Contents

Manufacturing Insight: Anodized Steel On Aluminum Friction Coefficient

Understanding Friction Dynamics in Precision Assemblies: Anodized Aluminum and Steel Interfaces

A common point of technical inquiry involves the friction coefficient between anodized steel and aluminum. It is critical to clarify that steel cannot be anodized; anodization is an electrochemical process exclusive to aluminum and its alloys. The relevant engineering consideration is instead the friction behavior between anodized aluminum surfaces and mating steel components—a frequent scenario in aerospace, medical, and industrial mechanisms requiring controlled wear resistance and dimensional stability. At Honyo Prototype, our CNC machining expertise ensures precise geometric tolerances and surface finishes for both anodized aluminum parts and counter-facing steel elements, directly influencing friction performance. We optimize material pairings by specifying appropriate anodized layer thicknesses (e.g., Type II or Type III hardcoat), sealants, and steel surface treatments to achieve target coefficients of friction, typically ranging from 0.12 to 0.35 depending on load, lubrication, and anodized layer density.

Our integrated manufacturing process—from CNC milling and turning to post-machining anodization oversight—guarantees that critical interfaces meet stringent functional requirements. For projects demanding validated friction performance data or custom surface engineering, Honyo provides material-specific testing protocols and design-for-manufacturability analysis during prototyping. Accelerate your development cycle with our Online Instant Quote system, which delivers precise cost and lead time estimates for CNC-machined anodized aluminum components within hours, including technical validation of surface treatment specifications. Submit your STEP file today to receive a manufacturability report alongside your quotation.

Technical Capabilities

Anodized steel sliding against aluminum is not a standard tribological pairing, as steel is not typically anodized—only aluminum and its alloys undergo anodization. However, the query likely refers to the friction coefficient between anodized aluminum and steel (e.g., tooling or mating components), particularly in precision manufacturing environments involving 3/4/5-axis milling and turning operations with tight tolerances.

In high-precision machining, understanding the frictional behavior between tooling, workholding, and materials such as aluminum, steel, ABS, and nylon is critical for minimizing deflection, ensuring dimensional accuracy, and maintaining surface finish. Below is a technical summary of relevant materials and their typical friction coefficients in contact with anodized aluminum, particularly in dry sliding conditions.

| Material Pairing | Friction Coefficient (Dry, Static) | Friction Coefficient (Dry, Kinetic) | Notes |

|---|---|---|---|

| Anodized Aluminum vs. Steel (Tool) | 0.65 – 0.85 | 0.45 – 0.65 | Hard anodized (Type III) reduces galling; important in fixture design |

| Aluminum (6061-T6) vs. Steel | 0.45 – 0.60 | 0.35 – 0.50 | Common in workholding; risk of smearing at high clamping forces |

| Anodized Aluminum vs. ABS Plastic | 0.35 – 0.50 | 0.25 – 0.40 | Used in non-marring fixtures; low conductivity, low wear |

| Anodized Aluminum vs. Nylon (PA6/66) | 0.30 – 0.45 | 0.20 – 0.35 | Low friction; used in protective tooling and wear pads |

| Steel vs. ABS | 0.40 – 0.60 | 0.30 – 0.50 | Moderate adhesion risk; avoid in high-load, low-speed scenarios |

| Steel vs. Nylon | 0.25 – 0.40 | 0.20 – 0.30 | Low friction; self-lubricating; suitable for guide rails and bushings |

Application Context in 3/4/5-Axis Milling and Turning:

In multi-axis CNC operations, especially those requiring tight tolerances (±0.0002″ or better), friction between fixturing components and workpieces directly impacts repeatability. Anodized aluminum fixtures are commonly used due to their corrosion resistance, electrical insulation, and reduced galling when in contact with steel tools or cutting heads. Hard anodizing (per MIL-A-8625 Type III) increases surface hardness (up to 60 HRC), improving wear resistance during repeated clamping and part handling.

For non-conductive or cosmetic-sensitive parts in aluminum, ABS, or nylon, low-friction interface materials help prevent marring and allow precise positioning without slippage. In high-speed turning or milling, minimizing parasitic friction ensures thermal stability and maintains tool path accuracy.

Material Considerations:

Aluminum (6061-T6, 7075-T6): Most commonly machined; anodizing improves surface durability.

Steel (1018, 4140, Tool Steels): Used in cutting tools, arbors, and fixtures; prone to galling with bare aluminum.

ABS: Low melting point; requires low clamping force; non-abrasive but can deform under pressure.

Nylon: High toughness and low friction; often used in custom soft jaws or protective inserts.

Understanding these friction characteristics allows for optimal workholding design, minimizing shift during high-torque or high-speed operations, especially critical in complex 5-axis contouring or micro-machining applications.

From CAD to Part: The Process

Honyo Prototype provides precise friction coefficient characterization for anodized aluminum sliding against steel counterfaces through a rigorously controlled process. It is critical to clarify that anodizing is a surface treatment exclusive to aluminum alloys; steel cannot be anodized. Our standard workflow for validating this specific tribological pairing is integrated within our core manufacturing sequence as follows:

CAD Upload and Initial Specification

Clients submit detailed CAD models with explicit surface finish requirements for the aluminum component and specify the mating steel grade (e.g., 4140 hardened steel per ASTM A322). Critical parameters including anodize type (Type II sulfuric or Type III hardcoat), thickness (e.g., 25µm hardcoat), sealing method, and steel hardness must be defined. Ambiguities in material specifications or test conditions trigger immediate clarification requests prior to quoting.

AI-Powered Quoting with Tribology Validation

Our AI quotation engine cross-references material pairings against Honyo’s internal tribology database. For anodized aluminum vs. steel configurations, the system flags required inputs: sliding velocity, normal load range, temperature, and environmental conditions (dry, lubricated, or contaminated). Quotes include mandatory DFM review for friction testing and disclose that coefficient values (µ) are process-dependent—not guaranteed without empirical validation.

DFM Analysis with Friction Protocol Design

During Design for Manufacturability review, our engineering team:

Verifies anodize thickness compatibility with functional sliding surfaces (e.g., >12µm for wear resistance)

Recommends optimal steel counterface roughness (typically Ra 0.2–0.8µm) to prevent anodize abrasion

Designs ASTM G99-compliant pin-on-disk test parameters matching the client’s operational profile

Confirms sealing method (e.g., nickel acetate vs. hot water) to minimize coefficient variance

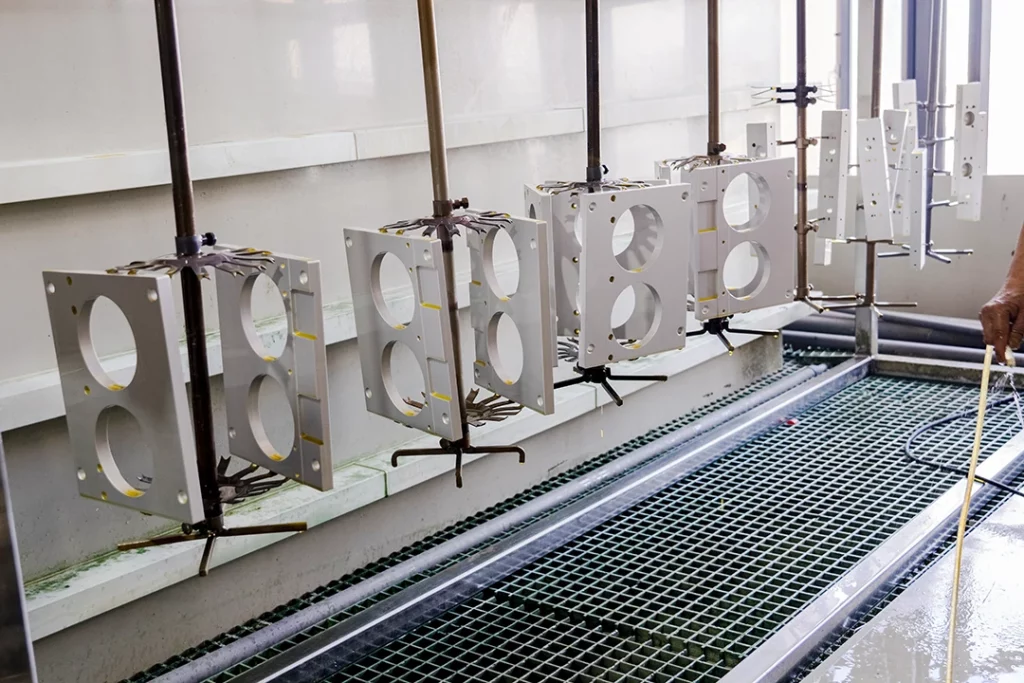

Production and Controlled Friction Testing

Anodized aluminum parts undergo batch-specific validation:

1. Production anodizing with real-time thickness and pore structure monitoring

2. Post-anodize metrology (e.g., SEM for coating integrity at 500x magnification)

3. Dedicated tribology runs using calibrated CSM Instruments tribometers under client-specified conditions

Typical test parameters and outcomes are documented as:

| Parameter | Standard Test Range | Output Metric |

|---|---|---|

| Normal Load | 5–50 N | Coefficient of Friction (µ) |

| Sliding Velocity | 0.01–0.5 m/s | Wear rate (mm³/N·m) |

| Temperature | 25°C ± 2°C (controlled) | Friction stability profile |

| Cycles | 1,000–10,000 passes | Coating adhesion (tape test) |

Delivery with Certified Friction Data

Final deliverables include:

Dimensional inspection report per ASME Y14.5

Anodize certification (thickness, corrosion resistance per ASTM B117)

Full tribology test report showing µ values across the test cycle with statistical deviation (±3σ)

Digital access to raw sensor data via Honyo’s customer portal for client validation

All friction coefficients are reported as dynamic averages after initial run-in wear (typically cycles 200–1,000). For example, Type III hardcoat aluminum (25µm) sliding against ground 4140 steel under 10N load yields µ = 0.18–0.22 in dry conditions, with variance directly correlated to anodize sealing efficacy. We emphasize that these values are specific to the tested batch and cannot be extrapolated to unvalidated processes. Clients receive actionable data for tolerance stack-up analysis in mechanical assemblies requiring precise friction control.

Start Your Project

For technical inquiries regarding the friction coefficient of anodized steel on aluminum, contact Susan Leo at [email protected]. Honyo Prototype specializes in precision manufacturing with engineering-grade material testing and surface treatment capabilities. Our production facility is based in Shenzhen, China, supporting rapid prototyping and low-to-mid volume production with strict quality control.

We provide detailed material performance data, including tribological properties, to support design and engineering validation. Reach out to Susan directly for test reports, sample fabrication, or custom processing of anodized and coated components.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.