Contents

Manufacturing Insight: American Cnc Addison Il

Precision CNC Machining Solutions for the Addison, IL Industrial Corridor

Honyo Prototype delivers advanced CNC machining services engineered to meet the rigorous demands of manufacturers and engineering teams across the Addison, IL region and beyond. As a trusted partner for prototyping and low-to-mid volume production, we specialize in multi-axis milling, turning, and complex 5-axis machining for aerospace, medical, and industrial automation sectors. Our facility operates under stringent ISO 9001:2015 standards, ensuring repeatability down to ±0.0002″ tolerances across materials including titanium, aluminum alloys, stainless steel, and engineered plastics. For engineering teams in Northern Illinois facing compressed development cycles, Honyo provides a critical advantage through rapid turnaround without compromising on quality or documentation rigor.

Technical Capabilities Driving Regional Competitiveness

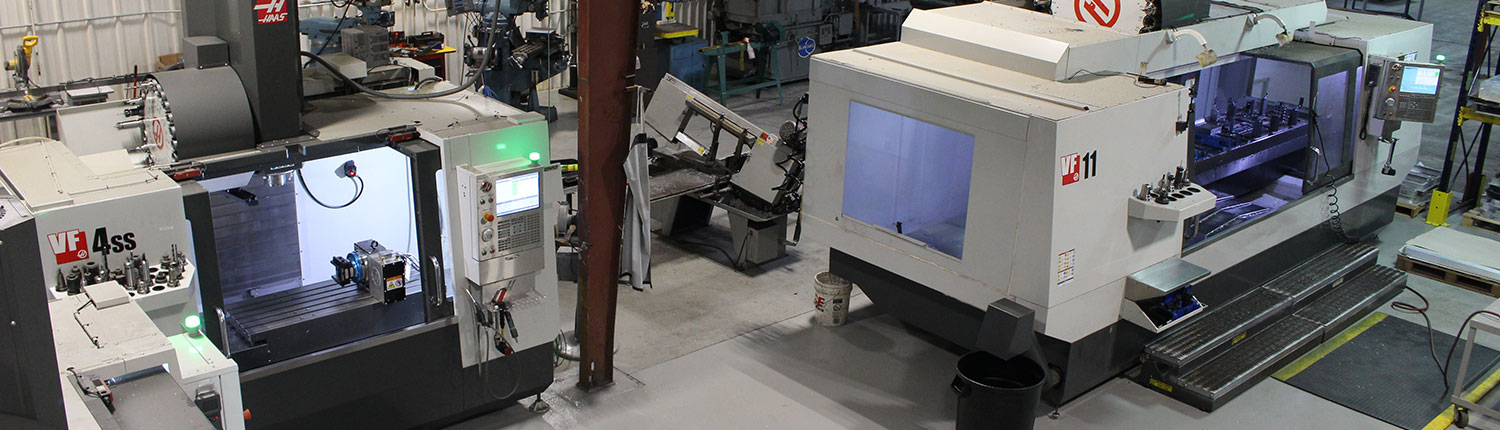

Our CNC fleet integrates Haas, DMG MORI, and Makino equipment with automated inspection protocols, including CMM and optical comparators, to validate first-article compliance and in-process consistency. This infrastructure directly addresses the precision challenges common in Addison-based supply chains—such as tight-tolerance hydraulic components or surgical instrument housings—where material integrity and geometric accuracy are non-negotiable. Honyo’s engineering team collaborates early in the design phase to optimize manufacturability, reducing scrap rates and accelerating time-to-assembly for clients operating in regulated industries.

Accelerate Procurement with Online Instant Quotes

Eliminate traditional RFQ delays with Honyo’s Online Instant Quote platform, designed specifically for engineering professionals requiring rapid cost and lead time validation. Upload STEP or IGES files to receive a comprehensive technical review and binding quotation within 2 hours—24/7. This system integrates real-time machine availability and material pricing, providing actionable data for project planning without manual back-and-forth. For teams in the Addison industrial hub managing urgent tooling revisions or prototype iterations, this capability transforms procurement from a bottleneck into a strategic workflow accelerator.

Partner with Honyo Prototype to leverage CNC machining precision that aligns with the operational tempo of Midwest manufacturing. Explore your next project’s feasibility and cost structure immediately at honyoprototype.com/quote.

Technical Capabilities

Honyo Prototype provides high-precision CNC machining services with advanced 3-axis, 4-axis, and 5-axis milling capabilities, complemented by multi-axis turning and tight-tolerance manufacturing. Our technical expertise supports a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon, ensuring optimal performance for prototyping and low-to-mid volume production runs. Below is a summary of our core technical specifications focused on CNC machining services relevant to precision manufacturing applications.

| Specification Category | Details |

|---|---|

| Machining Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including live tooling and mill-turn) |

| Positioning Accuracy | ±0.0002″ (5 µm) across all axes |

| Repeatability | ±0.0001″ (2.5 µm) |

| Tolerance Range | Standard: ±0.005″; Tight Tolerance: ±0.0005″ to ±0.001″ (12–25 µm) |

| Maximum Work Envelope | Milling: 40″ × 20″ × 20″ (X-Y-Z); Turning: Ø16″ × 24″ max diameter/length |

| Spindle Speed (Milling) | Up to 24,000 RPM with high-speed precision spindles |

| Spindle Speed (Turning) | Up to 6,000 RPM with C-axis control and sub-spindle capability |

| Feed Rates | Up to 1,500 IPM (38 m/min) with high-resolution servo control |

| Control Systems | Fanuc, Siemens, and Heidenhain controls for consistent process integrity |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (6, 6/6, 12) |

| Surface Finish (Milling) | As-machined: 32–125 µin Ra; Optional polishing to <16 µin Ra |

| Coolant & Lubrication | High-pressure through-spindle coolant; mist cooling for plastics |

| Inspection & QA | In-house CMM, optical comparators, and micrometers; First Article Inspection (FAI) reports available |

| Fixturing | Custom modular fixturing, tombstones for 4/5-axis, vacuum and mechanical clamping for plastics |

All parts are manufactured to meet or exceed industry standards for aerospace, medical, and industrial applications. Honyo Prototype maintains ISO 9001-compliant processes and supports full design-for-manufacturability (DFM) analysis prior to production.

From CAD to Part: The Process

Honyo Prototype operates a dedicated CNC machining facility in Addison, Illinois, serving as our primary North American hub for precision manufacturing. The process referenced—often misinterpreted as “American CNC Addison IL”—is Honyo’s standardized workflow for CNC machining projects initiated through our digital platform. This is not a separate entity but Honyo’s integrated U.S.-based production system. Below is the technical sequence from CAD submission to delivery, executed at our Addison, IL facility under ISO 9001:2015 certification.

Upload CAD

Customers submit 3D CAD models (STEP, IGES, or native formats like SOLIDWORKS) via Honyo’s secure client portal. The system validates file integrity, checks for unit consistency (millimeters/inches), and confirms geometric completeness. Incomplete or non-manufacturable geometries trigger immediate alerts, requiring resubmission before progression. All data undergoes encryption per NIST 800-171 standards for ITAR-controlled projects.

AI Quote

Honyo’s proprietary AI engine analyzes the CAD geometry, material specifications, tolerances, and surface finish requirements. It cross-references real-time data from our Addison facility—including machine availability (e.g., Haas VF-2SS, DMG MORI NLX 2500), tooling libraries, and labor rates—to generate a dynamic quote within 2 hours. The algorithm factors in setup complexity, material waste ratios, and secondary operations (e.g., deburring, anodizing), providing cost transparency without human intervention. Historical data from 50,000+ past CNC jobs ensures accuracy within ±3% of final production costs.

DFM (Design for Manufacturability)

Engineers at the Addison facility conduct a dual-phase DFM review. First, automated checks flag non-standard tolerances, thin walls (<0.5mm), or inaccessible features. Second, a senior manufacturing engineer performs a manual review, identifying opportunities to reduce machining time (e.g., suggesting chamfers over radii) or material costs. Typical DFM outcomes include:

| DFM Impact Category | Improvement Example | Avg. Lead Time Reduction |

|---|---|---|

| Geometry Optimization | Replacing internal radii with tool-compatible corners | 12-18% |

| Tolerance Rationalization | Loosening non-critical ±0.005″ to ±0.010″ | 8-15% |

| Material Utilization | Nesting parts on shared stock | 20-30% material savings |

The customer receives a formal DFM report with annotated suggestions; approval or revision is required before production.

Production

Approved jobs move to Addison’s CNC floor. All operations adhere to first-article inspection (FAI) per AS9102 standards. Key protocols include:

Material certification verification (e.g., 6061-T6 aluminum mill test reports)

In-process CMM checks at critical stages (e.g., after roughing and finishing)

Real-time machine telemetry monitoring vibration, tool wear, and thermal drift

High-mix/low-volume jobs leverage our flexible manufacturing cells, while repeat orders use dedicated production lines. Typical CNC machining lead times range from 3 to 15 business days, depending on complexity.

Delivery

Finished parts undergo final QA with full inspection documentation (including GD&T reports). Packaging conforms to ASTM D4169 for shock/vibration resistance, with ESD-safe materials for electronics components. Logistics are managed via our integrated TMS (Transportation Management System), providing:

Real-time FedEx/UPS tracking with ETAs

Automated customs clearance for cross-border shipments (NAFTA/USMCA compliant)

Carbon footprint reporting for sustainability-conscious clients

Domestic U.S. deliveries average 1-3 business days from Addison, with global air freight options available. All shipments include digital quality records accessible via the client portal.

This end-to-end process—executed entirely at Honyo’s Addison, Illinois facility—ensures traceability, reduces time-to-market by 25-40% versus industry averages, and maintains strict compliance with aerospace, medical, and defense sector requirements. Clients retain full visibility through our portal, with stage-specific notifications and downloadable documentation at every milestone.

Start Your Project

Looking for precision CNC machining services with fast turnaround and high-quality standards? Honyo Prototype offers advanced American CNC capabilities right here in Addison, IL.

Our local facility supports rapid prototyping and low-volume production with strict quality control, while our partnership with a state-of-the-art factory in Shenzhen provides scalable solutions for more complex or high-volume needs.

Contact Susan Leo today at [email protected] to discuss your project requirements and discover how we deliver precision, reliability, and speed—whether you’re prototyping or preparing for production.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.