Contents

Manufacturing Insight: Aluminum Machining Cost

Optimizing Aluminum Machining Costs for Precision Prototyping

Aluminum remains the cornerstone material for rapid prototyping and low-volume production due to its ideal balance of strength, machinability, and cost-efficiency. However, accurately projecting aluminum machining costs requires expertise in material utilization, precision tolerancing, and process optimization—factors often underestimated in early-stage project planning. At Honyo Prototype, our advanced CNC machining capabilities are engineered specifically to minimize waste and maximize throughput for aluminum components, directly reducing your per-part expenses without compromising quality.

Our ISO 9001-certified facility leverages multi-axis CNC milling and turning centers, optimized toolpath strategies, and real-time process monitoring to achieve tight tolerances (±0.005mm) while minimizing cycle times. This precision-driven approach ensures minimal material scrap—critical given aluminum’s significant raw material cost contribution—and eliminates costly rework. Crucially, Honyo’s Online Instant Quote platform empowers engineers to bypass traditional RFQ delays. By uploading your STEP or IGES file, our AI-powered system analyzes geometric complexity, material grade (e.g., 6061-T6, 7075-T6), and tolerance requirements to generate a detailed, transparent cost estimate in under 60 seconds.

This immediate cost visibility enables data-driven design decisions early in development, allowing iterative adjustments to balance performance targets with budget constraints. For prototyping teams under time-to-market pressure, Honyo transforms aluminum machining from a cost variable into a predictable, optimized process—accelerating validation while protecting your bottom line. Begin optimizing your project economics today with a real-time quote.

Technical Capabilities

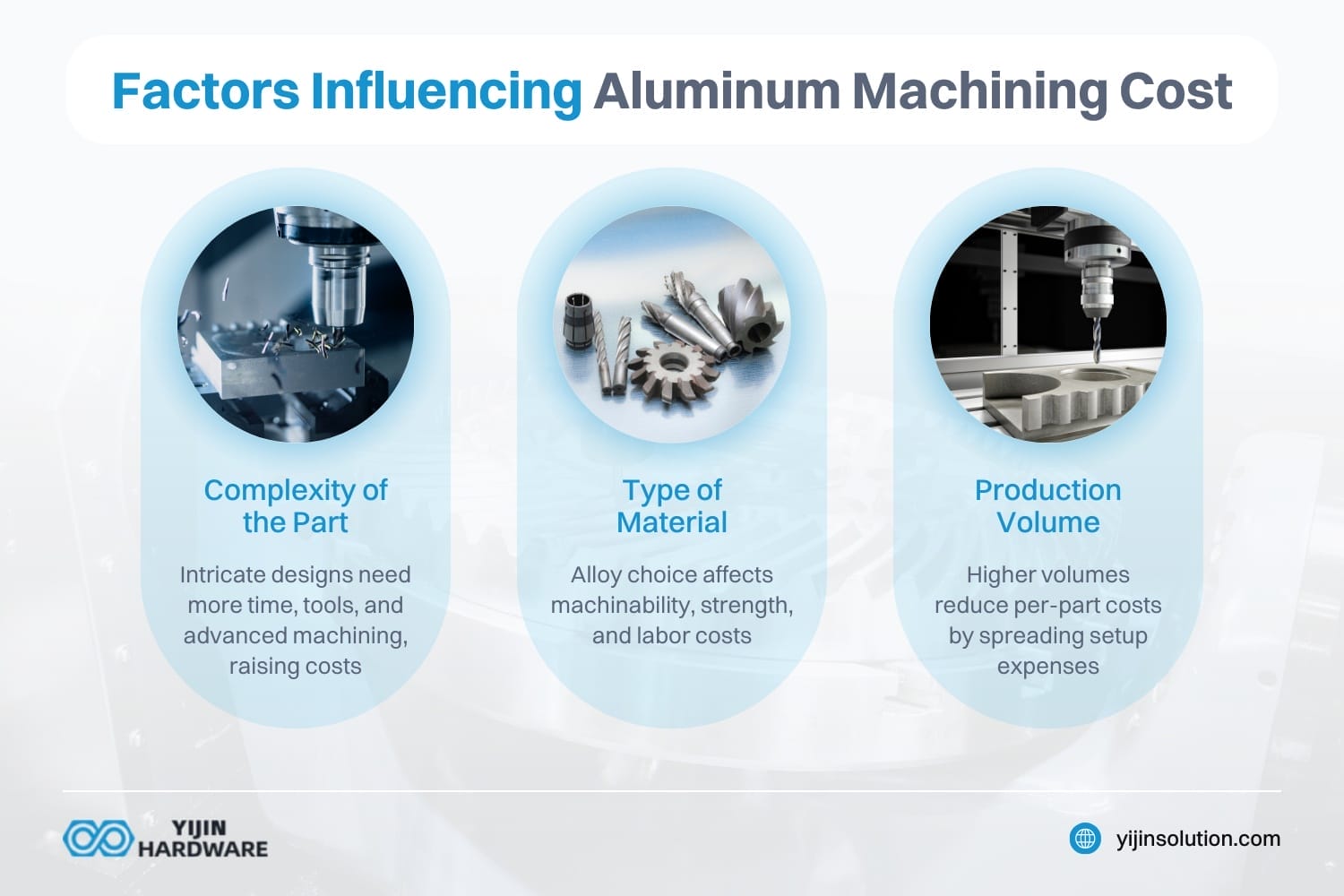

Technical specifications and cost drivers for aluminum machining across 3-axis, 4-axis, and 5-axis milling, as well as turning operations, depend on several factors including part complexity, required tolerances, material selection, and production volume. Below is a comparative overview focusing on cost-influencing technical parameters for Aluminum (6061-T6, 7075-T6), Steel (e.g., 4140, 17-4 PH), ABS, and Nylon (e.g., PA6, PA66).

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | Turning (CNC Lathe) | Notes |

|---|---|---|---|---|---|

| Typical Tolerance | ±0.005″ (standard), ±0.001″ (tight) | ±0.005″, down to ±0.001″ | ±0.001″ consistently achievable | ±0.001″ (tight), ±0.002″ (std) | Tight tolerance increases cost due to precision tooling and inspection |

| Surface Finish (Typical) | 32–64 μin | 32–64 μin | 16–32 μin (complex geometries) | 16–64 μin | Smoother finishes add cost via slower feed rates or post-processing |

| Material – Aluminum (6061) | $45–70/hr (machine time) | $60–85/hr | $90–130/hr | $40–60/hr | High machinability; low tool wear; cost-effective for prototypes |

| Material – Steel (4140) | $55–80/hr | $70–100/hr | $110–160/hr | $50–75/hr | Higher cutting forces, slower speeds, increased tooling cost |

| Material – ABS | $40–60/hr | $55–75/hr | $80–110/hr | $35–50/hr | Lower rigidity; requires light cuts; minimal tool wear |

| Material – Nylon (PA6) | $42–62/hr | $58–78/hr | $85–120/hr | $38–55/hr | Susceptible to thermal expansion; needs precise clamping and feeds |

| Setup Time Impact | Low (1–2 hrs) | Moderate (2–4 hrs) | High (4–8 hrs) | Low–Moderate (1–3 hrs) | 5-axis reduces fixture changes but increases programming complexity |

| Programming Complexity | Low (2.5D CAM) | Medium (indexing + CAM setup) | High (multi-plane toolpaths) | Low–Medium (G-code or CAM) | 5-axis requires advanced CAM software and skilled programmers |

| Lead Time (Prototype) | 3–5 days | 5–7 days | 7–10 days | 3–6 days | Tight tolerances and inspections extend delivery |

| Tight Tolerance Cost Adder | +15–25% | +20–30% | +25–40% | +15–30% | Includes CMM inspection, thermal stability, and process control |

| Common Applications | Brackets, housings | Indexed features, slots | Aerospace components, molds | Shafts, bushings, fittings | Material choice affects performance and cost |

Additional Notes:

Aluminum remains the most cost-efficient material for high-precision milling and turning due to excellent chip evacuation, high tool life, and faster material removal rates.

Steel increases machining cost significantly due to lower cutting speeds, higher tooling wear, and extended cycle times.

ABS and Nylon are cheaper to machine than metals but require careful fixturing and parameter control to avoid deformation.

Achieving tight tolerances (±0.001″) consistently demands environmental control, calibrated equipment, and iterative inspection, especially in 5-axis workflows.

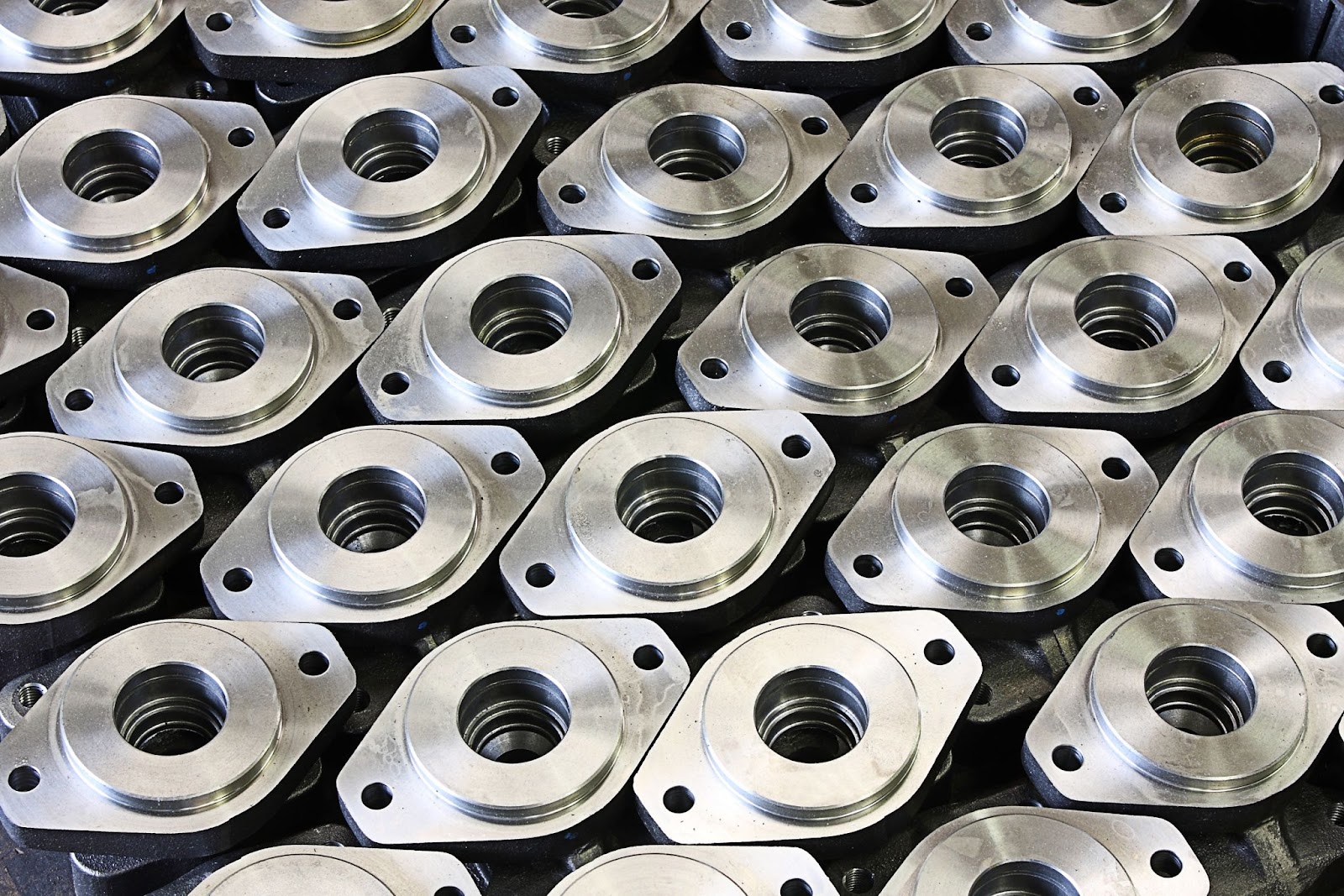

Unit cost decreases with volume due to amortized setup and programming time, especially in turning operations.

From CAD to Part: The Process

Honyo Prototype employs a streamlined, technology-driven workflow to optimize aluminum machining costs while ensuring precision and speed for B2B clients. Our five-phase process eliminates traditional quoting bottlenecks and reduces non-value-added time through integrated digital systems.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. The system automatically validates file integrity and extracts critical geometry data including part volume, feature complexity, tolerance requirements, and stock material dimensions. This digital-first intake ensures zero manual data re-entry errors and captures all manufacturing-relevant parameters upfront.

AI Quote

Our proprietary AI engine analyzes the CAD geometry against live machine capability databases, current material market rates, and shop floor utilization metrics. Within 2 hours, clients receive a detailed cost breakdown including machining time estimates based on toolpath simulation, raw material costs (6061-T6, 7075-T6, etc.), secondary operations, and surface finish requirements. Crucially, the AI flags potential cost drivers such as thin walls below 0.5mm, deep cavities exceeding aspect ratios of 10:1, or non-standard tap sizes before human review.

DFM

Engineers conduct a collaborative Design for Manufacturability review within 24 hours of quote acceptance. Using cloud-based markup tools, we provide specific, actionable recommendations such as adjusting fillet radii to match standard end mill sizes, consolidating features to reduce setups, or suggesting alternative alloys for improved machinability. This phase typically reduces total project cost by 15-30% through preemptive design optimization while maintaining functional requirements. All DFM feedback is tracked in the client’s project dashboard with revision history.

Production

Approved designs move to our climate-controlled aluminum machining cells featuring Haas and DMG MORI 5-axis centers with automated pallet systems. We implement real-time process monitoring via MTConnect-enabled tool wear sensors and in-process probing. For aluminum, we utilize high-speed machining parameters (spindle speeds >20,000 RPM) with optimized coolant strategies to prevent thermal deformation. First-article inspection reports with CMM data are provided before full batch runs, ensuring dimensional compliance to ISO 2768-mK tolerances or client-specified standards.

Delivery

Completed parts undergo final cleaning, deburring, and optional finishing (anodizing, bead blasting) in our integrated secondary operations zone. We provide full traceability including material certs, inspection reports, and batch-controlled shipping documentation. Standard lead time for aluminum prototypes is 5-7 business days from DFM approval, with expedited 72-hour options. All shipments include real-time logistics tracking with carbon-neutral shipping options.

The table below quantifies efficiency gains versus conventional machining vendors:

| Process Phase | Conventional Vendor Approach | Honyo Prototype Approach | Cost/Time Impact |

|---|---|---|---|

| Quote Generation | Manual engineer review (3-5 days) | AI analysis + human validation (2 hours) | 95% faster quoting, 40% lower admin costs |

| DFM Implementation | Reactive revisions post-quote | Collaborative pre-production optimization | 22% average cost reduction per project |

| Production Setup | Physical fixture fabrication | Modular fixturing + digital twin validation | 35% reduced setup time for complex parts |

| Quality Assurance | End-of-line inspection only | In-process probing + SPC monitoring | 99.2% first-pass yield rate for aluminum |

This integrated methodology ensures aluminum machining costs are transparent, minimized through engineering collaboration, and delivered with industrial-grade reliability. We maintain real-time cost tracking throughout production, notifying clients immediately of any deviations from the quoted parameters.

Start Your Project

Looking to optimize your aluminum machining costs? Contact Susan Leo at [email protected] to receive a detailed quote tailored to your project requirements. With our advanced manufacturing capabilities and efficient production processes at our Shenzhen-based factory, Honyo Prototype delivers high-precision machined aluminum components at competitive prices. Partner with us for faster turnaround times and consistent quality in every part. Reach out today to streamline your prototyping or production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.