Contents

Manufacturing Insight: All Electric Injection Molding Machines

Precision Manufacturing Through Advanced All-Electric Injection Molding

Honyo Prototype delivers unmatched precision and efficiency in low-to-mid volume production through our state-of-the-art all-electric injection molding machines. These systems eliminate hydraulic components, achieving superior energy efficiency—reducing power consumption by up to 70% compared to hydraulic alternatives—while ensuring micron-level repeatability critical for complex, high-tolerance components. The absence of oil-based systems guarantees a contaminant-free production environment, essential for medical, optical, and electronics applications where part integrity is non-negotiable.

Our integrated Rapid Tooling service accelerates your path from CAD to physical part, leveraging in-house CNC machining and EDM capabilities to produce production-ready molds in as little as 5 business days. Combined with our all-electric molding platforms, this enables consistent sub-0.5% process repeatability and reduced cycle times, directly translating to lower per-part costs and minimized scrap rates. Whether prototyping or launching limited production runs, Honyo’s end-to-end solution ensures your design intent is preserved from first article to final shipment.

Evaluate your project’s feasibility instantly with our Online Instant Quote system. Submit your 3D model and requirements to receive a detailed manufacturability analysis and competitive pricing within hours—no sales calls required. Accelerate your development timeline with Honyo’s precision-engineered molding and rapid tooling expertise.

Technical Capabilities

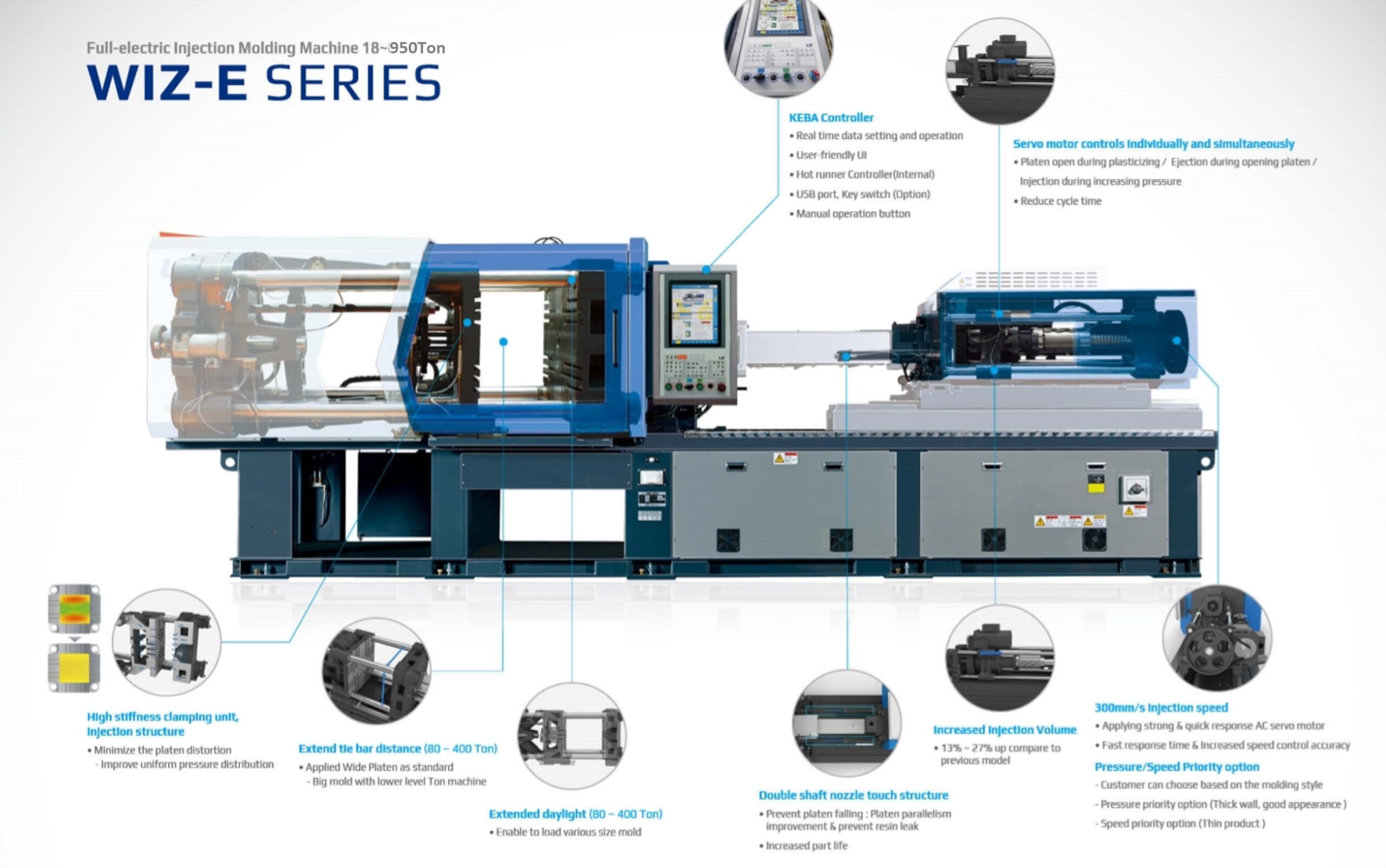

All electric injection molding machines are precision manufacturing systems designed for high repeatability, energy efficiency, and fast cycle times. These machines use servo-electric drives for all axes—clamping, injection, and ejection—eliminating the need for hydraulic fluid and reducing energy consumption and maintenance requirements. They are ideal for applications requiring tight tolerances and clean production environments, such as medical, automotive, and consumer electronics components.

For projects requiring T1 sample parts within 7 days, all electric machines offer rapid setup, precise process control, and compatibility with both aluminum and steel molds. Aluminum molds are typically used for prototyping and low-volume production due to faster machining and lower cost, while steel molds (e.g., P20, H13, 4140) are used for high-volume, long-life production. The machines support a wide range of engineering thermoplastics, including ABS and Nylon (PA6, PA66), which are commonly used for durable, heat-resistant parts.

Below are the key technical specifications relevant to T1 sampling with steel and aluminum molds using ABS and Nylon materials:

| Parameter | Specification / Detail |

|---|---|

| Machine Type | All Electric Injection Molding Machine |

| Clamping Force Range | 50 to 300 tons (suitable for small to medium molds) |

| Screw Diameter | 25–45 mm (optimized for ABS, Nylon, and other engineering resins) |

| Injection Pressure | Up to 2,000 bar (ensures complete mold filling, especially for nylon’s higher viscosity) |

| Injection Rate | 150–300 mm/s (adjustable for material flow characteristics) |

| 塑化 Capacity (ABS, 1.0 g/cm³) | 80–220 cm³/s (supports fast cycling with high throughput) |

| Control System | Closed-loop, PC-based with real-time monitoring and recipe storage |

| Position Repeatability | ±0.01 mm (critical for consistent T1 sample quality) |

| Mold Compatibility | Accepts aluminum (7075, 6061) and steel (P20, H13, 4140) molds with standard interfaces |

| Mold Setup Time | < 4 hours (with quick mold change systems and digital parameter presets) |

| Material Compatibility | ABS, Nylon (PA6, PA66, glass-filled grades), PC, PP, PE, PMMA |

| Drying Requirements | ABS: 80°C for 2–4 hrs; Nylon: 80–90°C for 4–6 hrs (external dryer recommended) |

| Barrel Temperature Range | 220–300°C (adjustable per zone for optimal melt control) |

| Cycle Time (Typical) | 15–45 seconds (depends on part geometry and wall thickness) |

| Power Consumption | 5–15 kW (30–70% lower than hydraulic equivalents) |

| T1 Sample Lead Time | 7 days from mold receipt (includes mold tryout, process optimization, and part delivery) |

| Machine Environment | Cleanroom compatible (ISO Class 8), low noise (<70 dB), no hydraulic oil leaks |

These specifications enable rapid prototyping and validation of injection molded parts using aluminum or steel tooling, with full compatibility for engineering materials like ABS and Nylon. The precision and repeatability of all electric systems ensure that T1 samples closely represent final production quality, reducing time-to-market and development risk.

From CAD to Part: The Process

Honyo Prototype employs a streamlined, technology-driven workflow for all-electric injection molding machine projects, ensuring precision, speed, and cost efficiency from concept to delivery. Our process leverages proprietary AI tools and deep manufacturing expertise specifically optimized for the capabilities and constraints of all-electric platforms, which offer superior energy efficiency, repeatability, and cleanroom compatibility compared to hydraulic alternatives.

The process begins when a client uploads their 3D CAD model via our secure customer portal. Our AI-powered quoting engine immediately analyzes the geometry, material specifications, and requested quantities. This system incorporates real-time data on machine availability within our all-electric fleet (primarily Toshiba IS Series and comparable high-precision models), material costs, and historical production parameters. Crucially, the AI cross-references the design against known all-electric machine limitations such as maximum injection pressure profiles, clamp tonnage requirements, and ejection force capabilities, generating a highly accurate, fixed-price quote with an estimated lead time within hours, not days. This initial analysis significantly reduces quoting errors common with manual methods.

Following quote acceptance, the project enters the Design for Manufacturability (DFM) phase. Honyo’s senior manufacturing engineers conduct a rigorous, no-charge DFM review focused explicitly on optimizing the part for all-electric molding. This involves analyzing wall thickness uniformity to prevent sink marks given the precise but potentially lower peak pressure of all-electric systems, verifying gate locations for optimal cavity filling with minimal shear heat, assessing draft angles for reliable ejection without hydraulic assist, and confirming part geometry compatibility with the machine’s tie-bar spacing and platen size. Engineers provide specific, actionable recommendations directly within the CAD environment or via detailed markup reports, collaborating closely with the client’s design team to resolve issues before tooling commences, thereby mitigating costly downstream revisions.

Upon DFM approval and tooling sign-off, production utilizes Honyo’s dedicated all-electric molding cells. These machines are meticulously maintained and calibrated, featuring advanced process monitoring with cavity pressure sensors and real-time closed-loop control essential for the tight tolerances demanded in prototyping and low-volume production. Material drying protocols are strictly enforced, and process parameters are optimized using scientific molding principles tailored to the electric drive system’s responsiveness. Every production run undergoes in-process quality checks against critical dimensions, with full First Article Inspection reports generated per AS9102 or client-specified standards. The inherent stability of all-electric machines ensures exceptional part-to-part consistency, minimizing scrap and rework.

Final delivery encompasses comprehensive documentation alongside the physical parts. Clients receive the molded components in ESD-safe or custom packaging as required, accompanied by a detailed inspection report including dimensional data, material certification, and process parameter logs. All-electric production data, highlighting energy consumption metrics and process stability indices, is also available upon request, supporting clients’ sustainability reporting needs.

The standard timeline for this integrated process is outlined below, reflecting typical scenarios for prototype or bridge tooling quantities:

| Process Phase | Typical Duration | Key Activities |

|---|---|---|

| CAD Upload to AI Quote | 4-8 Business Hours | Automated geometry analysis, machine/material feasibility check, fixed-price generation |

| DFM Review & Approval | 2-5 Business Days | Engineer-led analysis, client collaboration on design optimization, formal sign-off |

| Production | 7-15 Business Days | Tool setup/validation, molding run, in-process QC, final inspection |

| Delivery | 1-3 Business Days | Packaging, documentation finalization, shipment coordination |

This end-to-end process, uniquely refined for all-electric molding technology, delivers significant value through accelerated time-to-part, reduced risk via predictive DFM, and demonstrable quality outcomes. Honyo’s integration of AI-driven quoting with deep process-specific engineering expertise ensures clients achieve optimal results from the inherent advantages of all-electric injection molding for their critical applications.

Start Your Project

Discover the future of precision manufacturing with our all-electric injection molding machines, engineered for superior energy efficiency, accuracy, and repeatability. Built to meet the highest industry standards, these machines are ideal for demanding applications in medical, automotive, and consumer electronics.

Manufactured in Shenzhen, China, our machines combine advanced servo technology with robust build quality to deliver consistent performance and lower total cost of ownership.

For specifications, pricing, or to schedule a factory tour, contact Susan Leo at [email protected]. Let Honyo Prototype help you optimize your production with next-generation electric molding solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.