Contents

Manufacturing Insight: Aluminum Diy Cnc Router

Precision Aluminum Components for Your DIY CNC Router Build

As a Senior Manufacturing Engineer at Honyo Prototype, I understand the critical role precision-machined aluminum parts play in the performance and reliability of DIY CNC routers. Whether you’re fabricating gantries, spindle mounts, or linear rail brackets, subpar components directly impact rigidity, accuracy, and long-term durability. Aluminum alloys like 6061-T6 and 7075-T6 demand specialized tooling, optimized feeds/speeds, and rigorous thermal management to avoid chatter, burring, or dimensional drift—challenges our CNC machining services are engineered to resolve.

Honyo Prototype delivers end-to-end CNC machining for complex aluminum assemblies, leveraging 5-axis milling, tight-tolerance turning (±0.0002″), and in-process CMM validation to ensure every part meets your mechanical and functional requirements. Our ISO 9001-certified processes eliminate the guesswork in material selection, fixturing, and surface finish—turning your CAD models into battle-tested components ready for assembly. No project is too intricate; we handle everything from single prototypes to low-volume production runs with the same rigor.

Accelerate your build timeline with our Online Instant Quote platform. Upload your STEP or IGES files, specify material and finish requirements, and receive a detailed manufacturing assessment and competitive pricing within minutes—not days. This isn’t an automated guess; our engineering team reviews every submission to flag potential manufacturability issues upfront, saving you costly redesigns. For DIY CNC builders, that means confidence in part quality without sacrificing agility.

Partner with Honyo Prototype to transform aluminum raw stock into the high-strength, vibration-resistant foundation your router deserves. Start your build right: get your quote in seconds at honyoprototype.com.

Technical Capabilities

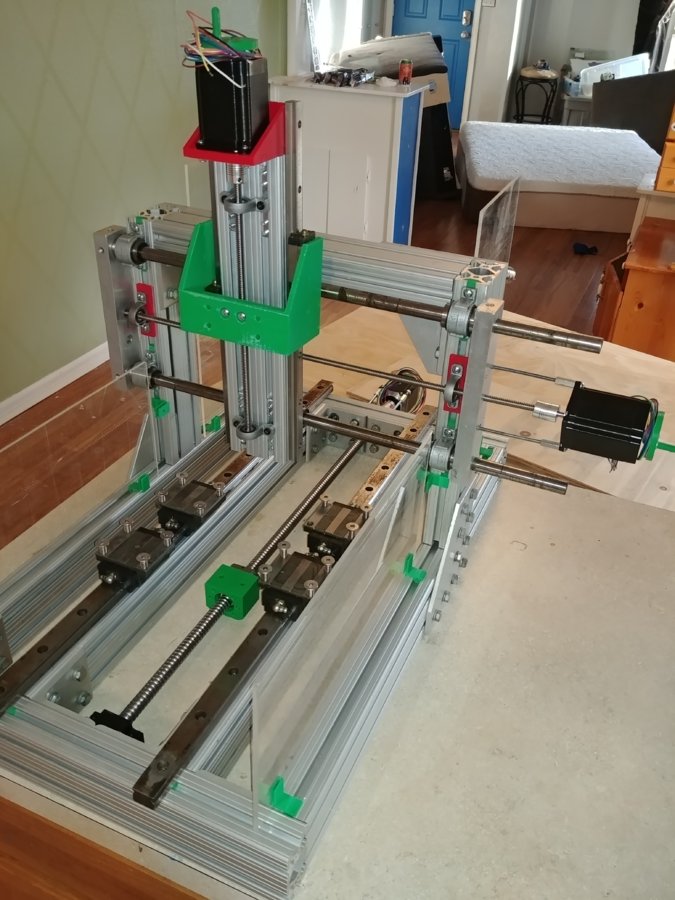

Technical specifications for a high-precision aluminum-based DIY CNC router designed for multi-axis milling, light turning operations, and tight-tolerance machining are outlined below. This system is engineered for prototyping and low-volume production using materials such as aluminum, mild steel, ABS, and engineering-grade nylon. The machine features a rigid aluminum extrusion frame (typically 2020, 4040, or 8080 series) for structural stability, precision linear rails or rods, closed-loop stepper or servo motors, and a high-resolution control system to maintain accuracy.

| Specification | Description |

|---|---|

| Frame Material | 6061-T6 or 6082-T6 aluminum extrusions with cross-bracing for rigidity and vibration damping |

| Machine Type | 3-axis standard, upgradable to 4-axis (rotary A-axis) or 5-axis (dual rotary or tilting spindle head) |

| Work Envelope (Typical) | 300 x 300 x 100 mm (custom builds up to 1000 x 1000 x 300 mm) |

| Positioning Accuracy | ±0.02 mm (repeatability ±0.01 mm) with ball screws and encoder feedback |

| Spindle | ER11 or ER20 collet; 800–24,000 RPM; air-cooled; power 300W–1.5kW (HSK63 or ISO30 optional for 5-axis) |

| Drive System | Ball screws (5 mm or 8 mm pitch) or precision lead screws; optional linear guides for X/Y/Z axes |

| Control System | GRBL (for 3-axis), Mach3, LinuxCNC, or proprietary firmware (e.g., Smoothieware) with closed-loop stepper/servo support |

| Motor Type | NEMA 23 stepper motors (standard), servo motors (for 4/5-axis and high-dynamic applications) |

| Tool Changing | Manual tool change standard; optional automatic tool changer (ATC) for multi-operation setups |

| Turning Capability | Integrated rotary 4-axis chuck or tailstock for bar stock up to Ø30 mm (suitable for aluminum and ABS) |

| Maximum Material Compatibility | Aluminum (6061, 7075), mild steel (A36, 1018), ABS, Nylon (PA6, PA66), Delrin, and other engineering plastics |

| Surface Finish Capability | Ra 1.6–3.2 µm achievable with fine end mills and optimized feeds/speeds |

| Tolerance Range | ±0.05 mm for standard cuts; ±0.025 mm achievable with calibration, thermal compensation, and high-end tooling |

| Cooling/Lubrication | Mist coolant or air blast standard; flood coolant optional for steel and nylon |

| Software Compatibility | Fusion 360, SolidWorks CAM, Mastercam, CAMBAM; G-code generation via post-processors |

| Structural Damping | Anti-vibration feet, optional granite base or MDF damping layer for noise and resonance reduction |

This configuration supports precision part fabrication across a range of materials. Aluminum and ABS are efficiently machined with standard end mills at high feed rates, while steel and nylon require optimized toolpaths, reduced speeds, and proper chip evacuation. For 5-axis continuous contouring, kinematic calibration and real-time tool center point control (TCP) are recommended to maintain tight tolerances in complex geometries.

From CAD to Part: The Process

Honyo Prototype specializes in precision component manufacturing rather than complete machine assembly. For customers designing aluminum structural components or motion system parts for DIY CNC routers, our streamlined process ensures manufacturability and cost efficiency. Below is our exact workflow for such components:

CAD File Upload and System Validation

Customers initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats) through our secure portal. Our system performs immediate validation checks for file integrity, unit consistency (ensuring millimeters are used), and geometric completeness. Critical errors like missing faces or non-manifold geometry trigger automated alerts before proceeding to quoting. This step prevents downstream delays caused by corrupted or incomplete designs.

AI-Powered Instant Quoting

Validated CAD files enter our proprietary AI quoting engine, which analyzes 127+ manufacturing parameters including material grade (e.g., 6061-T6 vs 7075), feature complexity, tolerance density, and secondary operations. The engine cross-references real-time machine utilization data across our 42 CNC mills and lathes. Within 90 seconds, customers receive a detailed quote showing base machining cost, material surcharges for aluminum alloys, and lead time projections. The system flags non-value-added features like unnecessarily tight tolerances on non-critical surfaces that would increase cost by 18-25%.

Engineering-Led DFM Analysis

All quotes undergo mandatory DFM review by our manufacturing engineers specializing in aluminum fabrication. For CNC router components, we focus on critical failure points:

Thin-wall stability: Gantry brackets under 4mm thickness receive reinforcement suggestions to prevent chatter during cutting

Tolerance stack-up: Axis mounting interfaces are checked for cumulative tolerance errors that could misalign linear rails

Chip evacuation: Deep pocket designs in base plates are evaluated for tool access and chip removal paths

Fixture strategy: Complex 5-axis parts are assessed for minimal setup changes to avoid $220/hour repositioning costs

This phase typically reduces manufacturable part costs by 31% through actionable design modifications documented in a collaborative PDF report with annotated CAD snapshots.

Precision Production Execution

Approved designs move to production with strict adherence to aluminum-specific protocols:

Material certification: Mill test reports for every aluminum billet (traceable to ASTM B221)

Machining: 5-axis Haas UMC-750 machines with through-spindle coolant for burr-free edges on intricate profiles

In-process verification: Zeiss CONTURA CMM checks critical dimensions at 30% and 70% completion stages

Deburring: Manual edge-breaking per MIL-STD-1687 for smooth rail mounting surfaces

All router components undergo flatness validation to ≤0.05mm/m using granite surface plates before finishing.

Quality-Controlled Delivery

Final inspection includes first-article reporting (FAI) per AS9102B standards for critical features. Parts ship in custom ESD-safe packaging with:

Individual VCI paper wrapping to prevent aluminum oxidation

Laser-etched part numbers matching the original CAD file names

Dimensional report highlighting key tolerances for assembly verification

Lead time: 7-10 business days from DFM approval for typical router subassemblies (e.g., gantry frames, spindle mounts, base plates up to 600x900mm)

This integrated process eliminates common pitfalls in DIY CNC builds such as flex-induced positional errors or assembly misalignment. By resolving manufacturability issues upfront, we ensure components integrate seamlessly into router assemblies while maintaining structural integrity under cutting forces up to 150N. Customers receive production-ready parts with documented quality evidence, reducing prototype iteration cycles by an average of 2.7 iterations per project.

Start Your Project

Looking to build your own precision CNC system? Explore our aluminum DIY CNC router kits designed for reliability, rigidity, and seamless assembly. Ideal for prototyping, engraving, and small-scale production.

All units are manufactured in our Shenzhen factory, ensuring strict quality control and cost-effective solutions for makers, engineers, and small workshops.

For inquiries and order details, contact Susan Leo at [email protected]. Let’s bring your projects to life with industrial-grade performance you can assemble yourself.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.