Guide Contents

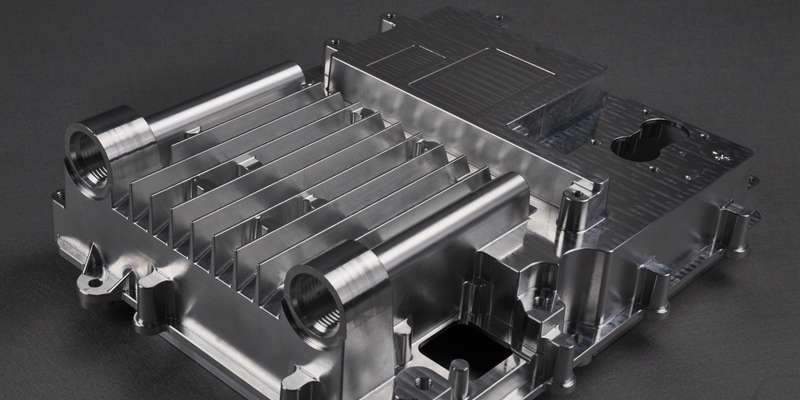

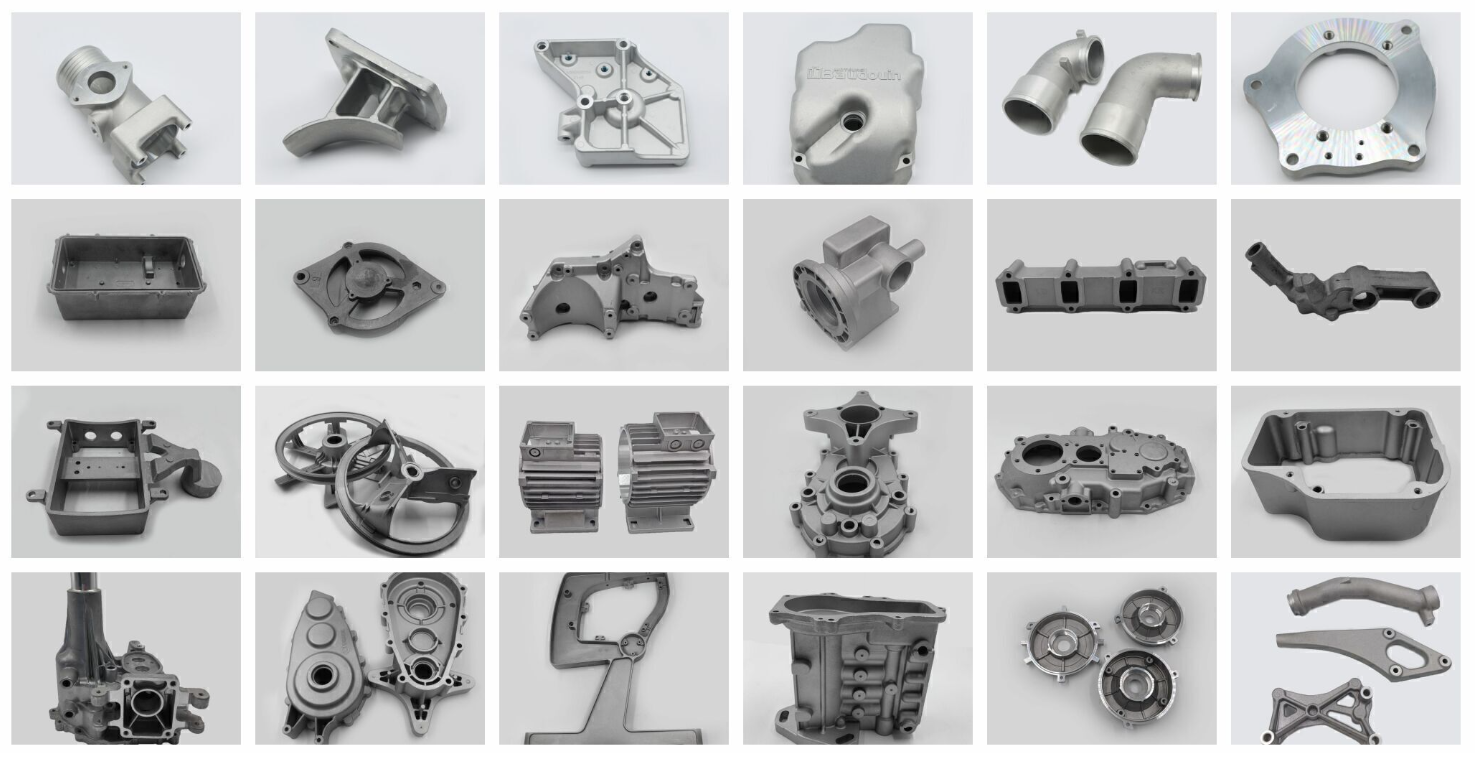

Project Insight: Aluminium Casting Projects

Speed & Precision: The Cornerstones of Modern Product Development

In today’s hyper-competitive hardware landscape, product development cycles are measured in days, not months. Startups and engineers face relentless pressure to validate designs, iterate rapidly, and scale production without compromising quality. Traditional aluminum casting processes—burdened by manual quotes, weeks-long tooling lead times, and fragmented workflows—often become the bottleneck. At Honyo Prototype, we’ve redefined manufacturing through our digital manufacturing ecosystem, ensuring speed and precision are never trade-offs.

Why Speed & Precision Matter in Aluminum Casting

Accelerated Time-to-Market: Every day saved in prototyping means faster validation, funding rounds, and market entry—critical for startups racing to secure investor confidence.

Reduced Rework Costs: Precision tolerances in early-stage casting prevent costly redesigns during mass production, preserving budgets and timelines.

Scalable Flexibility: Seamless transitions from low-volume prototypes to high-volume production without retooling delays ensure your project grows with your business.

How Honyo’s Digital Ecosystem Delivers Unmatched Efficiency

Online Instant Quote: AI-driven cost estimation in seconds—see transparent breakdowns for tooling, materials, and finishing before committing. No more guesswork or week-long quote delays.

AI-Powered Design Optimization: Our platform analyzes CAD files to suggest manufacturability improvements, reducing tooling costs by up to 30% and slashing lead times through automated DFMA (Design for Manufacturing and Assembly) insights.

5-Day Prototype Turnaround: From design upload to shipped parts—our end-to-end digital workflow ensures rapid iteration without sacrificing quality. Scale to thousands of units with consistent precision.

Seamless Production Scaling: Maintain cost efficiency and quality across all volumes. No retooling, no re-engineering—just smooth transitions from prototype to full-scale production.

One-Stop Solution: Full-service manufacturing—from engineering support to final finishing—so you focus on innovation, not logistics.

“Innovation thrives when manufacturing doesn’t hold you back. Our digital ecosystem turns complex casting projects into predictable, rapid outcomes—so your ideas reach the market faster, stronger, and smarter.”

— Susan Leo, Founder of Honyo Prototype

At Honyo Prototype, we don’t just manufacture parts—we accelerate innovation. With a digital-first approach, we deliver aluminum casting projects with precision, speed, and cost efficiency, turning your vision into reality in record time. Get your instant quote today.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities for Aluminum Casting Projects

Digital Manufacturing Ecosystem: AI-Powered Precision

Online Instant Quote: Upload your CAD file to receive a real-time, transparent cost breakdown – including tooling, material, and finishing – within seconds. No more waiting weeks for estimates.

AI-Driven Design Optimization: Our platform analyzes geometry, tolerances, and material requirements to suggest cost-saving modifications without compromising structural integrity.

Cloud-Based Collaboration: Track progress in real-time, share feedback instantly, and access complete project documentation through a unified digital workspace.

Scalable Production Capacity

Seamless Scale: From 1 prototype to 10,000+ production parts – choose sand casting for low-volume validation (low mold investment) or die casting for high-volume runs (superior surface finish).

50% Faster Lead Times: Proprietary rapid tooling and automated workflows eliminate bottlenecks, delivering prototypes in 3-5 days and production parts in 2-3 weeks.

Zero Minimums, Maximum Flexibility: Grow with confidence – no retooling delays or minimum order thresholds as your business scales.

ISO-Certified Quality Assurance

Rigorous Inspection Protocols: 100% dimensional and material integrity checks per ISO 9001 standards, with traceable documentation for every batch.

Mission-Critical Compliance: Custom testing for aerospace, medical, and industrial applications – including tensile strength, porosity, and chemical composition analysis.

Proactive Quality Control: AI-powered defect prediction and real-time process adjustments ensure consistent excellence from first piece to last.

“We don’t just cast parts – we engineer solutions that accelerate your product journey from concept to market.”

– Susan Leo, Founder of Honyo Prototype

Materials & Surface Finishes

Material Options & Finishes for Aluminum Casting Projects

Precision Material Selection for Your Project

Honyo Prototype leverages cutting-edge digital manufacturing to deliver high-performance aluminum castings tailored to your exact requirements. Our alloy selection process ensures optimal balance of strength, weight, and cost efficiency.

A380 Aluminum Alloy: Industry-standard for complex, high-strength parts. Ideal for automotive, aerospace, and industrial machinery due to exceptional fluidity and pressure tightness.

A356 Aluminum Alloy: Superior corrosion resistance and thermal stability. Perfect for marine, outdoor, and structural applications where longevity is critical.

6061-T6 Aluminum Alloy: Combines machinability, weldability, and moderate strength. Best for parts requiring post-casting machining or structural integrity.

Note: While aluminum casting focuses on metal components, Honyo Prototype offers integrated plastic solutions via injection molding for hybrid assemblies. Contact us to explore multi-material designs.

Surface Finish Options That Elevate Performance

Transform raw castings into production-ready components with finishes engineered for function and aesthetics.

Anodizing (Type II & III):

Type II: Standard corrosion protection with decorative color options (RAL/BS standards).

Type III (Hard Anodizing): 50μm+ wear-resistant layer for high-stress applications like hydraulic systems.

Powder Coating: Durable, UV-stable finishes in any RAL color. Ideal for consumer electronics and architectural components requiring scratch resistance.

Precision Polishing: Mirror-like finishes up to Ra 0.1μm for premium aesthetic applications (e.g., medical devices, luxury goods).

Spray Painting: Custom color matching with matte, gloss, or textured finishes for branding and environmental protection.

AI-Driven Material Selection & Instant Quotes

Our digital manufacturing ecosystem eliminates guesswork and accelerates your project timeline:

Real-Time Cost Estimation:

Upload your CAD file to our AI platform for instant quotes – dynamically calculating tooling, material, and finishing costs based on part complexity, volume, and specifications.

Optimized for Cost & Performance:

Our algorithm recommends the most cost-effective alloy and finish by analyzing load requirements, environmental exposure, and production volume – saving weeks of manual engineering work.

Fast Turnaround Guarantee:

From quote to delivery, our streamlined process cuts lead times by up to 50%. Prototypes in 3 days, production runs in 7–10 days – faster than industry averages.

💡 Pro Tip: Use our AI tool to compare trade-offs between A380 (cost-efficient for high-volume) vs. A356 (corrosion-critical) – all in under 60 seconds.

Ready to optimize your aluminum casting project?

Get an instant quote today – no hidden fees, no delays.

From Quote to Part: Our Process

How It Works: From CAD to Part

Upload Your CAD File

Drag-and-drop interface for STL, STEP, or native CAD files

Real-time validation checks ensure file readiness for manufacturing

Instant AI-Powered Quote

Get a transparent cost breakdown in under 60 seconds

AI analyzes geometry, material, and complexity to eliminate guesswork

No hidden fees – see tooling, material, and finishing costs upfront

Smart DFM Analysis

Automated design checks flag potential issues before production

Expert engineering team provides actionable optimization recommendations

Collaborative platform for quick iterations and cost-saving adjustments

End-to-End Production & Delivery

Digital manufacturing ecosystem ensures seamless quality control

Real-time tracking from casting to final inspection with milestone updates

Lead times up to 50% faster than traditional manufacturers

Start Your Project with Honyo

Start Your Project with Honyo

Stop wasting time on manual quotes and uncertain timelines. Honyo Prototype’s digital manufacturing ecosystem delivers precision aluminum casting with instant pricing, rapid turnaround, and seamless scalability—so you can focus on innovation, not logistics.

Instant, AI-Powered Quoting

Online Instant Quote: Upload your CAD, receive real-time pricing in seconds—no back-and-forth emails.

AI-Optimized Cost Analysis: Our platform identifies design-for-manufacturability improvements, reducing costs by up to 30% while ensuring structural integrity.

Transparent Pricing Breakdown: See every cost component—tooling, material, finishing—without hidden fees or surprises.

One-Stop Solution from Prototype to Production

Seamless Scalability: Move from 1 prototype to 10,000+ units with the same engineering team and quality standards.

End-to-End Digital Ecosystem: Integrated design, tooling, casting, and finishing—all under one roof.

Expert Guidance: Our engineers optimize alloy selection (e.g., A380, 6061), mold design, and surface treatments to maximize performance and minimize waste.

Fast Turnaround Without Compromising Quality

5-7 Day Prototypes: Accelerate validation cycles with rapid-turnaround samples for immediate testing.

40% Faster Production Lead Times: In-house capabilities eliminate third-party bottlenecks for agile scaling.

Zero-Quality Trade-Offs: ISO-certified processes ensure precision tolerances (±0.05mm) and surface finishes (Ra 0.8μm) even at high volumes.

Founder Susan Leo and our expert team are ready to bring your vision to life. Contact us today:

[email protected] | +86 139 2843 8620

Visit our Shenzhen/Dongguan facilities to see innovation in action.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.