Contents

Manufacturing Insight: Aluminum Die Cast Machines

Precision Aluminum Die Casting Components Enhanced by Honyo Prototype’s CNC Machining Expertise

Aluminum die casting delivers high-volume production of complex net-shape components, yet achieving stringent geometric tolerances, critical surface finishes, or integrated features often requires precision post-casting refinement. At Honyo Prototype, we bridge this gap with advanced CNC machining services specifically engineered to elevate die-cast aluminum parts to exacting aerospace, automotive, and industrial specifications. Our multi-axis milling and turning centers, operated by veteran manufacturing engineers, address dimensional variances, create tight-tolerance cavities, and add secondary features—transforming near-net shapes into fully validated components with micron-level accuracy. This integrated approach eliminates costly rework cycles and accelerates time-to-assembly for high-integrity applications.

Leverage our technical partnership to optimize your die-cast designs for machinability without compromising structural integrity. Honyo Prototype’s seamless workflow—from initial material analysis to final inspection—ensures consistent repeatability and compliance with ISO 9001 standards. Begin your project immediately with our Online Instant Quote platform, providing detailed manufacturability feedback and competitive pricing within minutes, not days. Submit your CAD files today to experience accelerated prototyping and low-volume production for mission-critical aluminum systems.

Technical Capabilities

Aluminum die cast machines are primarily used for high-volume production of complex metal components using molten aluminum injected under high pressure into reusable steel molds. While these machines themselves do not perform milling or turning operations, die cast parts often require secondary machining such as 3, 4, or 5-axis CNC milling and turning to achieve tight tolerances and refined features. Below are technical specifications relevant to the integrated or downstream machining systems used for post-processing aluminum die cast components, with compatibility across common materials including Aluminum, Steel, ABS, and Nylon.

| Specification | Description |

|---|---|

| Machine Type | CNC Machining Centers (3-axis, 4-axis, 5-axis) integrated into or downstream of die casting cells |

| Spindle Speed | Up to 24,000 RPM (high-speed for aluminum and plastics); lower speeds (8,000–12,000 RPM) for steel |

| Axis Configuration | 3-axis for standard milling/turning; 4-axis (rotary A or B axis) for complex contours; 5-axis (simultaneous multi-axis motion) for high-precision aerospace and automotive components |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Tool Changer Capacity | 20–60 tools (automatic tool changer, ATC) |

| Work Envelope (Typical) | X: 800–2000 mm, Y: 600–1200 mm, Z: 500–1000 mm (varies by machine size) |

| Maximum Material Compatibility | Aluminum (primary die cast material), Tool Steel (molds and hardened components), ABS (for prototyping or fixtures), Nylon (low-friction machined parts) |

| Tolerance Capability | ±0.01 mm (±0.0004″) typical; tight tolerances down to ±0.005 mm achievable with thermal compensation and precision probing |

| Surface Finish | Ra 0.8–3.2 µm (achievable with proper tooling and parameters; finer finishes possible with polishing passes) |

| Coolant System | High-pressure through-spindle coolant (for aluminum and steel); air cooling or minimum quantity lubrication (MQL) recommended for ABS and Nylon |

| Control System | Fanuc, Siemens, or Heidenhain CNC with 5-axis interpolation and collision avoidance |

| Fixture Options | Custom die cast locating fixtures, modular fixturing, vacuum tables (for plastics), and rotary-tilt tables (5-axis) |

Notes:

Aluminum die cast parts typically undergo CNC machining to add features such as threaded holes, sealing surfaces, and mounting interfaces with tight geometric tolerances. The same CNC systems may also machine steel molds used in the die casting process, as well as prototype components made from ABS or Nylon for design validation. 5-axis machining is particularly valuable for complex die cast housings (e.g., in electric vehicles or aerospace) where access to multiple faces without re-fixturing is critical.

From CAD to Part: The Process

Honyo Prototype executes aluminum die casting projects through a rigorously defined workflow optimized for precision, speed, and manufacturability. Our process begins with the client uploading a validated CAD model to our secure portal, which triggers immediate ingestion into our production ecosystem. This CAD data undergoes automated geometry validation against material-specific constraints for aluminum alloys such as A380 or ADC12, ensuring compatibility with die casting physics before proceeding.

The AI-powered quoting system then generates a preliminary cost and timeline estimate within 2 business hours. This system leverages historical production data, real-time machine availability, and material cost algorithms but always includes mandatory review by our applications engineering team to validate feasibility and refine parameters. Clients receive a formal quotation with technical assumptions documented, not an automated black-box output.

Design for Manufacturability (DFM) analysis constitutes our critical value-add phase. Our senior engineers conduct a multi-disciplinary review focusing on aluminum-specific challenges: wall thickness optimization to prevent shrinkage porosity, gate and runner system validation using MAGMAflow simulation, ejector pin placement analysis, and thermal management assessment. We provide actionable recommendations via a collaborative portal, typically reducing potential rework by 35-50% through early defect mitigation. All DFM feedback includes annotated CAD markups and simulation snapshots for transparency.

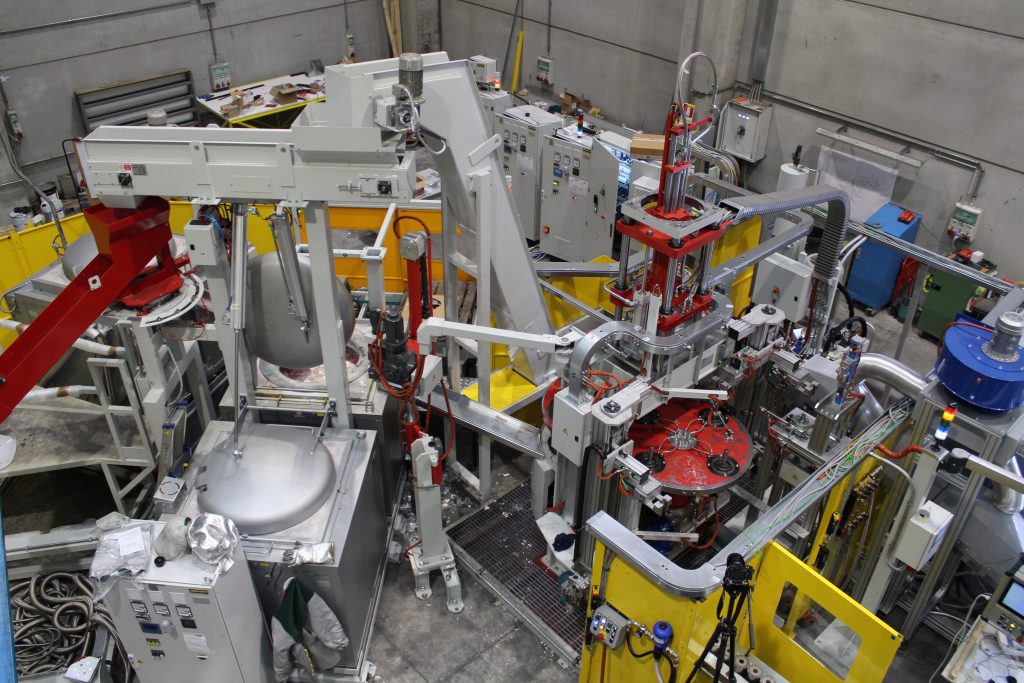

Production occurs exclusively on modern cold-chamber die casting machines with vacuum assist capability to minimize gas entrapment in aluminum. Key equipment specifications include:

| Machine Capacity | Clamping Force Range | Typical Part Weight Range | Process Control Features |

|---|---|---|---|

| Small | 150-400 tons | 50g – 500g | Real-time shot monitoring, Vacuum venting |

| Medium | 500-1250 tons | 500g – 3kg | 3-stage injection control, Thermal imaging |

| Large | 1600-2500 tons | 3kg – 15kg | Full vacuum systems, In-process CMM verification |

All production runs implement first-article inspection per AS9102 standards, with critical dimensions verified against CAD using coordinate measuring machines. Secondary operations including heat treatment, precision CNC machining, and surface finishing occur in-house under the same quality management system.

Final delivery includes comprehensive documentation: certified material test reports, dimensional inspection data packages, and process validation records. Standard lead times range from 15-25 days for production tooling completion after DFM sign-off, with expedited options available. We maintain rigorous traceability from raw material lot numbers through final shipment, ensuring full compliance with aerospace and medical industry requirements where applicable. This integrated approach guarantees that aluminum die cast components meet stringent dimensional and metallurgical specifications upon arrival at the client facility.

Start Your Project

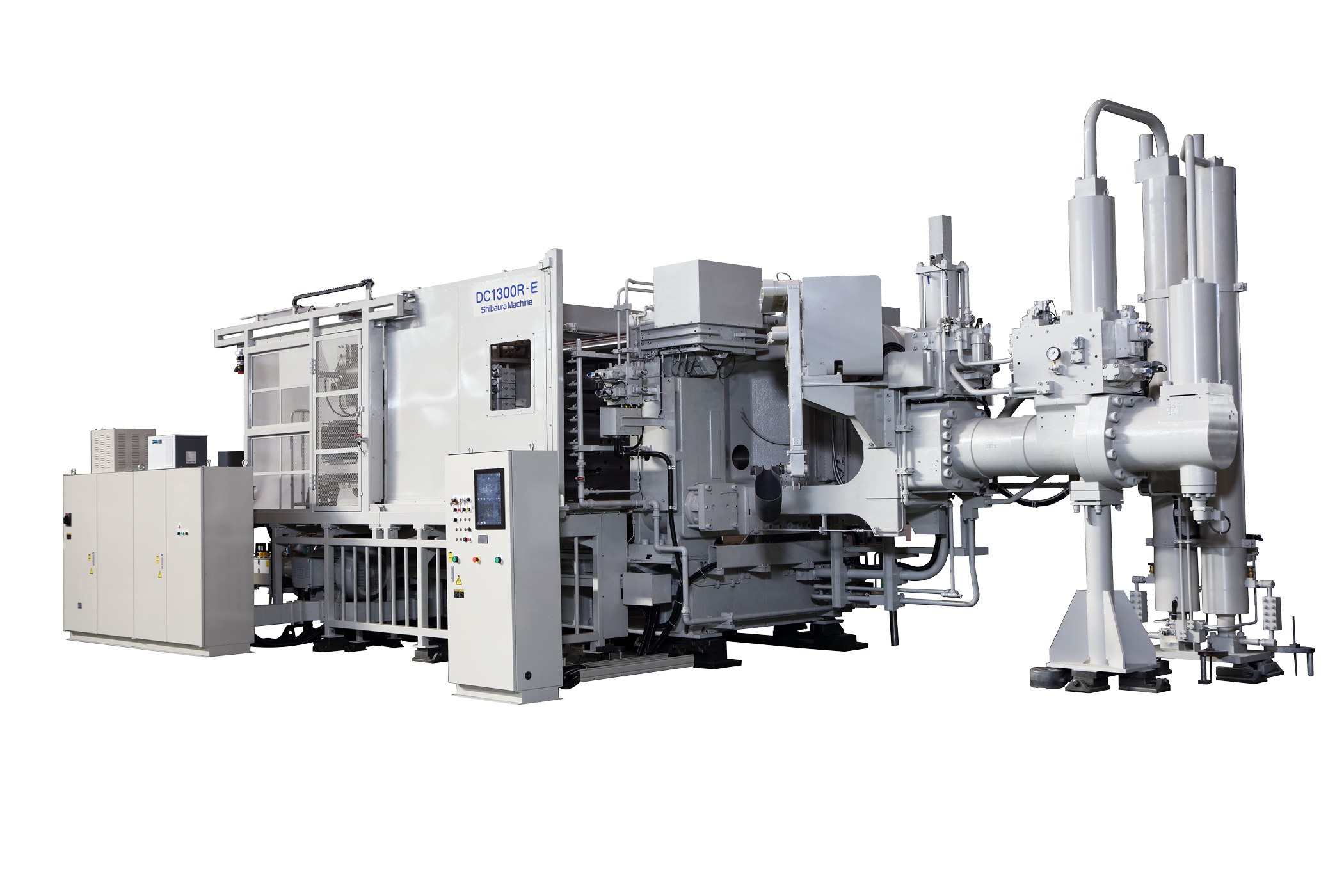

Explore high-performance aluminum die cast machines engineered for precision and durability. Built to meet the demands of modern manufacturing, our machines deliver consistent results for automotive, aerospace, and industrial applications.

All units are manufactured at our ISO-certified facility in Shenzhen, ensuring strict quality control and scalability for high-volume production.

For technical specifications, pricing, or custom configuration support, contact Susan Leo at [email protected]. Let’s discuss how we can optimize your die casting operations.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.