Contents

Manufacturing Insight: Aerospace Machining Companies

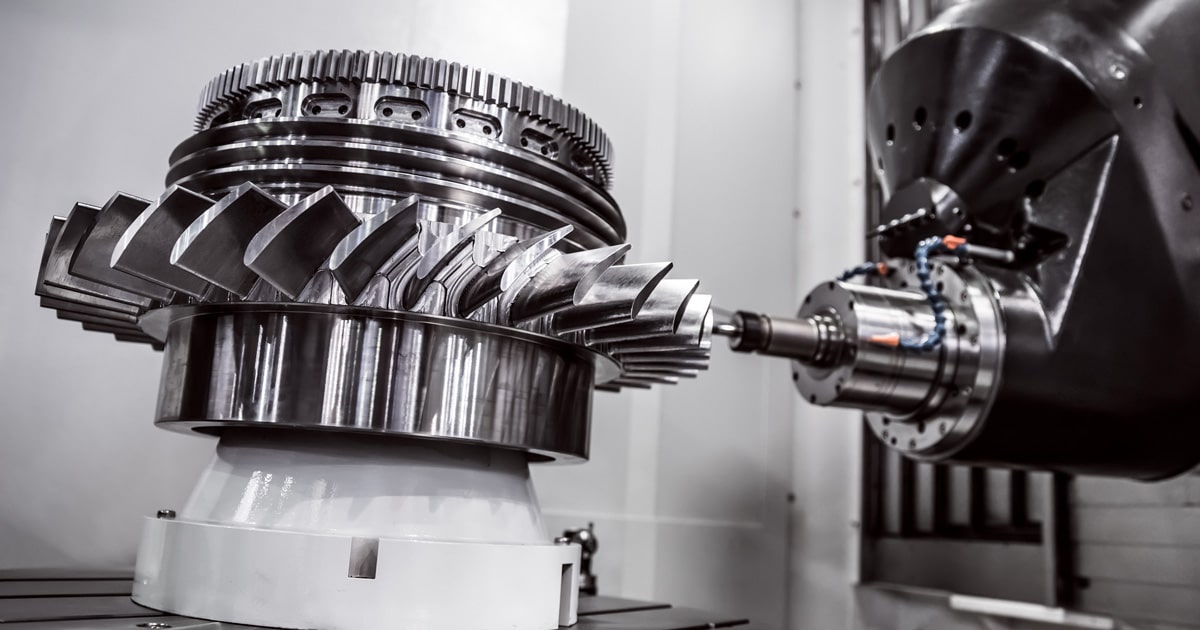

Precision Aerospace Machining Solutions Engineered for Mission-Critical Performance

Aerospace component manufacturing demands uncompromising precision, rigorous material integrity, and adherence to the highest regulatory standards. At Honyo Prototype, we specialize in delivering CNC machining services explicitly engineered for the aerospace sector, where tolerances measured in microns and material certifications directly impact flight safety and operational reliability. Our AS9100-certified facility combines advanced multi-axis machining capabilities with deep expertise in aerospace-grade alloys—including titanium, Inconel, 7075 aluminum, and composite materials—to transform complex designs into flight-ready components.

Advanced Capabilities for Demanding Aerospace Applications

Our technical infrastructure supports the full spectrum of aerospace machining requirements, from rapid prototyping to low-volume production runs. Utilizing state-of-the-art 5-axis milling, precision turning, and multi-tasking centers, we consistently achieve tolerances down to ±0.0002 inches while maintaining strict traceability and documentation per AMS, ASTM, and customer-specific specifications. Each process is backed by in-house metrology, including CMM and optical inspection, ensuring components meet the structural, thermal, and fatigue-resistant properties essential for avionics, engine systems, and airframe assemblies.

Accelerate Development with Our Online Instant Quote System

Recognizing the time-sensitive nature of aerospace innovation, Honyo Prototype eliminates traditional quoting bottlenecks through our proprietary Online Instant Quote platform. Upload CAD files directly to receive a comprehensive manufacturability analysis, material optimization suggestions, and a formal quotation within hours—not days. This digital workflow provides immediate cost transparency and technical feedback, enabling engineers to iterate designs faster while maintaining compliance with aerospace regulatory frameworks.

Partner with Honyo Prototype for CNC machining services where technical rigor meets operational agility. We bridge the gap between conceptual design and certified production, ensuring your components exceed the performance demands of modern aerospace systems while accelerating time-to-market.

Technical Capabilities

Aerospace machining companies specialize in high-precision manufacturing processes to meet the stringent requirements of the aerospace industry. These companies typically offer advanced 3-axis, 4-axis, and 5-axis CNC milling along with precision turning capabilities. They are equipped to work with a wide range of materials including aluminum alloys, stainless and alloy steels, and engineering thermoplastics such as ABS and nylon. Tight tolerances, often within ±0.0002″ (±0.005 mm), are standard to ensure component reliability under extreme conditions.

The following table outlines key technical specifications commonly found in aerospace machining services:

| Capability | Specification Details |

|---|---|

| Machining Types | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including multi-axis Swiss-type turning); mill-turning with live tooling |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) on linear axes; ±5 arc seconds on rotary axes |

| Repeatability | ±0.0001″ (±0.0025 mm) across all axes |

| Typical Tolerances | ±0.0002″ to ±0.001″ (±0.005 mm to ±0.025 mm) depending on feature and geometry |

| Surface Finish | As low as 16 μin (0.4 μm) Ra, with optional polishing or coating |

| Work Envelope (Milling) | Up to 40″ × 30″ × 25″ (1016 × 762 × 635 mm) for 5-axis systems; larger for specialized machines |

| Work Envelope (Turning) | Diameter up to 12″ (305 mm), length up to 48″ (1219 mm); micro-turned parts down to 0.020″ (0.5 mm) diameter |

| Materials – Metals | Aluminum 2024, 6061, 7075; Stainless Steel 17-4 PH, 303, 304, 316; Alloy Steels (4140, 4340); Titanium (Grade 5, 6Al-4V) |

| Materials – Plastics | ABS (Acrylonitrile Butadiene Styrene), Nylon 6, Nylon 6/6, PEEK, PTFE, Delrin (POM) |

| Certifications | AS9100D, ISO 9001:2015, NADCAP (for special processes), ITAR registration |

| Inspection Equipment | CMM (Coordinate Measuring Machine), optical comparators, laser scanners, surface roughness testers, vision systems |

| Secondary Operations | Heat treatment, anodizing (Type II & III), passivation, precision deburring, cleaning (ultrasonic), non-destructive testing |

These specifications enable aerospace machining companies to produce complex, mission-critical components such as turbine parts, housings, actuators, brackets, and fluid system components with high consistency and reliability.

From CAD to Part: The Process

Honyo Prototype delivers precision aerospace components through a rigorously controlled, AS9100-certified workflow designed for zero-defect outcomes and accelerated time-to-market. Our end-to-end process eliminates traditional bottlenecks while ensuring strict compliance with aerospace material, dimensional, and documentation standards. Below is the technical execution of each phase:

CAD Upload and System Integration

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) via our secure customer portal. Honyo’s system automatically validates file integrity against ASME Y14.41 standards, checks for geometric discontinuities, and cross-references material specifications against AMS, ASTM, and customer-specific material databases. Metadata including part number, revision level, and critical features (e.g., FOS, datums) is extracted for downstream traceability.

AI-Powered Quoting Engine

Our proprietary AI engine analyzes the validated CAD model using multi-parameter algorithms trained on 12,000+ aerospace projects. It calculates machine time based on feature complexity (e.g., deep pockets, thin walls), toolpath optimization, and material machinability coefficients (e.g., Inconel 718 vs. 7075-T7351). The system generates a technical quotation within 2 hours, including:

Cost breakdown by operation (5-axis milling, wire EDM, Swiss turning)

Material waste analysis with buy-to-fly ratio projections

Risk flags for features requiring special tooling or inspection methods

Compliance statement against referenced specifications (e.g., NAS907, MS standards)

Engineering-Driven DFM Analysis

Unlike generic DFM tools, Honyo’s aerospace engineering team conducts a collaborative review with the client’s design authority. This phase includes:

Tolerance stack-up verification per AS9102 FAI requirements

Machinability assessment of complex geometries (e.g., integral hinges, fluid passages)

Material grain flow analysis for critical rotating parts

Non-conformance prediction using Monte Carlo simulation for Cpk < 1.33 features

The output is a formal DFM report with actionable recommendations, typically reducing manufacturability risks by 35-60% through design-for-assembly and cost-saving alternatives.

AS9100-Compliant Production Execution

Production occurs in climate-controlled cleanrooms (ISO Class 8) with full material traceability via laser-etched part IDs. Key controls include:

Real-time SPC monitoring of critical dimensions using Renishaw probes

In-process CMM validation at defined hold points per control plan

Dedicated tooling for exotic alloys with documented wear compensation

NADCAP-accredited non-destructive testing (fluorescent penetrant, X-ray) for structural components

All processes adhere to work instructions validated through PPAP Level 3 documentation.

Certified Delivery and Documentation

Final shipment includes:

Complete AS9102B FAI package with ballooned drawings

Material certs (MIL-PRF-23377, EN 4500)

Dimensional reports with GD&T analysis

NDT results and process validation records

Parts are packaged per customer-specific ESD and corrosion prevention protocols (e.g., VCI bags for titanium). Honyo guarantees on-time delivery through dynamic scheduling that accounts for FAA/PMA certification lead times.

Process Performance Metrics

Our aerospace workflow consistently achieves industry-leading results compared to standard manufacturing partners:

| Metric | Honyo Prototype | Industry Average | Improvement |

|---|---|---|---|

| Quote-to-Order Cycle Time | 2-4 hours | 3-7 business days | 85% faster |

| DFM Issue Resolution Rate | 98.7% | 76.2% | 22.5% higher |

| FAI First-Pass Yield | 99.4% | 88.1% | 11.3% higher |

| Median Lead Time (Complex) | 18 days | 21 days | 15% faster |

This integrated approach ensures aerospace suppliers receive flight-ready components with full audit trails, eliminating rework cycles while meeting stringent airworthiness requirements. All process data is archived for 15+ years to support fleet lifecycle management.

Start Your Project

Looking for precision aerospace machining services? Partner with Honyo Prototype, a trusted name in high-accuracy CNC machining for the aerospace industry. Our Shenzhen-based manufacturing facility adheres to strict quality standards, ensuring reliable, repeatable results for mission-critical components.

Contact Susan Leo today at [email protected] to discuss your project requirements and discover how our advanced machining capabilities can support your aerospace engineering needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.