Contents

Manufacturing Insight: Aluminium Casting Projects

Precision Aluminium Casting Solutions Enhanced by Honyo Prototype CNC Machining Expertise

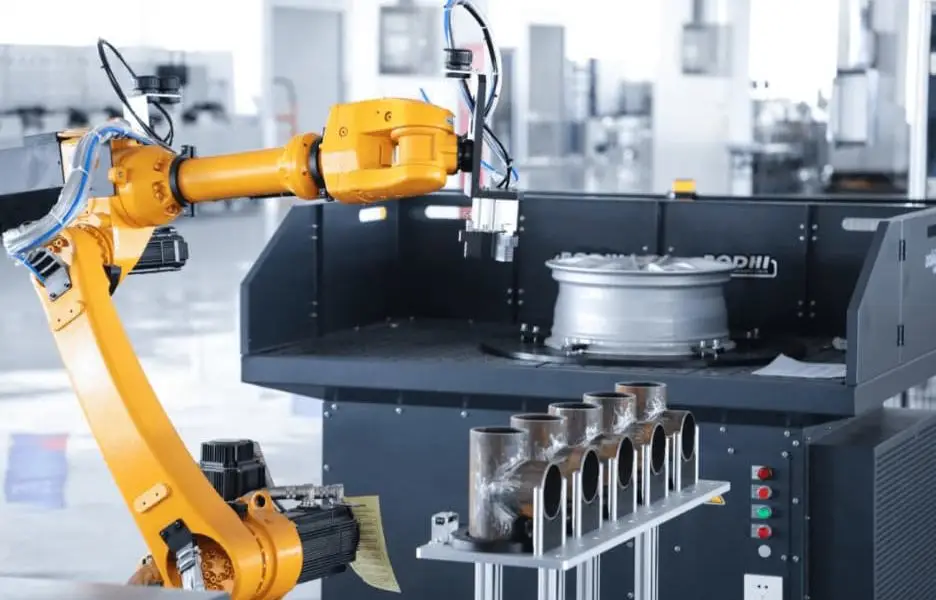

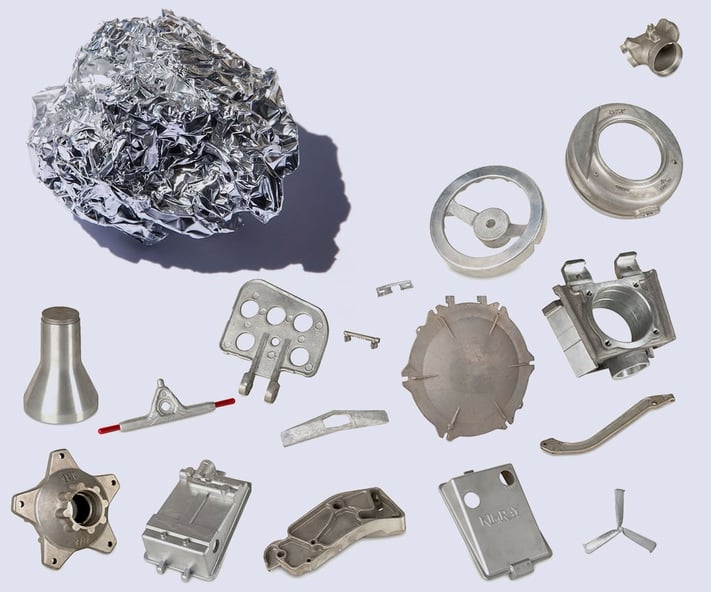

Aluminium casting delivers exceptional design flexibility and material efficiency for complex geometries, yet achieving final part specifications often requires precise secondary operations. Cast components frequently exhibit dimensional variations, surface imperfections, or critical features demanding tighter tolerances than the casting process alone can consistently provide. This is where Honyo Prototype’s integrated CNC machining capabilities become essential to your project’s success.

We specialize in transforming near-net-shape aluminium castings into fully finished, production-ready components through our advanced 3-, 4-, and 5-axis CNC machining services. Our engineering team collaborates directly with foundries and designers to develop optimized post-casting machining sequences that address specific tolerance requirements, critical datums, and surface finish specifications. Utilizing state-of-the-art equipment and rigorous quality control protocols—including CMM verification—we ensure every machined feature meets stringent aerospace, automotive, and industrial standards. This seamless integration eliminates costly supply chain handoffs and guarantees dimensional accuracy from raw casting to final assembly.

Accelerate your aluminium casting project timeline with Honyo Prototype’s Online Instant Quote system. Upload your CAD file today to receive a detailed, transparent manufacturing assessment—including casting compatibility analysis and CNC machining cost breakdown—within hours, not days. Our platform provides immediate insight into manufacturability, lead times, and actionable feedback to refine your design for optimal performance and cost-efficiency. Start your precision machining journey now at honyoprototype.com/quote.

Technical Capabilities

Honyo Prototype delivers high-precision aluminum casting projects with advanced CNC machining capabilities tailored for demanding industrial applications. Our processes integrate 3, 4, and 5-axis milling along with precision turning to achieve tight tolerances and superior surface finishes. While aluminum is the primary casting material, we also support hybrid assemblies involving steel inserts, ABS, and nylon components for complete system integration.

| Parameter | Specification Details |

|---|---|

| Primary Material (Casting) | A356, A380, ADC12, 6061-T6, 7075-T6 (Aluminum alloys) |

| Secondary Materials | Mild Steel, Stainless Steel (for inserts), ABS (for housings), Nylon (for wear parts) |

| Machining Capabilities | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including multi-axis turn-mill) |

| Tolerance Range | ±0.005 mm to ±0.025 mm (tight-tolerance machining for critical features) |

| Surface Finish | As-machined: Ra 0.8–3.2 µm; Optional polishing, anodizing, or coating available |

| Max Work Envelope (Milling) | 5-axis: 1,200 × 800 × 600 mm; 3/4-axis: up to 2,000 × 1,000 × 800 mm |

| Max Turning Diameter | Ø 500 mm (with live tooling for milling operations) |

| Positioning Accuracy | ±0.003 mm (5-axis systems) |

| Repeatability | ±0.002 mm |

| Common Applications | Aerospace housings, automotive prototypes, medical device enclosures, robotics parts |

| Quality Standards | ISO 9001:2015 compliant; First-article inspection (FAI), CMM and GD&T reporting |

Our integrated approach ensures that aluminum castings are precisely machined to meet functional and dimensional requirements, with secondary operations and multi-material compatibility supporting complex end-use assemblies.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined engineering workflow for aluminium casting projects designed to ensure manufacturability, cost efficiency, and on-time delivery. This structured process minimizes client risk and accelerates time-to-market through integrated digital and engineering validation steps.

CAD Upload and Validation

Clients initiate projects by uploading native or neutral format CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs immediate automated geometry validation checks for file integrity, unit consistency, and fundamental manufacturability flags. This initial scan identifies critical errors such as non-manifold edges or improper scaling before human engineering review begins, preventing downstream delays.

AI-Powered Quoting Engine

Validated CAD data feeds directly into our proprietary AI quoting system trained on 15+ years of aluminium casting production data across gravity die, low-pressure die, and sand casting processes. The AI analyzes geometric complexity, material utilization, required secondary operations, and historical machine time metrics to generate a preliminary cost estimate within 2 hours. Crucially, this stage includes automated feasibility screening against standard aluminium alloy capabilities (primarily A356, A380, ADC12) identifying potential issues like undercuts requiring complex core pulls or wall thicknesses below 2.5mm minimum thresholds.

Engineering DFM Analysis

All projects undergo mandatory Design for Manufacturability review by our specialist aluminium casting engineers. This phase moves beyond the AI’s preliminary assessment to conduct in-depth analysis using casting simulation software (MAGMAsoft). Engineers evaluate fill patterns, solidification sequences, thermal gradients, and potential porosity risks. We provide actionable feedback through marked-up 3D models and formal DFM reports detailing specific recommendations such as optimal gate locations, required draft angles (minimum 1.5° per side), fillet radius adjustments, and tolerance stack-up corrections. Client sign-off on the DFM report is required before tooling fabrication commences.

Production Execution

Approved designs enter production with strict adherence to our documented quality management system (ISO 9001:2015 certified). For aluminium castings, this includes:

Pattern/tooling fabrication using CNC-machined steel or aluminum dies with precision cooling channels

Controlled melting in electric resistance furnaces under inert gas cover to prevent oxidation

Real-time process monitoring of injection parameters (for die casting) or pouring temperatures (for gravity casting)

Mandatory T6 heat treatment per AMS 4110 specifications with documented quench rates

In-process dimensional verification via CMM at critical feature checkpoints

All castings undergo 100% visual inspection and fluorescent penetrant testing (MIL-STD-883 Method 2032) with X-ray inspection applied to safety-critical components.

Quality-Certified Delivery

Final shipment includes comprehensive documentation packaged with the physical parts:

Certificate of Conformance detailing alloy batch traceability (mill certs included)

Dimensional inspection report against ASME Y14.5 GD&T callouts

Hardness test results (HB per ASTM E10) and tensile test data (when specified)

Non-destructive testing records

Parts are shipped in custom-designed, anti-corrosion packaging with humidity indicators. Standard lead times from DFM approval are maintained through our production control dashboard which provides clients with real-time progress tracking.

Typical phase durations for standard aluminium casting projects follow this benchmark:

| Process Phase | Typical Duration | Key Dependencies |

|---|---|---|

| CAD Upload to AI Quote | < 2 hours | Valid CAD file submission |

| DFM Engineering Review | 3-5 business days | Design complexity, client feedback cycle |

| Production | 10-25 business days | Part size, casting process, finishing requirements |

| Final Quality & Delivery | 2 business days | Documentation completeness, shipping destination |

This integrated approach ensures that 92% of first-article aluminium castings meet all specifications without rework, directly attributable to the enforced DFM gate and simulation-driven process design. We maintain continuous feedback loops where production data refines our AI quoting models, creating a self-improving system for future client projects.

Start Your Project

For your aluminium casting projects, partner with Honyo Prototype for precision manufacturing and rapid turnaround. Our Shenzhen-based factory leverages advanced die casting and gravity casting techniques to deliver high-integrity aluminium components for automotive, industrial, and consumer applications.

Contact Susan Leo to discuss your project requirements and receive a competitive quote.

Email: [email protected]

We support low to medium volume production with strict quality control, material traceability, and post-casting machining capabilities—all from our dedicated facility in Shenzhen, China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.