Guide Contents

Project Insight: Aerospace Cnc Machined Parts

Precision & Speed: The Aerospace Development Imperative

In aerospace engineering, where safety and performance are non-negotiable, precision and rapid iteration are critical for successful product development. At Honyo Prototype, we engineer solutions that turn complex aerospace designs into reality with uncompromising accuracy and agility.

Why Precision is Non-Negotiable in Aerospace

Safety-critical components demand tolerances as tight as ±0.01mm to ensure structural integrity and regulatory compliance (AS9100, ISO 9001)

Material-specific challenges (titanium, Inconel) require advanced multi-axis machining to maintain dimensional stability under extreme conditions

Functional prototypes must mirror end-use part performance to prevent costly redesigns late in development

Digital Manufacturing: Accelerating Your Innovation Cycle

Online Instant Quote: Receive accurate pricing in seconds via our AI-driven platform, eliminating guesswork and delays

AI-Powered Design Optimization: Real-time DFM feedback to refine your part for manufacturability and cost efficiency

24-48 Hour Prototype Turnaround: From design to delivery, accelerating your iteration cycles without compromising precision

Honyo Prototype: Engineered for Aerospace Excellence

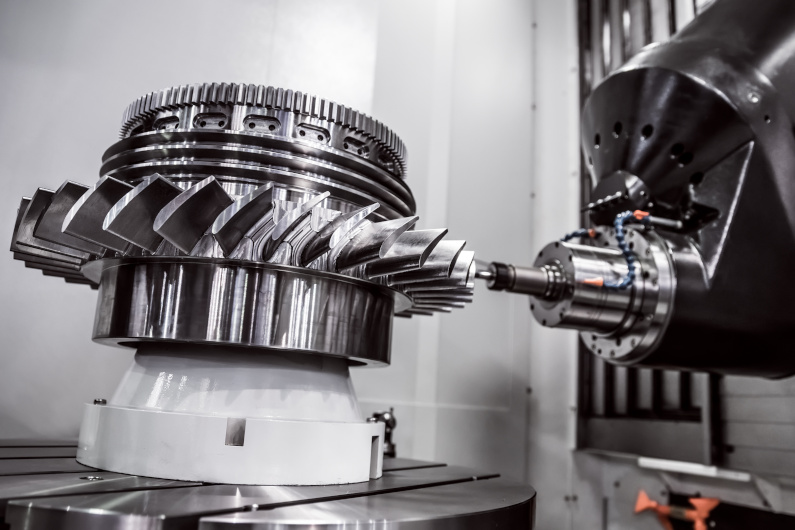

3/4/5-Axis CNC Machining: Capable of complex aerospace geometries with micron-level precision

ISO-Certified Quality Assurance: Rigorous inspection protocols validated for aerospace standards

Cost-Optimized Global Manufacturing: Delivering US-quality results with competitive pricing and no hidden fees

End-to-End Digital Workflow: Seamless integration from design to production with real-time progress tracking

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Precision Multi-Axis CNC Technology

3/4/5-axis CNC machining delivering ±0.01mm tolerances for complex aerospace geometries, ensuring compliance with stringent industry standards.

Advanced tooling and fixturing for high-performance materials (titanium, Inconel, aerospace-grade aluminum) with superior surface finishes and dimensional accuracy.

Real-time machine monitoring and adaptive control systems guaranteeing consistent quality across all production volumes.

Scalable Production from Prototype to Mass Production

Seamlessly transition from single-unit prototypes to 10,000+ production parts without compromising precision or delivery timelines.

Economies of scale reduce per-unit costs by up to 30% for orders over 500 pieces, optimizing budget efficiency for startups and enterprises alike.

Flexible scheduling and rapid tooling changes enable urgent requests to be prioritized without disrupting workflow.

Aerospace-Grade Quality Assurance

AS9100 and ISO 9001 certified quality management systems with 100% dimensional inspection using CMM and optical measurement tools.

Full traceability of materials and processes for every component, ensuring compliance with FAA, EASA, and other regulatory bodies.

Rigorous in-process checks and final validation to eliminate defects before shipment — critical for safety-critical aerospace applications.

Digital-First Production Workflow

Instant online quotes: Upload CAD files for real-time pricing and lead times — no back-and-forth, no delays.

AI-powered DFM analysis: Optimize designs for manufacturability, reducing costs by up to 25% while enhancing performance.

Industry-leading turnaround: Prototypes delivered in 3-5 days; production batches in 1-2 weeks — 50% faster than Western suppliers.

Honyo Prototype: Where cutting-edge precision meets scalable innovation for aerospace-grade parts. Shenzhen-based, globally trusted.

Materials & Surface Finishes

Material & Finish Options for Aerospace Applications

Selecting the right materials and finishes is critical for aerospace components where safety, weight, and performance are non-negotiable. At Honyo Prototype, we combine deep aerospace expertise with cutting-edge manufacturing capabilities to ensure your parts meet stringent industry standards while optimizing cost and lead time.

Precision Materials for Aerospace Applications

Aluminum 6061: High strength-to-weight ratio, excellent corrosion resistance. Ideal for structural components, brackets, and non-critical parts where weight savings are essential.

Aluminum 7075: Superior strength (comparable to steel), used in high-stress aerospace applications like landing gear and structural frames.

Stainless Steel 304: Good corrosion resistance, cost-effective for general-purpose components. Suitable for interior parts not exposed to extreme conditions.

Stainless Steel 316: Enhanced corrosion resistance due to molybdenum content. Critical for marine environments, fuel systems, and high-temperature applications.

Brass: Excellent electrical conductivity and machinability. Used in electrical connectors and instrumentation components.

PEEK: High-performance polymer with exceptional thermal stability and chemical resistance. Ideal for lightweight, high-temperature parts such as seals and bearings.

Surface Finishes for Performance & Durability

Anodizing (Type II/III): Enhances corrosion resistance, wear resistance, and surface hardness. Type III (hard anodize) meets aerospace standards for critical components.

Electroless Nickel Plating: Uniform coating for corrosion protection and wear resistance, ideal for hydraulic components.

Passivation (Stainless Steel): Removes surface contaminants, enhances corrosion resistance per ASTM standards.

Polishing (Mirror or Satin): Achieves aesthetic and functional smoothness for optical or fluid-handling parts.

Powder Coating: Durable, UV-resistant finish for non-critical exterior parts requiring color coding.

Why Choose Honyo Prototype for Aerospace Components

Online Instant Quote: Upload your CAD file for real-time pricing and material recommendations—get quotes in seconds, not days.

AI-Optimized Material Selection: Our algorithms analyze design requirements to recommend the most cost-effective and compliant materials, reducing prototyping time by 30%.

Fast Turnaround: 3–5 day prototyping, 2–3 weeks for production runs—50% faster than US suppliers with 30–50% lower costs.

Aerospace-Grade Precision: ISO 9001 certified processes with +/- 0.01mm tolerances and full traceability for mission-critical parts.

💡 Innovation meets efficiency: Our AI-powered platform eliminates guesswork, ensuring your aerospace components are engineered for performance, compliance, and cost savings from day one.

From Quote to Part: Our Process

How It Works: From CAD to Part

Our AI-driven workflow transforms your design into precision aerospace components—faster, smarter, and transparently. Here’s how:

✅ Seamless CAD Submission

Submit STEP, STL, or IGES files via our secure online platform in seconds.

No manual review delays—our system processes your design instantly for analysis.

💡 Instant AI-Powered Quote

Get real-time pricing with full transparency—no hidden fees or waiting days for estimates.

AI analyzes geometry, tolerances, materials, and quantity to deliver accurate cost breakdowns in under 60 seconds.

🔍 Proactive DFM Analysis

Our engineers conduct automated and manual Design for Manufacturability checks to identify potential issues before production.

Receive actionable feedback to optimize tolerances, reduce material waste, and accelerate time-to-market.

🚀 Precision Production & Delivery

Produced in our Shenzhen facility using state-of-the-art 5-axis CNC machines for ±0.01mm precision and aerospace-grade quality.

Track production in real-time; expedited shipping options ensure delivery within days, not weeks.

From concept to completion, Honyo’s end-to-end workflow eliminates guesswork—so you can focus on innovation, not logistics.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Machining, Redefined

Online Instant Quote: AI-driven platform delivers real-time pricing and manufacturability analysis in seconds—no manual quotes, no delays.

AI-Powered Cost Optimization: Save up to 75% vs. Western suppliers through intelligent toolpathing and material efficiency.

Fast Turnaround: Prototypes in 3–5 days; production runs in 2–3 weeks—powered by our Shenzhen/Dongguan integrated facilities.

Why Choose Honyo?

Founder-Led Expertise: Susan Leo and our aerospace specialists deliver ±0.01mm precision for functional prototypes and end-use parts.

End-to-End Support: Dedicated engineering team from design review to final delivery—zero surprises, zero delays.

Rigorous Aerospace Standards: Quality control processes meeting stringent industry requirements for safety and performance.

Ready to Accelerate Your Project?

Contact Susan Leo’s team: [email protected] | +86 139 2843 8620

Visit our facilities: Schedule a tour of our Shenzhen and Dongguan operations

Get started now: Access our AI-powered quote platform — Instant quotes in seconds

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.