Contents

Manufacturing Insight: Affordable 5 Axis Cnc

Elevate Your Prototyping with Affordable Precision 5-Axis CNC Machining

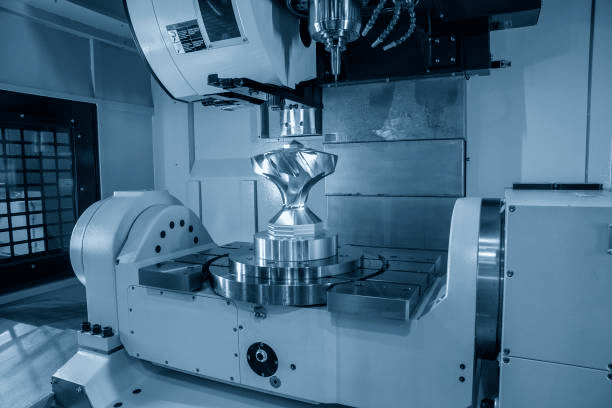

Achieving complex geometries and tight tolerances in prototype development often comes with prohibitive costs and extended lead times. At Honyo Prototype, we dismantle these barriers by delivering true 5-axis CNC machining capabilities at accessible price points—without compromising on precision, material versatility, or engineering expertise. Our dedicated fleet of advanced 5-axis CNC machining centers, operated by veteran manufacturing engineers, ensures intricate components for aerospace, medical, and industrial applications are produced with micron-level accuracy and exceptional surface finishes.

Honyo redefines affordability in high-end CNC services by optimizing workflows for low-volume and prototype production. We leverage streamlined processes, in-house tooling solutions, and strategic material sourcing to eliminate hidden costs while maintaining rigorous quality control. This approach makes sophisticated 5-axis technology feasible for R&D teams and startups, not just large-scale manufacturers.

Streamline your procurement with Honyo’s Online Instant Quote system. Upload your CAD file, specify materials and quantities, and receive a detailed, transparent cost estimate within minutes—not days. This real-time quoting capability empowers engineering teams to iterate faster, validate designs early, and accelerate time-to-market with confidence in budget certainty.

For complex geometries demanding multi-axis precision, Honyo Prototype delivers engineering-grade results at a fraction of traditional costs. Submit your CAD file today and experience how our 5-axis CNC machining services combine affordability, speed, and uncompromising quality for your next critical prototype.

Technical Capabilities

Affordable 5-Axis CNC Machine – Technical Specifications Overview

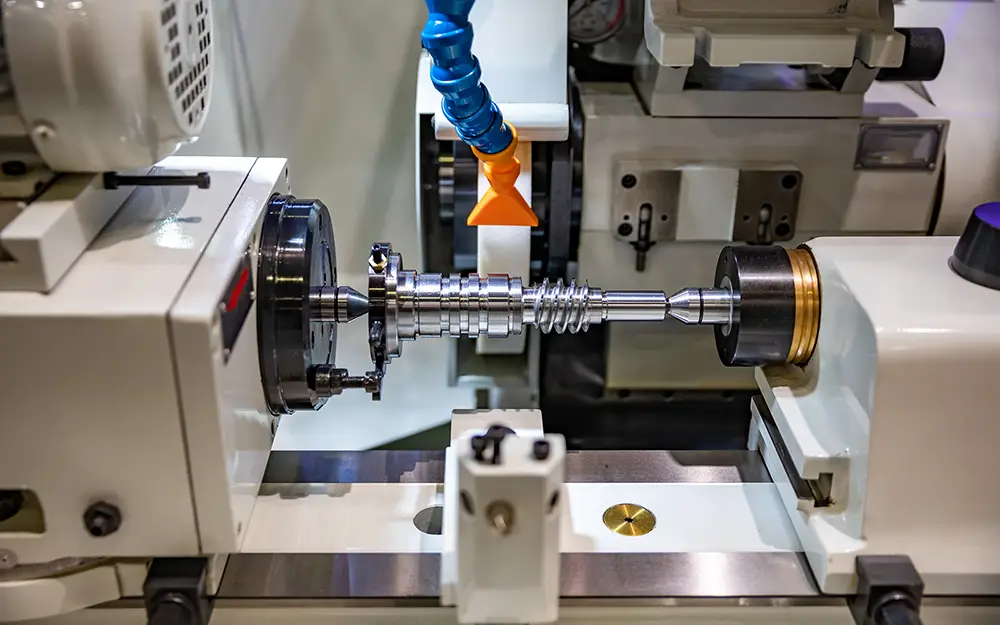

The following table outlines the key technical specifications for a cost-effective 5-axis CNC machining center designed for precision 3-axis, 4-axis, and full 5-axis milling, as well as turning operations. This machine is engineered to deliver tight tolerances and high repeatability, making it suitable for prototyping and low-to-mid volume production across a range of engineering materials including Aluminum, Steel, ABS, and Nylon.

| Specification | Detail |

|---|---|

| Axes Configuration | 5-axis simultaneous (X, Y, Z, A, B or C) with optional integrated turning (mill-turn capability) |

| Spindle Speed | 12,000 – 24,000 RPM (high-frequency spindle with ER collet or HSK-63 tool interface) |

| Positioning Accuracy | ±0.005 mm (0.0002″) |

| Repeatability | ±0.003 mm (0.0001″) |

| Tolerance Capability | ±0.01 mm (0.0004″) typical; down to ±0.005 mm with optimized tooling and fixturing |

| Work Envelope (X × Y × Z) | 500 mm × 400 mm × 350 mm (19.7″ × 15.7″ × 13.8″) |

| Rotary Axis Range | A-axis: ±110° (tilting spindle or table); B-axis: 360° continuous rotation |

| Tool Changer | Automatic Tool Changer (ATC) with 12–24 tool capacity |

| Control System | Fanuc 31i, Siemens 828D, or Heidenhain TNC7 (depending on configuration) |

| Rapid Traverse Rate | 30 m/min (X/Y/Z) |

| Maximum Material Removal Rate | 120 cm³/min (aluminum), 40 cm³/min (steel) |

| Supported Materials | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 304/316), Engineering Plastics (ABS, Nylon, POM, PEEK) |

| Coolant System | Through-spindle coolant (optional), flood coolant standard |

| Fixture Compatibility | Modular fixturing systems (e.g., Kurt-style vises, zero-point systems) |

| Surface Finish | Achieves Ra 0.8–1.6 µm (32–63 µin) on aluminum/steel with fine finishing tools |

| Machine Frame | Cast iron or reinforced polymer concrete base for vibration damping |

| Linear Guides | High-precision ground ball screws with preloaded linear guides |

| Optional Features | In-process probing, tool length sensor, high-pressure coolant, enclosure with fume extraction |

| Footprint | 2.5 m × 2.0 m (8.2 ft × 6.6 ft) including control cabinet |

| Power Requirement | 400V, 3-phase, 16–32 A (standard industrial supply) |

| Typical Applications | Aerospace components, medical devices, injection molds, complex prototypes, precision fixtures |

This 5-axis CNC platform balances performance and cost, targeting job shops, R&D departments, and contract manufacturers needing multi-axis flexibility without the premium price of high-end European systems. It supports tight tolerance machining across metals and engineering thermoplastics, enabling single-setup production of complex geometries.

From CAD to Part: The Process

Honyo Prototype delivers affordable precision 5-axis CNC machining through a tightly integrated digital workflow designed to eliminate waste, reduce manual intervention, and accelerate time-to-part without compromising quality. Our process leverages proprietary AI and engineering expertise to optimize costs at every stage.

CAD Upload and Validation

Customers initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate automated validation checks for geometry integrity, unit consistency, and manufacturability flags. This step prevents downstream delays by identifying issues like non-manifold edges or missing features before quoting, ensuring the model is production-ready and reducing iterative revisions.

AI-Powered Instant Quoting

Upon CAD validation, our AI engine analyzes the geometry, material requirements, tolerances, and surface finishes against real-time shop floor data including machine availability, tooling costs, and labor rates. The system generates a detailed quote within minutes, breaking down costs by machining time, material, fixturing, and secondary operations. Crucially, the AI cross-references historical production data to identify potential cost drivers—such as deep cavities requiring specialized tooling—and suggests near-real-time alternatives. All AI-generated quotes undergo mandatory review by a Senior Manufacturing Engineer to validate feasibility and accuracy, ensuring no hidden costs emerge later.

Collaborative DFM Optimization

This stage is where significant cost savings are engineered into the design. Our manufacturing engineers conduct a rigorous Design for Manufacturability review, focusing specifically on 5-axis efficiency. We provide actionable feedback through interactive markups in the portal, targeting features that impact cost disproportionately. Common optimizations include:

| DFM Focus Area | Typical Cost Impact | Honyo Optimization Strategy |

|---|---|---|

| Undercuts & Cavities | High (Tooling/time) | Redesign to use 5-axis simultaneous motion instead of custom fixtures |

| Tight Tolerances | Moderate-High | Relax non-critical GD&T; apply statistical process control only where essential |

| Thin Walls | High (Scrap risk) | Suggest minimum viable thickness based on material and part dynamics |

| Feature Grouping | Moderate | Recommend consolidating operations to minimize repositioning |

This phase is iterative and collaborative—engineers discuss alternatives with the client via video call or portal comments to balance performance requirements with cost targets. Most projects achieve 15-30% cost reduction through DFM before cutting metal.

Precision 5-Axis Production

Approved designs move to production on our Haas UMC-750 and Hermle C400 UMT machines, equipped with integrated probing and tool presetters. Key affordability drivers here include:

Dynamic batch scheduling where compatible parts are nested across multiple machines to maximize spindle uptime.

Automated toolpath verification using Mastercam Simulator to prevent costly collisions or scrap.

In-process inspection via Renishaw probes, reducing final inspection time by 40% while ensuring first-article compliance.

All operations follow standardized work instructions generated from the DFM output, eliminating guesswork and rework.

Guaranteed Delivery and Traceability

Parts undergo final CMM validation against the original CAD model, with full inspection reports accessible in the customer portal. We ship via tracked carriers with real-time logistics updates through HonyoTrack™, our digital delivery platform. Every component includes a unique QR code linking to its complete digital thread—material certs, machine logs, inspection data—enabling full traceability without administrative overhead. Standard lead times are 7-10 days for prototypes and 10-15 days for low-volume production, with expedited options.

This closed-loop process transforms 5-axis machining from a premium service into a cost-competitive solution by systematically removing non-value-added steps. The result is aerospace-grade precision at 20-35% below traditional job shop pricing, achieved through data-driven decision making from upload to delivery.

Start Your Project

Looking for affordable 5-axis CNC machining solutions? Honyo Prototype delivers high-precision parts with fast turnaround, supported by our state-of-the-art manufacturing facility in Shenzhen. As a trusted partner for prototyping and low-volume production, we combine advanced 5-axis CNC technology with cost-effective pricing to meet your project demands without compromising quality.

Contact Susan Leo today to discuss your next project. Email us at [email protected] for a quick quote and technical consultation. Let Honyo Prototype be your reliable manufacturing partner in China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.