services offered by machine shops, including engine rebuilds, machining services, and specialty repairs, allowing buyers to identify and connect with the right suppliers.

By leveraging the insights presented in this guide, B2B buyers will be empowered to navigate the complexities of the auto parts and machine marketplace confidently. Whether you are looking to establish partnerships with reliable suppliers or seeking innovative solutions to enhance your product offerings, this resource serves as a vital tool in your procurement strategy.

Understanding auto parts and machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engine Components | Includes pistons, crankshafts, cylinder heads | Engine rebuilds, custom builds | Pros: High performance, essential for repairs. Cons: Can be costly and require precise matching. |

| Machine Shop Services | Services like boring, resurfacing, welding | Engine repair, custom fabrication | Pros: Tailored solutions, expert craftsmanship. Cons: May have longer lead times due to custom work. |

| Aftermarket Parts | Replacement parts not made by original manufacturers | Vehicle repairs, upgrades | Pros: Often more affordable, wide variety. Cons: Quality can vary significantly between suppliers. |

| Performance Parts | Upgraded components for enhanced vehicle performance | Racing, high-performance vehicles | Pros: Increased power and efficiency. Cons: May require additional modifications. |

| Heavy-Duty Components | Designed for trucks and industrial vehicles | Commercial fleets, heavy machinery | Pros: Built to withstand extreme conditions. Cons: Heavier and may reduce fuel efficiency. |

What Are Engine Components and Their Importance in B2B Purchases?

Engine components are critical parts of an automotive engine, including pistons, crankshafts, and cylinder heads. These components are essential for the engine’s functionality and performance. B2B buyers should consider the compatibility of these parts with existing engines, as precise matching is crucial for optimal performance. Additionally, the quality of materials used can impact longevity and performance, making it essential to source these parts from reputable suppliers.

How Do Machine Shop Services Enhance Automotive Repair Capabilities?

Machine shop services encompass a range of specialized operations, including engine boring, resurfacing, and welding. These services allow for the repair and customization of engine components, enabling businesses to offer tailored solutions to their clients. B2B buyers should evaluate the expertise of the machine shop, turnaround times, and the technology used to ensure high-quality results. These services can significantly enhance repair capabilities, making them a valuable asset for automotive businesses.

What Should Buyers Know About Aftermarket Parts?

Aftermarket parts are replacement components manufactured by third-party companies rather than the original equipment manufacturer (OEM). They offer a cost-effective alternative for businesses looking to maintain or repair vehicles. However, buyers should be cautious, as the quality of aftermarket parts can vary widely. It’s essential to conduct thorough research on suppliers and consider factors such as warranty options and customer reviews to ensure reliability and performance.

What Are Performance Parts and Their Role in Automotive Upgrades?

Performance parts are designed to enhance the speed, handling, and overall efficiency of vehicles, particularly in racing and high-performance applications. These components can include upgraded exhaust systems, turbochargers, and suspension kits. For B2B buyers, investing in performance parts can provide a competitive edge in the market, but careful consideration of compatibility and necessary modifications is crucial to avoid issues during installation.

Why Are Heavy-Duty Components Essential for Commercial Applications?

Heavy-duty components are specifically engineered for trucks and industrial vehicles, designed to withstand demanding conditions. These parts are vital for businesses operating commercial fleets or heavy machinery, as they contribute to durability and reliability. When purchasing heavy-duty components, B2B buyers should assess the specifications, load ratings, and manufacturer reputation to ensure they meet the rigorous demands of their applications.

Key Industrial Applications of auto parts and machine

| Industry/Sector | Specific Application of auto parts and machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Precision machining of engine components | Improved engine performance and reliability | Quality certifications, machinery capabilities, and lead times |

| Heavy-Duty Transportation | Custom engine rebuilds for trucks and machinery | Enhanced durability and reduced maintenance costs | Availability of specialized parts and skilled labor |

| Agricultural Equipment | Reconditioning of tractor engines and components | Increased productivity and reduced downtime | Local regulations, part compatibility, and service support |

| Construction & Mining | Heavy machinery parts manufacturing and repair | Extended equipment lifespan and operational efficiency | Material sourcing, engineering expertise, and turnaround times |

| Renewable Energy | Parts for wind turbine gearboxes and other machinery | Sustainability and compliance with environmental standards | Technical specifications, supply chain reliability, and cost-effectiveness |

How is Auto Parts and Machine Used in Automotive Manufacturing?

In the automotive manufacturing sector, precision machining of engine components is critical. Businesses rely on high-quality auto parts to ensure optimal engine performance and reliability. This involves processes such as CNC machining, where components like crankshafts and cylinder heads are manufactured to exact specifications. For international buyers, particularly from regions like Africa and South America, it’s essential to source parts from suppliers with quality certifications and robust machinery capabilities to meet stringent performance standards.

What Role Does Auto Parts and Machine Play in Heavy-Duty Transportation?

In heavy-duty transportation, custom engine rebuilds for trucks and machinery are vital for maintaining operational efficiency. Companies often face challenges with engine wear and tear, leading to costly downtimes. By utilizing precision auto parts and machine services, businesses can enhance the durability of their vehicles while significantly reducing maintenance costs. Buyers should consider the availability of specialized parts and the expertise of the labor force when sourcing these services, ensuring they can meet the demands of their fleet.

How is Auto Parts and Machine Applied in Agricultural Equipment?

The agricultural sector frequently requires the reconditioning of tractor engines and components to maintain productivity. Aging machinery can lead to decreased efficiency and increased downtime, impacting overall yield. By sourcing high-quality auto parts and machine services, agricultural businesses can enhance the performance of their equipment. Buyers should be aware of local regulations regarding agricultural machinery, as well as part compatibility and the availability of service support when sourcing these solutions.

What is the Importance of Auto Parts and Machine in Construction & Mining?

In construction and mining industries, the manufacturing and repair of heavy machinery parts are essential for maintaining productivity. These sectors often face challenges related to equipment breakdowns, which can halt operations and incur significant costs. Utilizing auto parts and machine services can extend the lifespan of machinery and improve operational efficiency. Buyers need to focus on material sourcing, engineering expertise, and turnaround times to ensure they receive reliable and timely service.

How is Auto Parts and Machine Used in Renewable Energy?

The renewable energy sector, particularly in wind energy, relies on auto parts and machine services for manufacturing parts like gearboxes for wind turbines. These components must meet strict environmental and performance standards to ensure sustainability. Businesses benefit from sourcing high-quality parts that comply with these regulations, thereby enhancing their operational efficiency and reducing environmental impact. Buyers should consider technical specifications, supply chain reliability, and cost-effectiveness when sourcing these critical components.

3 Common User Pain Points for ‘auto parts and machine’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Auto Parts Efficiently

The Problem:

B2B buyers often struggle with finding reliable suppliers for high-quality auto parts, particularly when dealing with specialized or rare components. This is especially true for businesses operating in regions with limited access to established supply chains, such as parts of Africa or South America. Buyers may face long lead times, inconsistent product quality, or inflated pricing due to a lack of competition. These challenges can lead to costly delays in repairs or production, affecting customer satisfaction and overall business performance.

The Solution:

To overcome sourcing difficulties, B2B buyers should leverage digital platforms that specialize in auto parts procurement. These platforms often provide comprehensive catalogs, supplier ratings, and customer reviews to help buyers make informed decisions. Additionally, establishing relationships with multiple suppliers can create a competitive landscape that drives better pricing and quality. Buyers are encouraged to negotiate terms that include guarantees on parts quality and delivery times. Engaging with suppliers who offer drop-shipping services can also minimize inventory costs and streamline logistics.

Scenario 2: Inconsistent Quality of Machine Shop Services

The Problem:

Inconsistent quality from machine shop services can be a significant pain point for B2B buyers who rely on precision machining for their operations. Whether it’s for engine rebuilds, custom parts fabrication, or heavy-duty services, variations in craftsmanship can lead to operational inefficiencies. Poorly machined parts can result in equipment failures, increased downtime, and higher costs associated with rework or replacement. This inconsistency is often exacerbated by varying standards of service and equipment across different machine shops.

The Solution:

To ensure high-quality machine shop services, buyers should conduct thorough due diligence before selecting a provider. This includes visiting the shop to evaluate their equipment, checking certifications, and reviewing past work. Establishing clear specifications and expectations upfront can mitigate misunderstandings. Furthermore, implementing a quality assurance process that includes regular inspections and performance evaluations can help maintain standards over time. Buyers might also consider forming partnerships with a select few trusted machine shops to foster loyalty and improve service consistency.

Scenario 3: Navigating Complex Regulations and Compliance Issues

The Problem:

B2B buyers in the auto parts and machine sector often face complex regulations and compliance issues, particularly when importing parts or machinery from different countries. Different regions, such as Europe and the Middle East, have stringent standards regarding emissions, safety, and material quality. Navigating these regulations can be daunting, leading to potential legal issues, fines, and disruptions in supply chains. Buyers may also encounter challenges in ensuring that their suppliers comply with local and international standards.

The Solution:

To navigate regulatory complexities effectively, buyers should stay informed about the regulations that apply to their specific markets. This can involve subscribing to industry publications, attending relevant trade shows, or consulting with legal experts who specialize in trade compliance. Building relationships with suppliers who have a proven track record of regulatory compliance is essential. Buyers should request documentation and certifications that verify compliance with local and international standards. Utilizing third-party inspection services can also provide an additional layer of assurance that products meet required specifications before they are imported or utilized in production.

Strategic Material Selection Guide for auto parts and machine

What Are the Key Materials Used in Auto Parts and Machines?

In the manufacturing of auto parts and machines, material selection is critical to ensuring performance, durability, and cost-effectiveness. Below, we analyze four common materials used in this sector, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Steel Perform as a Material for Auto Parts?

Steel is one of the most widely used materials in the automotive industry due to its excellent strength-to-weight ratio and versatility. Key properties include high tensile strength, good ductility, and the ability to withstand high temperatures and pressures. However, steel is prone to corrosion, which can be mitigated through coatings or alloying with other elements.

Pros: Steel is durable, relatively inexpensive, and can be easily machined. It is suitable for a wide range of applications, from structural components to engine parts.

Cons: The main limitation is its susceptibility to corrosion, which can lead to premature failure if not properly treated. Additionally, manufacturing complexity can increase when using high-strength steels.

For international buyers, compliance with standards such as ASTM (American Society for Testing and Materials) and DIN (Deutsches Institut für Normung) is essential. Buyers should also consider local availability and the impact of shipping costs on overall expenses.

What Role Does Aluminum Play in Auto Parts Manufacturing?

Aluminum is favored for its lightweight properties and resistance to corrosion, making it ideal for applications where weight reduction is crucial, such as in engine components and body panels. Key properties include good thermal conductivity and excellent corrosion resistance.

Pros: Aluminum’s lightweight nature contributes to improved fuel efficiency in vehicles. It is also highly recyclable, which can appeal to environmentally conscious buyers.

Cons: The primary disadvantage is its lower strength compared to steel, which can limit its application in high-stress components. Additionally, aluminum can be more expensive than steel, impacting overall production costs.

International buyers should be aware of the common standards for aluminum alloys, such as JIS (Japanese Industrial Standards) and EN (European Norms). Understanding local recycling regulations can also be beneficial, especially in regions prioritizing sustainability.

Why Is Cast Iron a Preferred Material for Engine Components?

Cast iron is renowned for its excellent wear resistance and ability to withstand high temperatures, making it a popular choice for engine blocks and cylinder heads. Key properties include high compressive strength and good machinability.

Pros: Cast iron is highly durable and can absorb vibrations, contributing to a smoother operation. It is also cost-effective for large-scale production.

Cons: The main limitation is its brittleness, which can lead to cracking under certain conditions. Additionally, cast iron is heavier than alternatives like aluminum, which may not be suitable for all applications.

For international buyers, understanding the specific grades of cast iron and their compliance with standards such as ASTM or ISO is crucial. Buyers should also consider the logistics of sourcing cast iron, as it may vary significantly by region.

How Does Composite Material Fit into the Auto Parts Sector?

Composite materials, often a combination of fibers and resins, are increasingly being used in automotive applications due to their lightweight and high-strength properties. Key properties include excellent fatigue resistance and the ability to be molded into complex shapes.

Pros: Composites can significantly reduce vehicle weight, leading to improved fuel efficiency. They also offer excellent corrosion resistance and can be tailored for specific applications.

Cons: The primary downside is the higher manufacturing cost and complexity associated with production. Additionally, composite materials can be more challenging to recycle compared to metals.

International buyers should consider the specific manufacturing standards for composites, which can vary widely across regions. Understanding local regulations regarding the use of composites in automotive applications is also essential.

Summary Table of Material Selection for Auto Parts and Machines

| Material | Typical Use Case for auto parts and machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, engine parts | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Engine components, body panels | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Cast Iron | Engine blocks, cylinder heads | Excellent wear resistance | Brittle and heavy | Medium |

| Composite | Lightweight components, complex shapes | Reduces weight and excellent fatigue resistance | Higher cost and recycling challenges | High |

This guide provides a comprehensive overview of material selection for auto parts and machines, enabling international B2B buyers to make informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for auto parts and machine

What Are the Main Stages of Manufacturing Auto Parts and Machines?

The manufacturing process for auto parts and machines is intricate and involves several critical stages. Understanding these stages can help B2B buyers evaluate suppliers effectively.

Material Preparation: What Materials Are Used?

The first stage in the manufacturing process is material preparation. High-quality raw materials are essential for producing durable and reliable auto parts. Common materials include metals such as steel and aluminum, plastics, and composites. Suppliers often source these materials from certified vendors to ensure compliance with international standards.

Before manufacturing begins, materials undergo thorough inspection and testing. This includes checking for material properties such as tensile strength, hardness, and corrosion resistance. B2B buyers should inquire about the suppliers’ material sourcing and quality certifications to ensure they meet industry standards.

How Are Auto Parts Formed?

Once materials are prepared, the next step is forming. Various techniques are employed based on the part’s design and specifications. Common forming processes include:

- Casting: Molten metal is poured into molds to create complex shapes.

- Forging: Metal is shaped by applying compressive forces, enhancing its strength.

- Machining: Precision cutting processes, such as turning and milling, are used to achieve exact dimensions.

- Stamping: Sheet metal is cut and shaped using dies, often employed for high-volume production.

These techniques are crucial for achieving the required tolerances and surface finishes. B2B buyers should ask suppliers about their forming capabilities and technology to ensure they can meet specific needs.

What Is the Assembly Process Like for Auto Parts?

After forming, parts are assembled into final products. This stage may involve welding, fastening, or adhesive bonding. The assembly process is critical for ensuring that parts fit together correctly and function as intended.

Suppliers often employ automation and robotic systems to enhance precision and reduce labor costs during assembly. B2B buyers should assess a supplier’s assembly capabilities, including their ability to handle complex assemblies or modular designs.

How Are Auto Parts Finished?

Finishing is the final stage of the manufacturing process and involves surface treatments to enhance aesthetics, durability, and performance. Common finishing techniques include:

- Coating: Applying paints, powders, or platings to protect against corrosion and improve appearance.

- Heat Treatment: Altering the material’s properties to increase hardness and wear resistance.

- Polishing: Smoothing surfaces to reduce friction and enhance visual appeal.

B2B buyers should inquire about the finishing processes used by suppliers, as these can significantly impact the longevity and performance of auto parts.

What Quality Assurance Measures Are Common in Auto Parts Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of auto parts to ensure that products meet industry standards and customer expectations. B2B buyers should familiarize themselves with relevant quality assurance practices.

Which International Standards Should B2B Buyers Consider?

International standards play a vital role in quality assurance. ISO 9001 is one of the most recognized standards, focusing on quality management systems. Compliance with ISO 9001 ensures that suppliers have established processes for continuous improvement and customer satisfaction.

Additionally, industry-specific certifications may be relevant, such as CE marking for products sold in the European market or API certification for oil and gas equipment. B2B buyers should verify that their suppliers hold the necessary certifications to facilitate international trade.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints during the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted during production to identify and rectify defects early.

- Final Quality Control (FQC): Finished products undergo comprehensive testing and inspection before shipment.

Implementing these checkpoints helps suppliers maintain high-quality standards throughout production. B2B buyers should inquire about a supplier’s QC processes and how they manage inspections.

What Testing Methods Are Commonly Used?

Various testing methods are employed to ensure the quality and performance of auto parts. These include:

- Dimensional Inspection: Verifying that parts meet specified dimensions using tools like calipers and gauges.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic, magnetic particle, and dye penetrant testing are used to detect internal flaws without damaging the part.

- Performance Testing: Parts are subjected to operational conditions to assess their performance and durability.

B2B buyers should ask suppliers about their testing methodologies and the equipment used to ensure compliance with industry standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is essential for building trust and ensuring product quality. Here are several strategies to consider:

What Role Do Audits and Reports Play?

Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality management systems. Audits can be performed by the buyer or third-party organizations to assess compliance with standards such as ISO 9001.

Requesting quality assurance reports from suppliers can also provide valuable information. These reports often outline testing results, inspection records, and compliance with industry standards. B2B buyers should prioritize suppliers who are transparent about their QA practices.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can further enhance confidence in supplier quality. These independent organizations can conduct comprehensive evaluations of manufacturing processes, QC checkpoints, and testing methods. This impartial assessment can help mitigate risks associated with international sourcing.

B2B buyers should consider including third-party inspections as part of their procurement strategy, especially for high-value or critical components.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, may face unique challenges in quality control. Understanding these nuances can facilitate smoother transactions.

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying quality standards and regulatory requirements. For example, European markets have stringent regulations regarding product safety and environmental impact. B2B buyers should be aware of these regional differences and ensure that their suppliers comply with local standards.

What Should Buyers Know About Cultural Differences?

Cultural differences can also impact communication and expectations related to quality control. Building strong relationships with suppliers through clear communication and understanding of local business practices can help mitigate misunderstandings and ensure that quality expectations are met.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers in the auto parts and machine industry. By focusing on material preparation, forming, assembly, finishing, and quality control, buyers can make informed decisions and establish successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto parts and machine’

In the competitive landscape of auto parts and machinery sourcing, a structured approach is essential for B2B buyers. This guide offers a practical checklist designed to streamline the procurement process, ensuring that you partner with reliable suppliers who meet your technical requirements and business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of effective sourcing. This includes identifying the exact type of auto parts or machine services you require, such as engine components, precision machining, or custom fabrication. Detailed specifications help in communicating your needs to potential suppliers, ensuring they understand your requirements fully.

- Considerations:

- Material types and grades

- Required dimensions and tolerances

- Performance standards and certifications

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify potential suppliers who specialize in the auto parts and machine sector. Utilize industry directories, trade shows, and online marketplaces to compile a list of candidates. This step is crucial to ensure you have a range of options to evaluate.

- Sources to Explore:

- Trade associations and industry networks

- Online supplier directories

- Recommendations from industry peers

Step 3: Evaluate Supplier Certifications

Before moving forward, verify the certifications of potential suppliers. Certifications like ISO 9001 or specific automotive industry standards indicate a commitment to quality and reliability. This step is essential to mitigate risks associated with poor-quality parts or services.

- Key Certifications to Look For:

- ISO 9001 for quality management

- IATF 16949 for automotive quality

- Local regulatory compliance certifications

Step 4: Request Quotes and Compare Pricing

Once you have narrowed down your options, request detailed quotes from your shortlisted suppliers. Comparing pricing is not just about finding the lowest cost; it also involves assessing the value offered in terms of quality, delivery timelines, and after-sales support.

- Comparison Factors:

- Unit costs and bulk order discounts

- Terms of payment and delivery schedules

- Warranty and return policies

Step 5: Conduct Supplier Visits or Audits

If possible, visit the suppliers’ facilities or conduct virtual audits. This firsthand observation allows you to assess their operational capabilities, quality control processes, and overall professionalism. A site visit can reveal insights that are not apparent through documentation alone.

- What to Look For:

- Equipment and technology used

- Cleanliness and organization of the workspace

- Employee expertise and training programs

Step 6: Review Customer Feedback and References

Gather feedback from previous clients to gauge the supplier’s reliability and service quality. Reach out to references provided by the supplier, focusing on their experiences regarding delivery, quality, and customer support. This step can help you avoid potential pitfalls and ensure a smooth partnership.

- Questions to Ask:

- Were the parts delivered on time?

- How responsive was the supplier to issues?

- Would you work with them again?

Step 7: Establish Clear Contracts and Terms

Once you’ve selected a supplier, draft a clear contract outlining all terms and conditions. This should include delivery schedules, payment terms, quality expectations, and dispute resolution procedures. A well-defined contract protects both parties and sets expectations for the partnership.

- Contract Elements to Include:

- Scope of work and specifications

- Penalties for non-compliance

- Termination clauses and renewal terms

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing auto parts and machine services effectively, ensuring that they partner with reputable suppliers who meet their specific needs.

Comprehensive Cost and Pricing Analysis for auto parts and machine Sourcing

What Are the Key Cost Components in Auto Parts and Machine Sourcing?

When evaluating the costs associated with sourcing auto parts and machine services, understanding the various components that contribute to the overall cost structure is essential. The primary cost components include:

-

Materials: The cost of raw materials is often the largest portion of the total expense. Prices can fluctuate based on market demand, availability, and quality. For instance, high-performance auto parts may require specialized materials, increasing costs.

-

Labor: Skilled labor is crucial in machining and assembling auto parts. Labor costs can vary significantly based on the region, expertise required, and local wage standards. In regions like Europe, labor costs tend to be higher, influencing pricing strategies.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses incurred during production. Efficient overhead management can directly impact pricing competitiveness.

-

Tooling: The initial investment in machinery and tools is significant, especially for custom parts. Tooling costs are amortized over production runs, so larger orders can reduce the per-unit cost.

-

Quality Control (QC): Ensuring that parts meet strict quality standards incurs additional costs. Rigorous QC processes are essential, especially for international buyers who require certifications and compliance with local regulations.

-

Logistics: Transporting parts from suppliers to buyers involves freight costs, insurance, and handling fees. These expenses can vary widely depending on the shipping method and distance.

-

Margin: Suppliers typically add a profit margin to cover their risks and ensure business sustainability. Understanding the margin expectations in your market can aid in negotiations.

How Do Price Influencers Affect Auto Parts and Machine Pricing?

Several factors can influence the pricing of auto parts and machine services:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Establishing a strong relationship with suppliers can help in negotiating favorable terms for larger orders.

-

Specifications and Customization: Customized parts generally come at a premium due to the additional design and manufacturing complexities. Be clear about your specifications to avoid unexpected costs.

-

Materials: The choice of materials not only affects durability but also cost. Higher quality materials can lead to higher upfront costs but may reduce long-term maintenance expenses.

-

Quality and Certifications: Suppliers offering certified products may charge more due to the costs associated with obtaining and maintaining these certifications. International buyers should verify the relevance of these certifications in their local markets.

-

Supplier Factors: The supplier’s reputation, location, and capacity can all influence pricing. Established suppliers may command higher prices due to their proven reliability and quality.

-

Incoterms: Understanding the shipping terms outlined in Incoterms is critical. These terms define the responsibilities of buyers and sellers, impacting total costs.

What Are the Best Buyer Tips for Cost-Efficient Auto Parts Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate: Always negotiate prices and terms. Suppliers may have some flexibility, especially for larger orders or long-term contracts.

-

Consider Total Cost of Ownership (TCO): TCO goes beyond the initial purchase price. Assess maintenance, operational, and disposal costs when evaluating parts.

-

Understand Pricing Nuances: Be aware that pricing can vary significantly by region. For example, European suppliers may offer higher quality but at a premium price. Understanding local market dynamics can aid in making informed decisions.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and access to exclusive deals.

-

Stay Informed: Keep abreast of market trends, material costs, and technological advancements. This knowledge can provide leverage in negotiations and sourcing decisions.

Disclaimer on Indicative Prices

Pricing for auto parts and machine services can vary widely based on numerous factors, including market conditions, supplier pricing strategies, and specific buyer requirements. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure the best value.

Alternatives Analysis: Comparing auto parts and machine With Other Solutions

Introduction to Alternative Solutions in Auto Parts and Machinery

In the competitive landscape of automotive and machinery solutions, international B2B buyers are often faced with a variety of options. While traditional auto parts and machine services provide crucial support for vehicle maintenance and performance enhancement, several alternatives are available that may offer unique advantages depending on specific operational needs. Understanding these alternatives is essential for making informed purchasing decisions that align with business objectives.

Comparison Table

| Comparison Aspect | Auto Parts And Machine | 3D Printing of Auto Parts | Remanufactured Parts |

|---|---|---|---|

| Performance | High-quality, precision work | Variable; depends on printer quality | Comparable to new parts |

| Cost | Moderate to high | Potentially lower for small runs | Generally lower than new parts |

| Ease of Implementation | Requires skilled labor | Requires technical knowledge | Easier; often available off-the-shelf |

| Maintenance | Regular upkeep needed | Minimal; depends on design | May require periodic checks |

| Best Use Case | Custom builds and repairs | Prototyping and small-batch production | Cost-effective replacements |

Detailed Breakdown of Alternatives

1. 3D Printing of Auto Parts

3D printing technology has emerged as a viable alternative for manufacturing auto parts, particularly for prototypes and small-scale production runs. The main advantage of this method is its ability to create complex geometries that traditional manufacturing may not easily achieve. However, the performance can vary significantly based on the type of printer and materials used, leading to inconsistent quality. Additionally, while the initial setup costs can be high, the cost per unit decreases with larger production runs, making it an economically attractive option in some cases.

2. Remanufactured Parts

Remanufactured parts are another alternative that provides a cost-effective solution for businesses looking to minimize expenses without sacrificing quality. These parts undergo a thorough refurbishment process to restore them to like-new condition. The primary benefit is the significant cost savings compared to purchasing brand-new parts. Furthermore, remanufactured parts often come with warranties, providing additional assurance to buyers. However, there may be limitations in availability and specific models, which can impact sourcing flexibility.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating the right solution for auto parts and machinery, B2B buyers must consider their specific operational requirements, budget constraints, and performance expectations. While traditional auto parts and machine services offer reliability and precision, alternatives like 3D printing and remanufactured parts may provide unique advantages in terms of cost and production capabilities. Analyzing the pros and cons of each option can help buyers make informed decisions that enhance their operational efficiency while meeting their financial objectives. Ultimately, the best choice will depend on the particular needs of the business, including the scale of operations, the complexity of required parts, and long-term strategic goals.

Essential Technical Properties and Trade Terminology for auto parts and machine

What Are the Critical Technical Properties in Auto Parts and Machinery?

Understanding the technical specifications of auto parts and machinery is crucial for B2B buyers, especially when sourcing components for various applications. Here are some essential properties to consider:

1. Material Grade

Material grade refers to the classification of materials based on their mechanical properties and chemical composition. Common grades include stainless steel, carbon steel, and aluminum. For B2B buyers, selecting the appropriate material grade ensures durability, performance, and compliance with industry standards. For instance, high-grade materials are essential in high-stress applications like heavy-duty machinery.

2. Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension. It is critical in manufacturing as it affects the fit and function of parts. In the automotive industry, tight tolerances ensure that components work seamlessly together, reducing the risk of mechanical failure. Understanding tolerance specifications is vital for buyers to ensure that parts meet their operational requirements and quality standards.

3. Surface Finish

Surface finish describes the texture and smoothness of a component’s surface. It can affect friction, wear, and the overall performance of parts. A smoother surface finish can enhance performance in applications requiring high precision, such as engine components. Buyers should consider the required surface finish for their applications to improve efficiency and longevity.

4. Load Capacity

Load capacity refers to the maximum weight a component can support without failure. This specification is particularly important for parts like bearings, shafts, and suspension components. For B2B buyers, understanding the load capacity ensures that the selected parts can handle the demands of their specific applications, thereby preventing costly breakdowns or failures.

5. Heat Treatment

Heat treatment involves controlled heating and cooling processes that alter the physical and sometimes chemical properties of materials. This process is used to enhance hardness, strength, and resistance to wear. B2B buyers should be aware of heat treatment processes that might be necessary for certain components, especially those subjected to high temperatures or heavy use.

What Are Common Trade Terms Used in Auto Parts and Machinery?

Familiarity with industry jargon can significantly enhance communication and negotiation in B2B transactions. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold under another company’s brand. For B2B buyers, sourcing OEM parts is often synonymous with quality and reliability, as these parts meet the specifications set by the original manufacturer of the vehicle or machinery.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it impacts inventory management and procurement strategies. Buyers should negotiate MOQs to align with their operational needs and financial constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. It is a critical step in the procurement process, enabling buyers to compare prices and terms from different suppliers. Crafting a comprehensive RFQ can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. They clarify aspects such as shipping costs, risk, and delivery responsibilities. Understanding Incoterms is vital for B2B buyers engaged in international sourcing, as they help mitigate risks and ensure smooth logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. It is a critical factor in supply chain management. B2B buyers should consider lead times when planning inventory to avoid production delays and ensure timely project execution.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, streamline procurement processes, and build effective partnerships in the auto parts and machinery sectors.

Navigating Market Dynamics and Sourcing Trends in the auto parts and machine Sector

What Are the Key Market Dynamics and Trends Influencing the Auto Parts and Machine Sector?

The auto parts and machine sector is currently experiencing significant transformation driven by globalization, technological advancements, and changing consumer demands. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can offer not just quality products but also innovative solutions. One notable trend is the rise of e-commerce platforms that facilitate easier access to parts and machinery, enabling buyers to compare prices and features more efficiently. Additionally, the integration of artificial intelligence and machine learning in inventory management and supply chain logistics is streamlining operations, reducing lead times, and enhancing customer service.

Another critical driver is the growing demand for high-performance and specialized auto parts, particularly in regions with a strong automotive culture, such as Germany and Brazil. This trend is complemented by the increasing popularity of customization and performance tuning among consumers, which has led to a surge in demand for precision-engineered components. Furthermore, the shift towards electric vehicles (EVs) is reshaping sourcing strategies, as buyers seek suppliers who can provide innovative parts compatible with EV technology.

How Are Sustainability and Ethical Sourcing Impacting the Auto Parts and Machine Sector?

Sustainability and ethical sourcing have become paramount concerns for B2B buyers in the auto parts and machine sector. The environmental impact of production processes, particularly in manufacturing and logistics, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon footprints and utilizing recycled materials. This trend is particularly strong among European buyers, where regulations around environmental impact are stringent.

Moreover, ethical sourcing is gaining traction as consumers demand transparency in supply chains. B2B buyers are looking for partners who can provide certifications that prove adherence to ethical labor practices and environmental standards. Green certifications, such as ISO 14001 for environmental management and LEED for energy-efficient manufacturing, are becoming essential for suppliers aiming to attract international clients. As a result, buyers can mitigate risks associated with poor practices while enhancing their brand reputation through responsible sourcing.

What Is the Historical Context of the Auto Parts and Machine Sector for B2B Buyers?

The auto parts and machine sector has evolved significantly over the decades, transitioning from a fragmented and localized market to a globalized industry characterized by complex supply chains. Initially dominated by regional manufacturers, the sector has seen the rise of multinational corporations that leverage economies of scale and advanced technologies. This evolution has enabled B2B buyers to access a wider array of products and services, enhancing competition and driving innovation.

In the past, sourcing was often limited to local suppliers, which restricted options and increased costs. However, with the advent of global trade agreements and advancements in logistics, international sourcing has become commonplace. This shift has empowered buyers to seek the best quality at competitive prices, fostering an environment where quality assurance and supplier reliability are critical factors in the procurement process. Today, the emphasis is on strategic partnerships that not only meet immediate needs but also align with long-term goals in sustainability and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of auto parts and machine

-

How do I select the right auto parts supplier for my business needs?

When choosing an auto parts supplier, prioritize those with a strong reputation in your target market. Look for suppliers who have experience in international trade and understand the specific regulations and certifications required in your region. Request references and reviews from other B2B clients, and ensure they offer a wide range of parts that suit your business needs. Additionally, consider their logistics capabilities, including shipping times and costs, to ensure they can meet your supply chain demands. -

What are the key factors to consider when vetting an international auto parts supplier?

Key factors include the supplier’s reliability, quality control measures, and compliance with international standards. Evaluate their production capacity and lead times to ensure they can meet your order volumes. It’s also essential to assess their communication skills and responsiveness, as these are critical for resolving any issues that may arise. Finally, verify their payment terms and conditions, and consider conducting a background check to ensure they have a solid financial standing. -

What customization options are available for auto parts?

Many suppliers offer customization options tailored to specific vehicle models or performance requirements. Common customizations include machining parts to specific tolerances, modifying engine components for enhanced performance, or creating bespoke solutions for unique applications. When discussing customization, provide detailed specifications and requirements to ensure the supplier can meet your expectations. Request samples or prototypes when necessary to validate quality before placing larger orders. -

What is the minimum order quantity (MOQ) for auto parts, and why does it matter?

The minimum order quantity (MOQ) varies by supplier and can impact your purchasing strategy. MOQs are often set to ensure cost-effectiveness in manufacturing and logistics. Understanding MOQs is crucial for managing your inventory levels and cash flow. If the MOQ exceeds your immediate needs, discuss potential flexibility with the supplier or consider pooling orders with other businesses to meet the required quantity. -

What payment terms should I expect when sourcing auto parts internationally?

Payment terms can vary widely among suppliers, but common options include upfront payments, net 30/60/90 days, or letters of credit. Be sure to clarify the payment structure before placing an order, as this can affect your cash flow. Some suppliers may offer discounts for early payments or larger orders. Additionally, consider the currency exchange rates and transaction fees associated with international payments, which can impact the overall cost. -

How do I ensure quality assurance when sourcing auto parts?

Implement a rigorous quality assurance (QA) process by establishing clear quality standards and specifications with your supplier. Request certifications such as ISO 9001 or other relevant industry standards to verify their commitment to quality. Consider conducting regular audits or inspections of the supplier’s facilities, or using third-party inspection services to assess product quality before shipment. Maintain open lines of communication for feedback and improvements to ensure ongoing quality compliance. -

What are the logistics considerations when importing auto parts?

Logistics considerations include shipping methods, customs regulations, and import duties. Choose a reliable freight forwarder who understands the complexities of international shipping and can navigate customs processes efficiently. Ensure your supplier provides necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance. Additionally, factor in lead times for production and shipping when planning your inventory management to avoid stockouts. -

How can I handle potential disputes with my auto parts supplier?

To manage disputes effectively, establish clear terms and conditions in your purchase agreements, including clauses on conflict resolution. Maintain thorough documentation of all communications and transactions to support your case if issues arise. If a dispute occurs, engage in open dialogue with the supplier to find a mutually agreeable solution. Consider mediation or arbitration as alternative dispute resolution methods to avoid lengthy legal proceedings, and ensure you understand the local laws governing international trade in your jurisdiction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Auto Parts And Machine Manufacturers & Suppliers List

1. Yelp – Best Certified Auto Machine Shops in NYC

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Best Certified Auto Machine Shops in NYC, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Automotive Parts & Machine – Engine Rebuilding Services

Domain: automachineshop.net

Registered: 2001 (24 years)

Introduction: Automotive Parts & Machine is a complete Automotive Machine Shop in Frederick, MD, owned by Dave Featherstone since 1979. They offer services for any engine, including small lawnmowers, motorcycles, off-road heavy-duty equipment, and stationary engines. Key services include engine rebuilding, milling of heads, turning flywheels, brake drums, rotors, and bearing press work. Specialties include fusi…

3. Colvin Auto Parts – Precision Machine Shop Services

Domain: colvinautoparts.net

Registered: 2011 (14 years)

Introduction: Full-Service Precision Machine Shop Services, Hi-Performance Engine Builds, Heavy-Duty Engine Kits, Boring & Magnafluxing, Crankshaft & Flywheel Grinding, Drive Shaft Building and Balancing, Rod Reconditioning, Heavy Duty Casting Repair, Cylinder Resizing, Cast & Aluminum Cylinder Head Rebuilding.

4. Morningstar Auto Parts – Machine Shop Services

Domain: morningstarautoparts.net

Registered: 2011 (14 years)

Introduction: Machine Shop Services offered by Morningstar Auto Parts include: 1. Bore Engine Block – Re-drilling engine cylinders for better performance. 2. Brake Drum/Rotor Resurfacing – Resurfacing worn brake components as an economical alternative to replacement. 3. Check for Cracked Heads – Inspection for engine head issues that affect performance. 4. Fluid Recycling – Service for recycling used engine flu…

5. Egge Machinery – Piston Sets and Water Pumps

Domain: egge.com

Registered: 1995 (30 years)

Introduction: Egge Machinery Company specializes in manufacturing pistons and water pumps for domestic vehicle applications from the early 1900s to 1980. Key products include:

1. **Piston Sets**:

– Wisconson Industrial Piston Set with Pins – E1221-4: $645.39 (1922-34 Wisconson)

– Egge Piston Set with Pins – L991-8: $509.74 (1949-53 Ford 255 8cyl; Mercury 255 8cyl)

– Egge Piston Set with Pins – L2267-8…

6. Fulton Street Auto Machine Shop – Expert Engine Repair

Domain: fultonstreetautomachineshop.com

Registered: 2015 (10 years)

Introduction: This company, Fulton Street Auto Machine Shop – Expert Engine Repair, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. JAMSI Online – Automotive Engine Parts

Domain: jamsionline.com

Registered: 2018 (7 years)

Introduction: JAMSI Online offers a wide range of automotive engine parts categorized by engine family, including AMC/JEEP, BUICK, CADILLAC, CHEVROLET, and CHRYSLER. Key product categories include: Air and Fuel Intake Manifolds, Camshafts and Valvetrain, Engine Bearings, Engine Covers, Oil Pumps, Pistons, and Gaskets. Specific components include carburetors, fuel pumps, lifters, rocker arms, timing chains, conn…

Strategic Sourcing Conclusion and Outlook for auto parts and machine

In the competitive landscape of auto parts and machine services, strategic sourcing emerges as a pivotal factor for international B2B buyers. By leveraging a global network of suppliers, businesses can access high-quality parts and services tailored to specific needs, ultimately enhancing operational efficiency and reducing costs. Key takeaways highlight the importance of establishing long-term relationships with reliable suppliers, investing in precision machining capabilities, and prioritizing sustainability through practices like fluid recycling and parts cleaning.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for high-performance auto parts and machine services is expected to rise. Forward-thinking companies should focus on integrating innovative sourcing strategies that not only meet current demands but also anticipate future trends in automotive technology and sustainability.

International buyers are encouraged to explore partnerships with established machine shops and parts suppliers that understand local market nuances and can provide tailored solutions. By doing so, businesses can ensure they remain competitive and responsive in an ever-changing landscape. Embrace the opportunities that strategic sourcing presents and position your company for long-term success in the global auto parts market.