Introduction: Navigating the Global Market for aiplane parts

Navigating the complex landscape of sourcing airplane parts can be a daunting challenge for international B2B buyers. With the increasing demand for reliable and efficient aircraft components across Africa, South America, the Middle East, and Europe, understanding the nuances of the global market becomes crucial. This guide serves as an essential resource, providing insights into various types of airplane parts, their applications, and the intricacies of supplier vetting processes.

From engine components and avionics to airframe parts and specialized tools, our comprehensive overview will equip you with the knowledge needed to make informed purchasing decisions. We delve into cost considerations, quality standards, and the importance of compliance with international regulations, ensuring you are well-prepared to navigate the competitive landscape.

Additionally, this guide highlights key factors that influence pricing and availability, enabling buyers to identify trustworthy suppliers and negotiate effectively. By empowering B2B buyers with actionable insights and strategic recommendations, we aim to enhance your procurement process, ultimately leading to improved operational efficiency and reduced downtime. Whether you’re based in Germany or Nigeria, this resource will support your quest for quality airplane parts that meet your specific needs and standards.

Understanding aiplane parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Airframe Parts | Structural components, including fuselage and wings | Aircraft manufacturing and maintenance | Pros: Essential for structural integrity; Cons: High costs and complex sourcing. |

| Avionics | Electronic systems for communication and navigation | Installation in new and refurbished aircraft | Pros: Enhances safety and efficiency; Cons: Rapid technological changes can lead to obsolescence. |

| Engine Parts | Components essential for aircraft propulsion | Engine overhauls and repairs | Pros: Critical for performance; Cons: Requires specialized knowledge for installation. |

| Landing Gear | Systems that support aircraft during takeoff and landing | Aircraft assembly and repair | Pros: Vital for safety; Cons: Heavy and may require extensive maintenance. |

| Composite Materials | Lightweight materials used in airframe and component design | Advanced aircraft manufacturing | Pros: Reduces weight and improves fuel efficiency; Cons: Can be expensive and require specialized handling. |

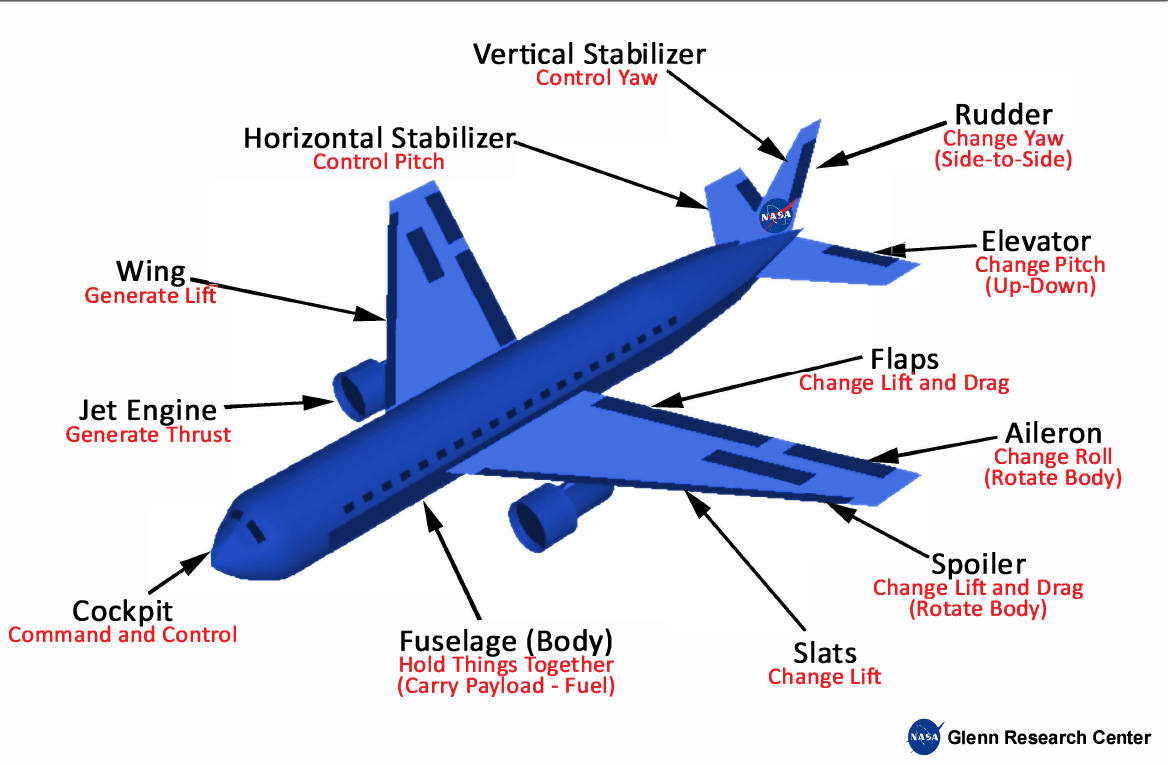

What Are the Key Characteristics of Airframe Parts?

Airframe parts form the backbone of any aircraft, encompassing the fuselage, wings, and tail sections. These components are typically made from metals or composite materials to ensure strength and durability. For B2B buyers, understanding the specific requirements for airframe parts is crucial, as they must meet stringent safety standards and regulations. Buyers should consider factors such as material specifications, manufacturing processes, and compatibility with existing aircraft models when sourcing these parts.

How Do Avionics Enhance Aircraft Functionality?

Avionics refers to the electronic systems that manage communication, navigation, and monitoring functions within an aircraft. This category includes instruments like GPS, radar, and autopilot systems. B2B buyers should prioritize avionics that comply with international aviation regulations and offer advanced features for enhanced safety and operational efficiency. Additionally, buyers must consider the lifecycle of avionics technology, as rapid advancements can quickly render older systems obsolete.

What Should Buyers Know About Engine Parts?

Engine parts are critical for the propulsion of aircraft and include components such as pistons, turbines, and fuel injectors. The performance and reliability of an aircraft heavily depend on the quality and condition of its engine parts. B2B buyers should focus on sourcing from reputable suppliers that offer OEM (Original Equipment Manufacturer) parts to ensure compatibility and performance. Furthermore, understanding the maintenance and overhaul cycles is essential for effective procurement.

Why Are Landing Gear Components Essential for Safety?

Landing gear systems are vital for the safe takeoff and landing of aircraft. They consist of wheels, struts, and shock absorbers designed to absorb the impact during landing. For B2B buyers, sourcing high-quality landing gear components is crucial, as failures can lead to catastrophic accidents. Buyers should assess the weight, durability, and maintenance requirements of landing gear systems and ensure they meet the specific aircraft design specifications.

How Do Composite Materials Impact Aircraft Design?

Composite materials, such as carbon fiber and fiberglass, are increasingly used in modern aircraft design due to their lightweight properties and high strength-to-weight ratios. These materials allow manufacturers to create more fuel-efficient aircraft and improve overall performance. B2B buyers should evaluate the specific applications of composite materials in their aircraft designs, considering factors like cost, manufacturing capabilities, and the need for specialized handling during installation and maintenance.

Key Industrial Applications of aiplane parts

| Industry/Sector | Specific Application of Airplane Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Commercial Aviation | Replacement parts for fleet maintenance | Ensures operational efficiency and reduces downtime | Compliance with international aviation regulations |

| General Aviation | Custom avionics installations | Enhances flight safety and navigation capabilities | Compatibility with existing aircraft systems |

| Aerospace Manufacturing | Supply of composite materials for aircraft construction | Lightweight and durable components improve performance | Certification and quality assurance of materials |

| MRO (Maintenance, Repair, Overhaul) | Engine part replacements and upgrades | Extends aircraft lifespan and improves reliability | Availability of OEM vs. aftermarket parts |

| Flight Training Organizations | Pilot training equipment and simulation devices | Provides realistic training environments for pilots | Sourcing from reputable suppliers for quality assurance |

How Are Airplane Parts Used in Commercial Aviation?

In the commercial aviation sector, airplane parts are crucial for maintaining fleet operations. Replacement parts for aircraft, such as landing gear and engine components, ensure that airlines can operate flights on schedule. This minimizes downtime and enhances customer satisfaction. International buyers, particularly from regions like Africa and South America, must consider compliance with aviation regulations and certifications when sourcing parts, as these factors can significantly impact operational legality and safety.

What Role Do Airplane Parts Play in General Aviation?

General aviation relies heavily on custom avionics installations that improve flight safety and navigation. Airplane parts such as advanced navigation systems and communication equipment are essential for enhancing pilot situational awareness. B2B buyers in this sector need to ensure that the avionics they purchase are compatible with their existing aircraft systems, which may require detailed specifications and testing to guarantee performance and reliability.

Why Are Composite Materials Important in Aerospace Manufacturing?

In aerospace manufacturing, the use of composite materials is increasingly prevalent due to their lightweight and durable characteristics. Airplane parts made from composites can significantly improve fuel efficiency and overall aircraft performance. For businesses in this sector, sourcing certified materials from reputable suppliers is vital to meet industry standards and ensure the integrity of the aircraft being built. International buyers should prioritize suppliers that provide comprehensive documentation and quality assurance processes.

How Do Airplane Parts Benefit MRO Operations?

Maintenance, Repair, and Overhaul (MRO) operations depend on the timely availability of engine parts and other critical components. Regular upgrades and replacements of airplane parts extend the lifespan of aircraft and enhance their reliability. For B2B buyers in MRO, the choice between OEM (Original Equipment Manufacturer) and aftermarket parts can influence both cost and quality. It is essential to evaluate the long-term benefits and warranties associated with each option, especially when operating in diverse regulatory environments.

What Equipment Do Flight Training Organizations Need?

Flight training organizations require specialized airplane parts, including pilot training equipment and simulation devices, to create realistic training environments. These components are essential for developing pilot skills and ensuring safety in real-world operations. B2B buyers in this industry should focus on sourcing high-quality training equipment from reputable suppliers to ensure that their training programs meet international standards and provide effective learning experiences for aspiring pilots.

3 Common User Pain Points for ‘aiplane parts’ & Their Solutions

Scenario 1: Navigating Complex Regulations for Aircraft Parts

The Problem:

International B2B buyers often face significant challenges in understanding and complying with the myriad of regulations governing the purchase and use of airplane parts. Different countries have varying standards set by aviation authorities, such as the FAA in the U.S. or EASA in Europe. These regulations can include certification requirements, safety standards, and documentation needed for importation. A buyer in Nigeria, for example, may struggle with ensuring that the parts sourced from Europe meet both local and international aviation safety standards, leading to potential delays and increased costs if non-compliance occurs.

The Solution:

To effectively navigate these regulatory landscapes, it is crucial for buyers to establish strong relationships with reputable suppliers who are well-versed in international regulations. Engage with suppliers that provide comprehensive documentation for each part, including certification and compliance information. Additionally, consider utilizing a compliance consultant who specializes in aviation regulations to ensure that all parts meet the required standards before purchasing. Regularly attending industry conferences and webinars can also keep buyers informed about changing regulations and best practices.

Scenario 2: Managing Lead Times and Supply Chain Disruptions

The Problem:

Supply chain disruptions have become increasingly common in the aviation industry, leading to extended lead times for essential airplane parts. A B2B buyer in South America might find that critical components are delayed due to shipping issues or supplier shortages, which can ground aircraft and lead to significant financial losses. The challenge is not just sourcing the parts but doing so in a timely manner to minimize operational downtime.

The Solution:

To mitigate lead time issues, buyers should adopt a proactive supply chain management strategy. This involves identifying multiple suppliers for critical parts to create a diversified supply base. Building strong relationships with these suppliers can facilitate priority processing during high-demand periods. Additionally, implementing inventory management software can help track usage rates and forecast demand, allowing businesses to order parts in advance and maintain a buffer stock. Utilizing local suppliers when possible can also reduce lead times significantly.

Scenario 3: Ensuring Quality and Compatibility of Aircraft Parts

The Problem:

Quality control is a significant concern for B2B buyers in the airplane parts market. The risk of receiving substandard or incompatible parts can lead to safety issues and operational inefficiencies. Buyers in regions like the Middle East may encounter counterfeit or unverified parts in the market, which could jeopardize aircraft safety and regulatory compliance. This challenge is particularly daunting when purchasing specialized components that require precise specifications.

The Solution:

To ensure quality and compatibility, buyers should prioritize sourcing parts from established manufacturers with a proven track record. Conduct thorough research on suppliers, including reading reviews and requesting references from other clients. Additionally, implementing a stringent quality assurance process that includes inspecting parts upon arrival and verifying them against specifications can help mitigate risks. Utilizing advanced technologies such as 3D scanning can assist in ensuring that parts fit and function correctly before installation. Establishing partnerships with certified distributors can also provide an added layer of assurance regarding the authenticity and quality of the parts sourced.

Strategic Material Selection Guide for aiplane parts

What are the Key Properties of Aluminum in Airplane Parts?

Aluminum is a widely used material in the aerospace industry due to its favorable properties. It boasts a high strength-to-weight ratio, making it ideal for components that require both lightness and durability. Aluminum also exhibits excellent corrosion resistance, particularly when treated with anodization, which enhances its protective qualities. Its thermal conductivity is another key property, allowing for efficient heat dissipation in engine components.

Pros and Cons of Using Aluminum

The primary advantage of aluminum is its lightweight nature, which contributes to fuel efficiency and overall performance. It is relatively cost-effective compared to other aerospace materials like titanium or composite materials. However, aluminum can be less durable under extreme conditions, such as high temperatures or significant stress, which may limit its application in certain critical components.

Impact on Application

Aluminum is commonly used in airframe structures, fuel tanks, and various fittings. Its compatibility with different media, including aviation fuels and lubricants, makes it a versatile choice. However, buyers must consider potential fatigue issues over time, especially in high-stress environments.

Considerations for International Buyers

For international B2B buyers, compliance with standards such as ASTM and DIN is crucial. Buyers from regions like Africa or South America should also be aware of local sourcing capabilities and the availability of certified aluminum grades to ensure quality and safety.

How Does Titanium Compare as a Material for Airplane Parts?

Titanium is known for its exceptional strength and resistance to corrosion, making it an excellent choice for high-performance applications. It can withstand extreme temperatures and pressures, which is particularly advantageous in engine components and structural parts exposed to harsh conditions.

Pros and Cons of Using Titanium

The key advantage of titanium is its high strength-to-weight ratio, which rivals that of aluminum but with superior durability. However, titanium is significantly more expensive and more challenging to manufacture due to its hardness and the specialized processes required for machining and welding.

Impact on Application

Titanium is often used in critical components such as landing gear, engine parts, and fasteners. Its compatibility with various media, including hydraulic fluids and high-temperature gases, makes it suitable for demanding applications. However, the higher cost can be a limiting factor for budget-sensitive projects.

Considerations for International Buyers

International buyers should ensure compliance with aerospace standards such as JIS and ASTM. Additionally, sourcing titanium may require navigating supply chain complexities, particularly in regions with less established aerospace industries, such as parts of Africa.

What Role Do Composites Play in Airplane Parts Manufacturing?

Composite materials, particularly carbon fiber reinforced polymers (CFRP), are increasingly used in aviation due to their lightweight and high-strength characteristics. Composites offer excellent fatigue resistance and can be engineered to meet specific performance requirements.

Pros and Cons of Using Composites

The primary advantage of composites is their ability to reduce weight significantly while maintaining structural integrity. They also provide excellent corrosion resistance. However, the manufacturing process can be complex and costly, requiring specialized skills and equipment. Additionally, repair processes for composites can be more involved than for metals.

Impact on Application

Composites are commonly used in aircraft skins, wing structures, and interior components. Their compatibility with various environmental conditions, including humidity and temperature fluctuations, makes them versatile. However, buyers must consider the long-term durability and potential for delamination under certain conditions.

Considerations for International Buyers

For international buyers, understanding the certifications required for composite materials is essential, as standards can vary widely. Buyers in Europe, for instance, may have different compliance requirements compared to those in Africa or South America.

Summary Table of Material Selection for Airplane Parts

| Material | Typical Use Case for Airplane Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Airframe structures, fuel tanks | Lightweight and cost-effective | Less durable under extreme conditions | Medium |

| Titanium | Engine components, landing gear | High strength-to-weight ratio | Expensive and complex to manufacture | High |

| Composites | Aircraft skins, wing structures | Significant weight reduction | Complex manufacturing and repair | High |

This guide provides a comprehensive overview of material selection for airplane parts, emphasizing key properties, advantages, and considerations for international buyers. Understanding these factors can aid B2B buyers in making informed decisions tailored to their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for aiplane parts

What Are the Main Stages of Manufacturing Aircraft Parts?

Manufacturing aircraft parts is a complex process that involves several critical stages, each contributing to the final quality and performance of the components. The key stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting the right materials, which are often high-strength alloys, composites, or plastics, depending on the part’s function and required performance. Materials undergo rigorous testing to ensure they meet specifications before being processed. Suppliers often provide certification documents that confirm the material’s properties and compliance with industry standards.

-

Forming: The forming stage encompasses various techniques such as machining, forging, and casting. Machining involves removing material from a solid block to achieve precise dimensions. Forging shapes the material through compressive forces, enhancing its strength. Casting allows the creation of complex shapes by pouring molten material into molds. Each technique has its advantages and is chosen based on the part’s design and functional requirements.

-

Assembly: In the assembly phase, individual components are brought together to form a complete part or system. This may involve welding, riveting, or the use of fasteners. Precision is critical here, as misalignments can lead to failures during operation. Advanced technologies, such as robotics and automated assembly lines, are increasingly used to enhance accuracy and efficiency.

-

Finishing: The final stage involves applying surface treatments, coatings, or paints to enhance durability, corrosion resistance, and aesthetics. Finishing processes may include anodizing, plating, or powder coating. This stage is crucial for ensuring that the part can withstand harsh operating environments typical in aviation.

What Quality Assurance Standards Are Relevant for Aircraft Parts?

Quality assurance in aircraft parts manufacturing is governed by both international standards and industry-specific regulations. Understanding these standards is essential for B2B buyers seeking reliable suppliers.

-

International Standards: ISO 9001 is a widely recognized standard that outlines criteria for a quality management system (QMS). It helps organizations ensure they meet customer and regulatory requirements while continuously improving their processes.

-

Aerospace Industry Standards: In addition to ISO 9001, aerospace manufacturers often comply with AS9100, a specific QMS standard for the aerospace industry. It incorporates additional requirements tailored to the needs of aerospace organizations, focusing on safety and reliability.

-

European Compliance: The CE marking indicates compliance with European health, safety, and environmental protection standards. It is crucial for parts intended for use in European markets.

-

API Standards: The American Petroleum Institute (API) provides specifications for parts used in aviation applications involving fuel and oil systems. Compliance with these standards ensures that components are safe and reliable under operational conditions.

How Are Quality Control Checkpoints Implemented in Aircraft Parts Manufacturing?

Quality control (QC) is integral to the manufacturing process, and various checkpoints are established to ensure that products meet the required standards.

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the production process. Suppliers must provide certifications and test reports, which are verified by quality assurance teams.

-

In-Process Quality Control (IPQC): During manufacturing, in-process inspections are conducted at various stages. This may involve measuring dimensions, checking tolerances, and verifying the integrity of welds or assemblies. Any deviations from specifications are addressed immediately to prevent defects from progressing.

-

Final Quality Control (FQC): After production, FQC ensures that the final product meets all specifications and quality standards. This often includes functional testing, visual inspections, and performance evaluations. Documentation of these checks is critical for traceability.

What Common Testing Methods Are Used to Ensure Quality in Aircraft Parts?

Several testing methods are employed to verify the quality and reliability of aircraft parts. These include:

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and magnetic particle inspection are used to identify internal and surface defects without damaging the part.

-

Destructive Testing: While less common, destructive tests may be performed on samples to determine material properties, such as tensile strength and fatigue resistance. These tests provide critical data for ensuring that parts can withstand operational stresses.

-

Functional Testing: This involves testing the part in conditions that simulate its operational environment to ensure it performs as expected.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for mitigating risks. Here are several strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can help buyers assess compliance with international standards and industry regulations.

-

Requesting Documentation: Buyers should request detailed quality assurance documentation, including certificates of compliance, inspection reports, and records of past audits. This documentation serves as proof of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These organizations can conduct inspections at various stages of manufacturing and provide comprehensive reports.

-

Understanding Certification Nuances: Different regions may have specific certifications or compliance requirements. Buyers should familiarize themselves with these nuances to ensure that suppliers can meet local regulations and expectations.

By understanding manufacturing processes and quality assurance standards, B2B buyers can make informed decisions when sourcing aircraft parts. This knowledge not only enhances procurement strategies but also contributes to the overall safety and reliability of aviation operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aiplane parts’

Introduction

In the highly specialized field of airplane parts procurement, having a structured approach is essential for successful sourcing. This guide aims to provide international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe—with a practical checklist to streamline the procurement process, ensuring quality, compliance, and cost-effectiveness.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications of the airplane parts you require. This step is vital as it ensures that you are sourcing components that meet the exact requirements of your aircraft. Consider aspects such as material standards, performance metrics, and compatibility with existing systems. Detailed specifications can prevent costly errors and delays during installation.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in the specific parts you need. Look for suppliers with a proven track record in the aviation industry. Utilize resources like industry directories, trade shows, and online marketplaces to compile a list of candidates. Pay attention to their product range, market reputation, and customer reviews.

Step 3: Evaluate Supplier Certifications

Verify the certifications and regulatory compliance of your shortlisted suppliers. This is crucial in the aviation sector, where safety and quality standards are paramount. Look for certifications such as ISO 9001 or AS9100, which indicate adherence to quality management standards. Ensure that the parts meet relevant aviation authority regulations, such as FAA or EASA standards.

Step 4: Request Detailed Quotations

Once you have a list of qualified suppliers, request detailed quotations for the required parts. This should include pricing, lead times, shipping options, and payment terms. A comprehensive quotation allows for a better comparison of costs and services. Be wary of extremely low quotes, as they may indicate inferior quality or hidden costs.

Step 5: Check References and Past Performance

Before finalizing your choice, ask for references from previous clients and assess their experiences. This step provides insights into the supplier’s reliability, product quality, and customer service. Look for case studies or testimonials that demonstrate the supplier’s ability to meet deadlines and manage challenges effectively.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to establish favorable terms and conditions for your procurement. This may include price adjustments, payment schedules, and warranty agreements. Clear communication during this phase is essential to ensure mutual understanding and to foster a long-term business relationship.

Step 7: Implement a Quality Assurance Process

After selecting a supplier, establish a quality assurance process to monitor the performance of the parts received. Implementing checks at various stages—such as during delivery and installation—ensures that the components meet your specifications and quality standards. This proactive approach can mitigate risks associated with defective parts and enhance operational safety.

By following these steps, B2B buyers can navigate the complexities of sourcing airplane parts effectively, ensuring that they procure high-quality components that enhance the safety and efficiency of their operations.

Comprehensive Cost and Pricing Analysis for aiplane parts Sourcing

What Are the Key Cost Components in Airplane Parts Sourcing?

When sourcing airplane parts, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials directly affects the pricing. High-grade metals, composites, and specialized alloys often come at a premium due to their performance characteristics and regulatory compliance requirements.

-

Labor: Skilled labor is essential for manufacturing airplane parts. The cost of labor varies significantly based on geographic location, with regions that have higher labor costs often reflecting this in their pricing.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and indirect labor. Efficient manufacturing processes can help reduce these overheads, which is essential for competitive pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom parts. These costs are often amortized over production runs, impacting the price per unit.

-

Quality Control (QC): Rigorous QC processes are vital in the aviation industry to ensure safety and compliance. The costs associated with testing and certifications can add a considerable amount to the overall price.

-

Logistics: Transportation costs, including shipping, customs duties, and insurance, can vary widely, especially for international transactions. These should be factored into the total cost.

-

Margin: Suppliers typically add a margin to cover their risks and profit. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Price Influencers Affect Airplane Parts Pricing?

Several factors influence the pricing of airplane parts, and buyers must be aware of these to make informed decisions:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom parts tailored to specific aircraft models typically incur higher costs. Buyers should clearly define their specifications to avoid unexpected costs.

-

Materials and Quality Certifications: The quality and certification of materials can significantly influence pricing. Parts that meet stringent aviation standards often command a higher price.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more but offer greater assurance.

-

Incoterms: Understanding the terms of shipping and responsibility for costs can impact the total price. Buyers should clarify who bears shipping costs, duties, and risks during transportation.

What Are the Best Practices for Negotiating Airplane Parts Prices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but all associated costs, including maintenance and logistics. This broader view can help justify a higher upfront cost if it leads to lower long-term expenses.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing and terms. Suppliers may offer preferential pricing to long-term partners.

-

Be Transparent About Needs: Clearly communicate your requirements and budget constraints. Suppliers are often willing to work with buyers to find a mutually beneficial price point.

-

Research Market Prices: Understanding current market prices helps in negotiations. Use industry reports and competitor pricing as leverage.

-

Be Aware of Pricing Nuances for International Buyers: Currency fluctuations, import duties, and regional market conditions can affect pricing. Buyers should factor these into their negotiations to avoid surprises.

Conclusion and Disclaimer on Pricing

While this analysis provides a comprehensive view of the cost structure and pricing influences in airplane parts sourcing, prices can fluctuate based on market conditions, supplier pricing strategies, and other factors. Buyers should conduct thorough due diligence and seek multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing aiplane parts With Other Solutions

Introduction: Why Consider Alternatives to Aiplane Parts?

In the competitive aviation market, B2B buyers must evaluate various solutions for aircraft parts. While traditional airplane parts offer reliability, several alternatives may provide unique advantages in performance, cost, or ease of use. Understanding these alternatives helps buyers make informed decisions that align with their operational needs and budget constraints.

Comparison Table of Aiplane Parts and Alternatives

| Comparison Aspect | Aiplane Parts | Composite Aircraft Materials | 3D Printed Components |

|---|---|---|---|

| Performance | High durability and reliability | Lightweight, high strength-to-weight ratio | Customizable, rapid prototyping |

| Cost | Generally high | Moderate initial investment, lower long-term maintenance | Potentially lower costs for small batches |

| Ease of Implementation | Requires skilled labor for installation | May need specialized training for handling | User-friendly with proper software |

| Maintenance | Regular checks and replacements needed | Requires specific care to prevent delamination | Minimal maintenance, but dependent on material quality |

| Best Use Case | Commercial and general aviation | Experimental and custom-built aircraft | Small production runs and prototypes |

Detailed Breakdown of Alternatives

Composite Aircraft Materials

Composite materials, such as carbon fiber and fiberglass, are increasingly used in aircraft manufacturing. These materials provide a high strength-to-weight ratio, improving fuel efficiency and overall performance. However, the initial investment can be moderate, and they require specialized knowledge for installation and maintenance. While composites are excellent for experimental and custom-built aircraft, they may not offer the same level of durability as traditional airplane parts in high-stress environments.

3D Printed Components

3D printing technology has revolutionized the production of aircraft parts, allowing for rapid prototyping and customization. This method can significantly reduce lead times and costs for small production runs, making it ideal for niche markets or specific aircraft modifications. However, the performance and durability of 3D-printed parts can vary widely based on the materials used and the printing process. Maintenance is generally low, but buyers must ensure they are using high-quality materials to avoid issues in performance.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating solutions for aircraft parts, B2B buyers should consider their specific operational requirements, budget, and long-term maintenance capabilities. While traditional airplane parts offer proven reliability, alternatives such as composite materials and 3D-printed components may provide strategic advantages in certain contexts. By carefully analyzing performance, cost, and ease of implementation, buyers can select the best solution that not only meets their immediate needs but also aligns with their future growth and innovation strategies.

Essential Technical Properties and Trade Terminology for aiplane parts

What Are the Key Technical Properties of Airplane Parts?

When sourcing airplane parts, understanding technical specifications is crucial for ensuring safety, compliance, and performance. Here are several critical specifications that international B2B buyers should consider:

-

Material Grade

The material grade refers to the specific classification of the materials used in airplane parts, such as aluminum alloys, titanium, or composite materials. Each material has unique properties such as weight, strength, and corrosion resistance, which directly impact the aircraft’s performance and longevity. Knowing the appropriate material grade is essential for ensuring that parts meet industry standards and safety regulations. -

Tolerance

Tolerance is the permissible limit of variation in a physical dimension or measured value. It is critical in aviation, where even minor deviations can lead to significant performance issues or safety risks. Understanding the tolerance levels for parts ensures that they fit and function correctly within the aircraft’s assembly, preventing costly downtimes or accidents. -

Certification Standards

Certification standards, such as FAA (Federal Aviation Administration) or EASA (European Union Aviation Safety Agency) regulations, govern the manufacturing and quality assurance processes for aircraft parts. Compliance with these standards is vital for international buyers to ensure the parts are safe and reliable. Being aware of the necessary certifications helps buyers avoid non-compliant products that could jeopardize operations. -

Weight Specifications

The weight of airplane parts is a critical factor in aircraft design and performance. Lighter components contribute to better fuel efficiency and overall performance, making weight specifications essential for procurement. Buyers must assess weight specifications to ensure that the parts will not adversely affect the aircraft’s balance and performance. -

Fatigue Strength

Fatigue strength is the ability of a material to withstand repeated loading and unloading cycles without failing. For airplane parts, which are subject to constant stress during flight, understanding fatigue strength is crucial. Ensuring that parts have adequate fatigue strength can prevent premature failure and enhance safety.

What Are the Common Trade Terms Used in the Aviation Parts Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B aviation market. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture parts that are used in the assembly of original aircraft. These parts are typically of higher quality and are designed to meet specific aircraft requirements. Understanding whether a part is OEM or aftermarket helps buyers assess quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers as it can affect inventory management and cash flow. Knowing the MOQ can help buyers negotiate better deals or plan for future purchases. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers for specific parts. This process is crucial for comparing offers and ensuring that buyers receive competitive pricing. Understanding how to prepare and respond to RFQs can significantly impact procurement success. -

Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and risks during the shipping process, ensuring smooth transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the aviation industry, where downtime can be costly, understanding lead times is critical for effective planning and inventory management. Buyers should always clarify lead times when negotiating with suppliers.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they procure the right airplane parts that meet their operational needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the aiplane parts Sector

What Are the Current Market Dynamics and Key Trends in the Airplane Parts Sector?

The global airplane parts market is poised for significant growth, driven by factors such as increasing air travel demand, advancements in technology, and a growing emphasis on safety and compliance. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe (notably Germany and Nigeria), are witnessing a surge in demand for both new and refurbished aircraft components. This increase is largely attributed to the expansion of low-cost carriers and the modernization of aging fleets, necessitating efficient sourcing strategies.

Emerging B2B technologies, including advanced analytics and blockchain, are transforming the sourcing landscape. These tools enable buyers to track parts more effectively, ensure transparency in the supply chain, and mitigate risks associated with counterfeit components. Additionally, the rise of e-commerce platforms dedicated to aviation parts, such as Aircraft Spruce and Airmart, facilitates easier access to a broader range of products, allowing buyers to make informed decisions quickly.

Another key trend is the shift towards collaborative sourcing strategies, where buyers engage directly with manufacturers to negotiate better pricing and lead times. This approach not only strengthens supplier relationships but also enhances supply chain resilience, a critical factor in today’s dynamic market environment.

How Is Sustainability Influencing Sourcing Practices in the Airplane Parts Sector?

Sustainability has emerged as a critical consideration for B2B buyers in the airplane parts sector. With growing awareness of environmental impacts, companies are increasingly prioritizing ethical sourcing practices. This includes selecting suppliers who adhere to sustainable manufacturing processes and comply with international environmental standards.

The use of ‘green’ certifications, such as ISO 14001, and materials with lower environmental footprints is gaining traction. Buyers are now more likely to seek parts made from recycled or eco-friendly materials, reflecting a broader commitment to reducing carbon emissions and waste. This trend not only aligns with corporate social responsibility goals but also appeals to environmentally conscious consumers, thereby enhancing brand reputation.

Furthermore, the aviation industry is actively pursuing innovations that promote sustainability, such as lightweight composite materials that improve fuel efficiency. Buyers who incorporate these materials into their sourcing strategies can significantly reduce the environmental impact of their operations while potentially lowering operational costs over time.

How Has the Airplane Parts Sector Evolved Over Time?

The airplane parts sector has undergone significant evolution since the early days of aviation. Initially characterized by a limited supply of components and a focus on basic functionality, the industry has transformed into a highly specialized field driven by technological advancements and regulatory requirements.

The post-World War II era marked a turning point, as commercial aviation expanded rapidly, leading to increased demand for diverse aircraft parts. This was further accelerated by the advent of jet engines and advanced avionics, which necessitated more sophisticated components.

In recent decades, globalization has reshaped the landscape, enabling international sourcing and collaboration. Today, B2B buyers are not only looking for quality and compliance but also for innovative solutions that meet the evolving challenges of the aviation industry, such as sustainability and digital transformation. This evolution underscores the importance of staying informed about market dynamics and sourcing trends to maintain a competitive edge in the airplane parts sector.

Frequently Asked Questions (FAQs) for B2B Buyers of aiplane parts

-

How do I solve issues with sourcing specific airplane parts?

To address sourcing challenges, first, clearly define the specific parts you need and their specifications. Utilize online platforms and directories that specialize in aviation parts, such as Aircraft Spruce or Airmart, to locate suppliers. Additionally, consider reaching out to multiple vendors for quotes and lead times. Establishing relationships with local distributors in your region can also facilitate easier access to parts and support. Finally, networking with industry professionals through aviation forums or trade shows can yield valuable recommendations and insights. -

What is the best approach for vetting airplane parts suppliers?

Vetting suppliers involves several key steps. Start by researching their reputation through online reviews and industry forums. Check their certifications and compliance with aviation regulations, such as FAA or EASA standards. Request references from other clients to gauge reliability and service quality. Evaluate their response time and customer service during initial inquiries, as this can indicate their commitment to customer satisfaction. Finally, consider their experience in the specific type of airplane parts you require, as specialized knowledge can be a significant advantage. -

What are the common payment terms for international airplane parts transactions?

Payment terms can vary widely among suppliers. Common arrangements include upfront payment, partial payment upon order confirmation with the balance upon delivery, or net 30/60 days after receipt of goods. It’s essential to discuss these terms early in negotiations and ensure they align with your cash flow capabilities. Additionally, consider using secure payment methods like letters of credit or escrow services, particularly for large transactions, to mitigate risks associated with international trade. -

What is the typical minimum order quantity (MOQ) for airplane parts?

MOQs for airplane parts can differ based on the supplier and the type of parts being ordered. Some manufacturers may have a low MOQ of just one unit for standard parts, while custom or specialized components might require a higher MOQ. It’s important to communicate your needs clearly and inquire about flexibility in order quantities, especially if you are looking to test a new supplier or if your requirements are not extensive. -

How can I ensure quality assurance in airplane parts?

To ensure quality assurance, request documentation for all parts, including certificates of conformity and test results. Partner with suppliers who adhere to recognized quality standards, such as ISO 9001 or AS9100. Conduct thorough inspections upon receipt of parts, and consider third-party quality audits if the order is substantial. Establish a clear return policy for defective parts and maintain open communication with your suppliers regarding any quality concerns. -

What logistics considerations should I keep in mind when importing airplane parts?

Logistics for importing airplane parts involve several factors, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling aviation parts to navigate international shipping regulations. Be aware of customs duties and taxes applicable to your region. Additionally, ensure all documentation is accurate and complete to avoid delays. Planning for potential delays in transit can also help mitigate disruptions to your operations. -

Can airplane parts be customized for specific aircraft models?

Yes, many suppliers offer customization options for airplane parts to fit specific aircraft models. Discuss your requirements with potential suppliers to determine their capabilities for customization. Be prepared to provide detailed specifications and any necessary documentation regarding your aircraft. Custom parts may involve longer lead times and potentially higher costs, so it’s crucial to factor these into your planning and budget. -

What are the best practices for maintaining relationships with airplane parts suppliers?

Maintaining strong relationships with suppliers is vital for long-term success. Communicate regularly to provide feedback and discuss future needs. Establishing trust through timely payments and consistent orders can enhance your credibility. Attend industry events and engage with your suppliers beyond transactions to strengthen rapport. Additionally, consider collaborating on joint projects or promotions that can benefit both parties, fostering a mutually beneficial partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Aiplane Parts Manufacturers & Suppliers List

1. Aircraft Spruce – Pilot Supplies & Aircraft Parts

Domain: aircraftspruce.com

Registered: 1999 (26 years)

Introduction: Pilot Supplies and Aircraft Parts available at Aircraft Spruce include various categories such as Airframe Parts, Avionics, Books & Videos, Composite Materials, Covering Supplies, Electrical, Engine Parts, Hardware, Instruments, Kits & Plans, Landing Gear, Metals & Plastics, Pilot Supplies, Tools, and Wood Products. Featured products include: BA1500 Battery Analyzer & BC1500 Charger, Spring-Fast G…

2. Vintage Aircraft Parts – Accessories & Supplies

Domain: univair.com

Registered: 1996 (29 years)

Introduction: Vintage Aircraft Parts for Sale including Accessories, Supplies, Electrical, Lighting, Engine Parts, Instruments, Gauges, Manuals, Videos, Blueprints & Drawings, and Paint, Dope, Fabric. Supported brands include Aeronca, Atlee Dodge, Cessna, De Havilland, EDO, Piper, Ercoupe, Luscombe, Mooney, Stinson, Taylorcraft, and others. Categories include Cockpit & Interior, Control System, Cowling, Engine …

3. Plane Parts Inc. – Aircraft Parts Distributor

Domain: planepartsinc.com

Registered: 2015 (10 years)

Introduction: Plane Parts Inc. is an aircraft parts distributor located in Rhinelander, Wisconsin. They offer a variety of products including service kits (strut kits, brake master cylinder kits, shimmy damper kits, parking brake valve kits, fuel selector valve kits, gear, door and flap actuator kits), aircraft lighting, ELT batteries, hardware, wheel and brake parts, engine baffle seals and trim, oil and fuel …

4. Aircraft Supply – Aircraft Parts & Repair

Domain: aircraftsupply.com

Registered: 1996 (29 years)

Introduction: Aircraft Supply & Repair, Inc. offers a wide range of aircraft parts and supplies including:

1. **Application Guides**: Champion Oil Filter, LP Aero Plastics, McFarlane Aviation, Rapco Inc., Tempest Oil Filter, and more.

2. **Piston Single/Twin Airframe Parts**: Brake discs, batteries, filters, tires, vacuum pumps, and dry air pumps.

3. **Electrical and Lighting**: GE landing and taxi lights, L…

5. Trade-A-Plane – Aircraft Marketplace

Domain: trade-a-plane.com

Registered: 1996 (29 years)

Introduction: Trade-A-Plane offers a comprehensive marketplace for aircraft and aircraft parts, including airplanes, jets, helicopters, UAVs, drones, and aviation real estate. Key categories include Airframe Covering, Repair Materials, Airframe Parts, Avionics, Brakes, Tires, Undercarriage, Electrical, Engine Parts, Ground Support Equipment, Hangars, Hardware, Helicopter Parts, Instruments, Interiors, Pilot Sup…

6. McFarlane Aviation – Replacement Aircraft Parts

Domain: mcfarlaneaviation.com

Registered: 2000 (25 years)

Introduction: McFarlane Aviation specializes in replacement parts for aircraft, focusing on superior quality, safety, and affordability. They offer a wide range of products including:

– Push-Pull Controls

– Flight Control Cables & Chains

– Seat Rails

– FAA-PMA direct replacements for Dukes and Weldon fuel pumps for various aircraft models (Beechcraft, Cessna, Diamond, Maule, Mooney, Lake, Navion, and Piper).

– …

7. Airmart – Aviation Parts & Equipment

Domain: airmart.com

Registered: 1998 (27 years)

Introduction: 1. 2 Blade McCauley Prop, Removed, OH 9/13/2022 – $6,900.00 (SKU: 2A34C239/90DMC-15)

2. Altitude Encoder – $100.00 (SKU: AR-850)

3. Attitude Indicator – $600.00 (SKU: 060-0017-01)

4. Avidyne IFD440 Tray and Connector Kit – $795.00 (SKU: 700-00184-000)

5. Bendixking KR-87 – $500.00 (SKU: 066-1072-00)

6. CHT/EGT Indicator – $300.00 (SKU: 58-380104-3)

7. Directional Gyro – $500.00 (SKU: 0…

8. Plane Reclaimers – Authentic Aircraft Parts

Domain: planereclaimers.aero

Registered: 2021 (4 years)

Introduction: Plane Reclaimers offers authentic plane parts for sale, including products from major aircraft manufacturers such as Airbus (A318, A319, A320, A321, A330, A340) and Boeing (B737, B747, B757, B767, B777). The product categories include aircraft storage, windows, demonstration kits, doors, engines, fuselage, lights/lenses, manuals, safety equipment, seat-related products, signage (cabin and exterior…

Strategic Sourcing Conclusion and Outlook for aiplane parts

In the dynamic world of aviation, strategic sourcing of airplane parts emerges as a critical factor for international B2B buyers. By leveraging a well-structured sourcing strategy, businesses can enhance their operational efficiency, reduce costs, and ensure compliance with stringent safety regulations. Key takeaways include the importance of establishing relationships with reliable suppliers, understanding the nuances of global logistics, and investing in quality assurance to mitigate risks associated with counterfeit components.

Furthermore, as the aviation industry continues to evolve, buyers must remain vigilant and adaptable to market trends, such as the rise of digital procurement tools and the growing emphasis on sustainability. Engaging with suppliers who prioritize innovation and environmental responsibility can provide a competitive edge.

Looking ahead, we encourage international buyers, particularly from Africa, South America, the Middle East, and Europe, to embrace strategic sourcing as a pathway to success. By fostering partnerships and staying informed about the latest advancements, businesses can position themselves for growth in the competitive aviation landscape. Now is the time to take action—evaluate your sourcing strategies, connect with trusted suppliers, and prepare for the future of aviation parts procurement.