Contents

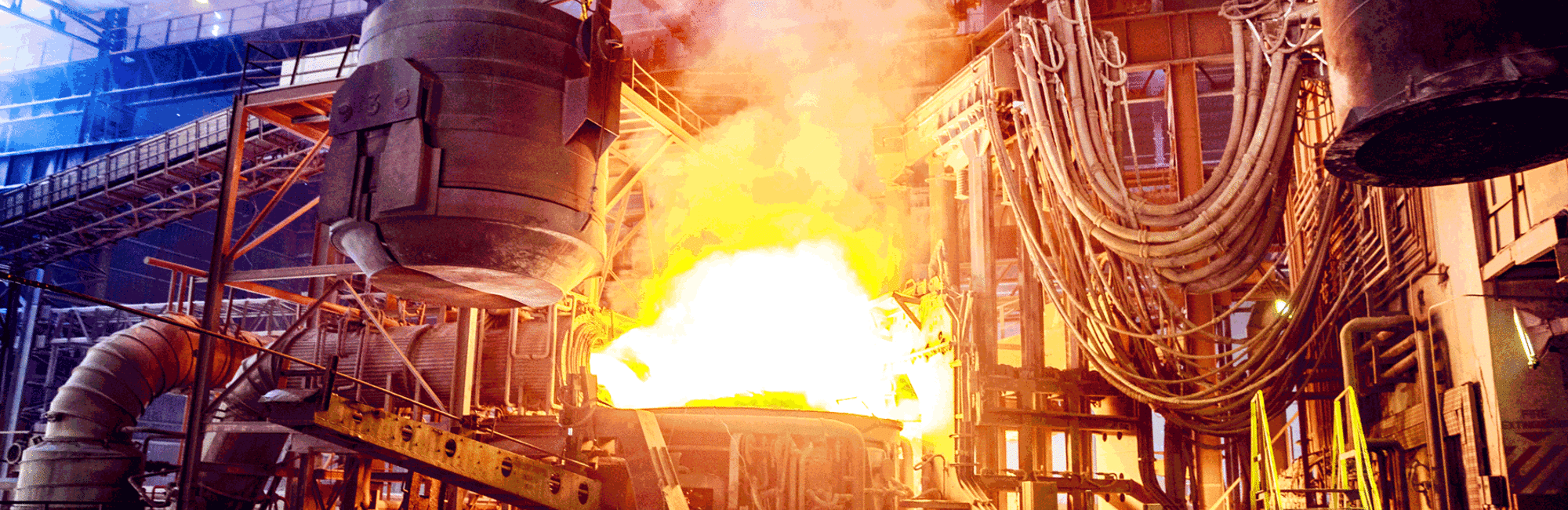

Manufacturing Insight: Alloying Of Steel

Precision Alloyed Steel Machining: Where Material Science Meets Manufacturing Excellence

The strategic alloying of steel fundamentally transforms its mechanical properties, enabling components to withstand extreme stress, corrosion, and thermal cycling in demanding applications across aerospace, medical, and energy sectors. At Honyo Prototype, we recognize that the precise composition of alloys—whether chromium in 4140 for strength, nickel in 4340 for toughness, or molybdenum in 4130 for weldability—directly impacts machinability, tool wear, and final part integrity. Our CNC machining services are engineered to navigate these complexities, leveraging material-specific expertise to optimize cutting parameters, minimize thermal distortion, and achieve micron-level tolerances unattainable with generic processes. We translate metallurgical requirements into precision-engineered components, ensuring your alloyed steel parts perform reliably under real-world conditions. Accelerate your project timelines by leveraging our Online Instant Quote system, where detailed RFQs for alloyed steel machining receive rapid, transparent cost and lead time assessments—turning design intent into manufacturable reality without delay.

Technical Capabilities

The term “alloying of steel” refers to the metallurgical process of adding alloying elements (such as chromium, nickel, molybdenum, etc.) to base iron to enhance mechanical properties like strength, hardness, corrosion resistance, and machinability. However, the machining operations—specifically 3/4/5-axis milling and turning—are applied to already-formed steel alloys (and other materials) to achieve complex geometries and tight tolerances in precision manufacturing.

Below is a technical overview of how these multi-axis machining processes are applied to common engineering materials including aluminum, steel, ABS, and nylon, with emphasis on tight tolerance capabilities and material suitability.

| Material | Typical Alloy/Form | Machinability Notes | 3/4/5-Axis Milling Capability | Turning Capability | Typical Tolerance Range (Machined) | Surface Finish (Typical Ra µm) | Coolant/Lubrication Requirement |

|---|---|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | Excellent machinability; high chip removal rates; low cutting forces | High: ideal for complex aerospace and automotive components | High: excellent for shafts, housings, and rotational parts | ±0.005 mm to ±0.025 mm | 0.8 – 3.2 | Soluble oil or emulsifiable coolant |

| Steel | 4140, 1018, A2, D2 | Moderate to difficult depending on hardness; higher tool wear | High: suitable for molds, tooling, and structural parts; requires rigid setup | High: widely used for precision shafts and mechanical components | ±0.010 mm to ±0.050 mm | 1.6 – 6.3 | High-pressure coolant recommended |

| ABS | Industrial-grade thermoplastic | Easy to machine but prone to melting if overheated; low thermal conductivity | Moderate: used for prototypes and jigs; sharp tools required | Moderate: limited to low-RPM turning for fittings or spacers | ±0.050 mm to ±0.100 mm | 3.2 – 6.3 | Air blasting or light mist; avoid excess coolant |

| Nylon | Nylon 6, Nylon 6/6 | Good machinability; low friction but can deform under clamping pressure | Moderate: used for gears and insulators; requires sharp cutting tools | Moderate: suitable for custom bushings and wear components | ±0.050 mm to ±0.125 mm | 3.2 – 6.3 | Air cooling preferred; minimal lubrication |

Notes on Multi-Axis Machining:

3-Axis Milling: Suitable for prismatic parts with features aligned to primary axes. Common for aluminum and steel components where geometry is not highly complex.

4-Axis Milling: Adds rotational capability (A-axis), enabling machining of angled features and cylindrical contours. Useful for impellers or fixtures in aluminum and steel.

5-Axis Milling: Full simultaneous motion on three linear and two rotary axes. Enables single-setup machining of complex geometries such as turbine blades, aerospace components, and mold cores—especially critical for tight tolerance steel and aluminum parts.

Tight Tolerance Considerations:

Achieving tolerances below ±0.025 mm requires thermal stability, high-precision spindles, in-process probing, and skilled programming (e.g., via CAM software with toolpath optimization). Material stability (e.g., stress-relieved steels or pre-aged aluminum) is critical to maintain dimensional accuracy post-machining.

Summary:

While alloying defines the base properties of steel, advanced CNC machining processes such as 3/4/5-axis milling and turning are essential for producing high-precision components from steel alloys, aluminum, and engineering plastics like ABS and nylon. Each material responds differently to cutting parameters, necessitating tailored tooling, speeds, feeds, and fixturing strategies to meet tight tolerance and surface finish requirements in industrial applications.

From CAD to Part: The Process

Honyo Prototype executes precision manufacturing of steel alloy components through a defined workflow optimized for rapid prototyping and low-volume production. Our process does not involve primary steel alloy creation (smelting/alloying), as we utilize certified pre-alloyed raw materials sourced from qualified metallurgical suppliers. The workflow focuses on transforming client CAD designs into finished parts using these specified alloys.

Upload CAD

Clients initiate the process by uploading detailed CAD models via our secure portal. Critical material specifications must be explicitly defined in the design file or accompanying documentation, including the required steel alloy grade (e.g., 4140, 17-4PH, 304SS). Our system validates file integrity and extracts geometric and material requirements for downstream processing.

AI-Powered Quoting

Our proprietary AI engine analyzes the CAD geometry, material specification, and requested quantities against real-time production capabilities and material inventory data. The quote generation evaluates manufacturability constraints specific to the selected steel alloy, such as machinability ratings, heat treatment requirements, and minimum feature sizes. Material cost is calculated based on certified mill test reports and current commodity pricing. The AI flags potential issues like non-standard alloy availability or geometry incompatible with the material’s properties.

Design for Manufacturability (DFM) Review

Engineers conduct a rigorous DFM analysis focusing on steel alloy characteristics. This includes verifying:

Feasibility of tolerances relative to the alloy’s thermal stability during machining/heat treatment

Suitability of wall thicknesses for the alloy’s weldability or castability

Identification of stress concentration points requiring specific alloy grades

Confirmation of surface finish achievability per alloy microstructure

Recommendations for alternative alloys if the specified grade presents cost or lead time challenges without compromising performance. Clients receive a detailed DFM report with actionable feedback before production commitment.

Production Execution

Upon DFM approval and order confirmation, production commences using certified alloy stock:

| Process Stage | Key Actions for Steel Alloys | Quality Verification |

|---|---|---|

| Material Sourcing | Traceable alloy stock pulled with mill test reports (MTRs) | MTR validation against ASTM/AMS standards |

| Machining/Forming | CNC machining with alloy-specific toolpaths and parameters | In-process dimensional checks per blueprint |

| Heat Treatment | Controlled processes (annealing, quenching, tempering) per alloy specs | Hardness testing and microstructure analysis |

| Finishing | Surface treatments appropriate for alloy (e.g., passivation for stainless) | Visual and metrology inspection |

All steel alloys undergo full material traceability from mill certificate through final part serialization. Critical applications receive additional validation via spectrographic analysis.

Delivery and Documentation

Finished components ship with comprehensive documentation including:

Certified mill test reports tracing the alloy chemistry and mechanical properties

Heat treatment records with time-temperature profiles

Dimensional inspection reports (First Article Inspection available)

Material certificates of conformance (CoC) meeting AS9100 and ISO 9001 requirements

Parts are packaged to prevent corrosion or damage specific to the alloy type, with delivery timelines strictly adhered to per the quoted schedule. This integrated workflow ensures steel alloy components meet stringent performance and regulatory requirements for aerospace, medical, and industrial applications.

Start Your Project

For expert alloying of steel solutions, contact Susan Leo at [email protected]. Honyo Prototype operates a fully equipped manufacturing facility in Shenzhen, providing precision steel alloy development and production for advanced engineering applications. Partner with us for reliable, high-performance material solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.