Contents

Manufacturing Insight: Aluminum Metal Melting Point

Understanding Aluminum’s Thermal Properties for Precision Fabrication

Aluminum’s melting point, ranging from 650°C to 665°C for pure grades and varying with alloy composition, is a critical parameter in metal fabrication processes. While sheet metal work typically operates well below this threshold, knowledge of aluminum’s thermal behavior—including its solidus temperature, thermal conductivity, and expansion characteristics—is essential for ensuring dimensional accuracy during cutting, bending, and welding. At Honyo Prototype, we leverage this expertise to mitigate risks like warping or microstructural changes, guaranteeing that your aluminum components meet exacting tolerances and performance standards.

Our Sheet Metal Fabrication services specialize in transforming aluminum into complex, high-integrity parts through precision laser cutting, CNC bending, and expert welding. Whether you’re prototyping or scaling to low-volume production, our engineers account for material-specific variables to deliver consistent quality. To streamline your sourcing process, Honyo offers an Online Instant Quote platform. Simply upload your design file, specify material grade and finish requirements, and receive a detailed cost estimate within hours—accelerating your path from concept to manufactured part. Trust Honyo Prototype to navigate aluminum’s thermal nuances while optimizing your production timeline and budget.

Technical Capabilities

The melting point of aluminum is a critical parameter in manufacturing processes such as laser cutting, bending, and welding, as it influences thermal input, tooling requirements, and compatibility with other materials. Below is a comparison of the melting points for aluminum and other commonly used materials in fabrication, with specific relevance to laser cutting, bending, and welding operations.

| Material | Melting Point (°C) | Melting Point (°F) | Relevance to Laser Cutting | Relevance to Bending | Relevance to Welding |

|---|---|---|---|---|---|

| Aluminum | 660 | 1,220 | Requires high-powered fiber lasers due to high reflectivity and thermal conductivity; nitrogen or oxygen assist gas used depending on precision needs | Excellent formability at room temperature; sharp bends may require heating near melting point for thick sections | TIG and MIG welding preferred; preheating may be needed for thick sections; filler alloys (e.g., 4043, 5356) selected based on base alloy |

| Steel (Mild) | 1,370–1,510 | 2,500–2,750 | Easily cut with CO₂ or fiber lasers; oxygen assist enhances cut speed and edge quality | Can be cold-bent for moderate radii; springback must be compensated; heating required for tight bends | Readily welded using MIG, TIG, or stick welding; preheating needed for thick sections to prevent cracking |

| ABS (Thermoplastic) | 105–125 | 221–257 | Not suitable for laser cutting due to melting and charring; CNC routing preferred | Easily thermoformed using heated molds; not applicable for cold bending | Ultrasonic or hot-plate welding used; not compatible with traditional arc welding |

| Nylon (PA6/PA66) | 215–265 | 420–509 | Poor laser cut quality due to melting and flare; mechanical cutting recommended | Flexible and impact-resistant; can be bent cold within elastic limit | Requires specialized techniques like hot-gas or vibration welding; not weldable via metal methods |

Note: Aluminum’s relatively low melting point compared to steel demands precise thermal control during laser processing and welding to avoid warping or burn-through. Its high thermal conductivity requires higher energy density in laser cutting. In bending applications, aluminum’s ductility allows for tight bend radii, though alloy type (e.g., 5052, 6061) affects formability. When working with hybrid assemblies involving steel, ABS, or nylon, differences in melting behavior must be accounted for in joint design and process selection.

From CAD to Part: The Process

Honyo Prototype’s manufacturing workflow for aluminum components rigorously integrates material science with precision engineering. It is critical to clarify that aluminum’s melting point (approximately 660°C for pure Al, varying by alloy) is a fixed material property—not a discrete process step. Our workflow systematically accounts for this property and other metallurgical factors at each phase to ensure part integrity. Below is the accurate sequence with technical integration points:

Upload CAD

Clients submit detailed 3D models specifying aluminum alloy (e.g., 6061-T6, 7075). Our system immediately flags material-dependent constraints: wall thickness relative to thermal conductivity, geometric features prone to solidification shrinkage, and draft angles for casting. Alloy selection directly informs downstream thermal parameters.

AI-Powered Quoting Engine

The AI cross-references CAD geometry with Honyo’s proprietary database of 200+ aluminum alloys. It calculates melt volume, predicts solidification behavior using thermal gradient algorithms, and factors in alloy-specific shrinkage rates (e.g., 6061: ~1.8%). Quotes include material certification costs and furnace calibration requirements tied to the alloy’s liquidus/solidus range.

DFM Analysis

Our engineers conduct physics-based simulations:

Solidification modeling to prevent hot tears at critical junctions

Thermal stress analysis accounting for aluminum’s high thermal expansion coefficient (23.6 µm/m·°C)

Gate/runner design validation for optimal metal flow at 680–730°C pouring temperatures

Non-compliant features (e.g., thin walls <0.8mm for sand casting) trigger automated design advisories with tolerance-adjusted solutions.

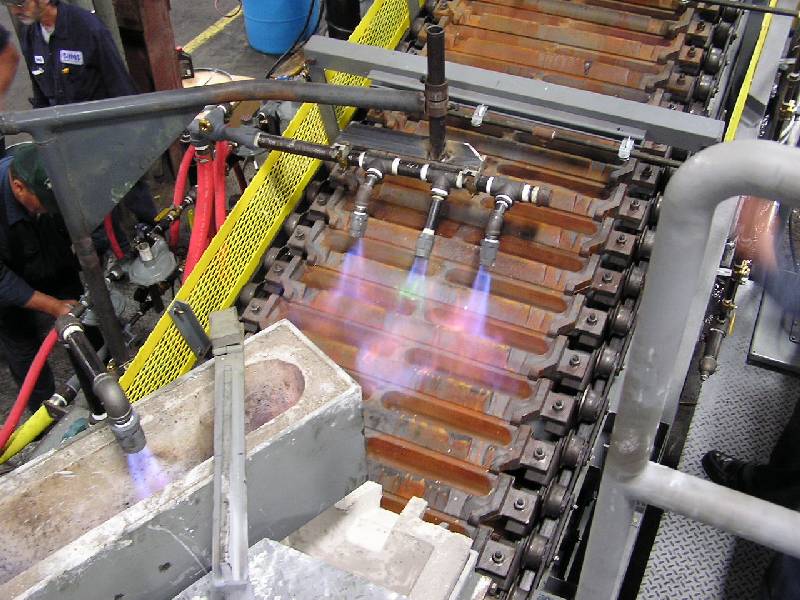

Production Execution

Aluminum melting occurs under controlled inert atmospheres (N₂/Ar) with precise temperature management:

| Alloy Type | Target Pour Temp (°C) | Furnace Calibration Tolerance |

|---|---|---|

| A356 | 690–710 | ±5°C |

| 6061 | 700–720 | ±3°C |

| 7075 | 680–700 | ±2°C |

Molten metal undergoes degassing (rotary impeller), grain refinement (TiB₂), and chemical composition verification via OES spectroscopy before casting. Solidification rates are actively managed through mold cooling channels to avoid micro-porosity.

Delivery & Traceability

Each shipment includes:

Material test reports (ASTM B557 tensile, ASTM E3061 chemical composition)

Thermal process logs showing real-time melt curve compliance

As-cast microstructure analysis (per AMS 4110) for critical applications

Full lot traceability links furnace batches to final inspection data via our digital twin system.

This workflow ensures aluminum components meet dimensional and metallurgical specifications by embedding material science into every phase—not as a standalone “melting point” step, but as a continuous thermal management protocol. We maintain NADCAP accreditation for non-ferrous casting, validating our process control rigor.

Start Your Project

The melting point of aluminum is approximately 660.3°C (1220.6°F), making it a preferred material for various casting and prototyping applications due to its favorable thermal properties and lightweight characteristics.

For engineering support or custom aluminum fabrication services, contact Susan Leo at [email protected]. Honyo Prototype operates a fully equipped manufacturing facility in Shenzhen, offering precision metal processing, rapid prototyping, and low-volume production tailored to industrial and commercial requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.