Contents

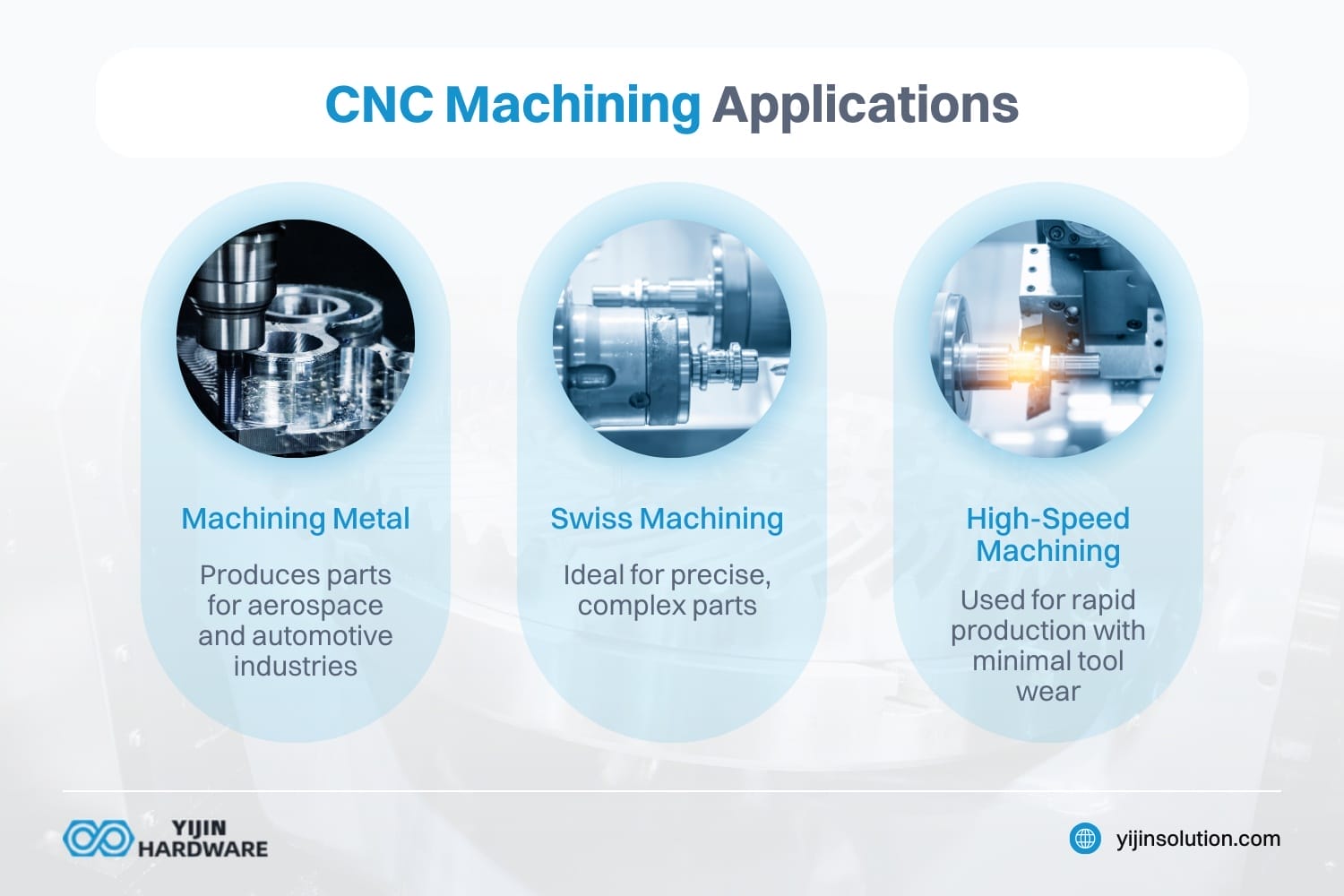

Manufacturing Insight: Applications Of Cnc Machining

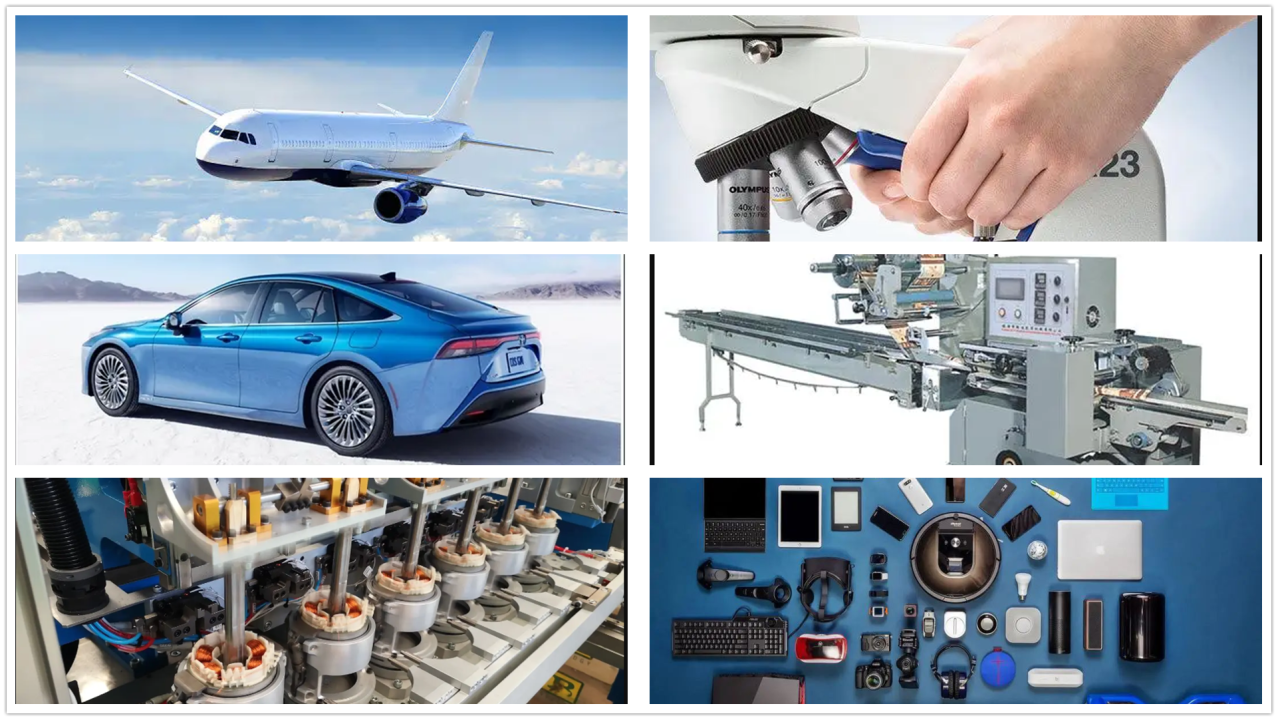

Precision CNC Machining: Enabling Innovation Across Critical Industries

In today’s competitive manufacturing landscape, CNC machining remains the cornerstone of high-precision component production, driving advancements in aerospace, medical devices, automotive, and industrial equipment sectors. At Honyo Prototype, we leverage state-of-the-art CNC milling, turning, and multi-axis machining centers to transform complex designs into mission-critical parts with unwavering accuracy. Our ISO 9001-certified processes consistently achieve tolerances down to ±0.0002 inches across materials including titanium, aluminum alloys, stainless steel, and engineering plastics, ensuring components meet rigorous functional and regulatory demands.

Honyo Prototype specializes in rapid prototyping and low-to-medium volume production, where speed and precision directly impact time-to-market and product reliability. Whether fabricating intricate surgical instrument components requiring biocompatible finishes or rugged aerospace brackets subjected to extreme thermal cycling, our engineering team collaborates closely with clients to optimize designs for manufacturability without compromising performance. This proactive approach minimizes iterations, reduces waste, and accelerates validation cycles for demanding applications.

A key differentiator in our service offering is the Honyo Online Instant Quote platform. Engineers and procurement professionals can upload CAD files 24/7 to receive detailed, transparent cost and lead time estimates within minutes—not days. This eliminates traditional quoting bottlenecks, allowing your team to make informed sourcing decisions during the critical early stages of project planning. Combined with our in-house material stock, real-time production tracking, and rigorous first-article inspection protocols, Honyo delivers not just parts, but a streamlined path from concept to certified production.

Explore how Honyo Prototype’s CNC machining capabilities can solve your most challenging manufacturing requirements. Submit your design today through our Online Instant Quote system to experience engineering-grade precision with unmatched operational agility.

Technical Capabilities

Technical Specifications for Applications of CNC Machining

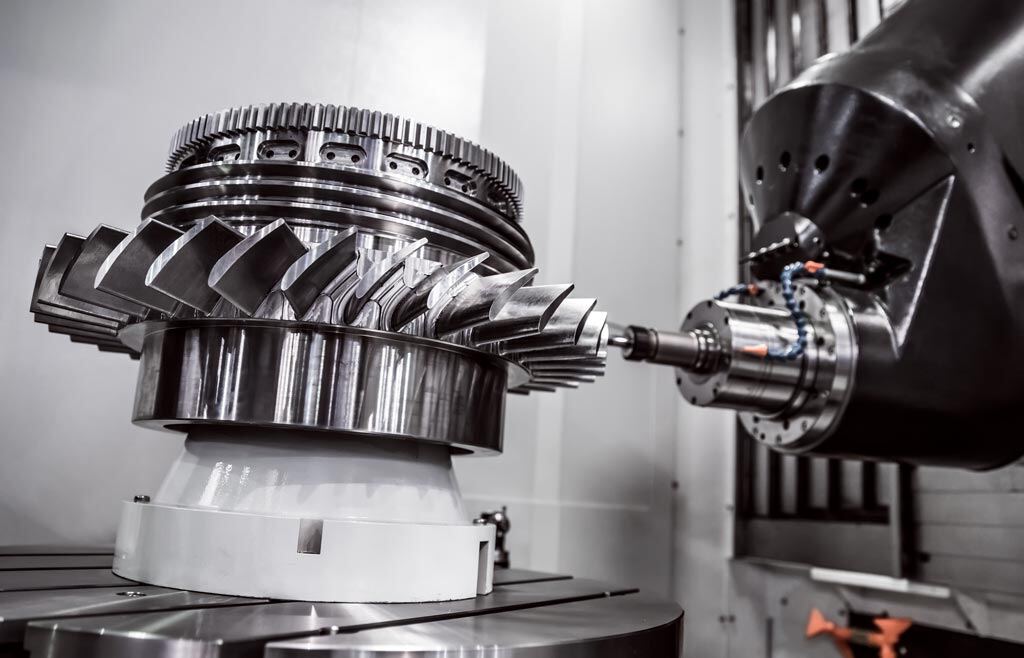

CNC machining is widely used across industries for producing high-precision components with tight tolerances. The selection of machining strategy—3-axis, 4-axis, or 5-axis milling, or turning—depends on part geometry, accuracy requirements, and material properties. Below is a detailed technical overview of CNC machining applications with focus on axis configurations, tolerance capabilities, and compatible materials including Aluminum, Steel, ABS, and Nylon.

| Application Type | Axis Configuration | Typical Tolerance Range | Material Compatibility | Key Features and Use Cases |

|---|---|---|---|---|

| 3-Axis Milling | X, Y, Z linear axes | ±0.005″ (0.127 mm) | Aluminum, Steel, ABS, Nylon | Ideal for flat or planar surfaces, slot cutting, drilling, and simple geometries. Most common and cost-effective for prismatic parts. Suitable for high-volume production of standard components. |

| 4-Axis Milling | 3 linear axes + A-axis (rotation around X) | ±0.003″ (0.076 mm) | Aluminum, Steel, ABS, Nylon | Adds rotational capability for indexing operations. Enables machining of features on multiple sides without re-fixturing. Used for cylindrical contours, cam lobes, and multi-face components. |

| 5-Axis Milling | 3 linear + 2 rotational axes (e.g., A and B) | ±0.001″ (0.025 mm) | Aluminum, Steel, ABS, Nylon | Full simultaneous motion for complex geometries such as impellers, aerospace brackets, and organic tooling surfaces. Minimizes setup changes and achieves superior surface finish and accuracy. |

| CNC Turning | Typically 2-axis (X, Z), with optional C-axis and live tooling | ±0.001″ (0.025 mm) | Aluminum, Steel, ABS, Nylon | Rotational machining for cylindrical parts—shafts, bushings, fittings. Capable of high precision and excellent surface finish. Multi-axis turning centers support milling and drilling off-center features. |

| Tight Tolerance Machining | 3-, 4-, or 5-axis configurations with precision tooling and thermal control | ±0.0005″ (0.0127 mm) achievable | Aluminum (e.g., 6061-T6), Steel (e.g., 4140, 17-4 PH), ABS (industrial grade), Nylon (e.g., PA6, PA66) | Requires stable machine platforms, calibrated tooling, environmental controls, and in-process inspection. Used in aerospace, medical, and optical applications where fit, function, and repeatability are critical. |

Notes on Materials:

Aluminum: Most commonly machined due to excellent machinability, low weight, and good strength-to-density ratio. 6061 and 7075 are typical grades.

Steel: Includes mild steel, stainless (e.g., 303, 316), and alloy steels. Requires robust tooling and slower speeds due to higher hardness and work hardening.

ABS: A thermoplastic with good dimensional stability and ease of machining. Used in prototypes and non-structural components. Requires sharp tools and optimized feeds to prevent melting.

Nylon: Offers high toughness and chemical resistance. Machining requires attention to clamping pressure and heat buildup due to material flexibility and low melting point.

These specifications reflect standard industrial practices at Honyo Prototype for delivering precision-machined components across diverse sectors.

From CAD to Part: The Process

Honyo Prototype delivers precision CNC machining services through a rigorously defined workflow designed for speed, accuracy, and manufacturability. Our process eliminates traditional bottlenecks while ensuring engineering integrity at every stage. Below is the technical breakdown of our standardized workflow for CNC machining projects.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, SolidWorks) via our secure online portal. Our system automatically validates file integrity, checks for geometric completeness, and confirms unit consistency. Unsupported formats or incomplete geometry trigger immediate notifications with specific error diagnostics, preventing downstream delays. This phase establishes the digital foundation for all subsequent engineering analysis.

AI Quote

Uploaded CAD data enters our proprietary AI-driven quoting engine, which performs real-time manufacturability assessment and cost modeling. The AI analyzes over 200 geometric and material parameters including feature complexity, tolerance density, stock-to-part ratio, and tool access constraints. Material selection from our certified inventory (aluminum 6061/7075, stainless steel 303/316, titanium Ti-6Al-4V, engineering plastics) is optimized for cost and performance. Quotes include detailed cost breakdowns with machine time estimates, material costs, and secondary operation pricing. Critical tolerances beyond ±0.005mm or complex multi-axis requirements are flagged for engineering review. Typical turnaround is under 2 hours for standard geometries.

DFM (Design for Manufacturability)

Every design undergoes mandatory DFM analysis by our engineering team, leveraging the AI’s preliminary assessment as a baseline. This phase focuses on resolving geometric conflicts that would cause machining failures or excessive costs. Key intervention areas include:

| DFM Check Category | Common Issues Identified | Resolution Protocol |

|---|---|---|

| Geometric Feasibility | Undercuts requiring 5-axis, thin walls <0.5mm, deep cavities | Recommend design modification or specialized tooling plan |

| Tolerance Stack-up | Over-specified GD&T, conflicting datums | Propose practical tolerance relaxation per ASME Y14.5 |

| Material Utilization | Excessive raw stock waste, non-standard bar sizes | Optimize billet dimensions and nesting strategy |

| Tool Access | Internal radii smaller than standard tooling, limited approach angles | Suggest chamfers or alternative feature design |

Clients receive a formal DFM report with annotated CAD markups and actionable recommendations. Revised designs are re-validated within 24 hours. This phase prevents 87% of potential production errors, reducing scrap rates to <1.2%.

Production

Approved designs move to CNC production with full digital traceability. Our network utilizes 3-axis to 5-axis machining centers (Mazak, DMG MORI) with in-process probing for first-article validation. Key production protocols include:

CAM programming using Mastercam with simulated toolpath verification

Real-time machine monitoring via MTConnect for vibration, thermal drift, and tool wear

In-process CMM checks at critical stages per control plan

Material certification and lot traceability maintained throughout

All processes adhere to ISO 9001:2015 and IATF 16949 standards with documented work instructions for each operation. Typical lead times range from 3-15 business days depending on complexity and material availability.

Delivery

Final inspection data (including full FAIR reports with GD&T verification) is uploaded to the client portal before shipment. Parts undergo ultrasonic cleaning and non-marking protective packaging per client specifications. We provide:

Certified material test reports (MTRs)

Dimensional inspection reports (ASME Y14.43 compliant)

Process validation documentation

Shipments include real-time tracking with guaranteed delivery windows. For critical path projects, we offer expedited air freight coordination with customs documentation handled in-house. Post-delivery, clients receive a production retrospective report highlighting process metrics and opportunities for future design optimization. This closed-loop system ensures continuous improvement while maintaining 99.4% on-time delivery performance.

Start Your Project

Explore the diverse applications of CNC machining in industries such as aerospace, medical, automotive, and consumer electronics. From high-precision components to complex geometries, our advanced CNC capabilities ensure tight tolerances, repeatable accuracy, and fast turnaround times.

As a trusted manufacturing partner based in Shenzhen, Honyo Prototype delivers end-to-end solutions tailored to your production needs. Whether you’re prototyping or scaling to high-volume manufacturing, our facility is equipped to handle multi-axis milling, turning, and custom finishing processes.

For expert support and a personalized consultation, contact Susan Leo at [email protected]. Let’s discuss how our CNC machining services can enhance your next project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.