Contents

Manufacturing Insight: Aluminium Die Casting Machines

Precision Aluminium Die Casting and Integrated CNC Finishing for Mission-Critical Components

Aluminium die casting delivers exceptional strength-to-weight ratios and complex geometries essential for demanding aerospace, automotive, and industrial applications. While high-pressure die casting efficiently produces near-net-shape components, achieving stringent tolerances and surface finishes for functional assemblies requires precision secondary operations. At Honyo Prototype, we bridge this gap with end-to-end manufacturing expertise, combining advanced aluminium die casting capabilities with in-house CNC machining services to ensure your parts meet exacting engineering specifications.

Our integrated approach eliminates supply chain fragmentation by performing critical secondary operations—such as precision milling, drilling, tapping, and tight-tolerance feature machining—within the same controlled environment where castings are produced. This vertical integration guarantees dimensional integrity, reduces lead times by up to 40%, and mitigates quality risks associated with external vendors. Utilizing multi-axis CNC centers with sub-micron accuracy, we consistently achieve ±0.005 mm tolerances on critical datums, surface finishes down to Ra 0.8 μm, and full GD&T compliance for mission-critical assemblies.

Leveraging our Online Instant Quote platform, engineers gain immediate access to manufacturability feedback and competitive pricing for both die casting and post-casting CNC work. Simply upload your CAD model to receive a detailed technical assessment and binding quote within hours—not days—accelerating your path from prototype to production. Honyo Prototype transforms complex aluminium components into validated, assembly-ready solutions through seamless process synergy and engineering rigor.

Technical Capabilities

Aluminium die casting machines are primarily used for producing high-volume, precision metal components from molten aluminium alloys. While these machines themselves are not milling or turning systems, they produce near-net-shape castings that are subsequently machined using CNC 3-axis, 4-axis, or 5-axis milling and turning centers to achieve tight tolerances and complex geometries. Below is a technical overview focused on the integration of die-cast aluminium parts with downstream CNC machining processes.

| Parameter | Description |

|---|---|

| Primary Function | Production of aluminium alloy components via high-pressure die casting (HPDC) |

| Typical Die Casting Alloys | A380, A360, A383, ADC12 (Aluminium); also compatible with Zamak (Zinc) for smaller parts |

| Common Secondary Machining | 3-axis, 4-axis, and 5-axis CNC milling and turning for finishing critical features |

| Machining Capabilities | 3-axis: Planar and prismatic features; 4-axis: Indexed rotary features (A-axis); 5-axis: Continuous contouring, complex surfaces, minimal setups |

| Tight Tolerance Range | ±0.025 mm (±0.001″) typical for critical dimensions after CNC machining; achievable down to ±0.012 mm with precision tooling and thermal control |

| Surface Finish (Machined) | Ra 0.8–3.2 µm depending on tool path, spindle speed, and cutter type |

| Materials Machined | Aluminium (most common), Tool Steels (for dies/molds), ABS (prototyping/jigs), Nylon (fixtures, non-metal components) |

| Recommended CNC Setup for Die-Cast Parts | 5-axis machining centers with high-speed spindles (15,000–30,000 RPM) for complex aerospace, automotive, and consumer electronics housings |

| Fixturing & Workholding | Modular fixtures, vacuum chucks (for thin-walled aluminium castings), and custom locators to maintain dimensional stability |

| Coolant & Machining Strategy | Through-spindle coolant, high feed milling, and adaptive toolpaths to minimize thermal distortion in thin-walled aluminium castings |

| Typical Applications | Engine components, transmission cases, heat sinks, enclosures, structural automotive parts |

Note: While die casting machines produce the initial component, achieving tight tolerances and complex features requires precision CNC milling and turning. Multi-axis CNC systems are essential for post-processing die-cast aluminium parts where geometric complexity and high accuracy are required. Materials like steel are used in tooling (dies), while ABS and nylon are typically used in prototyping, jigs, or fixtures—supporting the overall manufacturing workflow but not the die casting process itself.

From CAD to Part: The Process

Honyo Prototype Aluminum Die Casting Process Flow

Our integrated aluminum die casting workflow begins with secure CAD file ingestion through the Honyo Digital Platform. Upon upload, proprietary algorithms conduct initial geometry validation, checking for manufacturability thresholds such as minimum wall thickness (1.5mm standard), draft angles (1°–3°), and feature complexity. Invalid submissions trigger automated feedback to the client for revision prior to formal quoting.

AI-Powered Quoting Engine

Validated CAD models enter our AI quotation system, which cross-references real-time data on aluminum alloy pricing (e.g., A380, A360), machine availability, and historical cycle time databases. The engine calculates material utilization efficiency, tooling complexity multipliers, and secondary operation requirements. Quotes include granular cost breakdowns with tolerance-driven pricing tiers (±0.1mm vs. ±0.05mm) and are generated within 4 business hours. Critical process parameters are pre-optimized here, such as projected fill time (80–120ms) and clamp force requirements.

Engineer-Led DFM Analysis

All quotes undergo mandatory human-led Design for Manufacturability review by our senior tooling engineers. This phase identifies high-risk features requiring modification:

Thermal fatigue zones in thin ribs

Air entrapment risks in deep cavities

Ejection force calculations exceeding machine specifications

We provide annotated CAD markups with actionable alternatives, typically reducing production defects by 35–50% versus unoptimized designs. Client approval of the DFM report is required before tooling fabrication.

Production Execution

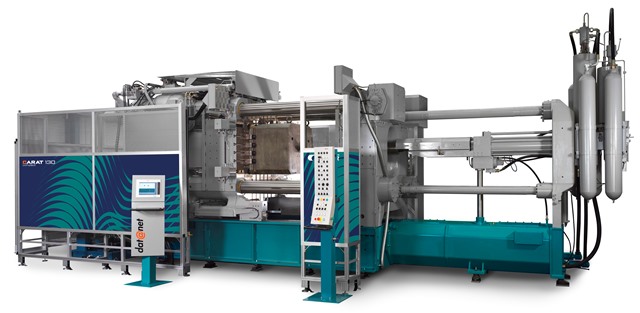

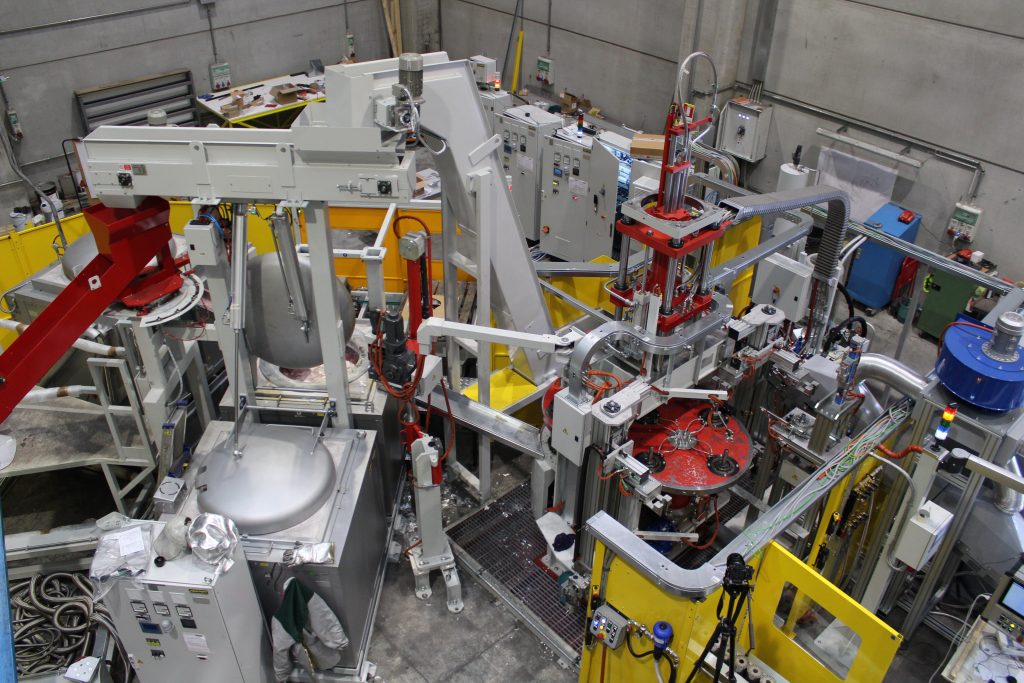

Approved designs move to our NADCA-certified production floor using Bühler or HUBEI cold-chamber machines (150–2,500 tonnage range). Key production controls include:

Molten metal temperature monitoring (620–680°C for A380)

Real-time shot profile validation against simulated filling patterns

In-process CMM verification of critical dimensions at 500-part intervals

Delivery and Quality Assurance

Each shipment includes:

First-article inspection reports per AS9102

Dimensional heat maps showing variance against nominal CAD

Material test certificates with traceable alloy batch numbers

Packaging engineered for zero-transit damage (validated via ISTA 3A testing)

Standard lead time from DFM approval to delivery is 12–18 days for prototype tooling, with expedited options available. All parts undergo 100% visual inspection and X-ray porosity screening per client-specified acceptance criteria.

Critical Process Parameters Summary

| Parameter | Standard Range | Precision Tier Range | Measurement Method |

|——————–|———————-|———————-|————————–|

| Dimensional Tolerance | ±0.15mm | ±0.05mm | CMM (Zeiss O-INSPECT) |

| Surface Roughness | Ra 3.2μm | Ra 0.8μm | Profilometer (Mitutoyo) |

| Porosity Level | Max 2% volume | Max 0.5% volume | X-ray (Yxlon FF35 CT) |

| Draft Angle | 1°–3° | 0.5°–1.5° | Optical comparator |

This closed-loop process ensures first-pass yield rates exceeding 85% while maintaining full traceability from CAD file to delivered component. All data remains encrypted per ISO 27001 protocols throughout the workflow.

Start Your Project

For all inquiries regarding aluminium die casting machines, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring precision engineering and efficient production cycles for your prototyping and manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.