Contents

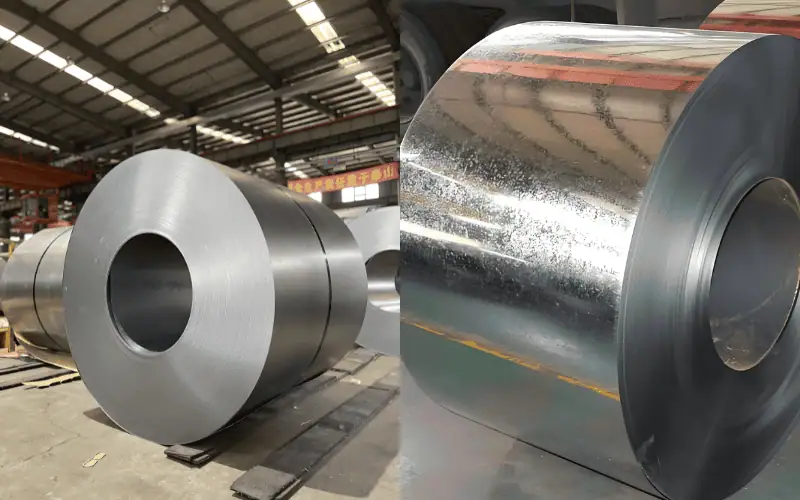

Manufacturing Insight: Alloy Steel Vs Galvanized Steel

Material Selection Impacts Precision Manufacturing Outcomes

Engineers face critical choices when selecting between alloy steel and galvanized steel for demanding applications. Alloy steel delivers exceptional strength, wear resistance, and hardenability through controlled elemental additions like chromium or molybdenum, making it ideal for high-stress aerospace or automotive components. Galvanized steel, with its zinc coating, provides superior corrosion resistance for outdoor infrastructure but introduces challenges during precision machining due to coating abrasiveness and potential for zinc fume generation. The wrong material selection can compromise dimensional accuracy, surface finish, and tool life in CNC operations, directly impacting production timelines and part performance.

At Honyo Prototype, our CNC machining expertise addresses these complexities head-on. Our advanced 3-, 4-, and 5-axis milling and turning centers maintain micron-level tolerances while adapting to the unique thermal and mechanical properties of both material families. We implement optimized toolpaths, specialized coatings for cutting tools, and strict environmental controls to mitigate galvanized steel’s zinc-related machining hazards and manage alloy steel’s hardenability during high-speed operations. This ensures consistent repeatability whether producing low-volume prototypes or bridging to full production runs.

Accelerate your material decision-making with Honyo’s Online Instant Quote platform. Upload your CAD file to receive a detailed manufacturability analysis, material-specific machining recommendations, and a transparent cost estimate within hours—not days. Stop guessing how steel selection affects your CNC workflow; leverage our engineering insights to validate designs and reduce time-to-market from the earliest stages.

Technical Capabilities

Technical Comparison: Alloy Steel vs Galvanized Steel in Precision Machining Applications

When evaluating alloy steel and galvanized steel for use in high-precision 3-axis, 4-axis, and 5-axis milling and turning operations—particularly under tight tolerance requirements—several material and processing factors must be considered. These include machinability, dimensional stability, surface integrity, tool wear, and suitability for secondary operations. For context, comparisons are also made with commonly machined materials such as aluminum, steel (general carbon steel), ABS, and nylon.

| Material | Composition & Form | Machinability (Relative) | Tool Wear | Surface Finish Quality | Dimensional Stability (±0.001″ or better) | Corrosion Resistance | Suitability for 3/4/5-Axis Milling | Suitability for Turning | Notes for Tight Tolerance Applications |

|---|---|---|---|---|---|---|---|---|---|

| Alloy Steel | Medium to high carbon steel with Cr, Ni, Mo, etc. | Moderate (HRc 25–35 typical) | High | Good to excellent with proper tooling | Excellent (after stress relief) | Low (unless passivated) | High (with rigid setups and coated tools) | High | Requires pre-hardened or stress-relieved stock; prone to warping if heat-treated post-machining; ideal for high-strength precision components |

| Galvanized Steel | Low-carbon steel with zinc coating (hot-dip or electro) | Poor to moderate | Very High (zinc causes rapid tool degradation) | Poor (coating interferes; uneven substrate) | Moderate (coating adds variability) | High (coating protects) | Low (not recommended for precision milling) | Low | Zinc coating creates abrasive interface; not suitable for tight tolerance work; deburring and coating inconsistencies affect accuracy |

| Aluminum (6061, 7075) | Al-Mg-Si or Al-Zn alloys | Excellent | Low | Excellent | Very Good (low thermal mass, stable) | Moderate (anodizing improves) | Very High | Very High | Preferred for complex 5-axis parts; high MRR; excellent for tight tolerances; minimal tool wear |

| Carbon Steel (1018, 1045) | Low to medium carbon steel | Good | Moderate | Good | Very Good (when stress-relieved) | Low | High | High | Common for shafts, fixtures; predictable behavior; requires corrosion protection |

| ABS | Thermoplastic polymer | Excellent | Very Low | Good (with sharp tools) | Moderate (creep under load) | High | High (light cuts, high RPM) | High | Low melting point; easy to machine; not for high-temp environments; good for prototypes |

| Nylon (6, 66) | Polyamide resin | Good | Low | Fair to Good | Moderate (hygroscopic—absorbs moisture) | High | Moderate | Moderate | Requires pre-drying; dimensional shifts possible; use for wear-resistant non-metallic parts |

Key Observations for Precision Machining:

Alloy steel is a preferred choice in high-tolerance, high-strength applications where post-machining heat treatment is controlled. It performs well in multi-axis milling when proper tool paths and cutting parameters are used to manage heat and tool deflection. Pre-hardened alloy steels (e.g., H13, 4140 QT) are commonly used in molds, aerospace, and tooling.

Galvanized steel is generally not recommended for tight tolerance machining due to the abrasive zinc coating, inconsistent surface layer, and accelerated tool wear. The coating also introduces dimensional uncertainty, making it unsuitable for ±0.001″ or tighter specifications. If corrosion resistance is required, consider machining alloy or carbon steel first, then applying post-finish galvanization or alternative coatings.

For 5-axis milling complexity, aluminum remains the most favorable due to its high machinability, low weight, and excellent surface finish. ABS and nylon are suitable for non-structural, high-detail prototypes but require environmental controls to maintain dimensional accuracy.

In turning operations, alloy steel and carbon steel offer predictable chip formation and dimensional control when using CNC lathes with live tooling. Galvanized steel should be avoided unless post-machining finishing is not critical.

For all materials, especially steels, stress relief prior to final machining is critical to achieving tight tolerances and long-term stability.

From CAD to Part: The Process

Honyo Prototype’s material-specific manufacturing workflow ensures optimal processing for both alloy steel and galvanized steel components. The distinction between these materials fundamentally alters technical handling at each stage due to divergent material properties and processing requirements. Below is the phase-by-phase execution protocol:

CAD Upload and Material Specification

Clients must explicitly declare the base material in their CAD model metadata or accompanying documentation. For alloy steel (e.g., 4140, 4340), critical parameters include heat treatment specifications (annealed, Q&T), hardness requirements, and mechanical property callouts. For galvanized steel (typically ASTM A123/A153 carbon steel substrates), mandatory inputs are coating class (e.g., Class 55 for 550g/m²), coating type (hot-dip vs. electro), and dimensional tolerances accounting for zinc buildup. Missing or ambiguous material data triggers an automated validation hold requiring client clarification before progression.

AI-Powered Quoting Engine

Honyo’s AI quotation system dynamically adjusts cost and lead-time calculations based on material-specific variables:

| Material Factor | Alloy Steel Impact | Galvanized Steel Impact |

|---|---|---|

| Raw Material Cost | 1.5x–3x carbon steel (Ni, Cr, Mo content) | +15%–25% carbon steel (zinc coating cost) |

| Processing Variables | Heat treatment complexity, hardenability control | Acid pickling time, zinc bath immersion parameters |

| Scrap Value | Higher residual value (alloy content recovery) | Lower residual value (zinc contamination risk) |

| Tolerance Adjustment | Minimal thermal distortion allowance | +0.05–0.15mm per surface for coating thickness |

The system cross-references real-time alloy surcharge indices (e.g., CRU Ferro-Alloy) and zinc LME prices, while applying material-specific scrap rate multipliers (alloy steel: 8–12%; galvanized: 5–8%).

DFM Analysis with Material Constraints

DFM protocols diverge significantly:

Alloy steel designs undergo hardenability assessment using Jominy curve simulations. Sections exceeding critical diameter for specified hardening depth trigger redesign alerts. Sharp internal corners (risk of quench cracking) and non-uniform cross-sections (distortion potential) are flagged with geometric correction suggestions. Heat treat racking feasibility is validated.

Galvanized steel components are analyzed for coating integrity risks. Closed sections without venting/drainage holes (>1.5mm wall thickness) generate mandatory modification requests. Protrusion density exceeding 3 features/ft² risks bare spots; racking point locations are optimized to minimize uncoated areas. Threaded features are checked against ASTM B633 coating thickness allowances.

Production Execution Pathways

Alloy steel components follow a strictly controlled thermal processing sequence: precision CNC machining → stress relief → final machining → quench & temper (monitored via SPC-controlled furnace logs with ±5°C tolerance) → post-temper grinding. All handling uses non-contaminating fixtures to prevent surface decarburization.

Galvanized steel parts undergo: abrasive blasting (Sa 2.5 cleanliness) → fluxing → hot-dip galvanizing (zinc bath: 445–455°C, immersion time per ASTM A123 Table 1) → quenching → inspection for dross inclusions. Racking geometry prevents part-to-part contact during dipping, and centrifugal spin-drying is applied to threaded features.

Delivery and Compliance Documentation

Alloy steel shipments include: certified mill test reports (ASTM A370 tensile/impact data), heat treat charts with soak times, and final hardness verification (Rockwell C scale per ASTM E18). Parts are VCI-paper wrapped with desiccant for moisture-sensitive grades.

Galvanized steel deliveries contain: coating thickness verification (magnetic gauge per ASTM E376), adhesion test results (quench-crack method), and zinc alloy composition certificates. Components are separated by non-absorbent spacers to prevent wet storage staining during transit, with humidity indicators in sealed packaging.

Material selection is not interchangeable—alloy steel serves structural integrity applications requiring high strength-to-weight ratios, while galvanized steel is exclusively for atmospheric corrosion resistance. Honyo’s process rigorously enforces this distinction at every workflow node to prevent material-incompatible processing that would compromise part functionality or regulatory compliance. Clients receive explicit material suitability advisories during DFM if initial selection conflicts with functional requirements.

Start Your Project

Considering the differences between alloy steel and galvanized steel for your next project? Understand the mechanical properties, corrosion resistance, and cost implications to make the right material choice for your application.

For expert guidance tailored to your manufacturing needs, contact Susan Leo at [email protected]. With our precision fabrication capabilities and quality control processes, Honyo Prototype delivers high-performance metal solutions from our factory in Shenzhen, China.

| Property | Alloy Steel | Galvanized Steel |

|---|---|---|

| Composition | Iron with added elements (e.g., chromium, nickel) | Carbon steel coated with zinc |

| Strength | High tensile and yield strength | Moderate strength |

| Corrosion Resistance | Moderate (depends on alloy) | Excellent due to zinc coating |

| Common Applications | Automotive, aerospace, tooling | Construction, outdoor structures |

| Weldability | Varies by alloy type | Good, but zinc fumes require care |

Reach out today to discuss material selection, prototyping, or volume production. Susan Leo and the Honyo team are ready to support your engineering and manufacturing goals.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.