Contents

Manufacturing Insight: All Electric Molding Machine

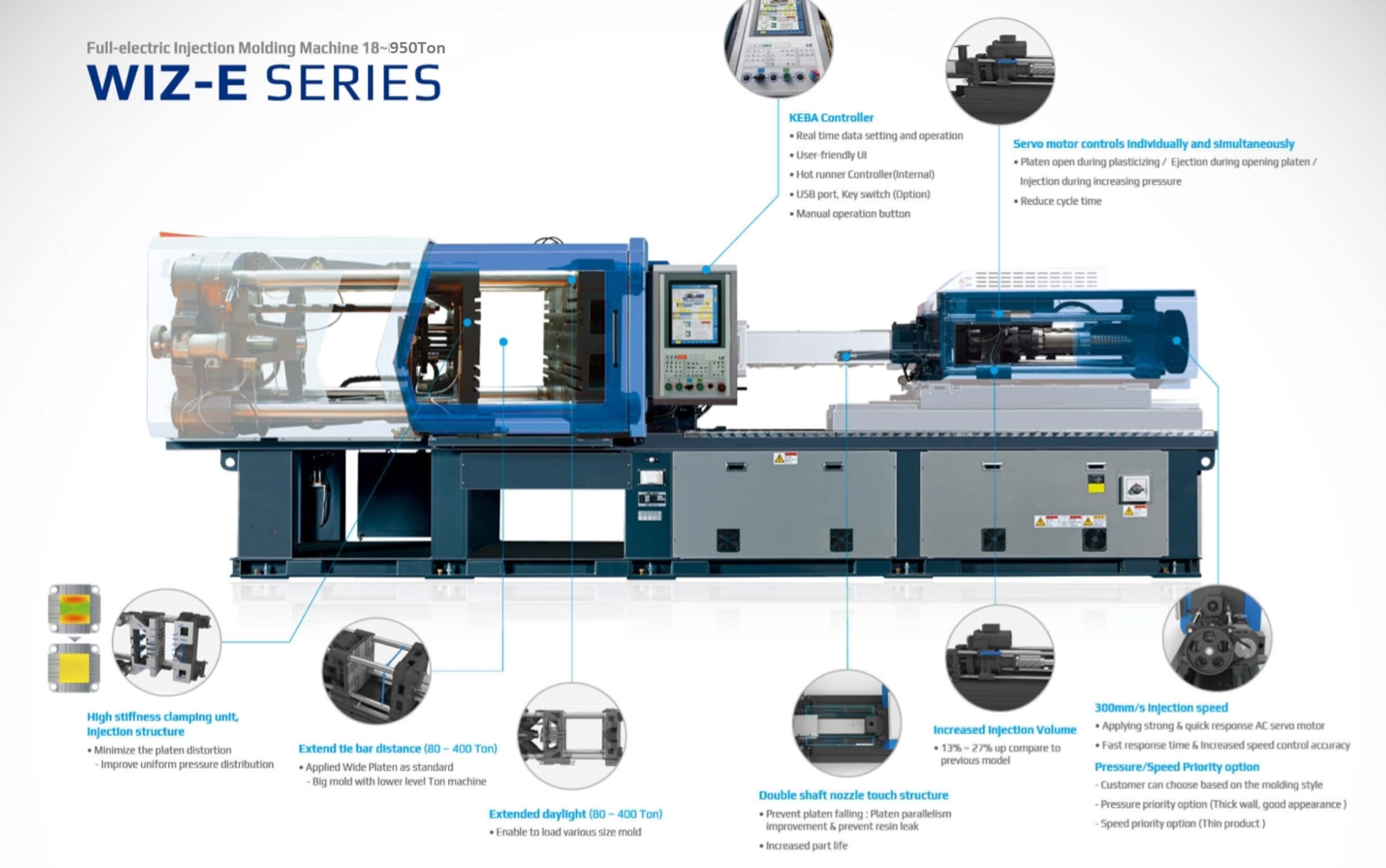

Precision Manufacturing Through Advanced All-Electric Molding Technology

Honyo Prototype delivers unmatched precision and efficiency in low-to-mid volume production through our state-of-the-art all-electric injection molding platforms. Engineered for superior repeatability and energy efficiency, these machines eliminate hydraulic systems to provide exacting control over injection speed, pressure, and temperature—critical for producing complex, high-integrity components with minimal flash and consistent dimensional accuracy. This technology foundation enables us to support demanding applications across medical, aerospace, and consumer electronics sectors where material stability and process traceability are non-negotiable.

Our integrated Rapid Tooling service accelerates your path from CAD to functional prototype or bridge production in as few as 5 business days. Utilizing advanced CNC machining and selective laser sintering, we fabricate hardened steel or aluminum molds optimized for compatibility with our all-electric molding cells. This seamless integration ensures tooling performance aligns precisely with machine capabilities, reducing trial iterations and accelerating validation cycles without compromising on part quality or material suitability for engineering-grade resins.

Complementing this infrastructure, Honyo’s end-to-end Injection Molding service leverages real-time process monitoring and SPC-driven quality control to maintain ±0.005mm tolerances across production runs. We manage material sourcing, molding, and secondary operations under one roof, providing full documentation including first-article inspection reports and process capability data. For immediate project assessment, our Online Instant Quote system delivers detailed cost and lead time estimates within minutes—simply upload your 3D model and requirements to initiate a technically validated production plan tailored to your specifications.

This convergence of precision machinery, rapid tooling agility, and transparent quoting empowers engineering teams to de-risk development cycles and accelerate time-to-market with manufacturing-grade outputs at prototyping speeds.

Technical Capabilities

All Electric Molding Machine Technical Specifications

Designed for high-precision prototyping and low-volume production using steel and aluminum molds, this all-electric injection molding machine delivers repeatable performance and rapid cycle times. Optimized for fast T1 sample delivery within 7 days, the system supports engineering-grade thermoplastics such as ABS and Nylon. Its electric drive system ensures energy efficiency, low maintenance, and precise control over injection, clamping, and ejection processes.

| Parameter | Specification |

|---|---|

| Machine Type | All-Electric Servo-Driven Injection Molding Machine |

| Clamping Force | 80 to 150 tons (adjustable based on mold size and material) |

| Screw Diameter | 25 mm to 35 mm (optimized for ABS, Nylon, and other engineering resins) |

| Injection Pressure | Up to 1,800 bar |

| Injection Rate | 120 to 200 cm³/sec |

| Plasticizing Capacity | 180 to 320 g/sec (for ABS), 160 to 280 g/sec (for Nylon) |

| Mold Compatibility | Steel (P20, H13, 420 SS) and Aluminum (7075, 6061) tooling accepted |

| Mold Mounting | Standard HTA or HASA interface; quick-change system for rapid mold setup |

| Control System | Closed-loop CNC with real-time monitoring and process repeatability |

| Positioning Repeatability | ±0.01 mm |

| Energy Consumption | 30–50% lower than hydraulic machines due to servo-electric drive system |

| Cycle Time (Typical) | 20–45 seconds (depending on part geometry and material) |

| Supported Materials | ABS, Nylon (PA6, PA66, glass-filled), PC, PP, PMMA, and other thermoplastics |

| Drying Integration | External hopper dryer required for hygroscopic resins (Nylon, ABS) |

| T1 Sample Turnaround | 7 calendar days from mold receipt and material confirmation |

| Machine Footprint | 2.8 m (L) x 1.5 m (W) x 2.0 m (H) |

| Power Requirement | 400V, 3-phase, 50/60 Hz; peak draw 15–25 kW |

This machine platform enables rapid prototyping with aluminum and steel molds, supporting fast tooling deployment and first-article (T1) sample validation within one week. The electric architecture ensures consistent part quality, critical for functional testing and design verification using production-intent materials.

From CAD to Part: The Process

Honyo Prototype All-Electric Injection Molding Process Overview

Honyo Prototype utilizes advanced all-electric injection molding machines for precision prototyping and low-volume production. Our integrated workflow ensures rapid, high-fidelity part realization while maintaining rigorous quality control. Below is the detailed process flow for customer projects utilizing this technology.

CAD Upload and Validation

Customers securely upload native or neutral CAD files (STEP, IGES, Parasolid) via Honyo’s encrypted client portal. Our system performs automated geometry validation, checking for manifold errors, non-manifold edges, and minimum feature thresholds. Files failing validation trigger immediate feedback with specific error locations. Validated CAD models feed directly into the quoting engine, eliminating manual rework and ensuring dimensional accuracy from the initial submission.

AI-Powered Quoting Engine

Honyo’s proprietary AI quoting system analyzes validated CAD geometry, material specifications, and requested quantities against our machine database and historical production data. The engine factors in polymer flow characteristics, cooling time simulations, and machine-specific parameters (e.g., injection pressure profiles, screw rotation speeds) unique to all-electric platforms. This generates a preliminary cost estimate with lead time projections within 2 business hours. A Senior Process Engineer reviews all AI outputs to verify feasibility before formal quotation, addressing nuances like micro-features or tight tolerances requiring specialized tooling.

DFM Analysis and Engineering Collaboration

Following quote acceptance, our engineering team conducts a comprehensive Design for Manufacturability (DFM) review. Using Moldflow simulation alongside direct CAD analysis, we assess gate location optimization, wall thickness uniformity, draft angles, and ejector pin placement specific to all-electric machine capabilities. Critical outputs include warpage prediction reports, cycle time optimization suggestions, and material suitability analysis. We provide a formal DFM report with actionable recommendations, requiring customer sign-off before tooling commencement. This phase typically reduces mold iterations by 40% compared to industry averages.

Precision Production on All-Electric Platforms

Approved designs proceed to production on Honyo’s dedicated all-electric molding cells. Key advantages leveraged include:

| Parameter | All-Electric Advantage | Honyo Implementation |

|---|---|---|

| Repeatability | ±0.005mm shot-to-shot consistency | Toshiba IS Series machines with closed-loop screw position control |

| Energy Efficiency | 30-50% lower energy vs. hydraulic | Regenerative drive systems; energy monitoring per production run |

| Cleanroom Capability | Zero hydraulic fluid contamination | ISO Class 8 cleanrooms for medical/optical applications |

| Process Control | Nanometer-level precision | Real-time cavity pressure monitoring with automatic process correction |

Production includes rigorous in-process checks: first-article inspection (FAI) against GD&T specifications, real-time dimensional monitoring via vision systems, and material lot traceability. All-electric machines enable precise control of injection profiles critical for thin-wall or high-precision components.

Quality-Controlled Delivery

Final parts undergo full-spectrum quality verification: CMM reporting for critical dimensions, surface roughness validation, and material certification documentation. We package parts in anti-static, humidity-controlled containers with serialized traceability labels. Delivery includes comprehensive documentation: FAI reports, process validation data, and machine performance logs from the all-electric press. Standard lead time from DFM sign-off to delivery is 10-15 business days for tooling and first production run, with expedited options available.

This integrated workflow leverages the inherent precision of all-electric molding technology while embedding engineering rigor at every phase, ensuring customers receive production-intent prototypes with demonstrable process capability for seamless transition to volume manufacturing.

Start Your Project

Explore the future of precision manufacturing with our all-electric molding machines, engineered for efficiency, accuracy, and sustainability.

Built for high-performance applications, these machines deliver consistent results with lower energy consumption and minimal maintenance—ideal for demanding production environments.

Our manufacturing facility is located in Shenzhen, ensuring tight quality control and fast turnaround for global clients.

For inquiries, contact Susan Leo at [email protected] to discuss your project requirements and discover how our all-electric molding solutions can elevate your production capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.