Introduction: Navigating the Global Market for aluminum diy cnc router

Navigating the complex landscape of sourcing an aluminum DIY CNC router can be a daunting challenge for international B2B buyers. With the demand for precision manufacturing and prototyping on the rise across industries, understanding the nuances of this technology is crucial. This guide delves into the various types of aluminum DIY CNC routers available, their diverse applications—from automotive to aerospace—and the essential considerations for selecting the right machine for your business needs.

In the following sections, we will explore critical aspects such as supplier vetting processes, cost analysis, and maintenance requirements, providing a holistic view that empowers you to make informed purchasing decisions. This comprehensive resource is particularly tailored for buyers from regions such as Africa, South America, the Middle East, and Europe, including emerging markets like Brazil and Vietnam, where the demand for localized manufacturing solutions is growing.

By leveraging the insights provided in this guide, you will be equipped to navigate the global market effectively, ensuring that your investment in an aluminum DIY CNC router not only meets your operational requirements but also enhances your competitive edge in an increasingly digital economy.

Understanding aluminum diy cnc router Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gantry CNC Router | Utilizes a moving gantry system; often aluminum frame | Prototyping, custom part fabrication | Pros: High stability, customizable size. Cons: Can be complex to assemble and align. |

| Aluminum Extrusion CNC Router | Built using aluminum extrusions; modular design | Educational institutions, small workshops | Pros: Easy to modify, lightweight. Cons: May require additional support for heavy milling. |

| Desktop CNC Router | Compact, often smaller work area; user-friendly | Hobbyists, small-scale production | Pros: Space-efficient, affordable. Cons: Limited cutting capacity, not suitable for large projects. |

| Heavy-Duty CNC Router | Designed for high-load applications; robust construction | Manufacturing, metalworking | Pros: High precision, capable of cutting thick materials. Cons: Higher cost, requires significant space. |

| Hybrid CNC Router | Combines CNC with 3D printing capabilities | Prototyping, custom manufacturing | Pros: Versatile, allows for complex designs. Cons: Complexity in operation and maintenance. |

What are the characteristics of Gantry CNC Routers and their suitability for B2B buyers?

Gantry CNC routers are characterized by their moving gantry system, which allows for a stable and precise cutting experience. Typically built with an aluminum frame, these routers are suitable for various B2B applications, particularly in prototyping and custom part fabrication. Buyers should consider the complexity of assembly and alignment, as well as the potential for customization in size and features, making them ideal for businesses requiring tailored solutions.

How do Aluminum Extrusion CNC Routers differ and what are their key benefits?

Aluminum extrusion CNC routers utilize modular designs, making them easy to modify and adapt for different tasks. They are particularly beneficial for educational institutions and small workshops, where flexibility and ease of assembly are crucial. While they offer lightweight construction and customization options, buyers must be aware that they may require additional support for heavy milling tasks, which can impact operational efficiency.

Why are Desktop CNC Routers popular among small businesses and hobbyists?

Desktop CNC routers are compact and user-friendly, making them an attractive option for hobbyists and small-scale production environments. Their space-efficient designs allow for easy integration into limited workspaces. However, their cutting capacity is limited, which may not meet the needs of businesses that require larger or more complex projects. Buyers should weigh the affordability against the operational limitations when considering this type.

What makes Heavy-Duty CNC Routers a preferred choice for manufacturing?

Heavy-duty CNC routers are built to handle high-load applications and are constructed for robust performance. They are ideal for manufacturing and metalworking environments, where precision and the ability to cut thick materials are paramount. While they provide high accuracy and durability, the higher costs and significant space requirements may be a consideration for potential buyers, particularly in smaller operations.

How do Hybrid CNC Routers enhance versatility in manufacturing?

Hybrid CNC routers combine traditional CNC machining with 3D printing capabilities, offering versatility for prototyping and custom manufacturing. This combination allows businesses to create complex designs and streamline their production processes. However, the complexity of operation and maintenance can pose challenges for some users. Companies should evaluate their technical expertise and operational needs to determine if a hybrid solution aligns with their production goals.

Key Industrial Applications of aluminum diy cnc router

| Industry/Sector | Specific Application of Aluminum DIY CNC Router | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Prototyping aircraft components | Cost-effective production of lightweight parts | Precision in machining, material sourcing, and compliance with aerospace standards |

| Automotive | Fabricating custom parts and tooling | Reduced lead times and enhanced design flexibility | Material quality, tolerance requirements, and tooling compatibility |

| Electronics Manufacturing | Creating enclosures and chassis for devices | Streamlined production and customization capabilities | Precision machining, thermal management properties, and surface finish requirements |

| Signage and Advertising | Producing custom aluminum signs and displays | High-quality finishes and tailored designs | Material thickness, engraving capabilities, and lead times |

| Renewable Energy | Manufacturing components for solar panel frames | Lightweight structures enhancing efficiency | Sourcing durable materials, corrosion resistance, and assembly requirements |

How is Aluminum DIY CNC Router Used in Aerospace Prototyping?

In the aerospace industry, aluminum DIY CNC routers are invaluable for prototyping aircraft components. They enable engineers to create precise, lightweight parts quickly and at a lower cost compared to traditional manufacturing methods. These routers solve the problem of high production costs and long lead times associated with outsourcing prototyping. Buyers in this sector must ensure their machines can achieve the necessary tolerances and comply with industry standards for safety and performance, particularly when sourcing components from regions like Europe or North America.

What Role Does Aluminum DIY CNC Router Play in Automotive Customization?

Automotive manufacturers utilize aluminum DIY CNC routers to fabricate custom parts and tooling. This capability allows for rapid prototyping of unique designs, leading to reduced lead times in production. The flexibility of these machines enables businesses to adapt to changing market demands without incurring significant costs. Buyers should focus on sourcing routers with robust cutting capabilities and compatibility with various aluminum grades, particularly if they operate in regions like South America or Africa, where material availability may vary.

How Can Aluminum DIY CNC Routers Enhance Electronics Manufacturing?

In electronics manufacturing, aluminum DIY CNC routers are used to create enclosures and chassis for devices. This application provides manufacturers with the ability to streamline production processes while offering customization options that meet specific client needs. By using CNC routers, businesses can address challenges related to mass production and achieve high-quality finishes. Buyers should prioritize sourcing machines that can accommodate detailed designs and ensure thermal management properties are suitable for electronic components.

Why Are Aluminum DIY CNC Routers Essential for Signage and Advertising?

The signage and advertising sector benefits from aluminum DIY CNC routers by enabling the production of custom signs and displays. These routers can create intricate designs and high-quality finishes that are visually appealing and durable. This flexibility addresses the challenge of meeting diverse client requirements efficiently. When sourcing, businesses should consider the router’s engraving capabilities and the thickness of materials used to ensure optimal results in various advertising applications.

How Do Aluminum DIY CNC Routers Contribute to Renewable Energy Solutions?

In the renewable energy industry, aluminum DIY CNC routers are utilized for manufacturing components such as solar panel frames. These lightweight structures enhance overall system efficiency and performance. By using CNC routers, companies can rapidly produce parts tailored to specific project requirements, solving issues related to material waste and production speed. Buyers should focus on sourcing durable materials and ensuring the CNC machine can handle the specific fabrication processes required for energy solutions, particularly in regions with growing renewable energy markets.

3 Common User Pain Points for ‘aluminum diy cnc router’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision Cuts

The Problem: Many B2B buyers venturing into the aluminum DIY CNC router market face significant challenges related to achieving precision cuts. In industries such as manufacturing and prototyping, tolerances are critical. Buyers often report issues with alignment, leading to inconsistent cuts that can result in wasted materials and increased production costs. This problem is particularly pronounced for businesses that require high-quality parts for applications like automotive components or intricate electronics housings. When precision is compromised, it can jeopardize the entire project timeline and client satisfaction.

The Solution: To overcome precision challenges, buyers should invest in high-quality linear guide rails and robust frame designs. Sourcing components from reputable suppliers is crucial; for instance, opting for 16mm steel shafts and bearing blocks can significantly enhance stability. Additionally, integrating anti-backlash nuts in the lead screw assembly can minimize play, ensuring that the cutting head remains aligned throughout the machining process. Buyers should also consider employing software like LinuxCNC, which provides advanced calibration tools to fine-tune the machine’s settings. Regular maintenance, including checking for wear on critical components, will help maintain precision over time. Establishing a routine for maintenance can prevent costly errors and extend the lifespan of the CNC router.

Scenario 2: High Initial Investment and Operational Costs

The Problem: The initial investment required for an aluminum DIY CNC router can be daunting, especially for small to medium-sized enterprises (SMEs) in regions like Africa and South America where budgets may be tighter. The costs associated with high-quality materials, electronic components, and software licenses can quickly accumulate, leading potential buyers to hesitate. Additionally, operational costs such as electricity, maintenance, and material wastage can strain budgets further, creating a barrier to entry for businesses looking to adopt CNC technology.

The Solution: To manage initial and ongoing costs, buyers should focus on creating a detailed budget plan that includes all aspects of the CNC router project. Exploring financing options or grants specifically aimed at technology adoption can alleviate financial pressure. Additionally, sourcing materials locally can reduce shipping costs and tariffs, making it more feasible to build the router. Buyers should also consider purchasing second-hand components or refurbished machines, which can provide significant savings while still delivering the required performance. To control operational costs, implementing efficient workflow practices, such as optimizing cutting paths and minimizing idle time, will maximize resource use and reduce wastage. Training staff on best practices for operating and maintaining the CNC router can further enhance efficiency and reduce long-term costs.

Scenario 3: Limited Technical Expertise and Support

The Problem: Many businesses, particularly those in emerging markets, may struggle with limited technical expertise when it comes to operating and maintaining an aluminum DIY CNC router. The complexity of CNC technology can be overwhelming for teams without a background in engineering or machining. This knowledge gap can lead to improper usage, resulting in machine failures, unsafe working conditions, and subpar product quality. The absence of local support can exacerbate these challenges, leaving buyers feeling isolated and frustrated.

The Solution: To bridge the expertise gap, buyers should prioritize training and education for their teams. Engaging with online communities, forums, and resources dedicated to CNC technology can provide invaluable insights and troubleshooting support. Many suppliers offer training sessions or workshops that can be beneficial. Additionally, buyers should look for CNC router packages that include comprehensive user manuals and access to technical support. Establishing a relationship with a local CNC expert or consultant can provide ongoing guidance and support, ensuring that the machine is used effectively. Investing in user-friendly software that includes intuitive interfaces and online tutorials can also empower teams to operate the CNC router competently. By fostering a culture of learning and continuous improvement, businesses can enhance their technical capabilities and maximize the value derived from their CNC investment.

Strategic Material Selection Guide for aluminum diy cnc router

What Are the Key Materials for Building an Aluminum DIY CNC Router?

When selecting materials for an aluminum DIY CNC router, it’s essential to consider their properties, advantages, limitations, and suitability for specific applications. This analysis focuses on four common materials: Aluminum Alloy 6061, Aluminum Alloy 2024, Steel, and MDF (Medium Density Fiberboard). Each material presents unique characteristics that can significantly impact the performance and cost-effectiveness of the CNC router.

How Does Aluminum Alloy 6061 Perform in CNC Router Applications?

Aluminum Alloy 6061 is one of the most widely used aluminum alloys in CNC applications. It offers excellent corrosion resistance, good weldability, and moderate to high strength. The alloy’s temperature rating is suitable for a variety of environments, making it ideal for both indoor and outdoor use.

Pros: Its lightweight nature contributes to easier handling and assembly, while its durability ensures longevity. Additionally, it has good machinability, which is crucial for achieving precise cuts.

Cons: The primary limitation of 6061 is its relatively higher cost compared to some other materials. It may also require specialized tools for machining, which can increase manufacturing complexity.

Impact on Application: This alloy is compatible with various media, including plastics and wood, making it versatile for different projects.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is essential. Buyers from regions like Africa and South America should ensure that suppliers can meet these standards to avoid quality issues.

What Advantages Does Aluminum Alloy 2024 Offer for CNC Routers?

Aluminum Alloy 2024 is known for its high strength-to-weight ratio and is often used in aerospace applications. It offers superior fatigue resistance, making it suitable for high-stress applications.

Pros: The alloy is incredibly strong, which is beneficial for maintaining structural integrity during heavy machining operations. It also has excellent machinability.

Cons: However, 2024 is less corrosion-resistant than 6061, requiring additional surface treatments for outdoor applications. Its cost is also on the higher end of the spectrum.

Impact on Application: This alloy is particularly effective for applications requiring high precision and durability, such as in the aerospace and automotive industries.

Considerations for International Buyers: Buyers should be aware of the specific grades and treatments required for corrosion resistance, especially in humid climates prevalent in parts of Africa and South America.

Why Consider Steel for CNC Router Frame Construction?

Steel, particularly mild steel, is another option for constructing CNC router frames. It offers high strength and rigidity, making it suitable for heavy-duty applications.

Pros: Steel is generally more affordable than aluminum and provides excellent stability during machining operations. It can handle higher loads without deforming.

Cons: The primary drawback is its susceptibility to corrosion, necessitating protective coatings. Additionally, steel is heavier, which can complicate the assembly process.

Impact on Application: Steel is ideal for applications requiring high rigidity and stability, such as industrial-grade CNC routers.

Considerations for International Buyers: Compliance with international standards like ASTM A36 is crucial. Buyers should also consider local availability and transportation costs, as heavy steel components may incur higher shipping fees.

What Role Does MDF Play in CNC Router Applications?

Medium Density Fiberboard (MDF) is often used for CNC router bases and tables due to its affordability and ease of machining.

Pros: MDF is cost-effective and provides a smooth surface finish, which is beneficial for precision work. It is also readily available in many markets.

Cons: However, MDF lacks the durability and strength of metals, making it unsuitable for heavy-duty applications. It is also susceptible to moisture damage.

Impact on Application: MDF is best suited for lighter applications, such as woodworking and prototyping, rather than for heavy aluminum cutting.

Considerations for International Buyers: Buyers should ensure that the MDF meets local standards for density and moisture resistance, particularly in humid regions.

Summary Table of Material Selection for Aluminum DIY CNC Router

| Material | Typical Use Case for aluminum diy cnc router | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy 6061 | General-purpose CNC frames and components | Excellent corrosion resistance | Higher cost compared to alternatives | Medium |

| Aluminum Alloy 2024 | High-stress applications (e.g., aerospace) | High strength-to-weight ratio | Less corrosion-resistant | High |

| Steel | Heavy-duty CNC router frames | High strength and stability | Susceptible to corrosion | Low |

| MDF | Lightweight CNC bases and prototypes | Cost-effective and easy to machine | Lacks durability and moisture-sensitive | Low |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions when sourcing materials for aluminum DIY CNC routers.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum diy cnc router

What Are the Main Stages of Manufacturing an Aluminum DIY CNC Router?

The manufacturing process for an aluminum DIY CNC router typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring that the final product meets quality standards and performs effectively.

Material Preparation: How Is Aluminum Processed for CNC Routers?

Material preparation starts with selecting the right grade of aluminum, commonly 6061 or 6063, which are known for their excellent machinability and strength-to-weight ratio. The aluminum is cut into specific dimensions using precise tools, such as miter saws fitted with carbide blades, to ensure accuracy.

Before cutting, suppliers often inspect the aluminum for any defects or inconsistencies, which helps to prevent issues during later manufacturing stages. This initial quality check, known as Incoming Quality Control (IQC), ensures that only materials meeting specific criteria proceed to the next stage.

What Techniques Are Used in Forming the Components?

The forming process involves machining the prepared aluminum into various components of the CNC router. Techniques such as milling, drilling, and tapping are employed to create parts like the frame, gantry, and other structural elements. CNC machining is favored here because it offers high precision and repeatability.

After forming, parts are often subjected to Intermediate Process Quality Control (IPQC) checks, where measurements are taken to confirm that components adhere to specified tolerances. This proactive approach helps identify issues early in the process, reducing the likelihood of costly rework.

How Are Components Assembled in a CNC Router?

The assembly stage is where all the machined components come together to form the complete CNC router. Key components include the frame, linear guide rails, stepper motors, and the CNC controller.

During assembly, technicians follow detailed assembly instructions and checklists to ensure that each part is correctly installed and aligned. Final assembly often includes additional quality checks, such as Functional Quality Control (FQC), which tests the assembled machine’s functionality before it leaves the factory.

What Finishing Processes Are Commonly Used in CNC Router Manufacturing?

Finishing processes enhance both the aesthetic and functional aspects of the CNC router. Common finishing techniques include anodizing, which provides a protective layer to the aluminum, and painting, which can improve appearance and resistance to wear.

Quality assurance during the finishing stage may involve visual inspections and surface roughness measurements to ensure that the finish meets industry standards. These checks help ensure that the router is not only visually appealing but also durable and capable of withstanding operational stresses.

What International Standards and Certifications Should B2B Buyers Consider?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding relevant industry standards is vital. ISO 9001 certification is a fundamental quality management standard that many manufacturers adhere to, demonstrating their commitment to quality processes.

In addition to ISO standards, certifications such as CE marking for compliance with European safety directives and API specifications for specific applications may also be necessary. Buyers should inquire about these certifications during the supplier selection process to ensure that the products meet their regulatory requirements.

How Can Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of potential suppliers. Conducting audits of the manufacturing facility is one effective method. This allows buyers to observe the processes firsthand and ensure that suppliers maintain high-quality standards.

Additionally, requesting quality reports and documentation can provide insights into the supplier’s quality assurance practices. Buyers may also consider hiring third-party inspection services to perform quality checks before shipment, ensuring that the products meet agreed-upon specifications.

What Are Common Testing Methods for Quality Assurance?

Testing methods play a crucial role in ensuring that the CNC routers meet performance and durability standards. Common testing methods include:

- Dimensional Inspection: Measuring components to verify they meet specified tolerances.

- Functional Testing: Running the CNC router through its operational parameters to ensure it functions correctly.

- Material Testing: Conducting tests such as tensile strength or fatigue tests to assess material properties.

These tests help identify potential issues before the product reaches the end user, reducing the risk of operational failures.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

International buyers should be aware of regional nuances in quality control. For instance, different countries may have varying regulations regarding product safety and quality standards. Understanding these regulations can help buyers make informed decisions and avoid compliance issues.

Moreover, cultural differences in business practices can influence the level of transparency and communication during the procurement process. Buyers should establish clear expectations with suppliers regarding quality assurance practices, documentation, and timelines to ensure a smooth transaction.

Conclusion: Ensuring Quality in Your Aluminum DIY CNC Router Purchase

Purchasing an aluminum DIY CNC router requires careful consideration of the manufacturing processes and quality assurance measures in place. By understanding the stages of manufacturing, relevant international standards, and how to verify supplier quality control, B2B buyers can make informed decisions that enhance their operational efficiency and product reliability. Prioritizing these factors not only safeguards investments but also ensures that the CNC routers will meet the demanding requirements of various applications across different industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum diy cnc router’

To assist B2B buyers in procuring an aluminum DIY CNC router, this guide provides a practical checklist that outlines key steps to ensure a successful sourcing process. This guide is particularly relevant for businesses in regions such as Africa, South America, the Middle East, and Europe, where understanding local market dynamics and supplier capabilities can significantly impact purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for aligning your CNC router with your operational needs. Consider factors such as the desired cutting area, material thickness, and precision requirements. This step ensures that potential suppliers can provide machines that meet your specific production criteria.

- Key specifications to define:

- Maximum working dimensions (length, width, height)

- Types of materials to be processed (aluminum, wood, etc.)

- Required precision and tolerances

Step 2: Research and Identify Suppliers

Conduct thorough market research to identify reputable suppliers of aluminum DIY CNC routers. Utilize online platforms, industry forums, and trade shows to compile a list of potential vendors. Understanding the landscape of available options can help you identify suppliers with a proven track record and relevant experience.

- Considerations during research:

- Supplier location and shipping capabilities

- Specialization in CNC routers versus general machinery

- Customer reviews and testimonials

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This evaluation helps ensure that suppliers can meet your quality and service expectations.

- Key evaluation criteria:

- Manufacturing capabilities and certifications

- After-sales support and warranty policies

- Delivery timelines and logistics

Step 4: Request Detailed Quotes

Once you’ve shortlisted suppliers, request detailed quotes that include pricing, shipping costs, and lead times. A comprehensive quote allows for accurate comparisons between suppliers and helps identify any hidden costs that may affect your budget.

- What to include in your request:

- Breakdown of costs (materials, labor, shipping)

- Payment terms and conditions

- Optional add-ons or services (installation, training)

Step 5: Verify Certifications and Compliance

Ensure that the suppliers comply with international standards and certifications relevant to CNC machinery. This step is essential for ensuring safety, reliability, and quality in your operations, particularly in regions with varying regulatory requirements.

- Certifications to look for:

- ISO 9001 for quality management

- CE marking for compliance with European safety standards

- Local certifications relevant to your region

Step 6: Assess After-Sales Support and Training

Evaluate the after-sales support and training offered by the suppliers. A robust support system is crucial for troubleshooting and maintenance, while training ensures your team can operate the CNC router effectively from day one.

- Support features to consider:

- Availability of technical support and response times

- Training programs for your staff

- Access to spare parts and maintenance services

Step 7: Finalize Purchase and Negotiate Terms

After selecting a supplier, finalize the purchase agreement by negotiating favorable terms. Ensure that all aspects of the agreement, including delivery schedules and payment terms, are clearly outlined to avoid misunderstandings.

- Important contract elements:

- Delivery timelines and penalties for delays

- Payment milestones and methods

- Terms for returns or exchanges if the product does not meet specifications

This checklist serves as a comprehensive guide for B2B buyers looking to source aluminum DIY CNC routers effectively, ensuring that all critical factors are considered for a successful procurement process.

Comprehensive Cost and Pricing Analysis for aluminum diy cnc router Sourcing

What Are the Key Cost Components for Sourcing Aluminum DIY CNC Routers?

When evaluating the costs associated with sourcing aluminum DIY CNC routers, several key components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the overall cost. Aluminum, particularly 6061 grade, is favored for its balance of strength and weight. Pricing can vary based on global aluminum market fluctuations, regional availability, and supplier relationships. Expect to allocate a substantial portion of your budget to high-quality aluminum and other necessary components such as linear guide rails, stepper motors, and electronics.

-

Labor: Labor costs can vary widely depending on the region and the complexity of the CNC router design. Skilled labor is essential for assembly and quality assurance, especially for custom builds. In regions with lower labor costs, such as parts of Africa or South America, you might find potential savings, but ensure that the quality of craftsmanship meets your standards.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, equipment maintenance, and administrative expenses. Understanding the overhead percentage charged by suppliers can provide insights into overall pricing strategies.

-

Tooling: Tooling costs encompass the expenses related to molds, dies, and specialized tools needed for production. If your design requires unique tooling, this can add significantly to the initial setup costs. Consider negotiating tooling costs as part of your contract with suppliers.

-

Quality Control (QC): Ensuring that the CNC routers meet quality standards is critical. QC processes can add to manufacturing costs, but they are essential for maintaining product integrity. Suppliers who provide certifications (e.g., ISO) may charge higher prices, reflecting their commitment to quality.

-

Logistics: The cost of transporting materials and finished products is another crucial factor. International shipping, customs duties, and handling fees can significantly affect total costs, especially for buyers in regions like Europe or the Middle East. Understanding Incoterms (International Commercial Terms) will help in estimating these logistics costs accurately.

-

Supplier Margins: Different suppliers will have varying profit margins based on their operational efficiencies and market positioning. Larger suppliers may offer lower margins due to economies of scale, while smaller, niche suppliers might charge a premium for specialized services or products.

How Do Price Influencers Affect Sourcing Aluminum DIY CNC Routers?

Several factors can influence the pricing of aluminum DIY CNC routers, including volume or minimum order quantities (MOQs), specifications and customization, material quality, and supplier-related factors.

-

Volume/MOQ: Ordering in bulk can lead to significant cost reductions. Suppliers typically offer discounts for larger orders, which can help spread fixed costs over a greater number of units.

-

Specs/Customization: Custom specifications can lead to increased costs due to the need for specialized materials or additional engineering. Clearly defining your requirements can help suppliers provide more accurate quotes and avoid unexpected expenses.

-

Materials: Higher quality materials may come at a premium but can lead to better performance and durability. Consider the long-term value of investing in superior materials.

-

Quality/Certifications: Suppliers offering recognized certifications often justify higher prices with quality assurances. For international buyers, especially in regulated markets, choosing certified suppliers may be non-negotiable.

-

Supplier Factors: The reliability and reputation of the supplier can impact pricing. Established suppliers with proven track records may charge more, but they often provide better service and support.

What Buyer Tips Can Help Optimize Costs in the Sourcing Process?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiation: Always negotiate terms, especially when dealing with larger orders. Suppliers may be willing to offer discounts or better payment terms to secure significant contracts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) beyond initial purchase prices. Consider long-term operational costs, maintenance, and potential downtime when assessing value.

-

Pricing Nuances: Be aware of regional pricing differences. For example, import duties and tariffs can vary significantly by country, impacting overall costs. Understanding these nuances can help in budgeting and financial planning.

-

Research and Relationships: Building strong relationships with suppliers can lead to better pricing and service. Regularly communicate and provide feedback to foster partnerships that can yield long-term benefits.

In conclusion, while sourcing aluminum DIY CNC routers can involve considerable investment, understanding the cost structure and pricing dynamics can empower buyers to make informed decisions that align with their operational needs and budget constraints. Always approach sourcing with a comprehensive strategy that considers both immediate costs and long-term value.

Alternatives Analysis: Comparing aluminum diy cnc router With Other Solutions

Exploring Alternatives for CNC Routing Solutions

When considering the implementation of a CNC routing solution, businesses have several options beyond the aluminum DIY CNC router. Each alternative presents unique advantages and challenges, making it essential for B2B buyers to evaluate their specific needs before making a decision. Below is a comparative analysis of the aluminum DIY CNC router against two viable alternatives: commercial CNC routers and laser cutting machines.

| Comparison Aspect | Aluminum DIY CNC Router | Commercial CNC Router | Laser Cutting Machine |

|---|---|---|---|

| Performance | Moderate; good for wood and light metals, precision may vary | High; designed for industrial applications with consistent precision | High; excellent for cutting intricate designs, limited to specific materials |

| Cost | Low initial investment (~$1,500) | High (typically $10,000+) | Moderate to high; varies by size and capabilities |

| Ease of Implementation | Moderate; requires DIY skills and time investment | Easy; ready-to-use with professional installation available | Easy; often plug-and-play with minimal setup |

| Maintenance | High; requires regular calibration and manual adjustments | Low; professional service support available | Low; minimal maintenance with proper operation |

| Best Use Case | Prototyping and small-scale production | High-volume production and complex machining tasks | Precision cutting of non-metal materials and thin metals |

In-Depth Analysis of Alternatives

Commercial CNC Router

Commercial CNC routers are designed for high-performance applications, making them suitable for businesses that require consistent and precise output. These machines often come with advanced features such as automatic tool changers and integrated software for streamlined operations. However, the significant investment required can be a barrier for small to medium-sized enterprises. Additionally, while they offer low maintenance due to professional support, the cost of ownership can escalate with operational demands.

Laser Cutting Machine

Laser cutting machines provide a unique solution for businesses focused on precision and intricate designs, particularly for non-metal materials like plastics and wood. Their ability to cut detailed patterns quickly and cleanly makes them ideal for industries such as signage, aerospace, and automotive prototyping. However, they are limited in their ability to cut thicker metals, which can be a downside for certain applications. The initial cost can vary widely based on capabilities, but many models offer a good balance between performance and price.

Making the Right Choice for Your CNC Needs

In conclusion, selecting the right CNC routing solution hinges on a thorough understanding of your business’s specific requirements. For companies focused on affordability and the ability to customize their machines, the aluminum DIY CNC router is an excellent option. Conversely, businesses that prioritize speed, precision, and lower maintenance might find that investing in a commercial CNC router or a laser cutting machine is more beneficial in the long run. By weighing the performance, cost, ease of implementation, and maintenance needs of each alternative, B2B buyers can make an informed decision that aligns with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for aluminum diy cnc router

What Are the Essential Technical Properties of an Aluminum DIY CNC Router?

When considering an aluminum DIY CNC router, understanding its technical specifications is crucial for B2B buyers looking to make informed purchasing decisions. Here are some key properties to evaluate:

-

Material Grade (e.g., 6061 Aluminum)

The grade of aluminum used in the construction of a CNC router significantly affects its strength, weight, and machinability. For instance, 6061 aluminum is commonly chosen for its excellent mechanical properties and corrosion resistance. It provides a good balance between weight and strength, making it ideal for the structural frame of CNC routers. Buyers should ensure that the selected material meets their specific operational requirements, especially when dealing with heavy-duty applications. -

Tolerance

Tolerance refers to the allowable variation in dimensions during machining. A tighter tolerance ensures higher precision in the final product, which is essential for applications requiring detailed work. In the CNC router industry, tolerances can range from ±0.001 inches to ±0.1 inches, depending on the application. Understanding the required tolerances helps B2B buyers determine the capabilities of their CNC machines and avoid costly reworks. -

Cutting Depth and Speed

These specifications indicate the maximum depth the router can cut into the material and the speed at which it operates. For example, a router that can cut aluminum at a depth of 1/32 inch at 15 inches per minute is suitable for light machining tasks. Buyers should assess their project requirements to ensure that the CNC router can handle the desired materials and cutting parameters effectively. -

Linear Motion System

This includes components like linear guide rails and lead screws, which are critical for the router’s movement accuracy. A robust linear motion system reduces backlash and improves repeatability, essential for high-precision machining. Buyers should investigate the types of systems used, as they can significantly impact the performance and longevity of the CNC machine. -

Controller Type

The type of controller can determine the ease of use and compatibility with various software. Controllers like the Gecko 540 are popular due to their reliability and user-friendly setup. A suitable controller can streamline operations and enhance productivity, making it a vital consideration for B2B buyers.

What Are Common Trade Terminology and Jargon in the CNC Router Industry?

Understanding industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC routers, OEMs may supply components like motors or controllers. B2B buyers often work with OEMs to ensure they receive high-quality parts compatible with their machines. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as understanding the MOQ can help in budgeting and inventory management. Suppliers may set MOQs based on production costs or inventory levels. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. It outlines the buyer’s requirements, including specifications and quantities. B2B buyers utilize RFQs to compare prices and services from different suppliers, ensuring they receive competitive offers. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international transactions to clarify the responsibilities of buyers and sellers. They define who is responsible for shipping, insurance, and tariffs during the transportation of goods. Familiarity with Incoterms helps B2B buyers mitigate risks and avoid misunderstandings in cross-border transactions. -

Lead Time

This term refers to the time between placing an order and receiving the product. In the CNC router industry, lead times can vary significantly based on the complexity of the machine and the supplier’s capabilities. Understanding lead times is essential for B2B buyers to plan their projects effectively and manage expectations with clients.

By grasping these essential technical properties and industry terms, B2B buyers can make informed decisions that enhance their operational efficiency and competitiveness in the market.

Navigating Market Dynamics and Sourcing Trends in the aluminum diy cnc router Sector

What Are the Key Market Dynamics and Trends Impacting the Aluminum DIY CNC Router Sector?

The aluminum DIY CNC router market is witnessing transformative changes driven by several global factors. The increasing demand for customized manufacturing solutions is encouraging businesses to adopt CNC technology for prototyping and small-scale production. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are leveraging the advantages of CNC routers to produce one-off parts without incurring high costs associated with traditional manufacturing methods. This trend is augmented by the rise of online platforms that facilitate the sourcing of components and materials, allowing buyers to tailor their machines to specific needs and budgets.

Emerging technologies, such as advanced CAD/CAM software and the integration of IoT in CNC operations, are also shaping the market. These tools enhance operational efficiency and facilitate remote monitoring, thus appealing to tech-savvy manufacturers. Additionally, as the market matures, there is a noticeable shift towards modular designs, where components can be easily replaced or upgraded, reducing long-term maintenance costs and improving machine longevity.

Furthermore, the proliferation of DIY communities and online resources has made it easier for businesses and individual entrepreneurs to access knowledge and support, thereby expanding the market. Buyers are now more inclined to invest in DIY solutions, leading to a surge in demand for aluminum as a primary material due to its favorable properties, such as lightweight and high strength.

How Is Sustainability and Ethical Sourcing Influencing the Aluminum DIY CNC Router Market?

Sustainability has become a critical focus in the aluminum DIY CNC router sector, with increasing pressure on manufacturers to adopt environmentally responsible practices. The extraction and production of aluminum have significant environmental impacts, including high energy consumption and greenhouse gas emissions. Consequently, B2B buyers are becoming more discerning, seeking suppliers who prioritize sustainability in their operations.

Ethical sourcing is equally important, with businesses striving to ensure that their supply chains are transparent and responsible. This includes sourcing aluminum from suppliers who comply with environmental regulations and labor standards. Certifications such as ISO 14001 (Environmental Management) and ASI (Aluminum Stewardship Initiative) are gaining traction, as they signal a commitment to sustainable practices.

Moreover, the use of recycled aluminum is on the rise, as it significantly reduces energy consumption compared to primary aluminum production. Buyers are encouraged to source recycled materials, which not only lessens environmental impact but can also be cost-effective. By aligning with suppliers who demonstrate a commitment to sustainability and ethical practices, businesses can enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

What Is the Evolution of the Aluminum DIY CNC Router Market?

The aluminum DIY CNC router market has evolved significantly over the past few decades, transitioning from rudimentary setups to sophisticated machines capable of precision engineering. Initially, CNC technology was primarily used in large manufacturing settings, but advancements in technology and a growing DIY culture have democratized access, enabling small businesses and hobbyists to build their own machines.

The introduction of aluminum as a preferred material can be traced back to its advantageous properties, which include strength, lightweight, and ease of machining. As DIY CNC kits became more popular, suppliers began to offer specialized components tailored for aluminum construction, further propelling its use in home-based manufacturing.

Today, the market continues to innovate with the integration of digital technologies, including software that streamlines design processes and enhances machine capabilities. This evolution reflects broader trends in manufacturing, where customization and efficiency are paramount, positioning the aluminum DIY CNC router as a vital tool for modern fabrication.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum diy cnc router

-

How do I choose the right aluminum DIY CNC router for my business needs?

Choosing the right aluminum DIY CNC router involves assessing your specific production requirements, such as the size and complexity of the parts you intend to manufacture. Consider the router’s working area, spindle power, and speed capabilities. Additionally, evaluate the machine’s rigidity and precision, as these factors directly affect the quality of your outputs. Research various brands and models, read user reviews, and, if possible, request demonstrations or samples from suppliers to ensure the machine meets your operational demands. -

What are the key specifications to consider when sourcing a CNC router?

Key specifications to consider include the machine’s dimensions (working area), spindle speed (RPM), type of material it can handle, and the maximum cutting depth. Also, check the control system compatibility (e.g., LinuxCNC), the type of motors used (stepper vs. servo), and the software support for CAD/CAM applications. These specifications will help you determine if the router is suitable for your production needs and whether it can efficiently handle the materials you plan to work with. -

What are the typical lead times for purchasing an aluminum DIY CNC router internationally?

Lead times can vary significantly based on the supplier’s location, stock availability, and shipping method. Typically, it may take anywhere from a few weeks to several months for international orders. Factors such as customs clearance, potential delays in logistics, and the complexity of the machine can also impact delivery times. When negotiating with suppliers, it’s advisable to confirm estimated lead times and consider including clauses in your contract to address delays. -

What is the minimum order quantity (MOQ) for aluminum DIY CNC routers?

The MOQ for aluminum DIY CNC routers varies by manufacturer and can depend on factors such as machine type, customization options, and production capacity. Some suppliers may offer single units, especially for DIY models, while others might require bulk orders to reduce costs. When sourcing, clarify the MOQ with potential suppliers and explore options for purchasing additional accessories or parts to meet the minimum requirements if necessary. -

How can I verify the reliability of a CNC router supplier?

To verify a supplier’s reliability, conduct thorough research by checking their business history, customer reviews, and case studies. Request references from previous clients and inquire about their experiences with the supplier’s products and services. Additionally, consider visiting their manufacturing facility, if feasible, or participating in trade shows where they exhibit. Certification and compliance with international quality standards, such as ISO 9001, can also indicate a supplier’s commitment to quality and reliability. -

What payment terms are commonly offered for international CNC router purchases?

Payment terms can vary widely among suppliers but typically include options such as advance payment, a deposit followed by the balance upon shipment, or letters of credit for larger orders. Some suppliers may offer financing or installment plans, particularly for high-value machines. It’s essential to discuss and negotiate payment terms upfront to ensure they align with your budget and cash flow needs while also protecting your interests. -

What quality assurance measures should I expect from a CNC router supplier?

A reputable CNC router supplier should provide quality assurance measures such as pre-shipment inspections, performance testing, and detailed documentation of machine specifications. They may also offer warranties or service agreements to ensure the machine operates as intended. Ask about their quality control processes, including how they handle defects or issues, and ensure that they provide support for installation and maintenance after the sale. -

How do I handle logistics and shipping for my CNC router purchase?

Handling logistics and shipping involves coordinating with your supplier and freight forwarder to determine the best shipping method and route. Consider factors such as shipping costs, transit times, and any customs regulations that may apply to your region. Ensure that the supplier provides proper packaging to protect the machine during transit. It’s also wise to familiarize yourself with import duties and taxes in your country to avoid unexpected costs upon arrival.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Aluminum Diy Cnc Router Manufacturers & Suppliers List

1. DIY CNC Machine – Essential Specifications

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the necessary specifications for a DIY CNC machine to effectively cut aluminum. Key points include:

– A 2.2kW spindle is being considered for the build.

– NEMA 23 stepper motors are mentioned, which are a common frame size for motors.

– The importance of rigidity over size is emphasized, with examples of successful small machines cutting aluminum.

– A DIY build u…

2. Instructables – Aluminum CNC Router

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Product: Aluminum CNC Router

Key Features:

– Frame Material: 1/4in 6061 aluminum

– Frame Construction: Built using a standard miter saw with a carbide blade

– Gantry System: 16mm steel shafts and bearing blocks

– Threaded Rods: 1/2in 2-start ACME threaded rods

– Electronics Controller: Gecko 540

– Power Supply: From automationtechnologiesinc.com

– Motors: 3x 280oz/in Gecko Stepper Motors

– Comput…

3. 8020 CNC – Customizable Aluminum Extrusion CNC Machine

Domain: 8020cnc.com

Registered: 2009 (16 years)

Introduction: DIY 80/20 Aluminum Extrusion CNC Machine designed for building custom CNC machines using aluminum extrusion. Key features include the ability to customize the machine to fit specific tasks, a working area that can be tailored (e.g., 3′ x 4′), and the option to use various materials and components (e.g., MDF, M8 allthread rods, ACME screws, or ballscrews). The machine is aimed at hobbyists looking …

4. OpenBuilds – CNC Router Builds

Domain: builds.openbuilds.com

Registered: 2012 (13 years)

Introduction: CNC Router Builds include various categories such as Cartesian Style CNC, Delta Mills, X/Y Table Style CNC Mill, and Other Style CNC Mills. Notable builds include a 5×10 wall-mounted CNC under $3000, a compact Mini Mite Router, and a Lead 1515 with upgrades. Features of builds vary, with some focusing on cost-effectiveness, while others emphasize rigidity and ease of construction. Common component…

5. Avid CNC – BenchtopPro 2424

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: CNC machines considered for aluminum work: Avid CNC BenchtopPro 2424, Phantom CNC (4′ x 4′ size), Langmuir MR1. Desired working area: 2′ x 2′, with consideration for larger sizes. Drilling performance inquiry for holes in the range of 0.040″ to 0.250″. Preference for milling over drilling for holes larger than 1/4″. Mention of a PrintNC router with a spindle speed of 10,000 – 24,000 RPM, capable o…

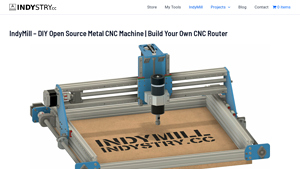

6. Indystry – IndyMill CNC Machine

Domain: indystry.cc

Registered: 2020 (5 years)

Introduction: IndyMill is a DIY open-source metal CNC machine project developed by Nikodem Bartnik, designed as an upgrade to the Dremel CNC. It aims to be easy to build and replicate worldwide using widely available components. The machine has a working area of approximately 520x400x115mm and outside dimensions of 760x660x360mm. Parts required for building include various profiles, lead screws, ball screws, li…

7. RouterForums – CNC Router Design

Domain: routerforums.com

Registered: 2004 (21 years)

Introduction: CNC Router Design: Conventional moving gantry design; Linear Slides: THK & Hiwin linear slides and bearings on all three axes; Cutting Area: Approx. 21″ X 28″; Materials: 8020 aluminum extrusions; Components: Bearing blocks from CNCRouterParts, anti-backlash nuts, clamps and couplings from dumpsterCNC, 370mm THK ballscrew (eBay), 5 start 1/2-10 ACME leadscrews (McMaster-Carr), Gecko 251 controller…

8. Make It From Metal – Cutting Tools and Lubrication Solutions

Domain: makeitfrommetal.com

Registered: 2018 (7 years)

Introduction: 1. Lubrication: Recommended to use lubrication for cutting aluminum; options include oil mist systems (under $100), WD-40, or cutting wax. 2. Small Tools: Use small cutting tools with great chip clearance, strong construction, smooth surfaces, and up-cutting (higher helix) designs. Preferred tools are carbide 2 or 3-flute endmills, typically 1/4″ for rigid machines, and 1/8″ or 3/16″ for smaller m…

Strategic Sourcing Conclusion and Outlook for aluminum diy cnc router

How Can Strategic Sourcing Enhance Your Aluminum DIY CNC Router Project?

In conclusion, strategic sourcing is essential for international B2B buyers looking to capitalize on the growing demand for aluminum DIY CNC routers. By carefully selecting suppliers of high-quality aluminum components, linear systems, and electronic controls, businesses can enhance their production capabilities while minimizing costs. The use of aluminum not only provides a stable framework but also allows for greater precision and durability in manufacturing processes.

As you consider your sourcing options, remember that investing in quality materials and components can significantly reduce long-term operational issues and maintenance costs. Collaborating with suppliers who understand the unique requirements of your region—be it Africa, South America, the Middle East, or Europe—can also lead to better logistical support and service.

Looking ahead, the market for DIY CNC routers is set to expand further, driven by the increasing need for custom manufacturing solutions. Engage with your suppliers proactively, explore innovative designs, and leverage local resources to stay competitive. The time to invest in your CNC capabilities is now—secure your strategic sourcing partnerships today to lead in this evolving landscape.