Introduction: Navigating the Global Market for aircraft parts company

Navigating the global market for aircraft parts can be a daunting task for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, including regions like Vietnam and Saudi Arabia. The challenge lies not only in sourcing high-quality components but also in ensuring compliance with stringent aviation regulations and standards. This guide addresses these complexities by providing a comprehensive overview of the aircraft parts industry, covering essential areas such as types of parts available, their applications, effective supplier vetting processes, and an analysis of cost factors.

As the aviation sector continues to grow globally, understanding the nuances of the aircraft parts market is crucial for making informed purchasing decisions. This guide is designed to empower B2B buyers by equipping them with actionable insights, best practices, and strategic approaches to sourcing aircraft parts that meet their operational needs. From evaluating the reliability of suppliers to understanding the intricacies of pricing, this resource serves as a vital tool for enhancing procurement strategies. With the right knowledge, international buyers can confidently navigate the complexities of the aircraft parts market, ensuring they invest in components that enhance safety, efficiency, and performance in their aviation operations.

Understanding aircraft parts company Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Parts Suppliers | Manufacture original equipment parts with strict quality controls | Aircraft manufacturers and major airlines | Pros: Guaranteed quality and compatibility. Cons: Higher costs and longer lead times. |

| Aftermarket Parts Providers | Supply alternative parts that may be cheaper and more accessible | Maintenance, repair, and overhaul (MRO) services | Pros: Cost-effective solutions. Cons: Varying quality and potential compatibility issues. |

| Specialty Parts Suppliers | Focus on niche markets or specific aircraft types | Custom builds and vintage aircraft restoration | Pros: Unique offerings tailored to specific needs. Cons: Limited availability and may require longer sourcing times. |

| Avionics and Electronics Suppliers | Provide advanced electronic systems and components | Upgrades and retrofitting of existing aircraft | Pros: Enhanced functionality and safety. Cons: Complex installation and potential for obsolescence. |

| Aircraft Parts Distributors | Offer a wide range of parts from various manufacturers | General aviation and small aircraft operators | Pros: One-stop shop for diverse needs. Cons: May lack specialized knowledge for specific parts. |

What Are the Characteristics of OEM Parts Suppliers?

OEM parts suppliers are essential for ensuring the integrity and safety of aircraft. They produce components that meet the original specifications set by aircraft manufacturers, adhering to rigorous quality control standards. B2B buyers in this category, such as major airlines and aircraft manufacturers, prioritize these parts for their reliability and compatibility with existing systems. However, the trade-off often includes higher prices and longer lead times, making it crucial for buyers to assess their operational timelines and budget constraints.

How Do Aftermarket Parts Providers Differ?

Aftermarket parts providers offer a more cost-effective alternative to OEM parts, supplying components that are compatible but not manufactured by the original equipment manufacturer. This type of supplier is particularly relevant for maintenance, repair, and overhaul (MRO) services, where budgets may be tighter. While aftermarket parts can significantly reduce costs, buyers must be cautious about quality and compatibility, as these can vary widely between suppliers. Conducting thorough due diligence and sourcing from reputable providers is essential.

Why Consider Specialty Parts Suppliers?

Specialty parts suppliers cater to niche markets, focusing on specific aircraft types or unique requirements, such as vintage aircraft restoration. These suppliers often provide custom solutions that are not available through larger distributors. Buyers in this segment should consider the specialized knowledge and product offerings that these suppliers bring. However, the limited availability of parts and potentially longer sourcing times can pose challenges, making it important for buyers to plan ahead.

What Should Buyers Know About Avionics and Electronics Suppliers?

Avionics and electronics suppliers are critical for enhancing aircraft safety and functionality. They provide advanced electronic systems, including navigation, communication, and monitoring equipment. B2B buyers looking to upgrade or retrofit aircraft will find this type of supplier invaluable. However, the complexity of installation and the rapid pace of technological advancement can lead to obsolescence, requiring buyers to stay informed about the latest developments in the field.

How Do Aircraft Parts Distributors Serve the Market?

Aircraft parts distributors serve as a centralized resource for a wide range of components from various manufacturers. They are particularly beneficial for general aviation and small aircraft operators who need quick access to diverse parts. While these distributors can simplify the purchasing process, buyers should be aware that they may lack the specialized knowledge required for specific parts, which can lead to challenges in sourcing the correct components. Establishing a good relationship with distributors can help mitigate these risks.

Key Industrial Applications of aircraft parts company

| Industry/Sector | Specific Application of aircraft parts company | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| General Aviation | Supply of airframe and engine parts for private aircraft | Ensures safety and compliance with aviation standards | Quality certifications, lead times, and after-sales support |

| Commercial Aviation | Parts for fleet maintenance and upgrades | Reduces downtime and enhances operational efficiency | Bulk purchasing options, warranty terms, and delivery reliability |

| Military Aviation | Specialized components for defense aircraft | Meets stringent military specifications and durability | Compliance with military standards, sourcing from certified suppliers |

| MRO (Maintenance, Repair, Overhaul) | Replacement parts for aircraft servicing | Extends aircraft lifespan and improves reliability | Availability of OEM parts, pricing competitiveness, and technical support |

| Aviation Training Schools | Training equipment and components for educational programs | Enhances training quality and safety for students | Compatibility with training aircraft, cost-effectiveness, and supply chain efficiency |

How Can Aircraft Parts Companies Support General Aviation Needs?

In the general aviation sector, aircraft parts companies play a crucial role by supplying airframe and engine parts necessary for the maintenance and operation of private aircraft. These companies ensure that parts meet rigorous safety and quality standards, which is vital for compliance with aviation regulations. Buyers from regions like Africa and South America should prioritize suppliers that offer certified parts and exceptional after-sales support to ensure seamless integration and operational safety.

What Are the Benefits of Aircraft Parts in Commercial Aviation?

For commercial aviation, aircraft parts companies provide essential components for fleet maintenance and upgrades, which are critical to minimizing aircraft downtime. Efficient supply chains and reliable delivery schedules enable airlines to maintain operational efficiency and comply with rigorous safety regulations. International buyers, particularly in the Middle East and Europe, should consider suppliers that offer bulk purchasing options and warranties to optimize cost management and operational reliability.

How Do Aircraft Parts Enhance Military Aviation Operations?

In military aviation, the need for specialized components that meet stringent specifications is paramount. Aircraft parts companies supply these critical parts, ensuring that defense aircraft are equipped for demanding operational environments. Buyers in this sector must prioritize suppliers with a proven track record of compliance with military standards and the ability to provide robust technical support, ensuring mission readiness in all circumstances.

Why Is MRO Vital for Aircraft Longevity?

Maintenance, Repair, and Overhaul (MRO) operations rely heavily on aircraft parts companies for replacement parts that extend the lifespan of aircraft. These parts are essential for routine maintenance and unexpected repairs, significantly enhancing the reliability of the aircraft. Buyers should focus on sourcing OEM parts to ensure compatibility and performance, while also considering the pricing competitiveness and technical support offered by suppliers, particularly in developing regions.

How Do Aviation Training Schools Benefit from Aircraft Parts?

Aviation training schools depend on aircraft parts companies to provide training equipment and components that are compatible with their training aircraft. This ensures that students receive high-quality education in a safe environment. Buyers in this sector should look for suppliers that offer cost-effective solutions while ensuring compatibility with various aircraft models, thereby enhancing the overall training experience and safety for future pilots.

3 Common User Pain Points for ‘aircraft parts company’ & Their Solutions

Scenario 1: Ensuring Timely Deliveries for Critical Aircraft Parts

The Problem: B2B buyers in the aviation industry often face significant challenges with timely deliveries of critical aircraft parts. Delays can stem from various factors, including supplier inefficiencies, customs clearance issues, and logistical challenges. For companies operating in regions like Africa or South America, where infrastructure may not be as robust, these delays can lead to grounded aircraft, lost revenue, and potential safety concerns. The pressure to keep aircraft operational while navigating these complexities can be overwhelming.

The Solution: To mitigate delivery delays, buyers should establish relationships with multiple suppliers and use a centralized procurement platform that allows for real-time tracking of orders. When sourcing from an aircraft parts company, it’s crucial to communicate specific delivery timelines and requirements upfront. Additionally, leveraging logistics partners experienced in international shipping can facilitate smoother customs processes. Implementing a just-in-time inventory strategy can also help maintain adequate stock levels without overcommitting resources. By proactively managing supplier relationships and logistics, B2B buyers can ensure that they receive critical parts on time, minimizing downtime.

Scenario 2: Navigating Regulatory Compliance in Aircraft Parts Procurement

The Problem: Regulatory compliance is a significant concern for B2B buyers in the aviation sector, especially when sourcing aircraft parts from different countries. Each region has its own set of regulations, which can affect the certification and quality of parts. For instance, buyers in the Middle East may struggle with ensuring that parts meet both local and international aviation standards, leading to potential legal issues and increased costs if non-compliant parts are procured.

The Solution: B2B buyers should prioritize sourcing from aircraft parts companies that offer comprehensive documentation and support for regulatory compliance. It’s essential to request detailed certificates of authenticity and compliance with the relevant aviation authorities. Conducting due diligence on suppliers to verify their adherence to quality standards, such as ISO certifications, can provide additional assurance. Furthermore, engaging with legal experts in aviation regulations can guide buyers through the compliance landscape, ensuring that all parts meet the necessary requirements before procurement. By understanding and addressing regulatory challenges upfront, buyers can streamline their purchasing processes and avoid costly compliance issues.

Scenario 3: Managing Quality Assurance for Aircraft Parts

The Problem: Quality assurance is a critical pain point for B2B buyers in the aircraft parts industry. The aviation sector requires parts that meet stringent safety and performance standards. However, with the rise of counterfeit parts and subpar suppliers, buyers often find themselves uncertain about the quality of the products they are purchasing. This situation is particularly concerning for buyers in Europe, where stringent safety regulations necessitate an unwavering commitment to quality.

The Solution: To ensure high-quality aircraft parts, buyers should adopt a thorough vetting process for suppliers. This includes requesting samples, reviewing past performance records, and checking for industry certifications. Establishing a long-term partnership with reputable aircraft parts companies can also lead to better quality control, as trusted suppliers are more likely to provide consistent, high-quality products. Additionally, implementing a robust inspection protocol upon receiving parts can help identify any discrepancies before they impact operations. By taking a proactive approach to quality assurance, B2B buyers can safeguard their operations and ensure that they are using only the best aircraft parts in their fleet.

Strategic Material Selection Guide for aircraft parts company

What Are the Key Properties of Aluminum in Aircraft Parts?

Aluminum is a predominant material in aircraft manufacturing due to its excellent strength-to-weight ratio and corrosion resistance. It typically withstands temperatures up to 150°C (302°F) and pressures relevant to aviation applications. The material is lightweight, making it ideal for airframe components, and its natural resistance to oxidation enhances durability.

Pros and Cons of Aluminum

The primary advantage of aluminum is its lightweight nature, which contributes to fuel efficiency and overall aircraft performance. Additionally, it is relatively cost-effective and widely available, making it a popular choice among manufacturers. However, aluminum can be less durable than some alternatives, particularly in high-stress environments, and may require protective coatings to prevent corrosion in harsh conditions.

Impact on Application

Aluminum is compatible with various media, including aviation fuels and lubricants, making it suitable for fuel tanks and structural components. However, its thermal expansion properties must be considered during design to prevent structural integrity issues under varying temperature conditions.

Considerations for International Buyers

For buyers in regions such as Africa, South America, the Middle East, and Europe, compliance with international standards like ASTM and EN is crucial. Additionally, local regulations regarding material sourcing and environmental impact may influence purchasing decisions.

How Does Steel Compare as a Material for Aircraft Parts?

Steel, particularly stainless steel, is another common material used in aircraft parts due to its exceptional strength and durability. It can handle high temperatures (up to 300°C or 572°F) and pressures, making it suitable for critical components like landing gear and engine mounts.

Pros and Cons of Steel

The key advantage of steel is its high tensile strength, which allows for the construction of robust components that can withstand significant stress. However, it is heavier than aluminum, which can negatively impact fuel efficiency. Additionally, while stainless steel offers good corrosion resistance, it may still require additional coatings in extreme environments.

Impact on Application

Steel’s compatibility with various media is generally favorable, but its weight can be a limiting factor in applications where weight savings are paramount. It is often used in applications where structural integrity is more critical than weight, such as in high-stress areas.

Considerations for International Buyers

International buyers should be aware of the different grades of steel and their compliance with standards like ASTM AISI. Understanding local sourcing regulations and the availability of specific steel grades can also impact procurement strategies.

What Are the Benefits of Composite Materials in Aircraft Parts?

Composite materials, particularly carbon fiber reinforced polymers (CFRP), are increasingly popular in aircraft manufacturing due to their high strength-to-weight ratio and excellent fatigue resistance. They can withstand temperatures up to 120°C (248°F) and are often used in fuselage and wing structures.

Pros and Cons of Composites

The primary advantage of composites is their lightweight nature, which significantly improves fuel efficiency. They also offer excellent resistance to corrosion and fatigue. However, composites can be more expensive to manufacture and repair, and their production processes can be complex.

Impact on Application

Composites are compatible with a variety of media, including fuels and oils, making them suitable for various aircraft components. However, their thermal properties require careful consideration in design to prevent issues related to thermal expansion.

Considerations for International Buyers

Buyers should be aware of the certifications required for composite materials, such as those from the FAA or EASA. Understanding the local market for composite materials and the availability of skilled labor for repair and maintenance is also essential.

How Does Titanium Fit into the Aircraft Parts Material Selection?

Titanium is known for its high strength, low weight, and exceptional corrosion resistance, making it ideal for high-performance applications in aerospace, such as engine components and structural parts. It can withstand temperatures up to 600°C (1112°F) and is highly resistant to fatigue.

Pros and Cons of Titanium

The key advantage of titanium is its strength-to-weight ratio, which allows for lighter components without sacrificing durability. However, titanium is significantly more expensive than aluminum and steel, and its machining can be complex and costly.

Impact on Application

Titanium’s compatibility with various media, including aggressive chemicals and extreme temperatures, makes it suitable for high-stress applications. However, its cost may limit its use to critical components where performance is paramount.

Considerations for International Buyers

International buyers must navigate complex sourcing and compliance issues, particularly regarding titanium grades and standards like ASTM B348. Additionally, understanding the supply chain dynamics for titanium, which can be affected by geopolitical factors, is essential for procurement strategies.

| Material | Typical Use Case for aircraft parts company | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Airframe components, fuel tanks | Lightweight, cost-effective | Less durable under high stress | Medium |

| Steel | Landing gear, engine mounts | High tensile strength | Heavier, may require coatings | Medium |

| Composites | Fuselage, wing structures | Excellent strength-to-weight ratio | Expensive, complex production | High |

| Titanium | Engine components, structural parts | Exceptional strength and corrosion resistance | High cost, complex machining | High |

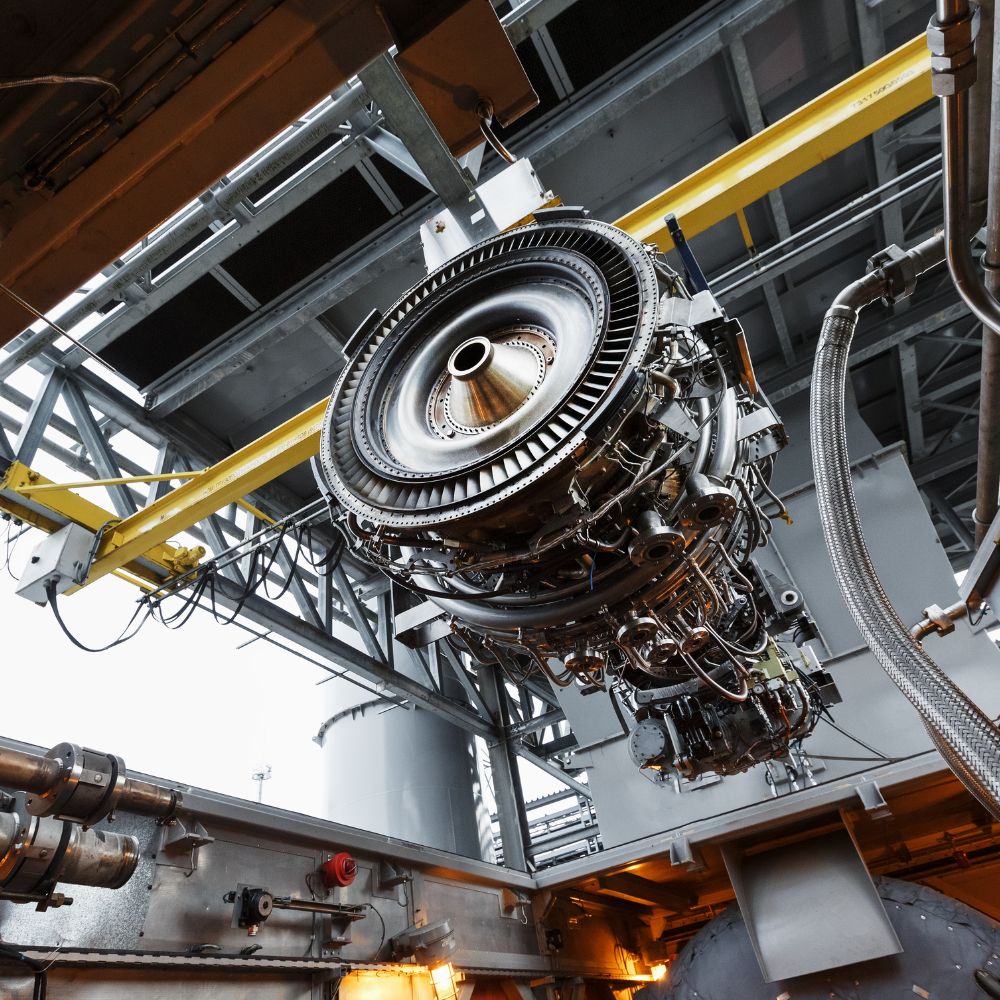

In-depth Look: Manufacturing Processes and Quality Assurance for aircraft parts company

What Are the Main Stages of Manufacturing Processes for Aircraft Parts?

The manufacturing processes for aircraft parts encompass several critical stages that ensure precision, reliability, and compliance with industry standards. The typical workflow includes:

-

Material Preparation: This initial stage involves selecting high-quality raw materials, often including aluminum alloys, titanium, and composite materials. These materials must undergo rigorous testing to confirm their suitability for aerospace applications. Suppliers often utilize advanced techniques such as metallurgical analysis and chemical composition testing to verify material integrity.

-

Forming: During the forming stage, raw materials are shaped into the required parts using techniques such as forging, casting, and machining. Each method has its advantages; for instance, forging provides enhanced strength, while casting allows for complex geometries. CNC (Computer Numerical Control) machining is widely used to achieve the precision required for aircraft components, as it enables high tolerances and repeatability.

-

Assembly: After forming, parts are assembled into larger components or systems. This stage may involve welding, riveting, or adhesive bonding, depending on the specific requirements of the part. It is crucial that assembly is carried out in controlled environments to prevent contamination and ensure optimal fit and function.

-

Finishing: The final stage of manufacturing includes surface treatments, coatings, and inspections. Processes such as anodizing, painting, and passivation enhance corrosion resistance and improve aesthetic appeal. This stage may also involve non-destructive testing methods like ultrasonic or X-ray inspections to identify any internal flaws without damaging the parts.

How Is Quality Assurance Implemented in Aircraft Parts Manufacturing?

Quality assurance (QA) is an essential aspect of aircraft parts manufacturing, ensuring that products meet stringent safety and performance standards. The following elements are key in establishing a robust QA framework:

-

International Standards Compliance: Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with industry-specific standards, such as AS9100 for aerospace quality management, is also critical. These certifications help establish a culture of continuous improvement and customer satisfaction.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. They typically include:

– Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Inspections conducted during various manufacturing stages help identify defects early, minimizing waste and rework.

– Final Quality Control (FQC): A comprehensive assessment is performed before products are shipped, ensuring they meet all design and performance criteria. -

Testing Methods: Various testing methods are employed to validate the performance and safety of aircraft parts. Common techniques include:

– Static Load Testing: Ensures that parts can withstand operational forces.

– Fatigue Testing: Assesses durability over prolonged use.

– Environmental Testing: Simulates conditions such as extreme temperatures and humidity to evaluate performance under stress.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct due diligence to ensure that their suppliers maintain high-quality standards. Here are actionable steps to verify supplier QC processes:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control systems, and adherence to standards. This can provide insights into a supplier’s commitment to quality and operational excellence.

-

Quality Reports and Certifications: Requesting detailed quality reports, including inspection and testing results, can help buyers understand a supplier’s QC practices. Certifications from recognized bodies (e.g., ISO, AS9100) should also be verified to ensure compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies can conduct random inspections and audits, offering additional assurance regarding product quality.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in international trade is crucial:

-

Regulatory Compliance: Different countries have varying regulations and standards for aircraft parts. Buyers must ensure that suppliers comply with local and international regulations, such as CE marking in Europe or FAA regulations in the United States.

-

Cultural Considerations: Understanding cultural differences in business practices and quality expectations can facilitate smoother negotiations and collaborations. Building strong relationships with suppliers can enhance communication regarding quality assurance.

-

Logistics and Supply Chain Management: The transportation of aircraft parts often involves complex logistics, which can impact quality. Buyers should assess the entire supply chain, from manufacturing to delivery, to ensure that quality is maintained throughout the process.

Conclusion

The manufacturing processes and quality assurance practices for aircraft parts are intricate and highly regulated. For international B2B buyers, particularly those from diverse markets, comprehending these processes and implementing robust verification methods is essential for ensuring that they source high-quality, reliable components. By focusing on quality control, compliance with international standards, and effective supplier management, buyers can mitigate risks and enhance operational efficiency in their aviation-related ventures.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aircraft parts company’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure parts from an aircraft parts company. It outlines essential steps to ensure that you select reliable suppliers, obtain quality products, and maintain compliance with industry standards. Following this guide will help streamline your procurement process, minimize risks, and enhance operational efficiency.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the aircraft parts you need. This includes specifications such as part numbers, materials, and compliance with aviation regulations.

– Why it’s important: Accurate specifications ensure that you receive the right parts that meet safety and performance standards.

– What to look for: Consult with your engineering team or relevant stakeholders to gather precise technical details.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in the aircraft parts you require. Utilize online directories, industry forums, and trade shows to gather information.

– Why it’s important: A wide pool of suppliers increases your chances of finding those with the best offerings.

– What to look for: Focus on suppliers with a strong reputation in the industry, positive customer reviews, and a robust product catalog.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with aviation authorities such as the FAA or EASA. Look for ISO certifications and other quality assurance credentials.

– Why it’s important: Certifications demonstrate that a supplier adheres to industry standards and practices, which is crucial for safety.

– What to look for: Request copies of certifications and check if they are up to date.

Step 4: Assess Quality Control Processes

Investigate the quality control measures that potential suppliers have in place. This includes their inspection processes, testing protocols, and warranty policies.

– Why it’s important: Ensuring the quality of aircraft parts is non-negotiable; defective parts can lead to safety hazards and costly downtimes.

– What to look for: Inquire about the supplier’s quality assurance documentation and any third-party audits they undergo.

Step 5: Request Samples and Conduct Performance Tests

Before finalizing your order, request samples of the aircraft parts you intend to purchase. Conduct performance tests to ensure they meet your specifications and quality standards.

– Why it’s important: Testing samples allows you to verify that the parts will perform as expected in real-world conditions.

– What to look for: Pay attention to the material quality, fit, and functionality during testing.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate the terms of the purchase, including pricing, delivery schedules, and payment terms. Ensure that all agreements are documented.

– Why it’s important: Clear terms help avoid misunderstandings and ensure both parties are aligned on expectations.

– What to look for: Look for flexibility in payment options and favorable delivery timelines.

Step 7: Establish a Long-Term Relationship

After the initial purchase, focus on building a long-term relationship with your supplier. Regular communication and feedback can enhance collaboration and lead to better service.

– Why it’s important: A strong relationship can lead to improved pricing, priority service, and tailored solutions in the future.

– What to look for: Engage in regular reviews of performance and address any issues promptly to foster trust and reliability.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing aircraft parts and ensure a successful procurement process.

Comprehensive Cost and Pricing Analysis for aircraft parts company Sourcing

What are the Key Cost Components in Aircraft Parts Sourcing?

When sourcing aircraft parts, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

-

Materials: The quality and type of materials directly impact pricing. High-grade materials used in manufacturing aircraft parts, such as aluminum alloys or composite materials, are generally more expensive. Buyers should consider not only the upfront cost but also the long-term durability and safety implications of these materials.

-

Labor: Labor costs can vary significantly based on geographic location and the complexity of the manufacturing process. Skilled labor in regions with high living costs may lead to increased prices. It’s essential for buyers to assess the labor market conditions in the supplier’s location.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Suppliers with efficient operations may pass on savings to buyers, making it worthwhile to evaluate their operational practices.

-

Tooling: Initial tooling costs can be significant, especially for custom parts. Buyers should inquire about the tooling required for their specific needs and whether these costs are included in the quoted price.

-

Quality Control (QC): Rigorous QC processes ensure that parts meet safety and regulatory standards, but they also add to the overall cost. Buyers should prioritize suppliers with robust QC systems, as this can prevent costly issues down the line.

-

Logistics: Shipping and handling costs can fluctuate based on distance, weight, and shipping methods. Buyers should consider the implications of logistics on their total cost of ownership.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the industry standards for margins can aid in evaluating whether a quote is competitive.

How Do Price Influencers Affect Aircraft Parts Costs?

Several factors can influence the pricing of aircraft parts:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Buyers should negotiate MOQs to achieve better pricing while ensuring their inventory needs are met.

-

Specifications and Customization: Custom parts tailored to specific requirements can significantly increase costs. Buyers must balance the need for customization with budget constraints.

-

Materials and Quality Certifications: Parts with specific certifications (e.g., FAA-approved) or made from premium materials will command higher prices. Buyers should evaluate the necessity of these certifications in relation to their operational needs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their proven track record, but this can often translate to better service and quality assurance.

-

Incoterms: The terms of shipping and responsibility (Incoterms) can affect overall costs. Buyers should clarify these terms to avoid unexpected expenses during the shipping process.

What Tips Should International B2B Buyers Consider for Cost-Efficiency?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of aircraft parts pricing is essential:

-

Negotiation: Always engage in negotiations to secure the best possible price. Be prepared to discuss volume discounts and long-term agreements that may offer better terms.

-

Total Cost of Ownership: Evaluate the complete lifecycle cost of parts rather than just the purchase price. Consider maintenance, downtime, and potential replacements when assessing value.

-

Pricing Nuances: Be aware of currency fluctuations, tariffs, and import duties that could affect the total cost. This is especially important when sourcing from suppliers in different countries.

-

Research Local Regulations: Familiarize yourself with local aviation regulations that may impact part specifications and certifications. Compliance can save significant costs related to delays or non-compliance penalties.

-

Establish Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Long-term partnerships often yield more favorable terms.

Disclaimer

Prices in the aircraft parts industry can vary widely based on numerous factors, including market demand, supplier conditions, and geopolitical influences. The information provided is indicative and should be verified with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing aircraft parts company With Other Solutions

Understanding Alternatives in Aircraft Parts Supply

When it comes to sourcing aircraft parts, B2B buyers have a variety of options to consider beyond traditional aircraft parts companies. The choice of supplier can significantly impact operational efficiency, cost-effectiveness, and overall performance. This section evaluates ‘Aircraft Parts Company’ against two viable alternatives: ‘Aircraft Spruce & Specialty Co.’ and ‘Air Power Inc.’ Each alternative presents unique advantages and challenges that can influence a buyer’s decision-making process.

Comparison Table

| Comparison Aspect | Aircraft Parts Company | Aircraft Spruce & Specialty Co. | Air Power Inc. |

|---|---|---|---|

| Performance | High-quality OEM parts | Extensive product range | Specialized engine parts |

| Cost | Moderate pricing | Competitive pricing | Varies by part, often low |

| Ease of Implementation | User-friendly online platform | Simple navigation and ordering | Requires registration for orders |

| Maintenance | Reliable support and service | Comprehensive support resources | Limited customer support |

| Best Use Case | General aviation components | Custom builds and general parts | Engine-specific components |

In-Depth Analysis of Alternatives

Aircraft Spruce & Specialty Co.

Aircraft Spruce offers a vast selection of aircraft parts, materials, and supplies, catering to both builders and owners. Its extensive inventory is beneficial for those engaged in custom builds or needing specific components. The competitive pricing and user-friendly website enhance the buying experience. However, the broad range may lead to confusion, and specialized support can sometimes be lacking, which might deter buyers seeking tailored advice.

Air Power Inc.

Air Power specializes in engine parts, providing a targeted selection for buyers focused on aircraft engines. Its cost-effective pricing and straightforward ordering process make it an attractive option for those needing specific components without the frills. However, this narrow focus may not suit buyers looking for a comprehensive array of parts across different aircraft systems. Additionally, customer support may be limited, which can be a drawback for businesses that require ongoing assistance or guidance.

Conclusion: How to Choose the Right Aircraft Parts Supplier

Selecting the right aircraft parts supplier hinges on understanding your specific needs and operational requirements. For general aviation parts and a reliable supplier, ‘Aircraft Parts Company’ stands out. However, if your focus leans toward extensive customization or engine-specific components, ‘Aircraft Spruce & Specialty Co.’ or ‘Air Power Inc.’ may be more suitable. Each alternative offers distinct advantages; thus, evaluating performance, cost, ease of implementation, and maintenance will help B2B buyers make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for aircraft parts company

Understanding the essential technical properties and trade terminology is crucial for B2B buyers in the aircraft parts industry. This knowledge not only facilitates informed purchasing decisions but also fosters effective communication with suppliers. Below are key specifications and terminology that every buyer should be familiar with.

What Are the Key Technical Properties of Aircraft Parts?

-

Material Grade

Material grade refers to the classification of the materials used in manufacturing aircraft parts, such as aluminum, titanium, or composite materials. Each material grade has specific properties like strength, weight, and corrosion resistance. Understanding material grades is vital for buyers as it impacts the durability and performance of aircraft parts, ensuring safety and compliance with aviation standards. -

Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension of a part. In aviation, precise tolerances are critical to ensure that parts fit and function correctly. For B2B buyers, knowing the tolerance levels required for specific components helps in selecting the right suppliers who can meet these specifications, thus minimizing the risk of operational failures. -

Surface Finish

Surface finish describes the texture and quality of a part’s surface. This property can influence aerodynamics, friction, and wear resistance. Buyers must consider surface finish when sourcing parts, as it can affect maintenance cycles and overall performance. Different applications may require specific finishes, such as anodizing or polishing, to enhance durability and appearance. -

Load Capacity

Load capacity refers to the maximum load a component can safely support. This property is essential for parts like landing gear or structural components. B2B buyers should ensure that the load capacities of the parts they procure meet or exceed the requirements of their aircraft models to guarantee safety and compliance with aviation regulations. -

Certification Standards

Certification standards, such as FAA (Federal Aviation Administration) or EASA (European Union Aviation Safety Agency) approvals, are vital for aircraft parts. These standards ensure that parts meet safety and quality regulations. Buyers should prioritize suppliers that can provide certified parts, as this minimizes risks associated with non-compliance and enhances the reliability of their operations.

What Are Common Trade Terms in the Aircraft Parts Industry?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the original manufacturing of aircraft. Buying OEM parts ensures compatibility and adherence to quality standards. For B2B buyers, sourcing OEM parts is often a priority to maintain the integrity and performance of their aircraft. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it affects inventory management and costs. Higher MOQs may lead to excess inventory, while lower MOQs can increase per-unit costs. Buyers should negotiate MOQs that align with their operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific parts or services. It is a vital tool for procurement, allowing buyers to compare quotes and evaluate suppliers. Crafting a precise RFQ helps ensure that buyers receive accurate and competitive pricing, which is essential for budgeting and cost control. -

Incoterms (International Commercial Terms)

Incoterms are a series of international trade terms that define the responsibilities of buyers and sellers in shipping and logistics. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and delivery responsibilities, facilitating smoother transactions and reducing potential disputes. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the parts. Understanding lead times is critical for planning maintenance schedules and ensuring that aircraft are operational when needed. Buyers should inquire about lead times when sourcing parts to avoid unexpected delays.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their procurement processes, ensure compliance, and ultimately contribute to safer and more efficient aviation operations.

Navigating Market Dynamics and Sourcing Trends in the aircraft parts company Sector

Global dynamics in the aircraft parts sector are shaped by various interconnected factors that influence international B2B sourcing and purchasing decisions. As the aviation industry rebounds from recent disruptions, the demand for aircraft parts is escalating, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key drivers include rising air travel demand, increasing fleet sizes, and the need for modernized aircraft to comply with stringent safety regulations.

Emerging technologies are revolutionizing the sourcing landscape, with digital platforms facilitating seamless procurement processes. B2B buyers are increasingly turning to online marketplaces that offer extensive catalogs of parts, competitive pricing, and streamlined logistics. Furthermore, data analytics and AI are being leveraged to optimize inventory management and predict demand, allowing buyers to make informed decisions.

Sourcing trends also reflect a growing preference for suppliers who can demonstrate agility and resilience in their supply chains. The COVID-19 pandemic highlighted vulnerabilities in global logistics, prompting buyers to seek localized suppliers and diversify their sourcing strategies to mitigate risks associated with single-source dependencies.

How Are Sustainability and Ethical Sourcing Shaping the Aircraft Parts Industry?

The environmental impact of the aviation industry is under scrutiny, prompting B2B buyers to prioritize sustainability in their sourcing decisions. The push for eco-friendly practices is driving demand for parts made from sustainable materials and produced through environmentally responsible processes. Buyers are increasingly seeking suppliers who adhere to ‘green’ certifications, such as ISO 14001, which denotes effective environmental management systems.

Ethical sourcing is equally vital, with a strong emphasis on transparency and social responsibility throughout the supply chain. Buyers are encouraged to evaluate suppliers based on their labor practices, community engagement, and adherence to ethical standards. By aligning procurement strategies with sustainability goals, international B2B buyers can not only reduce their environmental footprint but also enhance their brand reputation in an increasingly eco-conscious market.

What Is the Historical Context of the Aircraft Parts Industry and Its Evolution?

The aircraft parts industry has evolved significantly over the decades, marked by advancements in technology and changing market demands. Initially dominated by a few key players, the sector has seen a diversification of suppliers and the emergence of specialized companies catering to specific needs, such as general aviation and commercial aircraft.

The introduction of advanced manufacturing techniques, such as additive manufacturing and composite materials, has transformed the production landscape, enabling the creation of lighter, stronger parts that enhance aircraft performance and fuel efficiency. As the industry continues to innovate, international B2B buyers must remain adaptable, keeping abreast of technological advancements and evolving regulatory frameworks to ensure they are sourcing the best products available.

In conclusion, the aircraft parts sector is characterized by dynamic market conditions and a growing emphasis on sustainability and ethical sourcing. By understanding these trends, international B2B buyers can navigate the complexities of the market more effectively and make informed decisions that align with their operational goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of aircraft parts company

-

How do I ensure the quality of aircraft parts from international suppliers?

To guarantee quality, start by thoroughly vetting suppliers. Request certifications such as FAA approvals, ISO standards, or equivalent international certifications. Conduct due diligence through reviews, references, and previous client testimonials. If possible, arrange for a factory visit or a third-party inspection to verify the manufacturing processes and quality control measures in place. Finally, ensure that all parts come with a warranty and return policy to safeguard your investment. -

What are the key factors to consider when choosing an aircraft parts supplier?

Key factors include the supplier’s reputation, range of products, compliance with international regulations, and customer service responsiveness. Evaluate their experience in your specific aircraft model or type, as expertise can significantly influence reliability. Additionally, assess their logistics capabilities, including shipping times and costs, especially for international transactions, and inquire about their ability to provide technical support post-purchase. -

What is the typical minimum order quantity (MOQ) for aircraft parts?

MOQs can vary widely depending on the supplier and the type of parts being ordered. For common items, MOQs may be low, while specialized or custom parts might require larger orders to justify production costs. It’s important to discuss your needs directly with suppliers to negotiate terms that work for your business, especially if you are just starting or have limited capital. -

What payment terms should I expect when sourcing aircraft parts internationally?

Payment terms can vary based on supplier policies and your business relationship. Common arrangements include upfront payments, letters of credit, or net 30/60/90 terms. It’s advisable to negotiate terms that align with your cash flow while ensuring that the supplier feels secure in the transaction. Always confirm that payment methods are secure and compliant with international trade regulations. -

How can I customize aircraft parts to meet specific requirements?

Many suppliers offer customization options for aircraft parts. Begin by discussing your specific needs with the supplier’s engineering or sales team. Provide detailed specifications, including dimensions, materials, and any certifications required. Depending on the complexity of the customization, be prepared for longer lead times and potentially higher costs. Ensure that any custom work is documented in a contract to avoid misunderstandings. -

What are the logistics considerations for importing aircraft parts?

Logistics play a crucial role in international sourcing. Consider shipping methods (air freight vs. sea freight), transit times, and customs clearance processes in your destination country. Work with suppliers who have experience in international shipping and can provide accurate shipping estimates. Additionally, familiarize yourself with import regulations and tariffs to avoid unexpected costs or delays. -

How do I handle disputes with international suppliers?

To manage disputes effectively, ensure clear communication and documentation throughout the procurement process. If issues arise, first attempt to resolve them directly through dialogue. If necessary, refer to the terms outlined in your contract, which should include dispute resolution procedures. It may also be beneficial to involve a third-party mediator or legal advisor familiar with international trade law to facilitate a resolution. -

What certifications should aircraft parts have for international compliance?

International compliance often requires specific certifications, which can vary by region. Common certifications include FAA (Federal Aviation Administration) approval in the U.S., EASA (European Union Aviation Safety Agency) certification in Europe, and equivalent standards in other regions. Always request documentation proving compliance and ensure that the parts meet the regulations of your country to avoid legal and operational issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Aircraft Parts Company Manufacturers & Suppliers List

1. AirPartsCo – Aviation Parts & Accessories

Domain: airpartsco.com

Registered: 2002 (23 years)

Introduction: Airframe and Engine Parts, Tools, Equipment and Accessories for General Aviation.

2. Aircraft Spruce – Key Product Categories

Domain: aircraftspruce.com

Registered: 1999 (26 years)

Introduction: Key product categories include: Airframe Parts, Avionics, Books & Videos, Composite Materials, Covering Supplies, Electrical, Engine Parts, Hardware, Instruments, Kits & Plans, Landing Gear, Metals & Plastics, Pilot Supplies, Tools, and Wood Products. Featured products include: Bose A30 Aviation Headset, David Clark DC JET-X ANR Headset, Concorde Sealed Batteries, BA1500 Battery Analyzer, and vari…

3. Univair – Vintage Aircraft Parts

Domain: univair.com

Registered: 1996 (29 years)

Introduction: Vintage aircraft parts for sale including accessories, supplies, engine parts, electrical components, and various parts for specific aircraft brands such as Cessna, Piper, Aeronca, and more. Categories include cockpit and interior, control systems, cowling, fuel systems, landing gear, propellers, and manuals. Specific items listed include adhesives, cleaners, emergency locator transmitter parts, a…

4. AirPower Inc – Aircraft Parts & Engines

Domain: airpowerinc.com

Registered: 2001 (24 years)

Introduction: Aircraft Parts Supplier, Engines, Continental Engines (O-200 Series, IO-360 Series, IO-470 Series, 500 Series), Lycoming Engines (235 Series, 320 Series, 360 Series, 390 Series, 540 Series, 580 Series, 720 Series), Engine Parts, Engine Preheat Kits, MAX Spark Ignition Kits, Cessna Parts (Cessna 172, TTx, Columbia 400, Columbia 350), Airframe Parts, Avionics (ADS-B Antennas, Audio Panels, EFIS, Eng…

5. Aviation Parts Inc – Quality Aircraft Components

Domain: aviationpartsinc.com

Registered: 2000 (25 years)

Introduction: This company, Aviation Parts Inc – Quality Aircraft Components, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Aero-Mach Wilco – Aerospace Parts Distributor

Domain: wilcoaircraftparts.com

Registered: 2002 (23 years)

Introduction: Aero-Mach Wilco, LLC. is an aerospace parts distributor offering a wide range of products including: Alloy Steel (AMS6350, AMS6351, AMS6345) in various conditions and thicknesses; Cleaning Products; Dry Air Pumps; Electrical components such as Concorde Batteries (12V and 24V), Battery Maintenance, Alternator Controls (14V and 28V), Contactors & Solenoids (14V and 28V), De-Ice Timers, and Voltage R…

7. Camar Aircraft Parts – Aftermarket Military Aircraft Parts

Domain: camarac.com

Registered: 2003 (22 years)

Introduction: Camar Aircraft Parts Company provides first generation aftermarket military aircraft parts and export support services. They support military aircraft from manufacturers such as Sikorsky, Cessna, De Havilland, Boeing, North American, Pilatus, McDonnell Douglas, Lockheed Martin, and Northrup Grumman. The company is headquartered in Southern California and operates a 25,000 SF state-of-the-art wareh…

Strategic Sourcing Conclusion and Outlook for aircraft parts company

In today’s competitive landscape, strategic sourcing is paramount for aircraft parts companies aiming to optimize their supply chains and enhance operational efficiency. By leveraging a network of reliable suppliers, businesses can ensure timely delivery of high-quality parts, which is critical in maintaining aircraft safety and performance. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize establishing relationships with suppliers who demonstrate a commitment to excellence and accuracy, as seen in established companies with decades of industry experience.

Furthermore, understanding the unique needs of your market, including compliance with regional regulations and specific aviation standards, can provide a significant competitive edge. As international trade continues to evolve, embracing digital tools for procurement will streamline processes and foster transparency.

Looking ahead, the demand for aircraft parts will continue to grow, driven by advancements in aviation technology and an expanding global fleet. Now is the time for international buyers to take action—evaluate your sourcing strategies, engage with trusted suppliers, and position your business for future success in the aviation industry. Your proactive approach today will shape the efficiency and sustainability of your operations tomorrow.