Contents

Manufacturing Insight: Aerospace Cnc Machined Parts

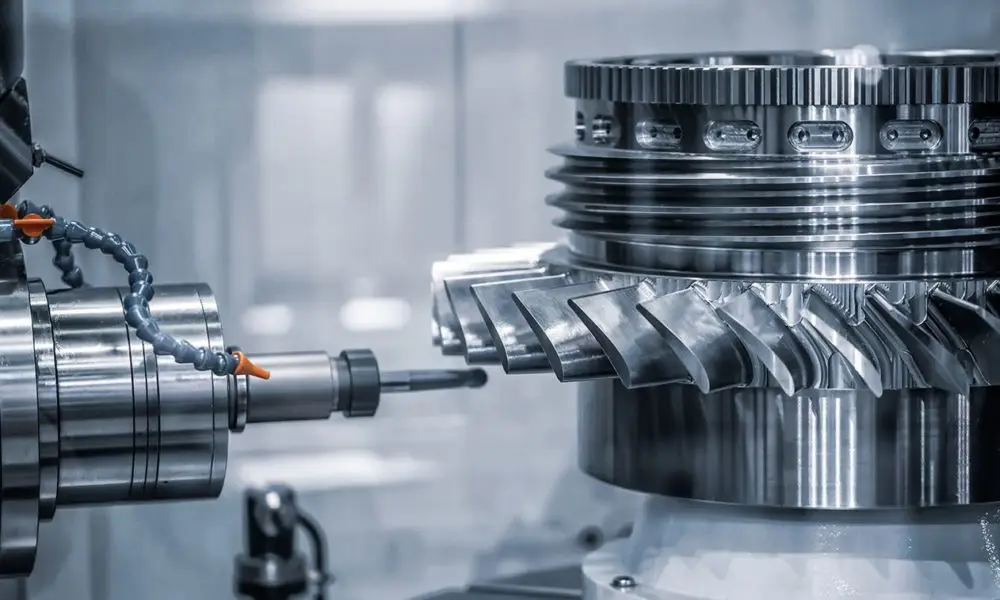

Precision Aerospace CNC Machined Parts: Engineered for Flight-Critical Performance

Honyo Prototype delivers mission-critical aerospace CNC machined components where uncompromising precision, material integrity, and regulatory compliance are non-negotiable. Serving Tier 1 suppliers, OEMs, and defense contractors, our AS9100-certified manufacturing ecosystem combines advanced multi-axis machining centers (5-axis simultaneous, mill-turn) with rigorous NADCAP-accredited processes to produce complex geometries in demanding alloys like Inconel 718, Ti-6Al-4V, and high-strength aluminum alloys. Every component undergoes stringent in-process inspection and full material traceability, ensuring adherence to AMS, ASTM, and customer-specific airworthiness standards from prototype through serial production.

Our technical advantage lies in integrated digital workflows that eliminate traditional prototyping bottlenecks. Utilizing Mastercam and Siemens NX for optimized toolpath generation, coupled with real-time machine monitoring, we achieve micron-level tolerances (±0.0002″) while maintaining thermal stability for thin-wall and close-tolerance features. This capability directly addresses aerospace industry pain points: reducing lead times for first-article approvals, mitigating scrap risk in exotic materials, and ensuring repeatability across production runs.

Accelerate your development cycle with Honyo Prototype’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed manufacturability analysis and competitive pricing within hours—no RFQ delays. This transparent, engineering-led quoting process validates design feasibility against aerospace material and tolerance requirements before commitment, empowering faster decision-making for critical path projects. Partner with us to transform complex aerospace designs into flight-ready hardware with certified quality and responsive scalability.

Technical Capabilities

Aerospace CNC machined parts require high precision, repeatability, and compliance with stringent industry standards such as AS9100 and NADCAP. These components are typically produced using advanced 3-axis, 4-axis, and 5-axis milling machines as well as CNC turning centers to achieve complex geometries and tight tolerances. The manufacturing process supports a wide range of materials commonly used in aerospace applications, including aluminum alloys, steel alloys, and engineering thermoplastics like ABS and nylon for non-structural or prototype components.

| Feature | Specification Details |

|---|---|

| Machining Process | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including multi-axis turning centers) |

| Typical Tolerances | ±0.0002″ (5 µm) for critical dimensions; feature-to-feature tolerances within ±0.0005″ (12 µm) |

| Surface Finish | 32–125 µin Ra, with tighter finishes achievable per requirement (e.g., 16 µin Ra for sealing surfaces) |

| Materials – Metals | Aluminum 6061-T6, 7075-T6, 2024-T3; Stainless Steel 17-4 PH, 303, 304, 316; Alloy Steels 4140, 4340 |

| Materials – Plastics | ABS (acrylonitrile butadiene styrene), Nylon (PA6, PA66), PEEK, PTFE (for non-structural or prototype use) |

| Max Work Envelope (Milling) | Up to 40″ × 20″ × 20″ (1016 × 508 × 508 mm) for 5-axis; larger for specialized machines |

| Max Work Envelope (Turning) | Diameter up to 12″, length up to 48″ depending on machine configuration |

| Tooling & Fixturing | High-precision collet systems, custom soft jaws, vacuum and mechanical fixturing; modular fixturing for 5-axis setups |

| Quality Standards | AS9100D, ISO 9001, NADCAP (for special processes), First Article Inspection (FAI) per AS9102 |

| Inspection Equipment | CMM (Coordinate Measuring Machine), optical comparators, laser scanning, surface profilometers |

| Secondary Operations | Deburring (manual and automated), passivation, anodizing (Type II & III), painting, masking, heat treatment |

These specifications ensure that aerospace CNC machined components meet the rigorous demands of flight-critical systems, including performance under extreme temperatures, vibration resistance, and long-term reliability.

From CAD to Part: The Process

Honyo Prototype Aerospace CNC Machined Parts Process Overview

Honyo Prototype delivers precision aerospace components through a rigorously controlled, standards-compliant workflow designed for AS9100 adherence and mission-critical reliability. Our end-to-end process begins with secure digital collaboration and culminates in certified delivery, ensuring dimensional accuracy, material integrity, and full traceability.

CAD Upload and Validation

Customers initiate the process via our secure client portal, uploading native CAD formats including STEP, IGES, or native Siemens NX/Creo files. Our system automatically validates file integrity, checks for geometric completeness, and confirms critical metadata alignment with aerospace requirements (e.g., ASME Y14.5-2018 tolerancing, surface finish callouts). Proprietary encryption ensures IP protection throughout transmission, with immediate acknowledgment of receipt and preliminary file assessment within 2 business hours.

AI-Powered Quoting with Engineering Oversight

Uploaded designs undergo rapid analysis via our proprietary AI quoting engine, which evaluates geometric complexity, material utilization, and machine time requirements against real-time capacity data. Crucially, this AI output is not final; it triggers mandatory review by our aerospace-dedicated manufacturing engineering team. Engineers validate the AI’s cost and lead time projections, cross-referencing against MIL-STD-883 compliance needs, NADCAP-accredited secondary processes (e.g., anodizing, non-destructive testing), and material certifications (e.g., AMS4928 titanium, AMS-QQ-A-250/11 aluminum). Clients receive a detailed technical quotation within 24–48 hours, inclusive of process routing, quality checkpoints, and compliance documentation scope.

Engineering-Driven DFM Analysis

Upon quote acceptance, our DFM phase commences with active collaboration between the client’s design team and Honyo’s NPI engineers. We conduct a formal Design for Manufacturability review focused on aerospace-specific risk mitigation: optimizing thin-wall stability, minimizing non-standard tooling dependencies, verifying fixturing feasibility for 5-axis machining, and ensuring inspection accessibility per AS9102 FAI requirements. This phase includes material certification validation (e.g., batch-traceable certs for AMS 4901 Inconel), thermal stability assessment for high-temp alloys, and explicit resolution of any tolerancing conflicts. A signed-off DFM report with actionable recommendations is provided before production release.

Precision Production and Quality Integration

Production occurs in our AS9100:2016-certified facility using Haas and DMG MORI 5-axis machining centers with sub-micron repeatability. Each work order includes:

Material verification via PMI (Positive Material Identification) upon receipt

In-process CMM inspections at critical stages per the control plan

Real-time SPC monitoring of key characteristics (e.g., hole concentricity, positional tolerances)

Dedicated cleanroom environments for sensitive components (e.g., fuel system parts)

All processes adhere strictly to documented work instructions aligned with customer-specific requirements and industry standards. First Article Inspection (FAI) per AS9102 is performed using calibrated FARO Arm systems, with full dimensional reports and material test documentation generated.

Certified Delivery and Traceability

Final delivery encompasses comprehensive traceability and compliance evidence. Components ship in ESD-safe, humidity-controlled packaging with serialized labels linking to:

Full material traceability (melt batch, heat treat records)

Dimensional inspection reports (including CMM probing data)

Process non-conformance logs (if applicable)

Certificates of Conformance (C of C) with AS9100 revision control

NADCAP audit trail for secondary processes

Shipments include digital access to the complete quality package via our client portal, with physical documentation meeting ITAR and DFARS requirements where applicable. Standard lead time from DFM sign-off to delivery is 15–25 days for prototype quantities, with expedited options available.

Key Aerospace Compliance Elements

The table below summarizes critical compliance touchpoints integrated throughout our workflow:

| Process Stage | Regulatory Standard | Honyo Implementation Detail |

|---|---|---|

| Material Handling | AMS 2750 | Real-time furnace monitoring with NIST-traceable thermocouples; documented soak times |

| Dimensional Inspection | AS9102 | FAI using 3D scan comparison against nominal CAD; CMM reports with GD&T analysis |

| Process Control | AS9100 Sec 8.5.1 | Operator certifications logged per machine; tool wear compensated via automated offset updates |

| Documentation | ITAR/DFARS | Encrypted digital archives; physical records stored in restricted access vaults |

This integrated approach ensures Honyo Prototype consistently delivers aerospace CNC machined parts meeting the highest standards of safety, precision, and regulatory compliance, minimizing client risk while accelerating time-to-flight.

Start Your Project

For precision aerospace CNC machined parts manufactured to the highest industry standards, contact Susan Leo at [email protected]. Our advanced production facility in Shenzhen ensures tight tolerances, superior quality, and on-time delivery for critical aerospace applications. Partner with Honyo Prototype for reliable, certified component manufacturing tailored to your engineering requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.