Contents

Manufacturing Insight: Aerospace Sheet Metal Fabrication

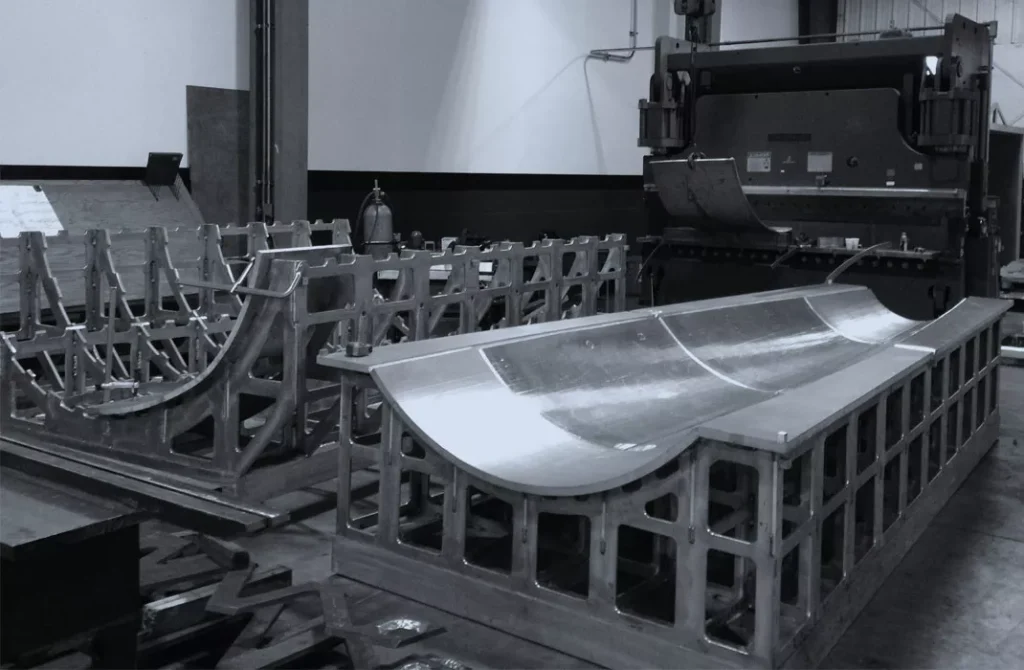

Aerospace Sheet Metal Fabrication Precision Engineered for Mission Success

Honyo Prototype delivers advanced sheet metal fabrication solutions engineered specifically for the demanding requirements of the aerospace industry. Our comprehensive capabilities encompass precision forming, laser cutting, CNC bending, welding, and finishing of critical components using high-performance alloys including titanium, Inconel, aluminum 7075-T6, and specialized composites. We understand that aerospace applications demand uncompromising adherence to AS9100 quality standards, strict material traceability, and the ability to consistently achieve tight tolerances on complex geometries. Our dedicated aerospace team leverages deep material science expertise and state-of-the-art manufacturing technology to produce mission-critical structural brackets, ducting, housings, and assemblies where failure is not an option.

We streamline the prototyping and low-volume production process for aerospace engineers through our Online Instant Quote system. This platform provides rapid, accurate cost and lead time estimates for sheet metal parts, significantly accelerating your design validation and procurement cycles. Submit your STEP or DXF files directly to receive a detailed quotation within hours, not days, enabling faster iteration and project momentum while maintaining the rigorous quality and documentation protocols essential for aerospace certification and flight readiness. Partner with Honyo Prototype for fabrication precision that meets the sky.

Technical Capabilities

Aerospace sheet metal fabrication involves high-precision manufacturing processes to meet stringent industry standards for performance, reliability, and weight efficiency. Key operations include laser cutting, bending, and welding, each requiring specialized equipment and process controls to maintain tight tolerances and material integrity. Below are the technical specifications for these processes, including compatibility with common aerospace materials such as Aluminum, Stainless Steel, ABS, and Nylon.

| Process | Technical Specifications | Material Compatibility | Notes |

|---|---|---|---|

| Laser Cutting | CO₂ or fiber laser systems with power ranges 1–6 kW; positional accuracy ±0.05 mm; kerf width 0.1–0.3 mm; max sheet thickness: Aluminum 20 mm, Steel 15 mm, ABS 10 mm, Nylon 8 mm | Aluminum (2024, 5052, 6061, 7075), Stainless Steel (304, 316, 17-4 PH), ABS, Nylon | Requires inert assist gas (N₂) for aluminum and reactive materials; minimal HAZ |

| Bending | CNC press brakes with tonnage 30–200 tons; angular accuracy ±0.2°; minimum bend radius 0.5× material thickness; tooling hardened steel | Aluminum, Stainless Steel, ABS (limited), Nylon (limited) | Springback compensation required; tooling must avoid surface marring |

| Welding | TIG (GTAW), Laser Beam, or Friction Stir Welding (FSW); shielding gas (Ar, He, or mix); weld penetration 1–6 mm; post-weld heat treatment often required | Aluminum (weldable grades), Stainless Steel (300 series); ABS and Nylon not weldable via fusion methods | ABS and Nylon joined via adhesive bonding or mechanical fastening only |

Note: ABS and Nylon are thermoplastics typically processed via machining, forming, or additive methods rather than traditional sheet metal welding. Their use in structural aerospace applications is limited to non-load-bearing or interior components. All aerospace fabrication must comply with AS9100 standards and NADCAP certification where applicable.

From CAD to Part: The Process

Honyo Prototype executes aerospace sheet metal fabrication through a rigorously controlled AS9100-certified workflow designed for precision, compliance, and rapid turnaround. Our process begins when a customer uploads native CAD files (STEP, IGES, or native CAD formats preferred) to our secure portal. This triggers an immediate automated validation check for file integrity, geometric completeness, and critical aerospace-specific attributes such as material thickness consistency and feature manufacturability within defined tolerance bands.

The validated CAD data feeds our proprietary AI-powered quoting engine. This system analyzes over 200 geometric and material parameters—including bend sequences, hole tolerances per AS7471, material grain direction requirements, and surface finish specifications—against real-time shop floor capacity and material costs. Crucially, the AI output undergoes mandatory review by a dedicated aerospace manufacturing engineer who validates material certifications (e.g., AMS 4928 for titanium), verifies non-conformance risk flags, and ensures alignment with customer-specified standards like NASM or Boeing D6-82479. This dual-layer approach delivers accurate quotes within 4 business hours while eliminating quoting errors common in fully automated systems.

Following quote acceptance, the project enters our collaborative DFM (Design for Manufacturability) phase. A dedicated engineering team conducts a formal review focusing on aerospace-critical constraints. Key parameters evaluated include:

| Parameter Category | Critical Checks | Typical Tolerance Bands (Aerospace) |

|---|---|---|

| Bend Geometry | Minimum flange width, bend relief adequacy, k-factor validation | ±0.005″ for critical bends |

| Hole Features | Hole-to-edge distances, countersink concentricity, fastener interference | ±0.002″ positional tolerance |

| Material Considerations | Grain direction for formed parts, weldability certifications, stress corrosion risks | Per AMS/ASTM material specs |

| Assembly Interfaces | Datum alignment for sub-assemblies, CMM inspection point accessibility | GD&T per ASME Y14.5 |

This phase includes direct engineering-to-engineering discussions to resolve conflicts—such as adjusting bend radii to prevent titanium cracking or modifying tooling access for complex brackets—before any metal is cut. Approved DFM outputs generate machine-ready programs with nested toolpaths optimized for minimal material waste and strict first-article inspection protocols.

Production occurs in our climate-controlled facility using state-of-the-art TruBend press brakes with in-process laser measurement, Amada turret punches with automatic tool changers, and fiber laser cutters capable of processing Inconel 718 and aluminum 2024-T3 to AMS-QQ-A-250/4 standards. Every operation adheres to documented work instructions with real-time SPC monitoring of critical dimensions. All aerospace components undergo mandatory first-article inspection per AS9102 with full FAIR documentation, including material test reports traceable to mill certificates and NADCAP-accredited non-destructive testing when specified.

Final delivery encompasses more than physical shipment. We provide a complete AS9100-compliant documentation package including: certified material test reports, FAIR with ballooned drawings, CMM inspection reports with NIST-traceable calibration data, and packing lists with serialized part tracking. Parts ship in ESD-safe, humidity-controlled packaging meeting ATA Spec 300 Category I requirements, with full chain-of-custody documentation. Our integrated logistics system provides real-time shipment visibility while ensuring compliance with ITAR or EAR restrictions where applicable. This end-to-end control guarantees that every component meets the uncompromising reliability demands of flight-critical aerospace applications.

Start Your Project

Looking for precision aerospace sheet metal fabrication? Partner with Honyo Prototype for high-quality, certified manufacturing solutions tailored to the aerospace industry. Our Shenzhen-based factory leverages advanced CNC forming, precision cutting, and assembly capabilities to meet strict aerospace tolerances and regulatory standards.

Contact Susan Leo to discuss your project requirements and receive a fast, detailed quote.

Email: [email protected]

Trusted by global aerospace innovators for rapid prototyping and low-volume production runs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.