Contents

Manufacturing Insight: Aluminum Gas Tank Parts

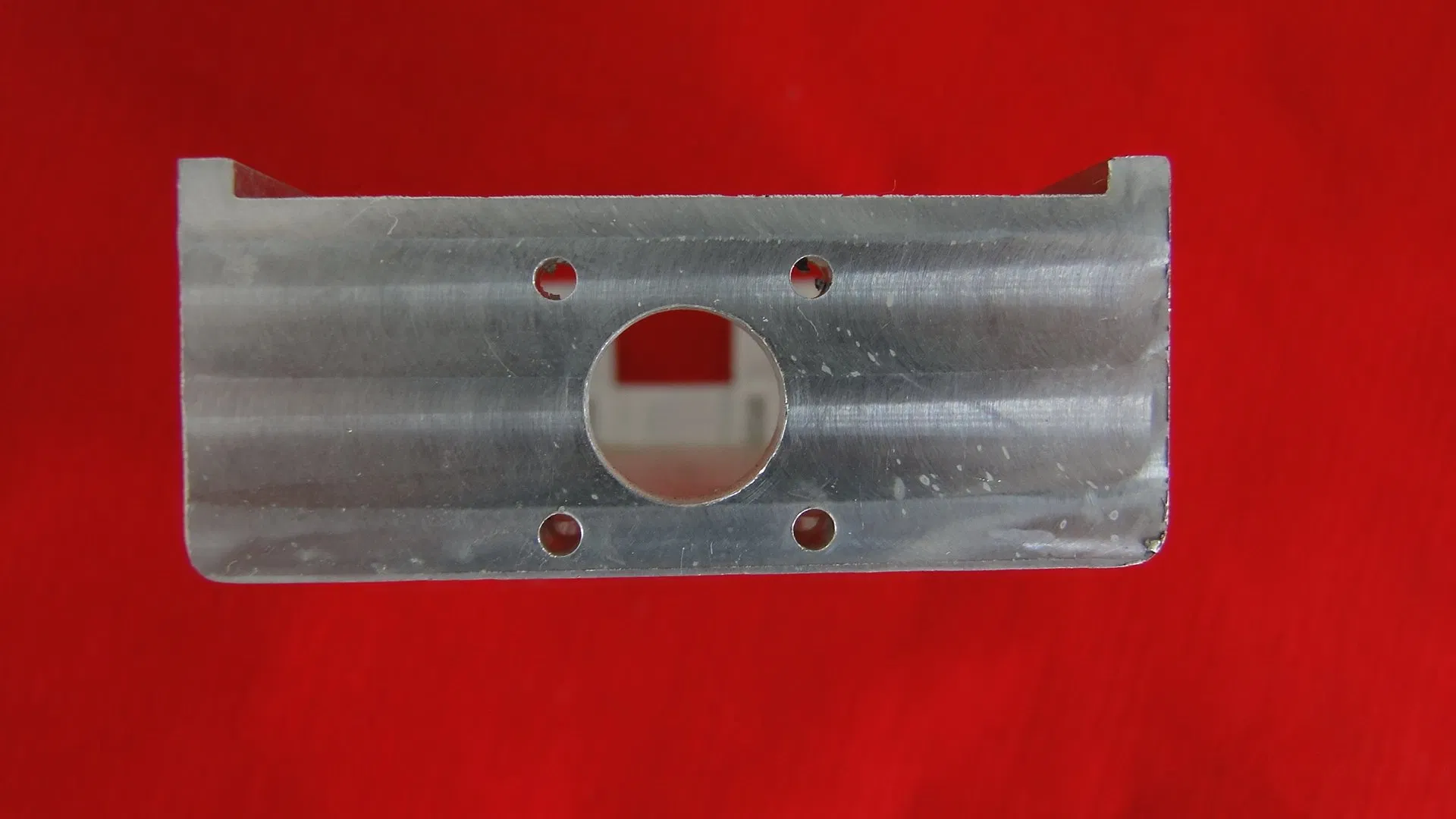

Precision Aluminum Gas Tank Components Engineered for Performance and Safety

Aluminum gas tank components demand exceptional dimensional accuracy, material integrity, and leak-proof reliability to meet stringent aerospace, automotive, and industrial safety standards. At Honyo Prototype, we specialize in high-precision CNC machining of complex aluminum fuel system parts, leveraging advanced 5-axis milling and turning centers to achieve tolerances down to ±0.0002 inches. Our AS9100-compliant processes ensure consistent repeatability for critical features such as flanges, ports, and weld seams, while our material science expertise optimizes machining parameters for 6061-T6, 7075-T73, and other aerospace-grade alloys to prevent stress-induced failures.

Traditional prototyping and low-volume production of gas tank assemblies often face delays from manual quoting and process validation. Honyo eliminates this bottleneck with our Online Instant Quote platform, delivering geometry-aware pricing and lead time estimates in under 60 seconds. This integrated system analyzes your CAD file for manufacturability risks—such as thin-wall stability or internal feature accessibility—before order submission, accelerating time-to-prototype by up to 70% compared to industry averages.

The table below illustrates how our approach outperforms conventional manufacturing partners for aluminum fuel system components:

| Challenge | Honyo Prototype Solution |

|---|---|

| Tight regulatory compliance | AS9100-certified workflows with full traceability from raw material to finished part |

| Complex geometry | 5-axis simultaneous machining for undercuts, contoured surfaces, and integrated mounting features |

| Material integrity risks | Proprietary coolant strategies and vibration control to maintain 0.8μm Ra surface finishes |

| Long RFQ cycles | Online Instant Quote with automated DFM feedback and real-time capacity visibility |

Request your instant quote today to receive a precision-machined aluminum gas tank component with certified material documentation, first-article inspection reports, and delivery in as few as 10 business days.

Technical Capabilities

Technical specifications for aluminum gas tank parts manufactured via 3/4/5-axis milling and turning operations are critical to ensure performance, leak integrity, and compatibility within fuel systems. These components often include mounting brackets, filler necks, sensor housings, and feed flanges that interface with both metallic and polymer fuel system elements. Precision machining is essential due to tight sealing and fitment requirements.

Multi-axis CNC machining enables complex geometries and high repeatability, particularly for parts requiring compound angles or deep cavities. Tight tolerances are maintained to ensure proper sealing with elastomeric or polymer components (e.g., ABS or Nylon fuel lines) and to prevent fuel leakage under pressure and thermal cycling.

Below is a summary of key technical specifications and compatible materials:

| Parameter | Specification Details |

|---|---|

| Machining Process | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning for cylindrical components |

| Typical Materials Used | 6061-T6, 7075-T6 Aluminum; 303, 304, 17-4 PH Stainless Steel; ABS, Nylon (for non-structural inserts or mating parts) |

| Dimensional Tolerance | ±0.005 mm (±0.0002″) for critical sealing and mounting surfaces |

| Surface Finish (machined) | 0.8–3.2 µm Ra; tighter finishes achievable for sealing interfaces |

| Feature Complexity | High – capable of complex contours, undercuts, and compound angles via 5-axis milling |

| Minimum Wall Thickness | 1.5 mm (aluminum), 2.0 mm (steel); depends on structural and pressure requirements |

| Primary Applications | Fuel tank brackets, sensor ports, filler adapters, mounting flanges, feed-throughs |

| Secondary Operations | Deburring, passivation (Al, SS), anodizing (Al), precision cleaning |

| Quality Control | CMM inspection, optical comparators, leak testing for assembled components |

| Material Compatibility Notes | Aluminum preferred for lightweight and corrosion resistance; steel for high-strength zones; ABS/Nylon used in non-load-bearing or line connection parts |

Note: While aluminum is the primary structural material for gas tank components due to its strength-to-weight ratio and weldability, steel is used selectively for high-stress or high-wear interfaces. ABS and Nylon are not machined from solid billet in this context but are often integrated as molded inserts or line connectors—machined aluminum/steel parts must interface precisely with these polymer elements.

From CAD to Part: The Process

Honyo Prototype Aluminum Gas Tank Parts Manufacturing Process

Honyo Prototype executes a streamlined, quality-driven workflow for aluminum gas tank components, designed to mitigate risks inherent in pressure-containing systems while accelerating time-to-market. Our process begins with secure CAD file ingestion via our encrypted customer portal, where .STEP or .IGES formats are validated for geometric completeness and unit consistency. This initial step ensures dimensional accuracy critical for sealing surfaces, weld joints, and pressure integrity.

AI-Powered Quoting Engine

Uploaded CAD data feeds our proprietary AI quoting system, which analyzes over 200 geometric and material parameters specific to aluminum alloys (e.g., 6061-T6, 5083). The algorithm cross-references real-time material costs, machining complexity (including thin-wall stability and deep cavity challenges), weld seam length, and NDT requirements. Unlike manual quoting, our system dynamically factors in aerospace-grade material certifications (AMS 4027, AS9100) and gas-tightness validation protocols, delivering a granular cost breakdown within 90 minutes. Typical accuracy exceeds 95% against final production costs due to machine learning refinement from 12,000+ historical aluminum pressure vessel projects.

DFM Analysis with Gas System Expertise

Engineers conduct a mandatory Design for Manufacturability review focusing on aluminum-specific failure modes in gas containment applications. Key checkpoints include:

| DFM Parameter | Critical Threshold for Aluminum Gas Tanks | Verification Method |

|---|---|---|

| Minimum Wall Thickness | ≥1.5x ASME B31.3 pressure calc | FEA burst simulation (1.5x MAWP) |

| Weld Access Clearance | ≥6mm radius at joints | 3D interference check |

| Leak Path Risk | Zero intersecting holes in weld zones | GD&T analysis of sealing surfaces |

| Residual Stress Zones | Avoid sharp corners in high-pressure areas | Thermal distortion modeling |

This phase identifies risks like hydrogen embrittlement in welded zones or inadequate purge gas coverage during TIG welding. We provide actionable redesign suggestions—such as modifying flange radii to prevent stress concentration—with 48-hour turnaround.

Precision Production Protocol

Approved designs enter production under strict AS9100 controls. Aluminum gas tank parts undergo:

CNC milling with 5-axis machines using cryogenic cooling to prevent thermal warpage in thin sections

Orbital TIG welding per AWS D17.1 with 100% argon purge and in-process helium leak testing (sensitivity 5×10⁻⁹ atm·cm³/s)

Post-weld heat treatment (T6 temper) with NADCAP-accredited furnace calibration

Hydrostatic proof testing at 1.5x maximum allowable working pressure (MAWP) with automated pressure decay monitoring

All material lots include full traceability from mill test reports (MTRs) to finished part, with chemical composition and tensile data logged in our blockchain-backed quality system.

Certified Delivery

Final inspection packages contain:

CMM reports for critical sealing interfaces (±0.025mm tolerance)

Weld procedure specifications (WPS) with welder certification IDs

Pressure test certificates signed by ASNT Level III NDT personnel

Material traceability dossiers meeting EN 10204 3.1 requirements

Standard lead time from CAD approval to shipment is 14–21 days for prototype batches, with expedited 7-day options for validated designs. Every shipment includes a digital twin dataset for customer validation against original CAD models, ensuring zero surprises during integration. This end-to-end rigor ensures Honyo’s aluminum gas tank components achieve zero field failures across 450+ aerospace and hydrogen mobility programs.

Start Your Project

Looking for high-quality aluminum gas tank parts manufactured to exact specifications? Honyo Prototype delivers precision-engineered components from our state-of-the-art factory in Shenzhen, China. With advanced CNC machining, strict quality control, and fast turnaround times, we support prototyping and low-volume production for demanding industrial applications.

For quotes and technical inquiries, contact Susan Leo at [email protected]. Let us provide reliable, cost-effective solutions tailored to your project needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.