Introduction: Navigating the Global Market for anodized aluminum color samples

Navigating the complexities of sourcing anodized aluminum color samples can be a daunting challenge for international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. The intricacies of color matching in anodized aluminum, influenced by factors like alloy composition and processing methods, often lead to uncertainty in achieving the desired aesthetic and performance for various applications. This guide aims to demystify the process by providing a comprehensive overview of anodized aluminum color samples, including types of finishes, their applications across industries, and essential considerations for supplier vetting.

Throughout this guide, buyers will find actionable insights into the nuances of color variation, the importance of standardized color ranges, and how to effectively manage expectations when sourcing. With an emphasis on quality assurance and consistency, we will explore strategies for evaluating suppliers, understanding cost implications, and leveraging best practices in procurement. By equipping international buyers with this knowledge, we empower them to make informed purchasing decisions that align with their specific project requirements and regional standards. Whether you are in Germany, Brazil, or elsewhere, this guide serves as your essential resource for navigating the global market for anodized aluminum color samples, ensuring your projects not only meet but exceed expectations.

Understanding anodized aluminum color samples Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear Anodized | Transparent finish, enhances natural aluminum look | Architectural applications, window frames | Pros: Maintains metallic sheen; Cons: Limited color options. |

| Bronze Anodized | Rich, warm tones ranging from light to dark bronze | Commercial buildings, signage | Pros: Aesthetic appeal; Cons: Color variation can occur. |

| Black Anodized | Deep, uniform black finish | High-end architectural projects, automotive parts | Pros: Modern look, excellent corrosion resistance; Cons: Heat absorption can be a concern. |

| Custom Color Anodized | Tailored colors based on client specifications | Specialized projects, branding | Pros: Unique branding opportunities; Cons: Higher lead times and costs. |

| Specialty Finishes | Unique textures or patterns (e.g., wood grain) | Interior design, furniture | Pros: Distinctive appearance; Cons: May require special maintenance. |

What Are the Characteristics and Suitability of Clear Anodized Aluminum?

Clear anodized aluminum is characterized by its transparent finish that enhances the natural metallic appearance of the aluminum. This type is particularly suitable for applications where the aesthetic of the raw material is desired, such as in architectural projects or window frames. For B2B buyers, it’s crucial to consider that while clear anodizing allows for a clean and modern look, it offers limited color options, which may not suit every design requirement.

How Does Bronze Anodized Aluminum Stand Out?

Bronze anodized aluminum offers a spectrum of warm tones, from light champagne to deep bronze. This variation makes it a popular choice for commercial buildings and signage, where visual appeal is paramount. Buyers should note that while bronze anodizing provides a rich aesthetic, the color can vary between batches and suppliers. Understanding these potential discrepancies is essential for maintaining brand consistency in large projects.

What Are the Benefits of Black Anodized Aluminum?

Black anodized aluminum is recognized for its deep, uniform finish, making it an ideal choice for high-end architectural applications and automotive parts. This finish not only provides a modern look but also enhances corrosion resistance. However, B2B purchasers should be aware of the heat absorption properties of black anodizing, which can be a concern in certain climates or applications, necessitating careful consideration during the selection process.

Why Consider Custom Color Anodized Aluminum?

Custom color anodized aluminum allows businesses to specify unique colors tailored to their branding or design needs. This flexibility makes it suitable for specialized projects where brand identity is critical. However, buyers should be prepared for longer lead times and potentially higher costs associated with custom finishes. It is vital to weigh these factors against the potential branding benefits when making purchasing decisions.

What Are Specialty Finishes and Their Applications?

Specialty finishes, such as wood grain or unique textures, provide distinctive appearances that can elevate interior design projects and furniture applications. These finishes can set a product apart in a competitive market. However, B2B buyers should consider the maintenance requirements and potential costs associated with these finishes, as they may not be as durable or easy to maintain as standard anodized options. Understanding these nuances can help businesses make informed decisions that align with their project goals.

Key Industrial Applications of anodized aluminum color samples

| Industry/Sector | Specific Application of anodized aluminum color samples | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architectural Design | Use of anodized aluminum in building facades and window frames. | Enhances aesthetic appeal while providing durability and corrosion resistance. | Ensure compliance with local building codes and aesthetic requirements. |

| Automotive Manufacturing | Application in vehicle trim and interior components. | Offers a sleek appearance and improved resistance to wear and tear. | Consider color consistency across different production batches. |

| Consumer Electronics | Anodized aluminum casings for devices like laptops and smartphones. | Provides a premium look and protection against scratches and corrosion. | Need for precise color matching to align with brand identity. |

| Aerospace Industry | Use in aircraft components for weight reduction and durability. | Reduces overall weight while maintaining high strength and safety standards. | Compliance with strict industry regulations and quality assurance protocols. |

| Furniture Production | Anodized aluminum in modern furniture design. | Combines aesthetic appeal with functional durability, appealing to contemporary markets. | Customization options to meet specific design requirements and trends. |

How Are Anodized Aluminum Color Samples Utilized in Architectural Design?

In architectural design, anodized aluminum color samples are pivotal for creating visually striking building facades and window frames. The anodizing process not only provides a range of colors but also enhances the material’s durability against environmental factors. For international buyers, especially in regions like Europe and the Middle East, understanding local building codes and aesthetic preferences is crucial. Ensuring that color samples align with these regulations can lead to successful project approvals and customer satisfaction.

What Role Do Anodized Aluminum Color Samples Play in Automotive Manufacturing?

In the automotive sector, anodized aluminum color samples are extensively used for vehicle trim and interior components. The samples allow manufacturers to visualize how different finishes will look on their products, ensuring a cohesive design language across the vehicle. For B2B buyers, maintaining color consistency across production batches is essential to uphold brand integrity. Buyers should also evaluate the anodized finishes for their resistance to wear, as this impacts the vehicle’s long-term aesthetic and functional performance.

How Are Anodized Aluminum Color Samples Important in Consumer Electronics?

Anodized aluminum is increasingly favored in the consumer electronics industry for casings of laptops and smartphones. The color samples provide manufacturers with the ability to select finishes that not only enhance the product’s visual appeal but also offer protection against scratches and corrosion. For international buyers, precise color matching is vital to align with branding strategies. Additionally, buyers must consider the environmental regulations regarding materials used in electronics, ensuring compliance with international standards.

Why Are Anodized Aluminum Color Samples Essential in the Aerospace Industry?

In aerospace applications, anodized aluminum color samples are critical for components where weight reduction and durability are paramount. The samples help manufacturers visualize how the anodized finish will appear on parts that must meet strict safety and performance standards. For B2B buyers in this sector, compliance with industry regulations and quality assurance protocols is non-negotiable. Buyers should seek suppliers that can guarantee consistency in color and finish across different production lots to avoid discrepancies that could affect safety and functionality.

How Do Anodized Aluminum Color Samples Benefit Furniture Production?

The furniture industry utilizes anodized aluminum color samples to create modern, aesthetically pleasing designs. These samples allow designers to experiment with various colors and finishes, ensuring that the final product is both attractive and durable. For international buyers, customization options are essential to meet specific design trends and consumer preferences. Buyers should also consider the supply chain logistics to ensure timely delivery of samples and finished products, which is vital for maintaining production schedules.

3 Common User Pain Points for ‘anodized aluminum color samples’ & Their Solutions

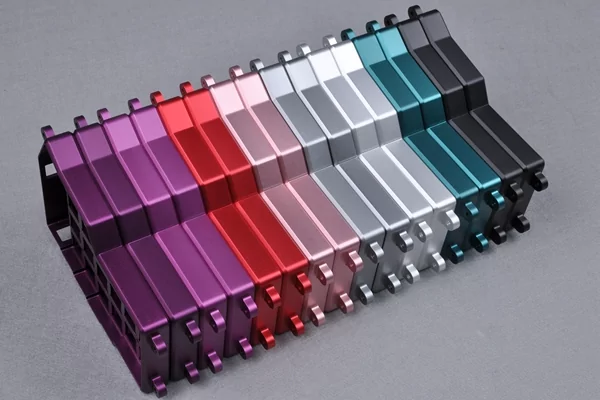

Scenario 1: Inconsistent Color Matching Across Suppliers

The Problem: B2B buyers often encounter significant challenges when trying to achieve consistent color matching across different suppliers of anodized aluminum. This issue arises because variations in aluminum alloys, temper, and even the anodizing process itself can lead to discrepancies in color. Buyers may receive samples that look perfect, but once the final products are delivered, the colors can vary by a noticeable margin, leading to dissatisfaction and potential project delays.

The Solution: To mitigate this problem, buyers should develop a robust specification process that includes a thorough understanding of the anodizing process and the specific aluminum alloy being used. Start by requesting color range samples from all potential suppliers to compare not just the color but also the finish. It’s crucial to specify the exact alloy and temper in the purchase order to ensure uniformity. Additionally, leveraging computerized color control systems, when available, can help maintain tighter color tolerances. Always conduct a sample test run with the chosen supplier before committing to a large order. This way, buyers can assess the final anodized color in their specific application context, reducing the risk of undesirable variations.

Scenario 2: Misleading Digital Representations of Color

The Problem: Digital representations of anodized aluminum colors can often be misleading. Buyers may find it difficult to trust the colors displayed on screens or in printed materials, which can lead to misaligned expectations. This is especially concerning for projects where color aesthetics are critical, such as architectural design or high-end product manufacturing. The discrepancy between what is seen online and the actual finished product can result in costly rework or even project failure.

The Solution: To address this challenge, buyers should prioritize obtaining physical samples before making a final decision. Requesting actual anodized color samples allows for a tangible comparison and a more accurate assessment of the finish. It’s also beneficial to consult with suppliers regarding their color representation processes, including how they manage color consistency across various media. When possible, visit the supplier’s facility to see their anodizing process firsthand and observe their quality control measures. Establishing a clear communication channel with the supplier about expectations can also help clarify potential differences between digital representations and physical outcomes.

Scenario 3: Limited Knowledge of Anodizing Processes and Color Variability

The Problem: Many B2B buyers lack a comprehensive understanding of the anodizing process and how it affects color variability. This knowledge gap can lead to unrealistic expectations regarding the consistency and vibrancy of anodized colors. Buyers may not realize that different batches of the same aluminum alloy can yield variations in color due to factors like the anodizing technique, environmental conditions, and even the dye used.

The Solution: To overcome this issue, buyers should invest time in educating themselves about the anodizing process and its impact on color outcomes. This can be achieved through supplier training sessions or industry seminars that focus on anodizing technology. Additionally, utilizing resources such as technical documentation from suppliers can provide valuable insights into the factors affecting color consistency. Buyers should also develop a strategy for managing color expectations by incorporating a color variance allowance into their project specifications. By understanding the inherent variability in anodizing, buyers can better navigate their purchasing decisions and align their project goals with realistic outcomes.

Strategic Material Selection Guide for anodized aluminum color samples

What Are the Key Materials for Anodized Aluminum Color Samples?

When selecting materials for anodized aluminum color samples, several factors must be considered, including the properties of the aluminum alloy, the anodizing process, and the specific requirements of the end application. Below, we analyze four common materials used in anodized aluminum color samples, focusing on their properties, advantages, disadvantages, and implications for international buyers.

1. Aluminum Alloy 5005

Key Properties: Aluminum Alloy 5005 is known for its excellent anodizing characteristics and superior corrosion resistance. It has a moderate strength-to-weight ratio and good workability, making it suitable for various applications.

Pros & Cons: The primary advantage of Alloy 5005 is its ability to achieve vibrant colors during anodizing, providing aesthetic appeal. However, its cost can be higher than other alloys, and it may not be as structurally strong, limiting its use in high-load applications.

Impact on Application: This alloy is particularly compatible with architectural applications where visual impact is essential. Its corrosion resistance makes it ideal for environments with high humidity or exposure to saltwater.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East often require compliance with standards such as ASTM and EN. The availability of Alloy 5005 may vary by region, affecting lead times and costs.

2. Aluminum Alloy 6063

Key Properties: Alloy 6063 is widely used for architectural applications due to its excellent extrudability and surface finish. It has good corrosion resistance and is often used in window frames and curtain walls.

Pros & Cons: The alloy’s primary advantage is its balance of strength and aesthetic finish, making it suitable for a variety of architectural designs. However, it may not anodize as brightly as Alloy 5005, leading to less vibrant color samples.

Impact on Application: Alloy 6063 is ideal for applications requiring structural integrity and aesthetic appeal, such as building facades. It performs well in moderate to high-stress environments.

Considerations for International Buyers: Compliance with local building codes is crucial, especially in regions like Africa and South America, where standards may differ significantly. Buyers should ensure that suppliers can provide documentation for compliance.

3. Aluminum Alloy 7075

Key Properties: Known for its high strength, Alloy 7075 is often used in aerospace and military applications. It has lower corrosion resistance compared to other alloys but offers superior mechanical properties.

Pros & Cons: The key advantage of Alloy 7075 is its strength, making it suitable for demanding applications. However, its susceptibility to corrosion limits its use in environments where moisture is prevalent, and it may require additional protective coatings.

Impact on Application: This alloy is suitable for applications where strength is paramount, such as in structural components. However, its color options may be limited due to its anodizing characteristics.

Considerations for International Buyers: Buyers in the aerospace sector, particularly in Europe, must adhere to stringent aerospace standards (e.g., MIL-A-8625). Ensuring compliance with these standards is critical for market entry.

4. Aluminum Alloy 2024

Key Properties: Alloy 2024 is another high-strength aluminum alloy, primarily used in aerospace applications. It has good fatigue resistance but is less corrosion-resistant than other alloys.

Pros & Cons: The main advantage of Alloy 2024 is its high strength-to-weight ratio, which is essential for aerospace applications. However, its lower corrosion resistance may necessitate additional treatments or coatings.

Impact on Application: This alloy is best suited for applications where weight savings and strength are critical, such as aircraft structures. The need for additional surface treatments can complicate the anodizing process.

Considerations for International Buyers: International buyers, especially in the aerospace sector, need to be aware of the specific compliance requirements for Alloy 2024, which may vary by region. Ensuring that suppliers meet these standards is essential for successful procurement.

Summary Table of Material Selection for Anodized Aluminum Color Samples

| Material | Typical Use Case for anodized aluminum color samples | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy 5005 | Architectural applications requiring vibrant colors | Excellent anodizing characteristics | Higher cost, lower structural strength | Medium |

| Aluminum Alloy 6063 | Window frames, curtain walls | Good balance of strength and finish | Less vibrant colors than 5005 | Medium |

| Aluminum Alloy 7075 | Aerospace and military applications | High strength | Lower corrosion resistance | High |

| Aluminum Alloy 2024 | Aerospace structures | High strength-to-weight ratio | Requires additional treatments | High |

This strategic guide aims to assist international B2B buyers in making informed decisions regarding the selection of anodized aluminum color samples, ensuring compliance with regional standards and optimizing application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for anodized aluminum color samples

What Are the Key Stages in the Manufacturing Process of Anodized Aluminum Color Samples?

The manufacturing process of anodized aluminum color samples involves several critical stages that ensure both the aesthetic quality and durability of the finished product. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Aluminum Readied for Anodizing?

The first step in the manufacturing process is material preparation. This involves selecting the appropriate aluminum alloy, which can significantly affect the final color outcome. Common alloys include 5005 and 6063, chosen for their anodizing qualities. The aluminum is then cleaned to remove any surface contaminants, such as oils or oxides, which can interfere with the anodizing process. This cleaning is typically achieved through a combination of chemical and mechanical methods, ensuring a smooth surface for the subsequent anodizing.

Forming: What Techniques Are Used to Shape Aluminum?

Once the aluminum is prepared, it undergoes forming, which can include processes like extrusion, rolling, or stamping, depending on the desired end product. Extrusion is particularly common for creating profiles that are later anodized. The forming process must be tightly controlled to ensure that dimensions meet specifications, as even slight deviations can affect the anodizing process and the final appearance of the color samples.

Assembly: How Are Components Put Together?

In some cases, multiple components may need to be assembled before anodizing. This could involve mechanical fastening or welding, depending on the design requirements. It is crucial to ensure that the assembly does not introduce contaminants or defects that could affect the anodizing process. Assembly must be completed carefully, with attention to detail, to maintain the integrity of the components.

Finishing: What Is the Anodizing Process Like?

The final stage is the anodizing process itself, where the aluminum is immersed in an electrolytic solution. This process involves applying an electrical current, which causes the aluminum to oxidize and form a protective layer. The color is achieved by adding dyes to the anodizing bath or by using an integral coloring process. The quality of the anodized finish can vary based on several factors, including the type of aluminum alloy used, the anodizing time, and the temperature of the bath.

How Is Quality Assurance Implemented in Anodized Aluminum Manufacturing?

Quality assurance is critical in the production of anodized aluminum color samples, as it ensures that the final product meets both aesthetic and functional standards. Adhering to international standards such as ISO 9001 helps manufacturers establish a quality management system that promotes continuous improvement.

What International Standards Are Relevant for Anodized Aluminum?

In addition to ISO 9001, several industry-specific standards apply to anodized aluminum products. For example, the American Architectural Manufacturers Association (AAMA) sets specifications for anodized finishes, particularly concerning color consistency and durability. Compliance with CE marking for products sold in the European market is also essential, ensuring that the products meet EU safety, health, and environmental protection requirements.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are crucial at various stages of the manufacturing process.

-

Incoming Quality Control (IQC): Before production begins, raw materials are inspected to ensure they meet the required specifications. This includes checking the aluminum alloy for consistency and quality.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor critical parameters such as temperature, voltage, and dye concentration in the anodizing bath. This helps identify any deviations that could affect the quality of the final product.

-

Final Quality Control (FQC): After the anodizing process, samples are taken to assess color consistency, thickness of the anodized layer, and overall appearance. The color variation is measured using tools that calculate Delta E values, ensuring that the product meets the specified standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of their anodized aluminum suppliers, especially when sourcing from international markets.

What Should Buyers Look for in Supplier Audits?

Buyers can request copies of quality control audits, which should detail the supplier’s adherence to international standards and internal quality processes. Regular audits, both internal and external, provide a transparent view of the supplier’s commitment to quality.

How Can Buyers Utilize Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and quality assurance measures in place. These inspections can confirm that products meet specified requirements and help mitigate risks associated with sourcing from international suppliers.

What Are the Nuances in Quality Control for International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is essential. Different countries may have varying requirements for product certification, and it is crucial to ensure that suppliers are compliant with both international standards and local regulations.

How Can Cultural Differences Impact Quality Expectations?

Cultural differences can also influence quality expectations and communication. Buyers should establish clear guidelines and expectations upfront, ensuring that both parties have a mutual understanding of quality standards. This may involve detailed specifications and regular communication to address any potential issues promptly.

Conclusion

Understanding the manufacturing processes and quality assurance measures for anodized aluminum color samples is vital for B2B buyers looking to source these products. By considering the intricacies of material preparation, forming, assembly, and finishing, along with robust quality control practices, buyers can make informed decisions that align with their project requirements and ensure the highest standards of quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘anodized aluminum color samples’

Introduction

This practical sourcing guide is designed for international B2B buyers seeking anodized aluminum color samples. Whether you are in Africa, South America, the Middle East, or Europe, following this checklist will help you navigate the procurement process effectively, ensuring you receive high-quality samples that meet your project requirements.

Step 1: Define Your Technical Specifications

Clearly outline your project requirements before reaching out to suppliers. Consider factors such as the desired color, finish type, and the specific aluminum alloy to be used. This clarity will help suppliers provide samples that align with your needs.

- Alloy Considerations: Different aluminum alloys can yield varying results in anodizing. Specify which alloy you plan to use to ensure accurate color representation.

- Finish Variations: Determine whether you need a matte, glossy, or textured finish, as these factors influence the overall appearance.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to compile a list of potential suppliers known for their anodized aluminum products. Look for companies with a strong reputation in the industry.

- Supplier Experience: Prioritize suppliers with extensive experience in anodizing and a proven track record in your target market.

- Certifications: Verify that suppliers hold relevant industry certifications, such as AAMA or ISO, which can indicate their commitment to quality and standards.

Step 3: Request Color Range Samples

Once you have identified potential suppliers, reach out to request color range samples. This step is crucial for assessing the quality and consistency of their anodized finishes.

- Sample Variability: Understand that color variation is inherent in anodizing. Request multiple samples to gauge the range of colors achievable with the specified alloy.

- Testing Samples: Evaluate how well the samples match your project’s aesthetic requirements and ensure they meet your specifications.

Step 4: Verify Quality Control Processes

Inquire about the quality control measures that suppliers implement during the anodizing process. This information is vital to ensuring that the samples you receive will reflect the quality of the final product.

- Computerized Color Control: Suppliers who utilize computerized color control systems can provide more consistent results, reducing the likelihood of color discrepancies.

- Production Consistency: Ask about their production practices to ensure that they can maintain color uniformity across different batches.

Step 5: Evaluate Pricing and Terms

Assess the pricing structure and terms offered by each supplier for the anodized aluminum color samples. This step is essential for budgeting and ensuring that you receive value for your investment.

- Transparent Pricing: Look for suppliers who provide clear pricing without hidden fees. Compare costs among suppliers to find competitive rates.

- Sample Costs: Determine whether the supplier charges for samples and if those costs can be credited toward your future orders.

Step 6: Check References and Previous Work

Before finalizing your choice, seek references and case studies from suppliers. This will give you insight into their reliability and the quality of their anodized aluminum products.

- Industry Alignment: Ensure that the references are from businesses in a similar industry or region to assess the supplier’s experience with comparable projects.

- Client Testimonials: Look for feedback on the supplier’s ability to meet deadlines, quality expectations, and overall customer service.

Step 7: Finalize the Order and Confirm Delivery Timelines

Once you have selected a supplier, finalize your order for anodized aluminum color samples. Confirm delivery timelines to ensure you receive your samples promptly.

- Clear Communication: Maintain open lines of communication with the supplier to address any questions or concerns during the ordering process.

- Delivery Expectations: Ensure that you understand the expected delivery dates and any potential delays that may arise.

Following these steps will facilitate a smooth procurement process for anodized aluminum color samples, allowing you to make informed decisions that enhance your project’s success.

Comprehensive Cost and Pricing Analysis for anodized aluminum color samples Sourcing

What Are the Key Cost Components in Sourcing Anodized Aluminum Color Samples?

When sourcing anodized aluminum color samples, various cost components must be considered to ensure a comprehensive understanding of the pricing structure. The primary cost components include:

-

Materials: The type of aluminum alloy used significantly impacts the cost. Different alloys exhibit varying anodizing qualities and color outcomes, influencing the final price. Specialty alloys or those with specific properties may incur higher costs.

-

Labor: Labor costs encompass the skilled workforce required for anodizing processes, quality control, and handling. Skilled labor is essential for achieving the desired finish and color consistency.

-

Manufacturing Overhead: This includes costs associated with running the facility, such as utilities, equipment maintenance, and indirect labor. Efficient production processes can help minimize these costs.

-

Tooling: The initial setup for anodizing processes, including custom tooling for specific projects, can add to the overall cost. Customization often requires more complex tooling, which drives up expenses.

-

Quality Control (QC): Ensuring that the anodized samples meet industry standards and customer specifications involves rigorous QC measures, which can increase costs. A well-defined QC process helps in maintaining color consistency and quality.

-

Logistics: Transportation costs for shipping samples internationally can vary based on the destination, weight, and chosen shipping method. Understanding these logistics is crucial for calculating total expenses.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on their market positioning and the competitive landscape.

How Do Price Influencers Impact Anodized Aluminum Color Samples?

Several factors can influence the pricing of anodized aluminum color samples, particularly for international B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Bulk purchases may yield significant discounts, while smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Custom colors or finishes may require additional processing, increasing costs. Be prepared to negotiate based on your specific needs.

-

Materials: The choice of materials affects pricing; higher-quality or specialty materials will generally be more expensive. Always inquire about the benefits of different alloys.

-

Quality and Certifications: Suppliers offering certified products, such as those meeting AAMA specifications, may charge a premium. Ensure that the certifications align with your project requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to penetrate the market.

-

Incoterms: Understanding Incoterms is critical for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly impact the total cost.

What Are the Best Tips for Negotiating Prices on Anodized Aluminum Color Samples?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating the best price on anodized aluminum color samples can lead to substantial savings. Here are some actionable tips:

-

Leverage Volume Discounts: If your project allows for it, consider consolidating orders to meet MOQ requirements for better pricing.

-

Clarify Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the samples, including maintenance and potential replacements, rather than just upfront costs.

-

Research and Compare Suppliers: Gather quotes from multiple suppliers to understand the market rate and leverage this information in negotiations.

-

Be Aware of Pricing Nuances: Different regions may have unique pricing structures based on local market conditions, tariffs, or logistical challenges. Understanding these nuances can provide leverage in negotiations.

-

Request Sample Comparisons: Before committing to a large order, request samples from various suppliers to assess quality and color consistency, which can justify your pricing discussions.

Disclaimer on Indicative Prices

The pricing for anodized aluminum color samples can vary widely based on specific project requirements, market conditions, and supplier capabilities. Therefore, it is advisable to consult directly with suppliers for accurate and up-to-date pricing tailored to your needs.

Alternatives Analysis: Comparing anodized aluminum color samples With Other Solutions

Introduction: Exploring Alternatives to Anodized Aluminum Color Samples

When considering the aesthetic and functional needs of aluminum products, anodized aluminum color samples are a popular choice among B2B buyers. However, there are several alternatives that also offer distinct advantages depending on the specific requirements of a project. This analysis aims to compare anodized aluminum color samples with other viable solutions, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Anodized Aluminum Color Samples | Powder Coating | Liquid Coatings |

|---|---|---|---|

| Performance | Durable, corrosion-resistant; color variation possible | Highly durable; offers vibrant colors | Wide range of colors; less durable than anodizing |

| Cost | Moderate; varies by supplier and color | Generally lower than anodizing | Typically lower than both anodizing and powder coating |

| Ease of Implementation | Requires specific anodizing processes; color matching can be complex | Easier to apply; can be done in-house | Easy to apply; requires less specialized equipment |

| Maintenance | Low; generally resistant to wear and tear | Moderate; can chip or fade over time | High; may require frequent touch-ups |

| Best Use Case | Architectural applications, high-end finishes | Industrial applications, furniture | Decorative items, short-term applications |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Powder Coating?

Powder coating is a finishing process that involves applying a dry powder that is then cured under heat to form a hard layer. Its primary advantage lies in its durability and resistance to chipping, fading, and scratching. It also offers a vast array of color choices, making it suitable for various applications. However, while it is generally more cost-effective than anodizing, powder coating does not provide the same level of corrosion resistance. Additionally, it can be less effective in high-temperature environments.

How Do Liquid Coatings Compare to Anodized Aluminum Color Samples?

Liquid coatings, such as paints and varnishes, provide another alternative to anodized finishes. They are available in an extensive range of colors and can be applied easily, often without the need for specialized equipment. However, liquid coatings typically do not offer the same durability and corrosion resistance as anodized finishes. They are more prone to wear and may require more frequent maintenance and touch-ups, making them less ideal for long-term applications.

Why Should B2B Buyers Consider the Context of Their Projects?

When evaluating these alternatives, B2B buyers should consider the specific context of their projects. Anodized aluminum color samples are often preferred for applications requiring high durability and aesthetic appeal, such as in architectural designs. In contrast, powder coating may be more suitable for industrial products where cost efficiency is a priority. Liquid coatings can serve well for decorative projects or items requiring frequent color changes.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right aluminum finish involves a careful evaluation of project requirements, including performance expectations, budget constraints, and maintenance considerations. Anodized aluminum color samples excel in durability and aesthetics, making them ideal for high-end applications. However, for projects where cost and ease of implementation are paramount, powder coating or liquid coatings may provide viable alternatives. By analyzing these factors, B2B buyers can make informed decisions that align with their specific needs and project goals.

Essential Technical Properties and Trade Terminology for anodized aluminum color samples

What are the Essential Technical Properties of Anodized Aluminum Color Samples?

Understanding the critical specifications of anodized aluminum is vital for B2B buyers in making informed purchasing decisions. Here are some key properties to consider:

1. Material Grade

Material grade refers to the specific classification of aluminum alloys used in anodizing. Common grades include 6061 and 5005, each with distinct mechanical properties and corrosion resistance. Selecting the right grade is crucial, as it affects not only the aesthetic quality of the anodized finish but also the product’s durability and performance in various environmental conditions.

2. Color Consistency (Delta E)

Delta E is a measurement of color difference, with values typically ranging from 0 to 5 in anodized aluminum applications. A Delta E value of less than 3 indicates a very close color match, while values above 5 may result in noticeable discrepancies. For B2B buyers, maintaining color consistency is essential to ensure uniformity across large projects, particularly when sourcing materials from multiple suppliers.

3. Anodic Thickness

The anodic thickness, measured in microns, denotes the depth of the anodic layer on the aluminum surface. This thickness directly impacts the finish’s durability, resistance to corrosion, and color retention. A thicker anodic layer typically results in better performance, making it a critical factor for buyers in industries where longevity and aesthetics are paramount.

4. Finish Type

Different anodized finishes, such as clear, bronze, and colored anodizing, can significantly affect the appearance and performance of aluminum products. Buyers should understand the implications of each finish type, including how they may react to environmental factors like UV exposure and temperature fluctuations. This knowledge is essential for ensuring the selected finish meets project requirements.

5. Alloy Composition

The alloy composition influences the anodizing process and the final color outcome. Variations in alloying elements, such as copper or magnesium, can lead to different visual results, even when the same anodizing process is applied. Recognizing the significance of alloy composition aids buyers in selecting materials that align with their specific aesthetic and performance needs.

6. Surface Preparation

Surface preparation methods, such as chemical etching or mechanical polishing, can affect the final appearance of anodized aluminum. Proper preparation ensures that the anodizing process adheres effectively to the surface, enhancing both the durability and the color vibrancy of the finish. Understanding these methods is critical for buyers who prioritize high-quality finishes in their projects.

What Are Common Trade Terms Related to Anodized Aluminum Color Samples?

Familiarity with industry terminology is essential for effective communication between buyers and suppliers. Here are several common terms that are frequently encountered:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers who are sourcing anodized aluminum components for integration into larger systems or products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and production planning. Knowing the MOQ helps businesses align their purchasing strategies with supplier capabilities.

3. RFQ (Request for Quote)

An RFQ is a formal document issued by a buyer to solicit pricing information from suppliers. This process is essential for B2B transactions, enabling buyers to compare costs and services before making purchasing decisions. A well-prepared RFQ can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, insurance, and risk responsibilities, which are critical for successful global procurement.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to the delivery of the product. Understanding lead times is vital for project scheduling and inventory management, especially in industries where timely delivery is crucial to maintain operational efficiency.

By comprehensively understanding these technical properties and trade terms, B2B buyers can enhance their decision-making processes and ensure successful procurement of anodized aluminum color samples.

Navigating Market Dynamics and Sourcing Trends in the anodized aluminum color samples Sector

What Are the Current Market Dynamics and Key Trends in Anodized Aluminum Color Samples?

The global market for anodized aluminum color samples is driven by several key factors, including the growing demand for lightweight materials in construction, automotive, and consumer goods. As international buyers from regions such as Africa, South America, the Middle East, and Europe seek innovative solutions, the anodized aluminum sector is witnessing an uptick in customization and aesthetic appeal. Notably, advancements in B2B technology are transforming sourcing practices. Digital platforms enable streamlined ordering processes and enhanced communication between buyers and suppliers, fostering transparency and efficiency.

Emerging trends highlight the increasing importance of quality control and color consistency, as variations in anodized finishes can significantly impact project outcomes. Suppliers are investing in computerized color control systems to ensure tighter ranges of color variation, which is critical for maintaining brand integrity. Additionally, the rise of eco-conscious consumerism is prompting buyers to look for suppliers that offer a range of sustainable anodizing options, including low-VOC dyes and environmentally friendly processes. This shift not only meets regulatory requirements but also resonates with end customers who prioritize sustainability.

How Is Sustainability Influencing Sourcing Decisions for Anodized Aluminum Color Samples?

Sustainability has become a pivotal factor in the sourcing of anodized aluminum color samples. The environmental impact of anodizing processes, including energy consumption and chemical usage, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices, such as utilizing recycled aluminum and implementing energy-efficient anodizing techniques. This not only reduces the carbon footprint but also aligns with global trends toward circular economy principles.

Ethical supply chains are also gaining prominence, as buyers seek to ensure that their sourcing decisions support fair labor practices and environmentally responsible operations. Certifications such as ISO 14001 for environmental management and Green Seal for sustainable products are becoming critical in supplier evaluations. Buyers should actively seek suppliers that hold these certifications, as they provide assurance of commitment to sustainable practices. This trend is particularly pronounced in regions like Europe, where regulatory frameworks favor environmentally friendly materials, but it is equally relevant for emerging markets in Africa and South America as they develop their industrial sectors.

What Is the Historical Context of Anodized Aluminum Finishes?

The evolution of anodized aluminum finishes dates back to the mid-20th century when the anodizing process was first industrialized. Initially, the focus was primarily on enhancing the durability and corrosion resistance of aluminum. Over the decades, advancements in technology and chemical processes have allowed for a broader spectrum of colors and finishes, catering to the growing demand for aesthetic appeal in architectural and consumer applications.

As the construction and automotive industries expanded, anodized aluminum became a favored choice due to its lightweight properties and versatility. The introduction of computerized systems for color control in the 1990s marked a significant turning point, enhancing the consistency and quality of anodized finishes. Today, the anodized aluminum color samples sector continues to innovate, driven by advancements in technology and a growing emphasis on sustainability, making it a dynamic area for B2B investment and sourcing opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of anodized aluminum color samples

-

How do I ensure accurate color matching for anodized aluminum samples?

To achieve accurate color matching, request anodized aluminum samples from multiple suppliers. It’s essential to specify the aluminum alloy, temper, and finish type, as these factors significantly influence color outcomes. Keep in mind that color variations may occur due to differences in production batches or suppliers. Use color range samples as a reference, but understand that actual results may vary. For critical projects, consider conducting on-site evaluations or obtaining custom samples to ensure consistency with your requirements. -

What is the best method for selecting anodized aluminum color samples?

The best method involves evaluating your project’s specific aesthetic and functional needs. Start by reviewing the supplier’s color charts and standard offerings, paying attention to the anodized finishes that align with your design vision. Request samples to assess how colors appear in different lighting conditions and against other materials. Additionally, consider your project’s end-use environment, as factors such as weather exposure may affect the performance and appearance of the anodized finish over time. -

What customization options are available for anodized aluminum colors?

Many suppliers offer customization options for anodized aluminum colors, including unique shades, textures, and finishes. Depending on the supplier, you may request specific Pantone colors or custom formulations that align with your brand or design requirements. Be prepared to meet minimum order quantities (MOQs) for customized colors and verify the supplier’s capabilities in producing consistent results. Engaging in early discussions with suppliers can help ensure they can meet your specific needs. -

What are the minimum order quantities (MOQs) for anodized aluminum samples?

Minimum order quantities for anodized aluminum samples can vary significantly between suppliers. Generally, MOQs may range from a few pieces for standard colors to larger quantities for custom colors or finishes. When sourcing samples, inquire about the supplier’s policies regarding MOQs to avoid unexpected costs. If your project requires a small quantity, some suppliers may offer sample kits or allow you to purchase individual samples at a lower cost. -

How can I vet suppliers of anodized aluminum color samples effectively?

To vet suppliers effectively, start by researching their industry reputation and customer reviews. Look for certifications that indicate quality control and adherence to international standards, such as AAMA specifications. Evaluate their production capabilities and ask for samples of previous work to assess color consistency and quality. Additionally, consider their customer service responsiveness and their ability to provide technical support or advice throughout your sourcing process. -

What payment terms should I expect when ordering anodized aluminum samples?

Payment terms can vary widely among suppliers, but common practices include upfront payment, partial payment upon order confirmation, or net payment terms (e.g., net 30 or net 60 days). It’s crucial to clarify payment expectations before placing an order. For international transactions, be aware of currency exchange rates and potential bank fees. Utilizing secure payment methods, such as letters of credit or escrow services, can provide added protection for larger orders. -

What quality assurance measures should I consider for anodized aluminum samples?

Quality assurance measures for anodized aluminum should include checking for color consistency, adherence to specifications, and overall finish quality. Request certifications or test reports that confirm compliance with industry standards. It’s also beneficial to discuss the supplier’s quality control processes, such as computerized color control and inspection protocols. Establishing clear expectations and conducting periodic reviews during production can help maintain quality throughout your project. -

What logistics considerations should I keep in mind when sourcing anodized aluminum samples internationally?

When sourcing anodized aluminum samples internationally, consider shipping times, costs, and customs regulations. Ensure that the supplier can provide accurate shipping estimates and documentation required for customs clearance. Be aware of potential duties and taxes that may apply upon import. It’s also wise to discuss options for expedited shipping if time is critical for your project. Establishing a reliable logistics partner can help streamline the process and mitigate potential delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Anodized Aluminum Color Samples Manufacturers & Suppliers List

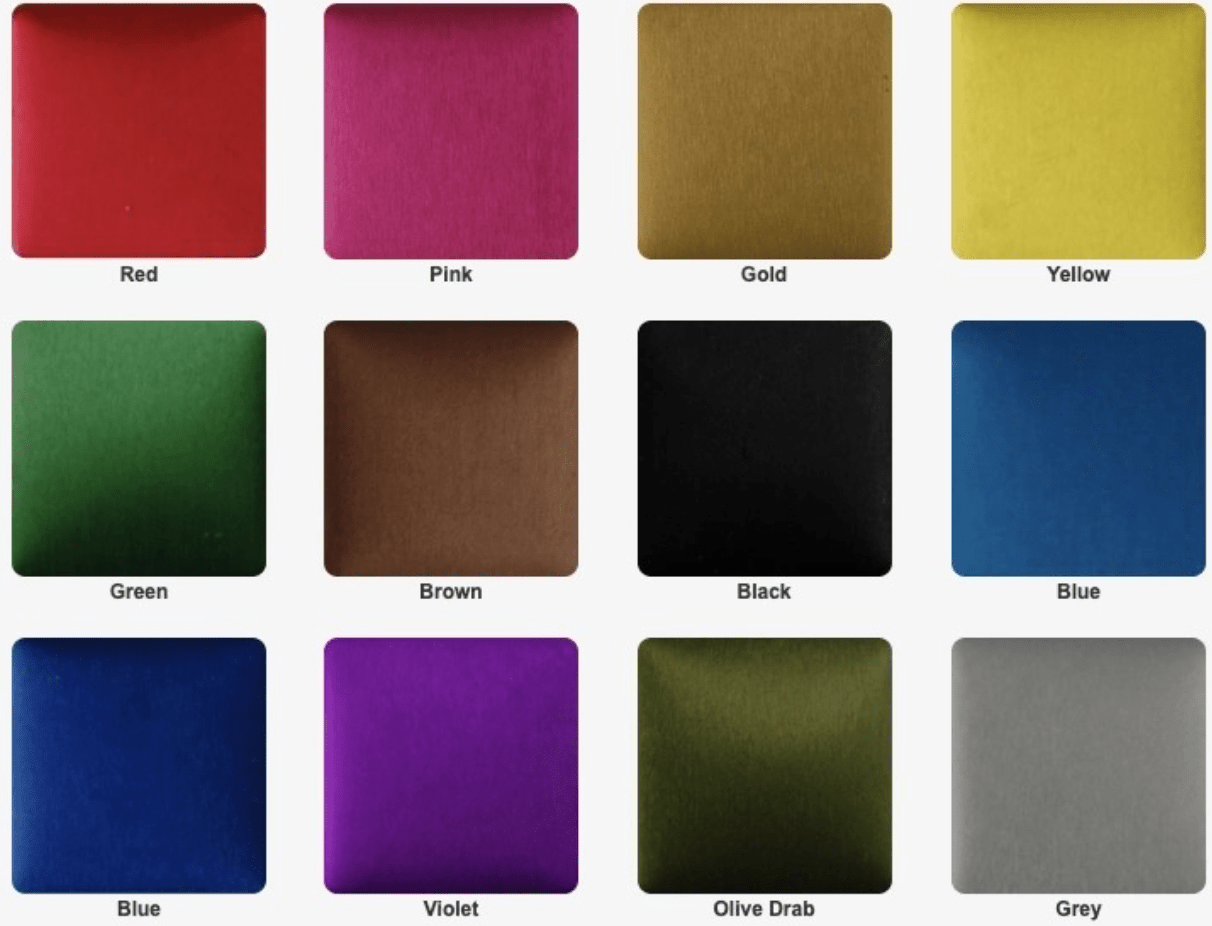

1. Linetec – Anodize Color Cards

Domain: linetec.com

Registered: 1996 (29 years)

Introduction: Linetec offers anodize color cards with 7 standard colors and individual color samples. The anodizing process results in color variation due to factors like aluminum alloy, temper, and shape. Linetec maintains a color range of 1 to 3 Delta E, which is tighter than the AAMA specification of 5 Delta E. Standard anodize colors include: Clear (ANO-215 AE or ANO-204 AE), Champagne (ANO-300 AE), Light B…

2. Eagle Aluminum – Anodized Aluminum Finishes

Domain: eagle-aluminum.com

Registered: 2010 (15 years)

Introduction: Eagle Aluminum offers a variety of anodized aluminum finishes and colors, including standard and customized options. Key anodized finishes include: Clear Satin, Champagne, Golden Bronze, Light Bronze, Medium Bronze, Dark Bronze, Deep Bronze, Black, Light Gold (Special Order), Medium Gold (Special Order), Dark Gold (Special Order), Nickel (Special Order), Brass (Special Order), Sandalwood (Special …

3. Lorin – Anodized Aluminum Colors and Finishes

Domain: lorin.com

Registered: 1996 (29 years)

Introduction: Lorin offers a variety of anodized aluminum colors and finishes designed to enhance architectural and design projects. Key product details include:

– **Trending Colors:** CopperBrite®, Colorin®, BlackMatt (UV), Champagne Gold (UV), Med Antique Copper (UV).

– **Warranty:** 70-year warranty on Architectural Class I and II Coil Anodized Aluminum, protecting against corrosion and wear.

– **Innovative…

4. Maintain Pro Supply – Anodized Aluminum Engraving Material

Domain: maintrophysupply.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Anodized Aluminum Engraving Material”, “sku”: “ALUM-ANODZD”, “price_range”: “$7.12 – $11.10”, “ideal_for”: “outdoor applications”, “surface_finish”: {“satin”: “non-reflective”, “bright”: “mirrored”}, “available_thicknesses”: [“.020”, “.025”, “.040”], “available_sizes”: [“12″ x 18″”, “12” x 24″”, “24” x 48″], “surface_colors”: [“Black”, “Blue”, “Gold”, “Mirror Gold”, “Mirror Silve…

5. Brownwood Inc – Anodized Aluminum Color Sample Cards

Domain: brownwoodinc.com

Registered: 2008 (17 years)

Introduction: Anodized Aluminum Color Sample Cards available in eight standard anodized aluminum finish options: brushed aluminum, chrome, satin brass, polished brass, flat black, warm bronze, satin stainless, and titanium. Matches the finish options of aluminum accent trim and most sleeves and ferrules. All sample orders have an approximate 7-10 business day lead time prior to shipping.

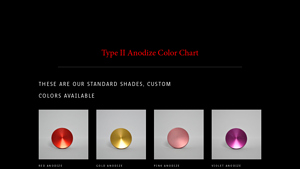

6. CT Anodizing – Type II Anodize Color Chart

Domain: ctanodizing.com

Registered: 2006 (19 years)

Introduction: Type II Anodize Color Chart includes standard shades such as Red, Gold, Pink, Violet, Blue, Grey, Green, Orange, Magenta, Clear, Black, and Bronze. Custom colors are also available.

Strategic Sourcing Conclusion and Outlook for anodized aluminum color samples

In conclusion, effective strategic sourcing of anodized aluminum color samples is essential for international B2B buyers aiming to enhance their projects’ aesthetic appeal and performance. Understanding the nuances of color variation, influenced by alloy types and anodizing processes, enables buyers to make informed decisions that align with their specific requirements. Leveraging a supplier’s expertise in maintaining tight color ranges, such as those adhering to AAMA specifications, can significantly mitigate risks associated with color mismatches and enhance overall project quality.

As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for high-quality anodized finishes will only increase. Buyers should prioritize establishing strong partnerships with reputable suppliers who offer a diverse range of color samples and customization options. By doing so, they can ensure that their projects not only meet aesthetic standards but also adhere to performance expectations.

The future of anodized aluminum applications is promising, and now is the time to act. Engage with your suppliers, request samples, and explore innovative anodizing solutions that can elevate your projects to new heights. Embrace this opportunity to stand out in the competitive marketplace.