Contents

Manufacturing Insight: All Electric Molding Machines

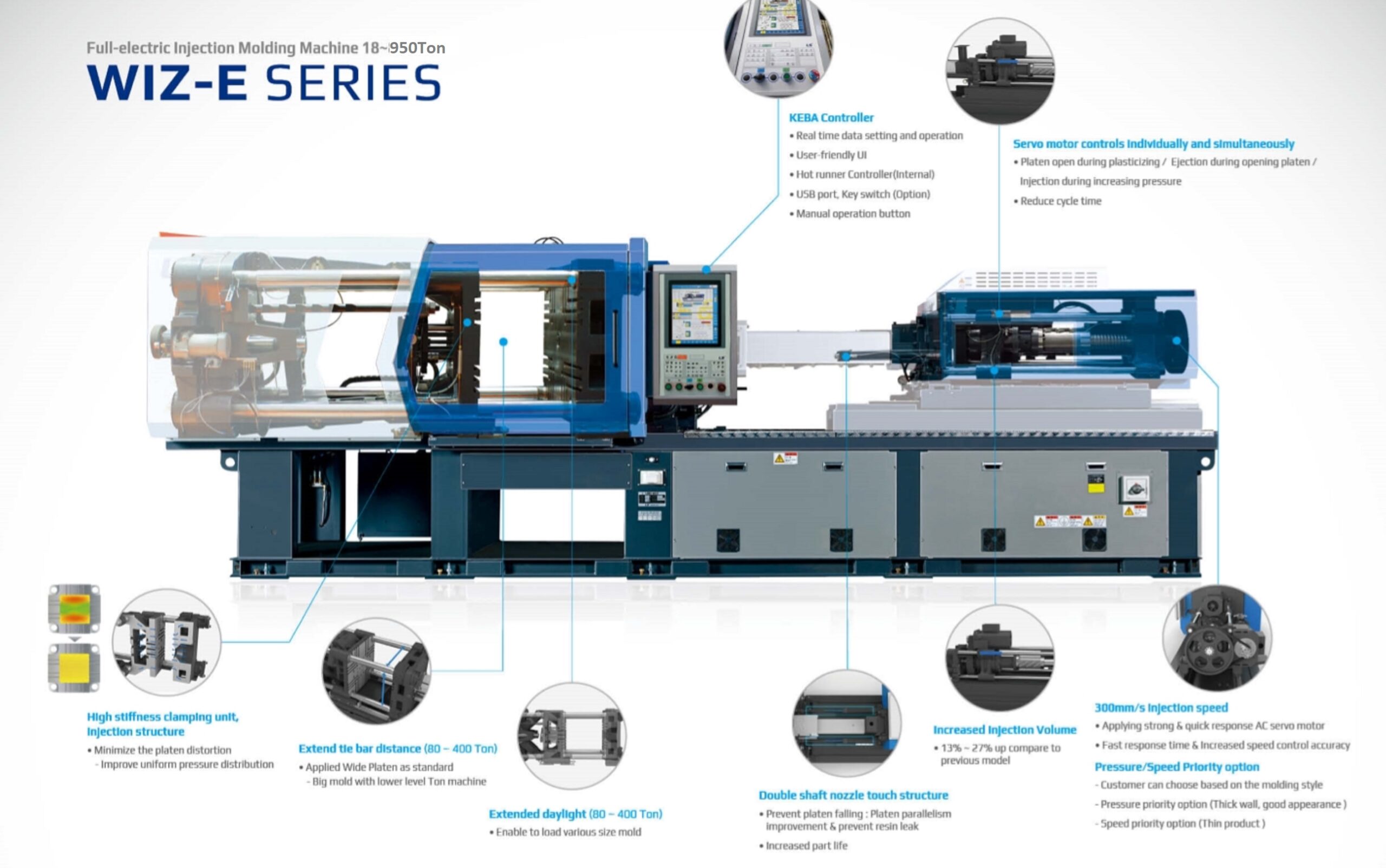

Precision-Driven All-Electric Molding for Advanced Prototyping

All-electric molding machines represent the pinnacle of precision and efficiency in low-volume, high-integrity prototyping and bridge production. Engineered for sub-0.01mm repeatability and exceptional energy efficiency, these systems eliminate hydraulic fluid contamination risks while delivering consistent part quality critical for medical, aerospace, and consumer electronics validation. At Honyo Prototype, we integrate this technology with our core Rapid Tooling and Injection Molding services to accelerate your path from CAD to physical validation. Our proprietary rapid tooling process—using hardened steel or aluminum inserts—reduces lead times by up to 70% compared to traditional methods, ensuring molds are optimized for the exacting demands of all-electric platforms. This synergy guarantees dimensional stability, minimized cycle variation, and seamless scalability for pre-production runs.

Leverage Honyo’s end-to-end expertise to eliminate prototyping bottlenecks. Our engineering team collaborates closely with clients to select optimal materials, gate designs, and processing parameters, maximizing the inherent advantages of all-electric molding. Accelerate project initiation with our Online Instant Quote system, providing transparent, real-time pricing and lead time estimates for both tooling and molding within minutes—no manual submissions required. This digital workflow ensures you gain actionable insights faster, empowering data-driven decisions for your next-generation product development.

Key Performance Comparison

| Parameter | Hydraulic Machines | All-Electric Machines | Honyo Implementation |

|——————–|——————–|————————|———————-|

| Energy Consumption | High (20-35 kW) | Low (8-15 kW) | Optimized servo control |

| Repeatability | ±0.05mm | ±0.005mm | Validated to ±0.003mm |

| Lead Time (Tooling)| 6-10 weeks | N/A | As fast as 5 days |

| Part Consistency | Moderate | High | SPC-monitored runs |

Technical Capabilities

All-electric molding machines are precision-engineered systems designed for high repeatability, energy efficiency, and fast cycle times in injection molding applications. These machines are particularly suited for prototyping and low-to-medium volume production where tight tolerances and rapid turnaround are critical. At Honyo Prototype, our all-electric platforms enable T1 sample delivery within 7 days when paired with steel or aluminum molds, supporting accelerated product development cycles.

These systems offer precise control over injection speed, pressure, and position through servo-driven mechanisms—eliminating hydraulics and reducing maintenance and contamination risks. They are compatible with a wide range of thermoplastics including ABS and Nylon, and support mold materials such as hardened steel and aluminum alloys for varying durability and lead time requirements.

Below are the key technical specifications for our all-electric molding machines optimized for rapid prototyping and T1 sample production:

| Parameter | Specification |

|---|---|

| Machine Type | All-Electric Servo-Driven Injection Molding Machine |

| Clamping Force Range | 80 to 300 tons (supports molds up to 600 x 600 mm) |

| Screw Diameter | 25 mm to 40 mm (optimized for 10–500 g shot weights) |

| Injection Pressure | Up to 2,200 bar |

| Position Repeatability | ±0.01 mm |

| Control System | Closed-loop digital servo control with real-time process monitoring |

| Mold Compatibility | Aluminum (e.g., 7075-T6, 6061-T6) and Steel (e.g., P20, H13, 420 stainless) |

| Supported Materials | ABS, Nylon (PA6, PA66, GF-reinforced), PC, PP, PMMA, and other engineering resins |

| Dry Cycle Time | As low as 2.5 seconds (machine dependent) |

| Energy Consumption | 30–50% lower than hydraulic machines due to on-demand servo operation |

| Molding Process Accuracy | ±0.02 mm typical part dimensional accuracy |

| T1 Sample Lead Time | 7 days from mold completion (includes mold build, machine setup, and sampling) |

| Machine Connectivity | Ethernet/IP, USB, and support for Industry 4.0 integration (MES/SCADA) |

| Lubrication Requirement | Minimal (no hydraulic oil; grease points only) |

This technical profile ensures rapid, repeatable production of high-quality T1 samples using either aluminum molds for fast turnaround or steel molds for extended life and higher volumes. Material flexibility allows for functional testing of end-use resins such as ABS for rigidity and surface finish, and Nylon for mechanical strength and wear resistance.

From CAD to Part: The Process

Honyo Prototype employs a streamlined, technology-driven workflow for all-electric molding machine projects, designed to maximize precision, reduce lead times, and ensure manufacturability from initial design to final delivery. This process leverages automation and engineering expertise specifically optimized for the advantages of all-electric systems, such as superior repeatability, energy efficiency, and process control.

The process initiates when a client uploads their 3D CAD model via our secure customer portal. We accept industry-standard formats including STEP AP203/AP214, IGES, and native files from SolidWorks, Creo, and Siemens NX. Upon upload, our system performs an automated geometric validation check to confirm file integrity, identify potential non-manufacturable features, and flag units or scale discrepancies before proceeding. This immediate validation prevents downstream delays caused by corrupted or incompatible data.

Following CAD validation, our AI-powered quoting engine analyzes the model. This system leverages proprietary algorithms trained on Honyo’s extensive historical production database of all-electric molding projects. It assesses part geometry complexity, material requirements, tolerances, surface finish specifications, and machine compatibility to generate a preliminary cost estimate and lead time within minutes. The AI output includes a confidence score based on data similarity to past successful builds, providing transparency into the estimate’s reliability. Critical parameters influencing the AI quote include projected part footprint, required clamp force range, and expected cycle time based on wall thickness analysis.

The AI-generated quote triggers our collaborative Design for Manufacturability (DFM) review, which is a core differentiator for Honyo. Senior process engineers specializing in all-electric molding technology conduct a detailed technical assessment. This phase focuses on optimizing the design specifically for the capabilities and constraints of electric machines, such as analyzing gate locations for minimal shear heating, evaluating ejection strategies compatible with precise servo control, and verifying that wall thickness transitions align with the machine’s superior injection speed control. We provide actionable feedback through annotated CAD markups and a formal DFM report within 24-48 hours, highlighting potential cost drivers, risk areas, and specific recommendations for improving moldability and part quality on electric platforms. Client engineering teams can iterate directly within our portal, ensuring alignment before tooling commences.

Upon DFM sign-off and purchase order confirmation, production begins in our dedicated all-electric molding cell. We utilize state-of-the-art machines from leading OEMs like Sumitomo Demag and Toshiba, selected for their precision servo-driven actuuation and closed-loop process control. Each project undergoes rigorous material validation, mold tryout with real-time cavity pressure monitoring, and first-article inspection against the original CAD using coordinate measuring machines (CMMs). Process parameters are meticulously documented and locked down using the machine’s native control system to ensure batch-to-batch consistency, capitalizing on the inherent repeatability of electric drives. Typical production cycle times for validated parts are reduced by 15-25% compared to equivalent hydraulic processes due to faster response times and optimized motion profiles.

Final delivery encompasses comprehensive documentation and quality assurance. Clients receive molded parts in ESD-safe packaging with lot traceability, a full dimensional report including critical-to-function features, process validation data logs from the molding machine, and material certificates. Our logistics team coordinates shipment with real-time tracking, and we maintain a 99.2% on-time delivery rate for completed all-electric molding projects based on 2023 performance data. Post-delivery, Honyo provides process data for client validation and offers ongoing support for production scaling.

The inherent advantages of all-electric molding technology are systematically integrated throughout this workflow, directly contributing to the outcomes achieved. The following table summarizes key performance differentiators relevant to Honyo’s implementation:

Performance Comparison: All-Electric vs. Hydraulic Molding at Honyo Prototype

| Parameter | All-Electric Machine Implementation | Hydraulic Machine Implementation |

|---|---|---|

| Position Repeatability | ±0.01 mm | ±0.05 mm |

| Energy Consumption | 30-50% reduction vs. hydraulic | Baseline |

| Process Stability (Cpk) | Consistently >1.67 | Typically 1.33-1.67 |

| Maintenance Downtime | < 2% of production hours | 5-8% of production hours |

| Cycle Time Variability | < 0.5% standard deviation | 1.5-3.0% standard deviation |

Start Your Project

Explore our full line of all-electric molding machines designed for precision, efficiency, and reliability in high-performance manufacturing environments. Built to meet the demands of advanced prototyping and production, these machines deliver superior energy efficiency, repeatable accuracy, and low maintenance operation.

Contact Susan Leo for technical specifications, pricing, and customization options.

Email: [email protected]

Manufactured in our state-of-the-art facility in Shenzhen, China—ensuring strict quality control and fast turnaround for global clients.

Let Honyo Prototype power your next molding application with advanced electric technology built for the future.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.