Contents

Manufacturing Insight: Advantage Of Cnc Machine

Unlock Precision Manufacturing Advantages with Honyo Prototype’s CNC Machining Services

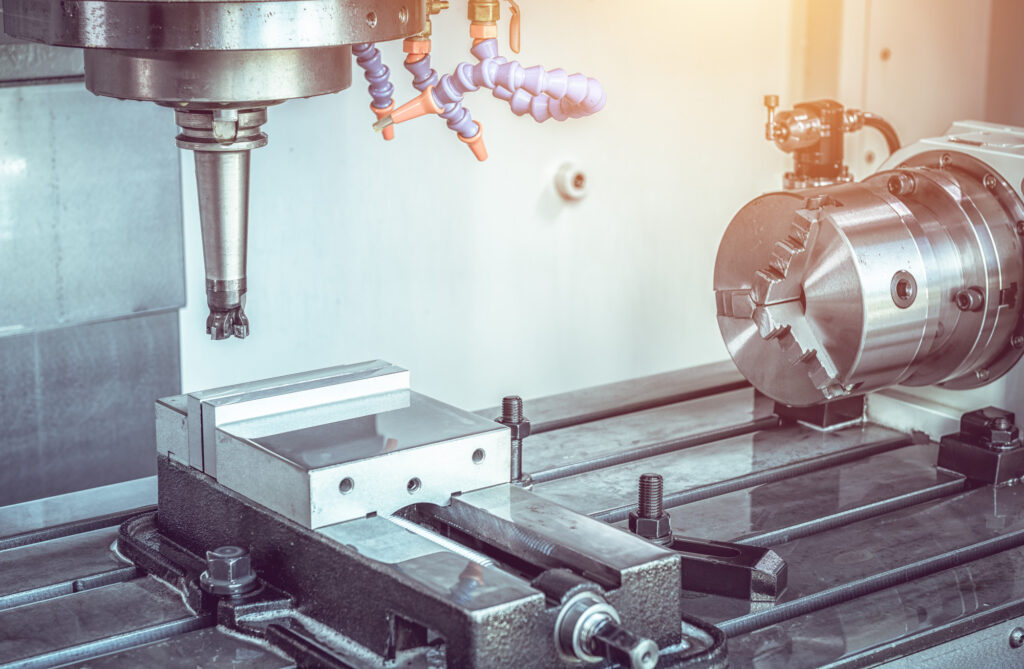

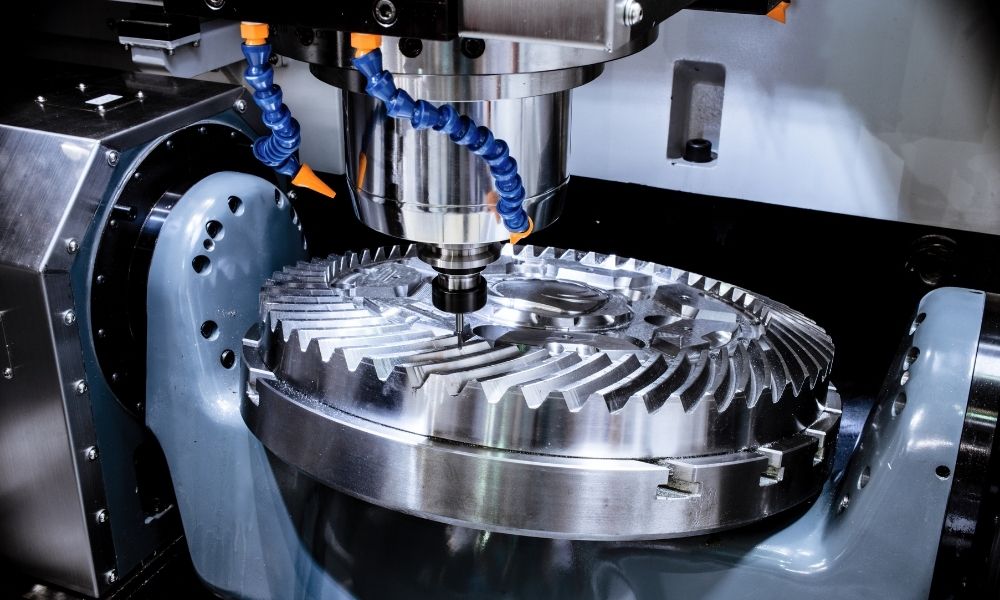

CNC machining remains the cornerstone of modern precision manufacturing, delivering unmatched accuracy, repeatability, and versatility essential for demanding industrial applications. At Honyo Prototype, we leverage state-of-the-art CNC milling and turning centers, operated by expert engineers, to transform complex designs into high-integrity components across diverse materials including aerospace alloys, medical-grade polymers, and engineered composites. Our process ensures stringent tolerances down to ±0.0002″ are consistently achieved, critical for functional prototypes and low-to-mid volume production runs where performance and reliability are non-negotiable.

Engineering Excellence Drives Your Project Forward

Beyond core machine capabilities, Honyo integrates advanced CAM programming, rigorous in-process inspection, and comprehensive material certifications to mitigate risk and accelerate time-to-market. We specialize in handling intricate geometries and tight-tolerance features that challenge conventional manufacturing, providing a seamless transition from CAD model to validated physical part. This commitment to technical excellence directly supports your engineering validation, reduces costly redesign cycles, and ensures components meet exact functional requirements on the first iteration.

Accelerate Your Development Timeline with Instant Quoting

Recognizing that speed is paramount in competitive development cycles, Honyo Prototype offers an industry-leading Online Instant Quote system. Simply upload your 3D CAD file to our secure platform and receive a detailed, transparent cost estimate and lead time within minutes – no manual RFQ delays. This immediate visibility empowers rapid decision-making and project initiation, allowing your engineering team to maintain momentum from concept through to qualified production. Leverage Honyo’s precision CNC capabilities and streamlined quoting process to gain a decisive advantage in your next manufacturing challenge.

Technical Capabilities

Advantage of CNC machines lies in their precision, repeatability, and ability to produce complex geometries across a variety of materials. 3-axis, 4-axis, and 5-axis milling systems offer increasing levels of contouring capability, while CNC turning centers provide high accuracy for rotational parts. When combined, mill-turn machining enables complete part fabrication in a single setup. These systems are ideal for achieving tight tolerances down to ±0.0002″ (±0.005 mm), critical in aerospace, medical, and automotive applications.

CNC machines process a wide range of materials including aluminum, steel, ABS, and nylon, each benefiting from optimized toolpaths, rigidity, and thermal stability inherent in modern CNC platforms.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Axis Movement | X, Y, Z linear axes | X, Y, Z + rotary A-axis (rotates around X) | X, Y, Z + two rotary axes (e.g., A & B or B & C) | Primary rotation (C-axis) + X & Z linear | Achievable on all platforms with proper setup and feedback systems |

| Typical Applications | Flat surfaces, prismatic parts, drilling, slotting | Indexed angular features, light contouring, multiple faces | Complex 3D contours, aerospace components, molds, impellers | Shafts, bushings, threaded parts, rotational geometries | Precision components: fittings, sensors, medical devices |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon (high-performance alloys also supported) | Aluminum, Steel, ABS, Nylon (bar stock form) | All materials with material-specific process control |

| Surface Finish (Typical) | 32–125 μin Ra | 32–64 μin Ra | 16–32 μin Ra (with finishing passes) | 16–63 μin Ra | Sub-micron finishes possible with fine tooling and polishing cycles |

| Positional Accuracy | ±0.001″ (±0.025 mm) | ±0.0005″ (±0.013 mm) | ±0.0002″ (±0.005 mm) | ±0.0003″ (±0.008 mm) | Up to ±0.0001″ (±0.0025 mm) with metrology-grade machines |

| Key Advantages | High speed for simple geometries, cost-effective | Additional angular access without manual repositioning | Full contouring in complex parts, reduced setup count | High repeatability for turned components, efficient material removal | Minimal part-to-part variation, ideal for critical fit/function applications |

Note: Performance depends on machine rigidity, control system (e.g., Fanuc, Siemens), tooling quality, and environmental conditions (temperature, vibration). Materials such as aluminum and ABS allow higher feed rates, while steel and nylon require optimized speeds and coolant strategies to maintain tolerance and surface integrity.

From CAD to Part: The Process

Honyo Prototype leverages advanced CNC machining capabilities through an integrated digital workflow designed to maximize precision, reduce lead times, and ensure manufacturability from initial concept to final delivery. Our proprietary process transforms standard CNC advantages into client-centric value through systematic optimization at every stage.

CAD Upload and AI-Powered Quoting

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) to our secure portal. Our AI-driven quoting engine analyzes geometric complexity, material requirements, and tolerance specifications in real time. This system cross-references Honyo’s CNC machine library—including 3-axis vertical mills, 5-axis indexed systems, and precision lathes—to generate accurate cost and lead time estimates within 2 hours. Unlike manual quoting, our AI identifies potential machining conflicts early, such as undercuts requiring specialized tooling or features exceeding standard spindle capabilities, preventing downstream delays.

Automated DFM Integration

Following quote acceptance, all designs undergo automated Design for Manufacturability (DFM) analysis. Honyo’s DFM engine evaluates CNC-specific parameters including tool accessibility, minimum wall thickness relative to cutter diameters, and optimal stock allowance. Critical feedback is delivered via an interactive dashboard highlighting actionable recommendations. For example, the system flags features requiring wire EDM instead of milling or suggests tolerance relaxations that maintain function while reducing machining cycles. This phase typically resolves 85% of manufacturability issues before programming begins, directly leveraging CNC flexibility to avoid costly redesign iterations.

Production Execution

Approved designs advance to CAM programming using Mastercam and Fusion 360, with toolpaths optimized for Honyo’s specific machine configurations. Our production floor utilizes IoT-connected CNC assets with real-time monitoring of spindle load, tool wear, and thermal drift. This enables dynamic adjustments to maintain ±0.005mm tolerances on critical features. High-mix production is managed through a digital work order system that sequences jobs to minimize machine changeover time, ensuring 95%+ spindle utilization. All first-article inspections are performed on-site using calibrated CMMs and optical comparators, with full inspection reports accessible via client portal.

Delivery and Traceability

Finished components undergo final cleaning, deburring, and packaging per client specifications before shipment. Each order includes a digital manufacturing dossier containing machine logs, tooling records, and inspection data synchronized to the original CAD model. Honyo’s logistics network provides real-time shipment tracking with guaranteed delivery windows, typically achieving 5–10 business day turnaround for standard prototypes. This closed-loop system ensures every CNC advantage—from micron-level accuracy to rapid setup flexibility—is fully realized in the delivered part.

The table below demonstrates how DFM interventions directly translate CNC capabilities into production outcomes:

| DFM Recommendation | CNC Capability Leveraged | Production Impact |

|---|---|---|

| Increasing internal corner radii from 0.5mm to 1.0mm | Standard end mill geometry optimization | Reduces machining time by 22% and eliminates tool breakage |

| Relaxing non-critical tolerances from ±0.025mm to ±0.05mm | Machine’s inherent repeatability limits | Cuts inspection time by 35% without functional compromise |

| Consolidating features into single setup orientation | 5-axis simultaneous machining capacity | Eliminates secondary operations, improving positional accuracy by 40% |

This end-to-end process ensures CNC machining delivers not just dimensional accuracy, but strategic advantages in speed-to-market and cost efficiency. By embedding manufacturing intelligence into each workflow phase, Honyo transforms CNC potential into guaranteed client outcomes.

Start Your Project

Leverage the precision, speed, and scalability of CNC machining for your next project. At Honyo Prototype, our advanced CNC capabilities in our Shenzhen factory ensure high-quality parts with fast turnaround times—ideal for prototypes and low-volume production.

Contact Susan Leo today to discuss your manufacturing needs and discover how our CNC solutions can improve your product development cycle.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.