Contents

Manufacturing Insight: Austin Cnc

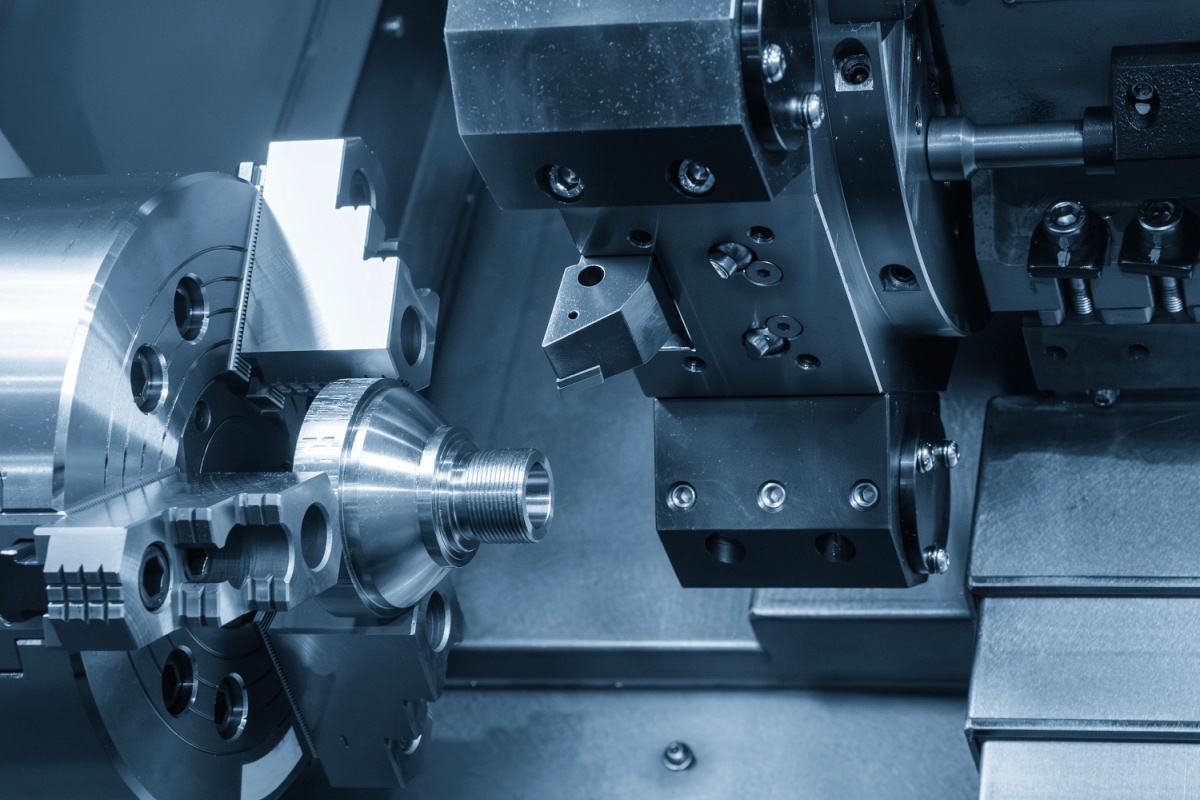

Precision CNC Machining Solutions Engineered for Austin’s Innovation Leaders

Honyo Prototype delivers advanced CNC machining services tailored to meet the demanding requirements of Austin’s aerospace, medical device, and technology sectors. As your dedicated manufacturing partner, we specialize in producing tight-tolerance components with exceptional repeatability, leveraging state-of-the-art 3-, 4-, and 5-axis milling and turning centers. Our ISO 9001:2015 and ITAR-compliant facility ensures rigorous quality control from material certification through final inspection, providing Austin-based engineers with reliable, on-specification parts for prototyping and low-to-mid volume production.

Accelerate your development timeline with Honyo’s Online Instant Quote System—designed specifically for engineering teams prioritizing speed without compromising accuracy. Upload your STEP or IGES file, specify materials and quantities, and receive a detailed manufacturing assessment and competitive pricing within minutes. This transparent, no-obligation platform eliminates traditional RFQ delays, enabling Austin innovators to iterate faster and move confidently from design to physical validation.

Performance Comparison: Honyo vs. Industry Standard Lead Times

| Service Phase | Honyo Prototype | Typical Industry Average |

|---|---|---|

| Quote Generation | < 15 Minutes | 2-5 Business Days |

| Prototype Machining | 3-7 Days | 10-20 Days |

| First Article Inspection | Included | Optional (+3-5 Days) |

Partner with Honyo to resolve complex manufacturability challenges while maintaining the agility Austin’s dynamic market demands. Our engineering team collaborates directly with your designers to optimize for precision, cost, and scalability—ensuring your CNC-machined components perform flawlessly in application. Request your instant quote today and experience the Honyo advantage in responsive, high-integrity manufacturing.

Technical Capabilities

Austin CNC Technical Specifications Overview

Austin CNC systems are engineered for high-precision machining across a range of industrial applications. These machines support 3-axis, 4-axis, and 5-axis milling configurations, as well as multi-axis turning operations, enabling complex geometry production with tight tolerance control. Designed for prototyping and low-to-mid volume production, they deliver consistent accuracy and surface finish across a variety of engineering materials.

| Specification Category | Details |

|---|---|

| Machining Capabilities | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including mill-turn with live tooling) |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.00005″ (±0.0013 mm) |

| Typical Tolerance Range | ±0.001″ (±0.025 mm) standard; tight tolerances down to ±0.0002″ (±0.005 mm) achievable with process control |

| Spindle Speed (Milling) | Up to 24,000 RPM (configurable based on spindle package) |

| Spindle Power (Milling) | 20–40 HP (15–30 kW), depending on model |

| Turning Capacity (Diameter) | Up to 12″ (305 mm); length up to 30″ (762 mm) |

| Tool Changer | Automatic Tool Changer (ATC) with 24–60 tool capacity |

| Control System | Fanuc, Siemens, or Heidenhain (model-dependent) |

| Work Envelope (5-axis Milling Example) | X: 39″ (1000 mm), Y: 31″ (800 mm), Z: 24″ (600 mm); A: ±120°, C: 360° continuous |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (including glass-filled grades), and other engineering plastics and alloys |

| Surface Finish (Typical) | 32–64 μin (0.8–1.6 μm) Ra, achievable down to 16 μin (0.4 μm) Ra with finishing passes |

| Coolant System | High-pressure through-spindle coolant; optional mist cooling for sensitive materials |

| Fixturing Compatibility | Modular fixturing, vacuum tables, custom soft jaws, tombstones for 4/5-axis pallet systems |

These specifications reflect standard configurations for high-performance Austin CNC platforms used in precision manufacturing environments. Material-specific toolpaths and process validation ensure optimal results across metals and plastics, especially in applications requiring tight tolerances and repeatable accuracy.

From CAD to Part: The Process

Honyo Prototype’s standardized CNC machining workflow for all regional facilities including Austin follows a rigorously defined sequence to ensure quality and efficiency. This process applies uniformly across our global network with regional fulfillment centers handling localized production demands. The complete workflow is detailed below.

CAD Upload and Initial Processing

Clients initiate the process through our secure online portal by uploading native or neutral CAD formats including STEP IGES and Parasolid. The system performs immediate file validation checking for geometric integrity unit consistency and manufacturing readiness. Invalid submissions trigger automated notifications with specific error diagnostics requiring client correction prior to progression.

AI-Powered Quoting Engine

Validated CAD files enter our proprietary AI quoting system which analyzes over 200 geometric and material parameters. This includes automated feature recognition tolerance mapping and material utilization calculations. The AI generates preliminary cost estimates within 90 seconds incorporating real-time machine availability raw material pricing and regional labor rates specific to the Austin facility. All AI outputs undergo mandatory engineering review before client submission.

Engineering DFM Analysis

Following quote acceptance our Austin-based manufacturing engineers conduct comprehensive Design for Manufacturability analysis. This phase identifies critical issues requiring resolution before production commences. Key focus areas include:

| DFM Category | Specific Checks | Resolution Protocol |

|---|---|---|

| Geometric Feasibility | Undercuts thin walls complex cavities | Recommend design modifications or alternative processes |

| Tolerance Stackup | Interdependent GD&T callouts | Propose achievable tolerances with capability data |

| Material Constraints | Aluminum steel titanium alloy suitability | Suggest material substitutions if necessary |

| Tool Access | Feature depth to width ratios | Redesign suggestions for tool reach limitations |

Engineers collaborate directly with clients to address flagged items through our digital markup system requiring formal sign-off on all modifications. No production begins without documented DFM approval.

Production Execution

Approved designs move to the Austin production floor where our certified machinists execute the workflow. Each part receives a unique digital work order tracking all process parameters. Key production phases include:

Material verification against AMS and ASTM standards

Precision CNC machining on Haas DMG MORI and Makino equipment

In-process CMM inspections at critical stages

Post-processing operations including deburring surface finishing and optional anodizing

All machining parameters are recorded in our MES system with full traceability from raw material to finished component. Austin facility maintains ISO 9001 and AS9100 certifications ensuring aerospace-grade compliance.

Quality-Controlled Delivery

Final inspection occurs using Zeiss coordinate measuring machines with full FAIR documentation provided. Parts undergo dimensional verification material certification and visual inspection per ASME Y14.5 standards. Upon clearance logistics coordinates shipment through our partnered carriers with real-time tracking. Standard lead time for Austin-based CNC projects is 7-12 business days from DFM sign-off with 98.7% on-time delivery performance over the past 12 months. All shipments include digital quality dossiers accessible through our client portal.

Start Your Project

Looking for precision CNC machining services in Austin? Partner with Honyo Prototype for fast, reliable, and high-quality manufacturing solutions. Our state-of-the-art factory in Shenzhen supports global clients with seamless production and on-time delivery.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Let’s bring your prototypes and production parts to life—efficiently and accurately.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.