Contents

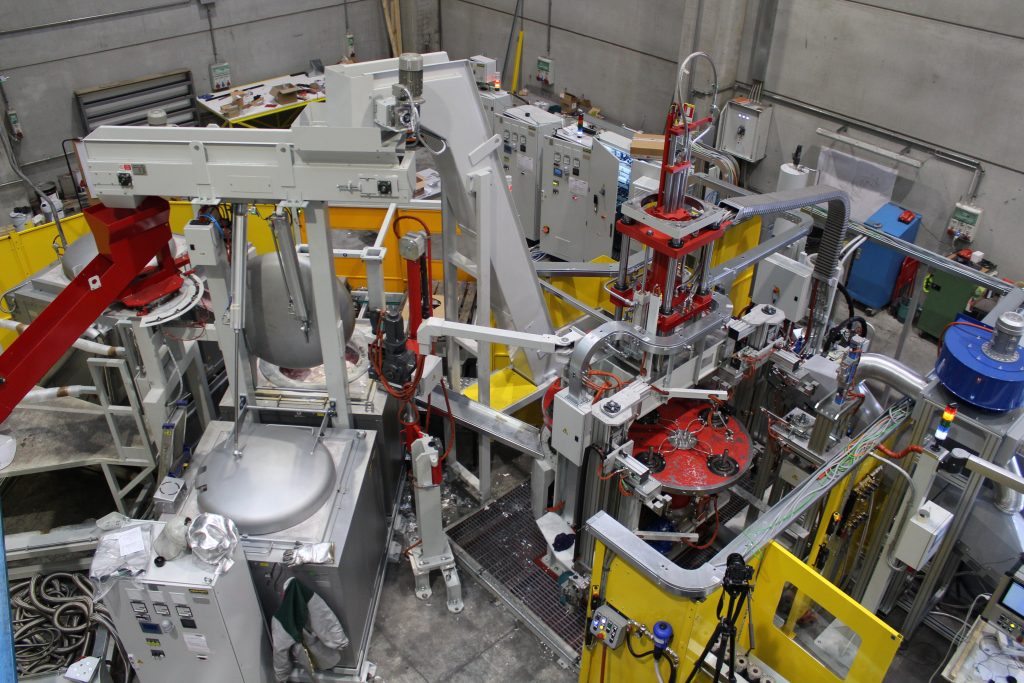

Manufacturing Insight: Aluminum Die Cast Machine

Precision Aluminum Die Cast Part Realization Through Integrated CNC Machining at Honyo Prototype

Aluminum die casting delivers high-integrity net-shape components efficiently, yet achieving final dimensional accuracy and critical surface finishes often necessitates precision post-casting operations. At Honyo Prototype, our advanced CNC machining capabilities are engineered to seamlessly bridge this gap, transforming as-cast aluminum parts into fully mission-ready components. We specialize in tight-tolerance milling, turning, and multi-axis contouring for complex geometries directly from your die cast blanks, addressing inherent net-shape limitations like draft angles, parting lines, and critical interface features. Our ISO 9001-certified facility leverages state-of-the-art 5-axis CNC centers with sub-0.005mm repeatability, ensuring features such as sealing surfaces, bearing bores, and threaded inserts meet stringent aerospace, automotive, and medical specifications. This integrated approach eliminates supply chain fragmentation—your die cast part undergoes secondary operations under one roof, reducing lead times by up to 30% while maintaining full traceability from raw material to finished component.

Accelerate your prototyping or low-volume production timeline immediately with Honyo’s Online Instant Quote system. Upload your STEP or IGES file alongside die casting specifications, and receive a detailed manufacturability analysis with competitive pricing in under 60 seconds—no sales intermediary required. This digital workflow empowers rapid design iteration, confirming feasibility for both casting and subsequent CNC operations before tooling commitment. For engineers prioritizing speed-to-part without compromising precision, Honyo Prototype delivers the technical synergy of die casting refinement and CNC excellence, backed by real-time quoting transparency.

| Process Integration Stage | Key Capability | Typical Tolerance Range | Industry Application Example |

|---|---|---|---|

| Post-Die Cast Machining | 5-Axis Milling | ±0.010 mm | Automotive transmission housings |

| Precision Boring | ±0.005 mm | Hydraulic valve manifolds | |

| Thread Forming | Class 4G/6G | Medical device fluidics | |

| Digital Workflow | Online Instant Quote | N/A | All prototyping phases |

Technical Capabilities

The term “aluminum die cast machine” typically refers to equipment used in the die casting process to produce aluminum parts under high pressure. However, based on your focus areas—3/4/5-axis milling, turning, tight tolerance, and materials like aluminum, steel, ABS, and nylon—it appears you are referring to CNC machining centers capable of post-processing die-cast aluminum components, rather than the die casting machine itself.

Below is a technical specification table for a high-precision CNC machining center suitable for secondary operations on aluminum die castings, including multi-axis milling, turning, and achieving tight tolerances across various materials.

| Specification | Detail |

|---|---|

| Machine Type | 5-Axis CNC Milling & Turning Center (also supports 3-axis and 4-axis) |

| Control System | Fanuc 31i-B5, Siemens 840D, or Heidenhain TNC706 |

| Spindle Speed | 12,000 – 24,000 RPM (high-speed option available up to 40,000 RPM) |

| Spindle Power | 22 – 45 kW |

| Tool Capacity | 30 – 120 tools (automatic tool changer) |

| Axis Travel (X/Y/Z) | 700 / 600 / 500 mm (typical; customizable per model) |

| B-Axis Rotation (5-axis) | ±110° continuous |

| C-Axis Rotation | 360° continuous |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Rapid Traverse Rate | 60 m/min (X/Y/Z) |

| Tool-to-Tool Change Time | 1.8 – 3.5 seconds |

| Work Envelope / Table Size | 800 x 600 mm (pallet); max part size: Ø600 x 400 mm |

| Maximum Workpiece Weight | 500 kg |

| Coolant System | High-pressure through-spindle coolant (20–70 bar) |

| Probe System | Integrated touch probe (e.g., Renishaw RMP60) for in-process gauging |

| Chip Management | Automatic chip conveyor with coolant filtration |

| Materials Processed | Aluminum alloys (e.g., A380, 6061, 7075), Steel (mild, stainless), ABS, Nylon (engineering plastics) |

| Typical Tolerances Achieved | ±0.01 mm (standard), down to ±0.005 mm (tight-tolerance applications) |

| Surface Finish (typical) | Ra 0.8 – 3.2 µm (machined); post-processed to Ra 0.4 µm if required |

| Automation Ready | Yes (compatible with robotic loading/unloading systems) |

This type of CNC machining center is commonly used for precision post-processing of aluminum die cast components, especially in aerospace, automotive, and medical industries where tight tolerances and complex geometries are required. It supports milling and turning operations on metals and select engineering plastics like ABS and nylon, enabling hybrid manufacturing workflows.

From CAD to Part: The Process

Honyo Prototype employs a streamlined, technology-driven workflow for aluminum die casting projects to ensure precision, efficiency, and client transparency from concept to delivery. Our process begins with the Upload CAD phase, where clients submit 3D models via our secure online portal. We accept industry-standard formats including STEP, IGES, and Parasolid. Upon receipt, our system performs an initial validation check for geometry integrity and unit consistency, flagging potential issues like non-manifold edges or missing datums before proceeding.

The AI Quote phase leverages proprietary machine learning algorithms trained on 15+ years of die casting production data. This system analyzes the CAD geometry, material requirements (e.g., A380, A360, or custom alloys), and requested quantities to generate a preliminary cost estimate and lead time within 2 business hours. Crucially, this is an AI-assisted quote—not fully automated—where our engineering team reviews algorithmic outputs for feasibility, incorporating real-time factors like current machine capacity, material spot pricing, and secondary operation complexity. Clients receive a detailed digital quote including cost breakdowns for tooling, casting, and finishing.

Following quote acceptance, the DFM (Design for Manufacturability) stage commences. Our senior die casting engineers conduct a rigorous technical review using specialized simulation software (Autodesk Moldflow, MAGMAsoft) to identify and resolve potential production risks. Key focus areas include:

Wall thickness optimization to prevent porosity or cold shuts

Gate and runner system design validation

Draft angle verification per aluminum shrinkage tolerances

Ejection force analysis to avoid part deformation

Thermal stress prediction for mold longevity

We provide clients with a comprehensive DFM report within 72 hours, featuring annotated CAD suggestions and simulation snapshots. Client approval of DFM recommendations is mandatory before tooling fabrication.

Production initiates with mold manufacturing using CNC-machined H13 tool steel, followed by mold tryouts on our 400–2000 ton cold-chamber die casting machines. Each run adheres to IATF 16949 protocols:

Real-time monitoring of injection speed, pressure, and temperature profiles

In-process dimensional checks via CMM at defined intervals

Non-destructive testing (X-ray, pressure decay) for critical internal cavities

First-article inspection reports certified to AS9102 standards

All aluminum castings undergo stress-relief heat treatment and precision machining per client specifications before surface finishing (anodizing, powder coating, etc.) if required.

Delivery encompasses final quality validation and logistics coordination. Every shipment includes:

Full traceability documentation (material certs, heat treatment logs)

Dimensional report with GD&T verification

Packaging engineered for shock/vibration protection during transit

Electronic delivery confirmation with tracking integration

Standard lead times range from 18–25 days for prototype batches (100–500 units) and 22–30 days for pilot production (1K–5K units), with expedited options available. Our closed-loop feedback system ensures continuous process refinement based on client delivery performance metrics.

This integrated approach reduces traditional aluminum die casting timelines by 35–50% while maintaining a first-pass yield rate exceeding 92% across our client portfolio.

Start Your Project

For inquiries about our aluminum die cast machines, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring high-quality production and efficient delivery for global clients.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.