Introduction: Navigating the Global Market for aerospace sheet metal fabrication

In the fast-evolving aerospace sector, sourcing high-quality aerospace sheet metal fabrication can pose significant challenges for international B2B buyers. Factors such as material selection, precision requirements, and compliance with stringent industry standards can complicate the procurement process. This comprehensive guide addresses these challenges head-on, providing insights into various types of materials and fabrication techniques, as well as practical applications of aerospace sheet metal components.

Buyers will gain an understanding of critical factors such as cost considerations, supplier vetting processes, and the importance of certifications like AS9100D and NADCAP in ensuring quality and reliability. The guide also delves into the latest trends in aerospace manufacturing, equipping decision-makers with the knowledge needed to navigate the complexities of sourcing sheet metal parts that meet their specific operational needs.

For international buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Brazil and Vietnam—this guide serves as an essential resource. It empowers them to make informed purchasing decisions, ensuring they secure the best materials and services to enhance their aerospace projects while adhering to safety and performance standards. By leveraging the insights provided, buyers can streamline their supply chains and foster partnerships that contribute to their competitive edge in the global market.

Understanding aerospace sheet metal fabrication Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydroforming | Uses fluid pressure to shape metal; minimal defects | Complex shapes for aircraft components | Pros: High precision, excellent finish. Cons: Higher initial setup costs. |

| CNC Brake Press Bending | Utilizes CNC technology for accurate bending | Structural components like fuselage parts | Pros: High repeatability, tight tolerances. Cons: Limited to specific shapes. |

| Robotic Welding | Automated welding for consistent results | Assembly of critical structural components | Pros: Improved safety and efficiency. Cons: Requires significant investment in technology. |

| Stretch Forming | Simultaneous stretching and bending of materials | Complex parts with superior surface finish | Pros: High-quality finish, versatile. Cons: More challenging to set up. |

| Laser Cutting | High-precision cutting using laser technology | Custom parts for various aircraft applications | Pros: Quick turnaround, intricate designs. Cons: Can be costly for thick materials. |

What Are the Key Characteristics of Hydroforming in Aerospace Fabrication?

Hydroforming is a highly effective method for producing intricate shapes in aerospace sheet metal fabrication. This technique uses fluid pressure to mold sheet metal into complex forms, resulting in parts with minimal imperfections. Hydroforming is particularly suitable for materials like aluminum and titanium, which are common in aerospace applications. B2B buyers should consider the initial setup costs, as hydroforming requires specialized equipment, but the resulting high-quality components can significantly reduce post-production finishing.

How Does CNC Brake Press Bending Enhance Aerospace Fabrication?

CNC Brake Press Bending leverages computer numerical control technology to achieve precise bends in sheet metal. This method is ideal for creating structural components, such as fuselage parts, where accuracy is paramount. The key advantage of CNC brake press bending is its ability to produce parts with tight tolerances and high repeatability. However, buyers should note that this process may limit the range of shapes produced, making it essential to evaluate specific project requirements before proceeding.

In What Ways Does Robotic Welding Improve Aerospace Manufacturing?

Robotic welding represents a significant advancement in aerospace sheet metal fabrication, providing automated solutions that enhance consistency and safety. This technique is particularly useful for assembling critical structural components, ensuring that welds are uniform and reliable. The efficiency of robotic welding can lead to lower labor costs and faster production times. However, the investment in robotic systems can be substantial, so B2B buyers must weigh the long-term benefits against the initial financial outlay.

What Are the Advantages of Stretch Forming for Aerospace Parts?

Stretch forming is a unique technique that combines stretching and bending of sheet metal simultaneously, allowing for the creation of complex parts with superior surface finishes. This method is especially beneficial for applications that require high-quality aesthetics and structural integrity. While stretch forming offers versatility and an excellent finish, it can be more challenging to set up compared to other methods. Buyers should consider the specific requirements of their projects to determine if stretch forming aligns with their production goals.

How Does Laser Cutting Facilitate Custom Fabrication in Aerospace?

Laser cutting is a modern technique that provides high precision and speed in cutting sheet metal. This method is particularly advantageous for producing custom parts needed in various aircraft applications. Laser cutting allows for intricate designs and quick turnaround times, making it a popular choice among aerospace manufacturers. However, the cost may escalate for thicker materials, so B2B buyers should evaluate their material choices and project budgets to ensure cost-effectiveness while meeting design specifications.

Key Industrial Applications of aerospace sheet metal fabrication

| Industry/Sector | Specific Application of Aerospace Sheet Metal Fabrication | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aircraft Manufacturing | Fuselage and Wing Structures | High strength-to-weight ratio, essential for fuel efficiency | Certification compliance (AS9100), material specifications |

| Defense and Military | Aircraft Engine Components | Enhanced durability and performance under extreme conditions | Proven reliability, custom fabrication capabilities |

| Space Exploration | Satellite Components | Lightweight and robust designs for space missions | Advanced materials, precision engineering capabilities |

| Commercial Aviation | Cabin Interiors and Seating | Comfort and safety for passengers | Customization options, adherence to safety regulations |

| Drone Technology | Drone Frame and Components | Lightweight design for improved maneuverability | Rapid prototyping, scalability for production |

How is Aerospace Sheet Metal Fabrication Utilized in Aircraft Manufacturing?

In aircraft manufacturing, aerospace sheet metal fabrication plays a crucial role in creating fuselage and wing structures. These components require a high strength-to-weight ratio to enhance fuel efficiency and overall performance. For international buyers, particularly from regions like Africa and South America, sourcing these parts involves ensuring compliance with industry certifications such as AS9100. Additionally, buyers must consider the specific material specifications that meet rigorous safety and performance standards.

What are the Applications in the Defense and Military Sector?

The defense and military sectors utilize aerospace sheet metal fabrication for producing critical aircraft engine components. These parts must withstand extreme environmental conditions, ensuring reliability and performance during missions. International buyers from the Middle East and Europe should prioritize suppliers with proven reliability and custom fabrication capabilities to meet the unique demands of military applications. Ensuring that the supplier has the necessary certifications for high-stress components is also vital.

How Does Aerospace Fabrication Support Space Exploration?

In space exploration, aerospace sheet metal fabrication is essential for manufacturing satellite components. The lightweight yet robust designs are crucial for missions where weight savings can significantly impact launch costs and performance. Buyers in this sector should focus on suppliers that offer advanced materials and precision engineering capabilities to ensure the integrity of components under harsh space conditions. Understanding the specific requirements for thermal resistance and durability is also important.

What are the Benefits for Commercial Aviation?

Aerospace sheet metal fabrication is extensively used in creating cabin interiors and seating for commercial aviation. These components not only enhance passenger comfort but also ensure safety during flights. International B2B buyers must consider customization options that adhere to safety regulations and industry standards. It’s essential to partner with suppliers that can provide innovative designs while maintaining compliance with aviation safety requirements.

How is Aerospace Sheet Metal Fabrication Advancing Drone Technology?

In the rapidly evolving field of drone technology, aerospace sheet metal fabrication is utilized to produce drone frames and components. The emphasis on lightweight design allows for improved maneuverability and efficiency in operations. Buyers looking to source these components should prioritize suppliers capable of rapid prototyping and scalable production to meet the growing demands of the drone market. Ensuring that the supplier understands the specific performance requirements for drones is crucial for successful collaboration.

3 Common User Pain Points for ‘aerospace sheet metal fabrication’ & Their Solutions

Scenario 1: Struggling with Material Selection for Aerospace Applications

The Problem: B2B buyers often face the daunting task of selecting appropriate materials for aerospace sheet metal fabrication. Given the unique requirements of aerospace components—such as high strength-to-weight ratios, corrosion resistance, and the ability to withstand extreme temperatures—choosing the right material can be overwhelming. Buyers may have limited experience with aerospace materials or lack access to comprehensive data, leading to costly mistakes in material selection that can compromise the integrity of the final product.

The Solution: To overcome this challenge, it is essential to partner with experienced suppliers who specialize in aerospace applications. Engage with manufacturers who provide detailed specifications and guidance on material properties, such as aluminum alloys (e.g., 6061, 7075) and titanium (e.g., Ti-6Al-4V). Utilize tools like material selection software or consult with aerospace engineers to analyze the specific performance requirements of your components. Additionally, create a checklist of criteria that materials must meet, including weight, strength, corrosion resistance, and cost. By taking a systematic approach to material selection and leveraging the expertise of seasoned professionals, buyers can ensure they are making informed decisions that enhance the quality and performance of their aerospace parts.

Scenario 2: Inconsistent Quality Control in Fabricated Parts

The Problem: Quality assurance is critical in aerospace sheet metal fabrication, yet many buyers struggle with inconsistent quality in their fabricated parts. This inconsistency can arise from various factors, including variations in supplier capabilities, lack of standardized processes, or insufficient quality control measures during production. Such issues not only affect product performance but can also lead to significant safety risks and financial losses for aerospace manufacturers.

The Solution: To address this pain point, buyers should prioritize working with AS9100D certified suppliers who adhere to rigorous quality management systems specifically tailored for the aerospace industry. Establish clear quality standards and expectations upfront, and request documentation of quality control processes, including inspection reports and certifications. Implement a robust supplier evaluation process that includes regular audits and performance reviews. Additionally, consider integrating advanced technologies such as automated inspection systems or machine learning algorithms to monitor production quality in real-time. By fostering strong partnerships with reputable manufacturers and implementing stringent quality assurance protocols, buyers can significantly reduce the risk of inconsistencies in their aerospace sheet metal components.

Scenario 3: Navigating Complex Fabrication Processes and Techniques

The Problem: The intricacies of aerospace sheet metal fabrication processes can be a significant hurdle for B2B buyers. With various techniques such as hydroforming, laser cutting, and CNC machining available, understanding which method is best suited for specific applications can be complex. Buyers may feel overwhelmed by the technical jargon and the specialized equipment required, leading to delays in production timelines and increased costs.

The Solution: To navigate this complexity, buyers should invest in education and training on the different fabrication techniques and their applications within the aerospace sector. Collaborate closely with engineering teams to identify the unique requirements of each project and how different fabrication methods can meet those needs. Consider hosting knowledge-sharing sessions with suppliers to gain insights into their capabilities and the advantages of specific techniques. Moreover, leverage simulation software to visualize how various processes will affect the final product, allowing for informed decision-making. By embracing a proactive approach to understanding fabrication processes and maintaining open communication with suppliers, buyers can streamline production workflows and achieve better outcomes in their aerospace projects.

Strategic Material Selection Guide for aerospace sheet metal fabrication

What Are the Key Properties of Common Materials Used in Aerospace Sheet Metal Fabrication?

Aerospace sheet metal fabrication relies on materials that exhibit exceptional performance under extreme conditions. The selection of materials is critical, as they must withstand high pressures, temperatures, and corrosive environments. Here, we analyze four common materials used in aerospace applications: aluminum alloys, stainless steel, titanium, and nickel alloys.

Aluminum Alloys: The Lightweight Champion

Aluminum alloys, particularly 6061, 7075, and 7475-02, are predominant in aerospace sheet metal fabrication due to their excellent strength-to-weight ratio and corrosion resistance. These alloys can endure temperatures up to 150°C and exhibit good mechanical properties under stress.

Pros: Aluminum is lightweight, making it ideal for aircraft where reducing weight is crucial for fuel efficiency. It is also relatively cost-effective and easy to fabricate, which can lower manufacturing complexity.

Cons: While aluminum alloys are strong, they may not be suitable for high-temperature applications beyond their rated limits. They can also be prone to fatigue over time, necessitating regular inspections.

Impact on Application: Aluminum is commonly used for fuselage structures, wing skins, and interior components. Its compatibility with various media, including aviation fuels, makes it a versatile choice.

Considerations for International Buyers: Compliance with ASTM standards is essential, especially for buyers in Europe and the Middle East. Buyers should also consider the availability of specific alloys in their regions, as supply chains may vary.

Stainless Steel: The Durable Workhorse

Stainless steel, particularly grades like 17-4 PH, is known for its corrosion resistance and ability to maintain mechanical properties across a wide temperature range. It can withstand temperatures up to 600°C, making it suitable for high-stress applications.

Pros: Stainless steel offers superior durability and strength, making it ideal for critical components such as engine parts and structural elements. It also provides excellent resistance to corrosion and oxidation.

Cons: The primary drawback is its weight compared to aluminum, which can impact overall aircraft performance. Additionally, stainless steel is generally more expensive and can complicate the manufacturing process due to its toughness.

Impact on Application: Stainless steel is frequently used in engine components, landing gear, and structural parts that require high strength and durability.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards like ASTM and ISO certifications. In regions like Africa and South America, sourcing and material availability can be challenging, impacting lead times.

Titanium: The High-Performance Material

Titanium, particularly the Ti-6Al-4V alloy, is renowned for its high strength-to-weight ratio and exceptional corrosion resistance. It can withstand temperatures up to 600°C and is highly resistant to fatigue.

Pros: Titanium is lightweight and incredibly strong, making it ideal for aerospace applications where performance is paramount. Its corrosion resistance extends its lifespan, reducing maintenance costs.

Cons: Titanium is significantly more expensive than aluminum and stainless steel, which can impact project budgets. Its fabrication requires specialized techniques and equipment, adding to manufacturing complexity.

Impact on Application: Titanium is often used in high-performance applications, such as airframe structures, engine components, and fasteners, where weight savings and strength are critical.

Considerations for International Buyers: Compliance with specific aerospace standards is crucial, especially for buyers in Europe and the Middle East. Understanding the local market for titanium and its alloys is essential for effective procurement.

Nickel Alloys: The High-Temperature Solution

Nickel alloys, such as Inconel, are designed for high-temperature applications, capable of withstanding extreme conditions up to 1,100°C. They offer excellent corrosion resistance and mechanical properties at elevated temperatures.

Pros: Nickel alloys are ideal for components exposed to high heat and stress, such as combustion liners and turbine blades. Their durability ensures long-term performance in demanding environments.

Cons: The cost of nickel alloys is generally high, and they can be challenging to machine, which may extend lead times and increase manufacturing costs.

Impact on Application: These alloys are crucial for engine components and other parts that operate in high-temperature environments, ensuring reliability and safety.

Considerations for International Buyers: Buyers must be aware of the specific certifications required for nickel alloys, particularly in the aerospace sector. Understanding regional compliance standards is vital for successful procurement.

Summary Table of Material Selection for Aerospace Sheet Metal Fabrication

| Material | Typical Use Case for aerospace sheet metal fabrication | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Fuselage structures, wing skins, interior components | Lightweight and cost-effective | Prone to fatigue, limited high-temp use | Medium |

| Stainless Steel | Engine components, landing gear, structural parts | Superior durability and strength | Heavier, more expensive | High |

| Titanium | Airframe structures, engine components, fasteners | High strength-to-weight ratio | Expensive, complex fabrication | High |

| Nickel Alloys | Combustion liners, turbine blades | Excellent high-temperature resistance | High cost, challenging to machine | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for aerospace sheet metal fabrication, ensuring informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for aerospace sheet metal fabrication

What Are the Main Stages of Aerospace Sheet Metal Fabrication?

The manufacturing process for aerospace sheet metal fabrication is complex and involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensure that the final product meets the stringent requirements of the aerospace industry.

How Is Material Prepared for Aerospace Fabrication?

Material preparation begins with selecting the appropriate metal, which is typically aluminum, stainless steel, or titanium. These materials are chosen for their strength-to-weight ratios, corrosion resistance, and ability to withstand extreme temperatures. Once selected, the metal sheets undergo cutting, shearing, or blanking to create the desired shapes and sizes.

Pre-treatment processes such as cleaning and surface preparation are crucial to remove contaminants that could affect adhesion in subsequent steps. This may include chemical cleaning, abrasive blasting, or degreasing. Accurate material preparation is essential, as any flaws at this stage can lead to defects later in the fabrication process.

What Techniques Are Used in the Forming Stage?

The forming stage involves transforming the prepared metal sheets into the required shapes through various techniques. Some of the most common methods include:

-

CNC Brake Press Bending: This technique uses computer numerical control (CNC) technology to bend metal sheets with high precision, ensuring that each part meets exact specifications.

-

Hydroforming: A process that utilizes high-pressure fluid to shape metal sheets, allowing for complex geometries without compromising material integrity. This method is particularly beneficial for producing lightweight and strong components.

-

Stretch Forming: This technique stretches the metal sheet while simultaneously bending it, resulting in high-quality parts with excellent surface finishes.

-

Laser and Waterjet Cutting: These methods provide precise cutting capabilities, allowing for intricate designs and tight tolerances essential in aerospace applications.

What Does the Assembly Process Entail?

The assembly process involves joining fabricated parts using various techniques, such as welding, riveting, and adhesive bonding. Robotic welding is commonly employed for its consistency and accuracy, ensuring that joints can withstand the mechanical stresses experienced during flight. Each assembly method has its own set of advantages, and the choice often depends on the specific requirements of the component being manufactured.

During assembly, it’s critical to maintain alignment and positioning to prevent any structural weaknesses. Advanced technologies, such as augmented reality (AR), are increasingly being used to assist with assembly tasks, improving precision and reducing the likelihood of errors.

How Are Finishing Touches Applied to Aerospace Components?

Finishing operations are crucial for enhancing the durability and aesthetics of aerospace components. Common finishing techniques include:

-

Anodizing: This electrochemical process increases corrosion resistance and wear resistance while allowing for various color finishes.

-

Powder Coating: A dry finishing process that offers a durable layer of protection against environmental factors.

-

Painting and Plating: These methods are used to provide additional protection and improve the visual appeal of components.

Post-finishing, parts undergo rigorous inspection to ensure they meet quality standards before being shipped for assembly into aircraft.

What Quality Control Measures Are Essential in Aerospace Sheet Metal Fabrication?

Quality assurance in aerospace manufacturing is non-negotiable, as it directly impacts safety and performance. Adhering to international standards and implementing rigorous quality control measures at each stage of fabrication is essential for B2B buyers.

Which International Standards Should Be Followed?

The aerospace industry is governed by several international quality standards. The most relevant include:

-

ISO 9001: A general quality management standard that outlines requirements for a quality management system (QMS).

-

AS9100: This standard specifically addresses quality management systems in the aerospace industry, incorporating ISO 9001 requirements with additional industry-specific provisions.

-

NADCAP: A certification that focuses on special processes, ensuring consistent quality in areas such as welding, heat treatment, and non-destructive testing.

Compliance with these standards not only enhances product quality but also builds trust with international clients.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure compliance with specifications. Key checkpoints include:

-

Incoming Quality Control (IQC): Inspections performed on raw materials upon receipt to verify compliance with material specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early. This may involve process audits and real-time inspections.

-

Final Quality Control (FQC): A thorough inspection of the finished product, ensuring it meets all quality and safety standards before shipment.

Common testing methods employed during these checkpoints include:

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic, radiographic, and magnetic particle inspections are used to detect internal and surface defects without damaging the parts.

-

Dimensional Inspection: Using precision measurement tools to verify that components adhere to specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability. Here are several strategies to consider:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing capabilities and quality control measures firsthand. This is particularly important for buyers from regions such as Africa and South America, where local suppliers may vary significantly in quality.

-

Reviewing Quality Reports: Requesting detailed quality control reports can provide insights into a supplier’s adherence to standards. Look for documentation related to past inspections, certifications, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and product compliance.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various challenges when assessing quality control across different regions. Factors such as local regulations, material availability, and manufacturing practices can vary significantly. It’s advisable to:

-

Understand Regional Standards: Familiarize yourself with local quality standards and certifications that may differ from international norms.

-

Build Relationships with Suppliers: Establishing strong relationships can facilitate better communication and transparency regarding quality control practices.

-

Leverage Technology: Utilize digital tools for real-time monitoring and communication, ensuring that quality standards are consistently met across borders.

In conclusion, understanding the manufacturing processes and quality assurance practices in aerospace sheet metal fabrication is essential for B2B buyers looking to source reliable and high-quality components. By prioritizing these elements, businesses can ensure they meet the demanding requirements of the aerospace industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aerospace sheet metal fabrication’

Introduction

Navigating the complexities of sourcing aerospace sheet metal fabrication requires a strategic approach. This checklist serves as a practical guide for B2B buyers to ensure they select the right suppliers and materials, ultimately leading to successful procurement and manufacturing outcomes.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is crucial for ensuring that the fabricated parts meet your operational requirements. Consider factors such as dimensions, tolerances, and material properties.

– Key Considerations:

– Identify the specific aerospace standards (e.g., AS9100D) that apply to your project.

– Determine the environmental conditions the parts must withstand, such as temperature extremes or corrosion resistance.

Step 2: Select Suitable Materials

Choosing the right materials is essential in aerospace applications, where performance and reliability are paramount. Common materials include aluminum alloys, stainless steel, and titanium, each offering distinct advantages.

– Material Properties to Consider:

– Lightweight options, such as aluminum, are often preferred for fuel efficiency.

– Ensure the selected materials have a high strength-to-weight ratio and comply with industry standards.

Step 3: Verify Supplier Certifications

Before engaging with suppliers, verify their certifications to ensure they meet the rigorous standards of the aerospace industry. Relevant certifications include AS9100D and NADCAP for welding.

– Certification Importance:

– Certifications indicate a supplier’s commitment to quality and adherence to safety protocols.

– They also reassure you of the supplier’s capability to deliver parts that meet regulatory requirements.

Step 4: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to ensure they can meet your needs effectively. Request company profiles, case studies, and references from similar industries.

– Evaluation Criteria:

– Assess their production capabilities, technology used (e.g., CNC machining, hydroforming), and lead times.

– Inquire about past projects and their outcomes to gauge reliability and performance.

Step 5: Request Prototypes and Samples

Before finalizing your order, request prototypes or samples of the fabricated parts. This step allows you to assess the quality and precision of the supplier’s work.

– Prototype Benefits:

– Prototypes enable you to conduct functional tests and verify that the parts meet your specifications.

– They also provide an opportunity to identify any potential issues before full-scale production.

Step 6: Discuss Quality Control Processes

Engage in discussions with suppliers about their quality control processes. Understanding how they monitor and maintain quality throughout the fabrication process is vital.

– Quality Control Aspects:

– Inquire about inspection methods, testing protocols, and any certifications related to quality assurance.

– Ensure that the supplier has a robust quality management system in place to prevent defects.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate terms and conditions that protect both parties. This includes pricing, delivery schedules, and warranty agreements.

– Negotiation Tips:

– Be clear about your expectations regarding timelines and payment terms.

– Ensure that warranty conditions are favorable and provide adequate coverage for the parts supplied.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for aerospace sheet metal fabrication, ensuring that they partner with reliable suppliers who can meet their specific needs while adhering to industry standards.

Comprehensive Cost and Pricing Analysis for aerospace sheet metal fabrication Sourcing

What Are the Key Cost Components in Aerospace Sheet Metal Fabrication?

Understanding the cost structure for aerospace sheet metal fabrication is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials like aluminum, stainless steel, and titanium are often used, with aluminum being the most cost-effective due to its favorable strength-to-weight ratio. Specialty alloys may incur higher costs due to their unique properties.

-

Labor: Skilled labor is essential for precision fabrication. Labor costs can vary significantly based on geographic location and the complexity of the manufacturing process. Regions with a skilled workforce may offer competitive rates, but this can also lead to increased costs.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. High-precision machinery used in aerospace fabrication, such as CNC machines and hydroforming equipment, can be capital-intensive, influencing overall pricing.

-

Tooling: Investment in specialized tooling for processes like laser cutting or stamping can be substantial. Tooling costs can be amortized over higher production volumes, making it critical to consider order quantities.

-

Quality Control (QC): Given the stringent safety standards in the aerospace industry, rigorous quality control measures are necessary. The costs associated with testing and validation processes can add to the overall price.

-

Logistics: Transportation costs are influenced by the distance from the manufacturing facility to the buyer. For international buyers, factors such as shipping, customs duties, and tariffs must be considered.

-

Margin: Suppliers will factor in their profit margins, which can vary based on competition and market demand.

How Do Price Influencers Affect Aerospace Sheet Metal Fabrication Costs?

Several factors can influence pricing in aerospace sheet metal fabrication:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Customized parts often require additional time and resources for design and production, increasing costs. Clear communication about specifications can help manage these expenses.

-

Material Selection: The choice of material not only affects cost but also impacts lead times and quality. Premium materials may offer better performance but come with higher price tags.

-

Quality and Certifications: Compliance with industry standards such as AS9100D can affect supplier pricing. Suppliers with recognized certifications may charge more due to the assurance of quality and reliability.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers with advanced technologies may command higher prices due to their expertise.

-

Incoterms: The terms of shipping and delivery (Incoterms) can also impact costs. Understanding who bears the cost and risk at each stage of transportation is crucial for budgeting.

What Negotiation Tips Can Help Buyers Optimize Costs?

To achieve cost-efficiency in aerospace sheet metal fabrication sourcing, buyers should consider the following strategies:

-

Understand Total Cost of Ownership (TCO): Look beyond initial pricing. Consider factors like maintenance, durability, and lifecycle costs to make informed purchasing decisions.

-

Negotiate Bulk Discounts: If your organization anticipates high volume orders, leverage this potential to negotiate better pricing with suppliers.

-

Clarify Specifications Early: Providing clear, detailed specifications from the outset can minimize costly revisions and delays during production.

-

Explore Multiple Suppliers: Engaging with multiple suppliers can provide leverage during negotiations and help identify competitive pricing.

-

Stay Informed on Market Trends: Understanding the dynamics of the aerospace market, including material availability and labor costs, can empower buyers to negotiate more effectively.

What Should International B2B Buyers Consider When Sourcing?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be mindful of:

-

Currency Fluctuations: Variations in exchange rates can affect pricing and overall budget planning.

-

Logistics and Delivery Times: International shipping may introduce delays. Buyers should account for lead times in their project timelines.

-

Cultural and Regulatory Differences: Understanding local regulations and customs can facilitate smoother transactions and compliance.

-

Quality Assurance Practices: Ensuring that suppliers adhere to international quality standards is vital for maintaining safety and performance in aerospace applications.

Conclusion

Navigating the costs associated with aerospace sheet metal fabrication requires a comprehensive understanding of the various components and influences at play. By focusing on effective negotiation strategies and considering the nuances of international sourcing, B2B buyers can optimize their procurement processes and ensure that they receive high-quality, cost-effective solutions tailored to their needs. Always remember that indicative prices may vary based on the specific requirements and market conditions.

Alternatives Analysis: Comparing aerospace sheet metal fabrication With Other Solutions

Understanding Alternatives to Aerospace Sheet Metal Fabrication

In the aerospace industry, fabricating components with precision and reliability is paramount. While aerospace sheet metal fabrication is a widely adopted method for producing critical aircraft parts, there are alternative technologies that can also meet the industry’s stringent requirements. This analysis compares aerospace sheet metal fabrication with additive manufacturing and composite materials, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Aerospace Sheet Metal Fabrication | Additive Manufacturing (3D Printing) | Composite Materials |

|---|---|---|---|

| Performance | High precision and strength | Good for complex geometries, less material waste | Excellent strength-to-weight ratio |

| Cost | Moderate initial setup, low production costs | High initial costs, variable production costs | Higher material costs, but savings in weight and fuel |

| Ease of Implementation | Established processes, requires skilled labor | Requires specialized knowledge, evolving technology | Requires specific tooling and expertise |

| Maintenance | Moderate, routine checks needed | Minimal, but dependent on printer maintenance | Regular inspections needed for structural integrity |

| Best Use Case | High-volume production of standard parts | Custom, low-volume, complex parts | Lightweight, high-strength applications in critical areas |

Analyzing Additive Manufacturing as an Alternative

Additive manufacturing, commonly known as 3D printing, has emerged as a viable alternative for producing aerospace components. This method allows for the creation of complex geometries that traditional methods may struggle to achieve. One of the significant advantages of additive manufacturing is the reduction of material waste, as parts are built layer by layer. However, the initial investment in 3D printing technology can be substantial, and the need for specialized knowledge can be a barrier for many organizations. Additionally, while 3D printing can produce custom parts efficiently, it may not always match the mechanical properties required for high-stress applications compared to traditional sheet metal fabrication.

Evaluating Composite Materials in Aerospace Manufacturing

Composite materials are increasingly utilized in aerospace applications due to their exceptional strength-to-weight ratio and resistance to corrosion. Composites can outperform metals in specific applications, particularly where weight reduction is critical, such as in aircraft wings and fuselage components. While the performance benefits are clear, the costs associated with composite materials can be higher than traditional metals. Furthermore, the manufacturing process for composites often requires specialized tooling and expertise, which can complicate implementation. Regular inspections are necessary to ensure structural integrity, making maintenance a consideration in long-term operational costs.

Making an Informed Decision for Your Aerospace Needs

When evaluating the best solution for aerospace component fabrication, it is crucial for B2B buyers to consider specific project requirements, including production volume, part complexity, and budget constraints. Aerospace sheet metal fabrication remains a robust choice for high-volume, standardized parts due to its established processes and cost-effectiveness. In contrast, additive manufacturing is ideal for custom, low-volume applications, while composite materials excel in lightweight, high-strength scenarios. Ultimately, the decision should align with the strategic objectives of the organization, weighing the trade-offs of each method against operational needs and future scalability.

Essential Technical Properties and Trade Terminology for aerospace sheet metal fabrication

What Are the Key Technical Properties in Aerospace Sheet Metal Fabrication?

Understanding the critical specifications in aerospace sheet metal fabrication is essential for B2B buyers. Here are some key properties that influence material selection and manufacturing processes:

1. Material Grade

Material grade indicates the specific alloy composition and mechanical properties of the metal used. In aerospace applications, common materials include aluminum (e.g., 6061, 7075), stainless steel (e.g., SS 17-4 PH), and titanium (e.g., Ti-6Al-4V). The selection of material grade affects weight, strength, and corrosion resistance, making it crucial for ensuring aircraft safety and efficiency.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of a manufactured part. In the aerospace industry, tight tolerances (often within ±0.001 inches) are critical due to the high-stakes environment where parts must fit precisely to ensure structural integrity and performance. Understanding tolerance requirements helps buyers specify parts that meet safety and regulatory standards.

3. Strength-to-Weight Ratio

This property measures the strength of a material relative to its weight, a critical factor in aerospace design. Materials with a high strength-to-weight ratio, such as titanium and advanced aluminum alloys, enable manufacturers to create lightweight components that do not compromise safety or performance. This property directly impacts fuel efficiency and overall aircraft performance.

4. Corrosion Resistance

Corrosion resistance is the ability of a material to withstand degradation in harsh environmental conditions, such as high humidity and extreme temperatures. In aerospace applications, materials like stainless steel and specific aluminum alloys are chosen for their corrosion-resistant properties. This characteristic is vital for ensuring the longevity and reliability of aircraft components.

5. Fatigue Resistance

Fatigue resistance refers to a material’s ability to withstand repeated stress over time without failing. This property is especially important in aerospace, where components are subjected to fluctuating pressures and temperatures. Selecting materials with high fatigue resistance helps prevent in-flight failures and enhances overall safety.

Which Trade Terms Are Essential for Understanding Aerospace Sheet Metal Fabrication?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several important terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In aerospace, OEMs design and manufacture components that meet specific industry standards, ensuring reliability and performance. Understanding OEM relationships is crucial for buyers seeking quality assurance in their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In aerospace sheet metal fabrication, MOQs can vary significantly based on material and complexity. Knowing the MOQ helps buyers plan their budgets and inventory more effectively, especially when custom parts are involved.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities of products or services. For aerospace buyers, submitting an RFQ is an essential step in sourcing components, allowing them to compare costs and capabilities before making purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers in aerospace, as they clarify shipping, risk, and cost responsibilities, reducing the potential for disputes.

5. NADCAP (National Aerospace and Defense Contractors Accreditation Program)

NADCAP is a global cooperative accreditation program for aerospace and defense suppliers. It establishes industry-wide standards for quality assurance and compliance in manufacturing processes. For buyers, sourcing from NADCAP-certified suppliers ensures adherence to rigorous quality and safety standards.

By grasping these technical properties and trade terms, B2B buyers in the aerospace industry can make informed decisions, ensuring the procurement of high-quality, compliant parts for their aircraft manufacturing needs.

Navigating Market Dynamics and Sourcing Trends in the aerospace sheet metal fabrication Sector

What Are the Current Market Dynamics and Key Trends in Aerospace Sheet Metal Fabrication?

The aerospace sheet metal fabrication market is experiencing robust growth driven by several global factors. The increasing demand for lightweight and fuel-efficient aircraft is propelling manufacturers to adopt advanced materials such as aluminum alloys, titanium, and high-temperature alloys. Additionally, the aerospace sector’s shift towards automation and precision manufacturing, including techniques like CNC machining and hydroforming, is transforming production capabilities. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should note the growing trend of integrating Industry 4.0 technologies, such as IoT and AI, into manufacturing processes. These technologies enhance operational efficiency, reduce lead times, and improve quality control, thus providing a competitive edge in the global market.

Emerging markets are increasingly becoming focal points for aerospace manufacturing, with countries like Brazil and Vietnam investing in local capabilities. This trend allows international buyers to source components closer to their operations, minimizing logistics costs and enhancing supply chain resilience. Furthermore, partnerships between established aerospace firms and local manufacturers are fostering knowledge transfer and technological advancements, positioning these regions as viable alternatives for sourcing high-quality aerospace components.

How Is Sustainability Influencing Sourcing Decisions in Aerospace Sheet Metal Fabrication?

Sustainability is becoming a cornerstone in aerospace sheet metal fabrication, with companies prioritizing eco-friendly practices and ethical sourcing. The environmental impact of manufacturing processes is under scrutiny, leading to a shift towards sustainable materials and practices. For B2B buyers, this means not only considering the cost and quality of aerospace components but also evaluating suppliers based on their environmental credentials.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for manufacturers that adhere to rigorous sustainability certifications, such as ISO 14001, which demonstrates a commitment to minimizing environmental impact. The use of recycled materials and low-emission manufacturing processes is gaining traction, particularly in regions with stringent environmental regulations. Moreover, ‘green’ certifications for materials, such as aluminum produced via sustainable methods, are becoming critical factors in supplier selection. By prioritizing sustainability, B2B buyers can enhance their brand reputation and align with global efforts to combat climate change.

What Is the Brief Evolution of Aerospace Sheet Metal Fabrication?

The evolution of aerospace sheet metal fabrication has been marked by significant technological advancements that reflect broader trends in manufacturing. Historically, the aerospace industry relied on manual processes for metal fabrication, which limited precision and efficiency. However, the introduction of CNC machines in the late 20th century revolutionized the sector, enabling high levels of accuracy and repeatability in component production.

As the aerospace industry grew, so did the need for lightweight yet durable materials. This led to the increased use of aluminum and titanium alloys, which are now standard in aircraft design. Today, the integration of advanced manufacturing techniques, such as additive manufacturing and automation, continues to reshape the landscape, allowing for more complex and efficient designs. This evolution not only meets the demands for safety and performance but also aligns with the growing emphasis on sustainability and ethical practices in the aerospace supply chain.

Frequently Asked Questions (FAQs) for B2B Buyers of aerospace sheet metal fabrication

-

How do I choose the right aerospace sheet metal fabrication supplier?

Selecting the right supplier involves evaluating their certifications, experience, and capabilities. Look for suppliers with AS9100D certification, as it indicates adherence to quality management standards in the aerospace sector. Additionally, assess their manufacturing processes, materials used, and the range of services offered. Request references and case studies to gauge their reliability and performance in similar projects. It’s also beneficial to conduct site visits to inspect their facilities and quality control measures firsthand. -

What are the key materials used in aerospace sheet metal fabrication?

Common materials include aluminum alloys (like 6061, 7075), stainless steel, and titanium. Aluminum is favored for its lightweight and corrosion-resistant properties, making it ideal for fuselage and wing structures. Stainless steel provides excellent mechanical strength, suitable for components exposed to harsh environments. Titanium is often used in high-performance parts due to its high strength-to-weight ratio and resistance to extreme temperatures. The choice of material should align with the specific application requirements and regulatory standards. -

What is the typical lead time for aerospace sheet metal fabrication projects?

Lead times can vary widely based on project complexity, material availability, and the supplier’s production capacity. Generally, it can take anywhere from a few weeks to several months. For custom projects, initial prototyping and testing phases may extend the timeline. It’s advisable to discuss timelines upfront with your supplier and factor in any potential delays due to international shipping or regulatory compliance, especially when sourcing from different regions. -

What customization options are available for aerospace sheet metal parts?

Aerospace sheet metal fabrication offers extensive customization, including dimensions, shapes, and finishes. Techniques such as CNC machining, hydroforming, and laser cutting allow for intricate designs tailored to specific requirements. Additionally, surface treatments like anodizing or powder coating can enhance durability and aesthetics. When discussing your project with suppliers, clearly outline your specifications and any unique challenges to ensure they can meet your needs. -

What are the minimum order quantities (MOQs) for aerospace sheet metal fabrication?

MOQs can vary depending on the supplier and the complexity of the parts being fabricated. Many suppliers may set MOQs to cover production costs and ensure efficiency, which can range from a few units to several dozen. For custom parts, it’s essential to negotiate MOQs upfront, as smaller quantities may incur higher per-unit costs. Discuss your project needs with potential suppliers to find a mutually agreeable quantity that aligns with your budget and timeline. -

How do I ensure quality assurance in aerospace sheet metal fabrication?

Quality assurance is critical in aerospace manufacturing due to stringent safety standards. Verify that your supplier implements rigorous quality control processes, including in-process inspections and final testing. Look for certifications such as NADCAP for specific processes like welding and machining, which indicate compliance with industry standards. Regular audits and inspections during production can help ensure that parts meet the required specifications and performance criteria. -

What payment terms should I expect when sourcing aerospace sheet metal fabrication?

Payment terms can differ based on supplier policies and the scope of the project. Typically, you might encounter options such as upfront payments, milestone payments during production, or payment upon delivery. It’s crucial to discuss and negotiate payment terms before finalizing contracts, ensuring they align with your cash flow and project timeline. Additionally, consider the implications of international transactions, such as currency exchange rates and potential banking fees. -

What logistics considerations are important when sourcing internationally for aerospace sheet metal fabrication?

Logistics play a vital role in international sourcing. Assess shipping methods, lead times, and customs regulations that may affect delivery schedules. Choose suppliers with experience in exporting aerospace components and who can assist with documentation and compliance. Understanding the total landed cost, including shipping, taxes, and duties, is essential for budgeting. Building strong communication with your supplier can help navigate any logistical challenges and ensure timely project completion.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Aerospace Sheet Metal Fabrication Manufacturers & Suppliers List

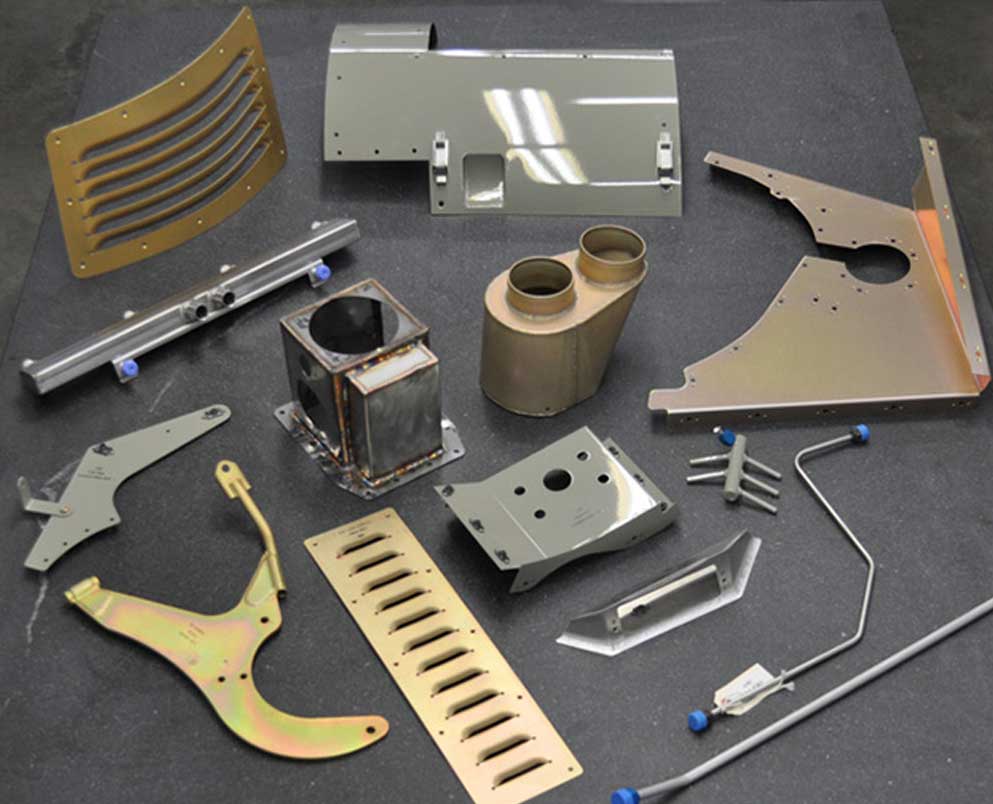

1. KDM Fab – Aerospace Sheet Metal Fabrication

Domain: kdmfab.com

Registered: 2022 (3 years)

Introduction: Aerospace sheet metal fabrication involves manipulating sheet metal to create aircraft parts and components. Key benefits include low production costs, fast production times, easy customization of parts, and quality control through precision fabrication. Common materials used in aerospace fabrication include stainless steel (SS 17-4 PH), titanium (Ti-6Al-4V), aluminum alloys (6061, 7075, 7475-02),…

2. Avalon Tec – Aerospace Sheet Metal Fabrication

Domain: avalontec.com

Registered: 2000 (25 years)

Introduction: Avalon’s aerospace sheet metal fabrication capabilities include in-house engineering and manufacturing, delivering high-quality parts. They work with high-temperature alloys such as nickel and cobalt alloys. Product offerings include engine parts (combustion liners, labyrinth seals) and cabin interiors (seating, cargo, smoke detectors). Certifications include AS9100D, CEMILAC for TIG and resistanc…

3. Stanron – Precision Aerospace Sheet Metal Fabrication

Domain: stanron.com

Registered: 2000 (25 years)

Introduction: Aerospace sheet metal fabrication and forming services, specializing in precision and accuracy for safety and efficiency in aircraft. Capable of handling various metals including aluminum, copper, brass, bronze, titanium, and carbon steel. Services include custom sheet metal design, cutting, shearing, punching, and more. Products include thermal shields, minimally thinned components, assemblies fo…

4. Protolabs – Aerospace Sheet Metal Fabrication

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Aerospace Sheet Metal Fabrication services include rapid prototyping and low-volume production for aerospace components. Key features include:

– Diverse capabilities and capacity for consistent, repeatable parts.

– Automated manufacturing services applicable throughout the product life cycle, from prototyping to launch.

– Application and technical expertise at every development stage.

– Abilit…

5. Align Precision – Sheet Metal Fabrication

Domain: alignprecision.com

Registered: 2021 (4 years)

Introduction: Sheet-metal fabrication for Tier One suppliers and aerospace OEMs. Capabilities include brake press, hydroforming, and stretch forming. Specializes in complex hydroforming with rubber block and hydraulic bladder presses. Offers vertical integration, high-volume production, AOG quick-turn services, and Bluestreak support. In-house heat-treating capabilities for production efficiency. Skin stretch u…

6. ATWF Inc – Custom Aircraft Sheet Metal Fabrication

Domain: atwf-inc.com

Registered: 1998 (27 years)

Introduction: Custom aircraft sheet metal fabrication and welding services for the aerospace industry. Extensive experience with aerospace-grade metals, including high-grade aluminum and stainless steel. Certified aerospace welders, engineers, and inspectors ensure precision and quality. Quick turnaround times for original equipment manufacturers (OEMs). Compliance with tight quality controls and certifications…

7. Buyken – Aerospace Sheet Metal Fabrication

Domain: buyken.com

Registered: 1999 (26 years)

Introduction: Aerospace Sheet Metal Fabrication, AS9100 certified operation, support for aerospace/space customers, focus on smaller intricate parts and assemblies.

8. Dyco Inc – Aerospace Metal Fabrication Services

Domain: dycoinc.com

Registered: 1998 (27 years)

Introduction: Dynamic Design and Manufacturing, Inc. is an ITAR and ISO 9001:2015 compliant aerospace manufacturer, certified AS9100D. They provide a range of aerospace metal fabrication services including CNC machining, laser cutting, metal punching, press brake forming, metal rolling, and welding. Their facility in Niwot, Colorado, spans 31,000 sq. ft. and specializes in complex aerospace parts using material…

Strategic Sourcing Conclusion and Outlook for aerospace sheet metal fabrication

In the rapidly evolving aerospace sector, strategic sourcing for sheet metal fabrication is paramount. By partnering with experienced manufacturers, buyers can leverage advanced techniques such as hydroforming, CNC machining, and robotic welding to ensure precision and reliability in their aircraft components. The choice of materials—like aluminum and titanium—plays a crucial role in achieving the desired strength-to-weight ratio and corrosion resistance, which are essential for meeting stringent aerospace standards.

For B2B buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of aerospace sheet metal fabrication can lead to significant cost savings, enhanced product performance, and faster turnaround times. Engaging with certified suppliers not only facilitates compliance with industry regulations, such as AS9100D, but also fosters innovation through collaborative design and engineering.

As the aerospace industry continues to grow, now is the time for international buyers to evaluate their sourcing strategies. By investing in quality partnerships and embracing cutting-edge fabrication technologies, companies can position themselves for success in a competitive market. Explore your options today to secure a reliable supply chain that meets the demands of tomorrow’s aerospace challenges.