Guide Contents

Project Insight: Advantage Of Cnc Machine

Precision & Speed: The Engine of Modern Product Innovation

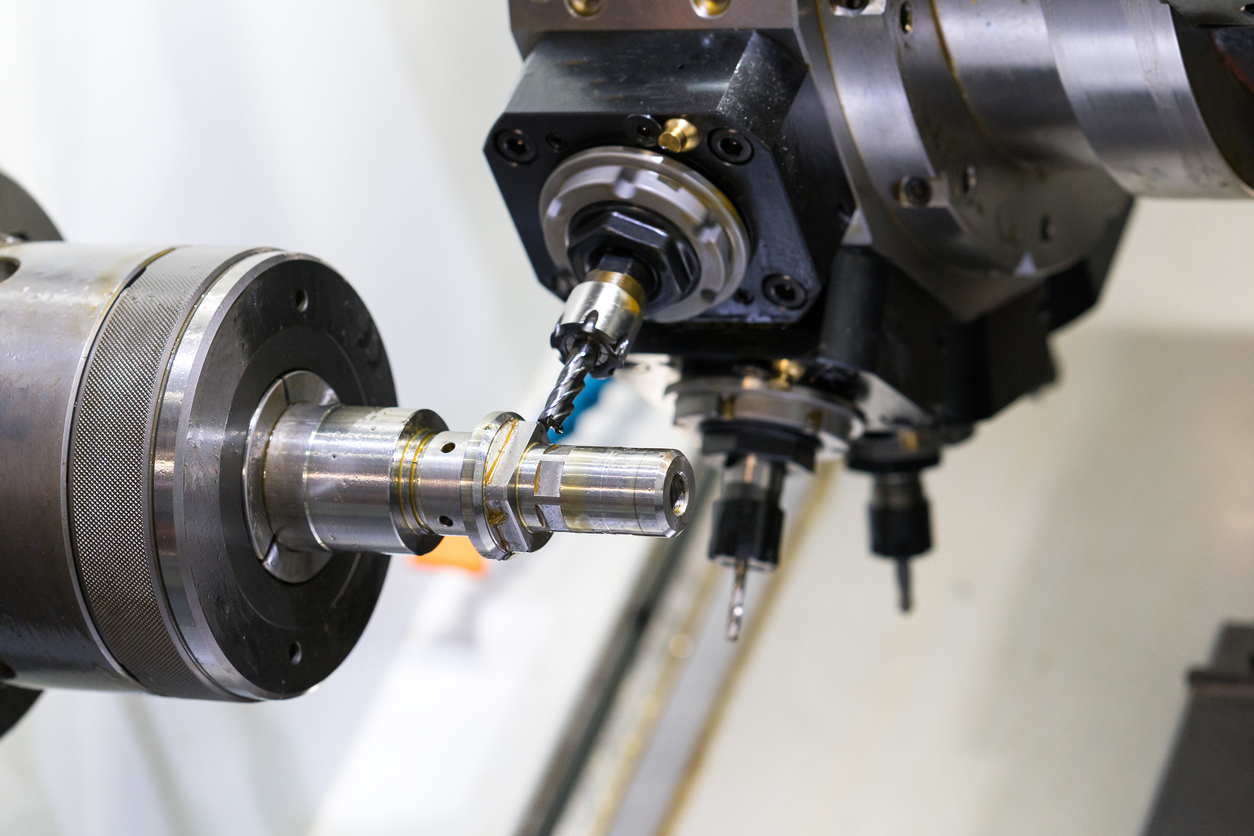

Uncompromising Precision for Mission-Critical Components

We achieve ±0.01mm tolerances with 3/4/5-axis CNC machining—critical for functional prototypes and end-use parts in aerospace, medical, and high-performance electronics.

Eliminate human error through fully automated, repeatable processes, ensuring consistency across every batch and eliminating costly rework.

Seamlessly handle complex geometries and tight tolerances, reducing assembly steps and enhancing product reliability for your most demanding applications.

Accelerated Time-to-Market Through Smart Manufacturing

Deliver prototypes in as little as 24 hours and production runs in 5–7 days—30% faster than industry averages.

Our AI-driven workflow optimization minimizes delays, maximizes machine utilization, and adapts to your project’s unique requirements in real time.

Real-time production tracking via digital dashboard keeps you informed at every stage—no more manual follow-ups or guesswork.

Digital-First Manufacturing Partner: Your 24/7 Innovation Ally

Instant online quotes in under 60 seconds—no more waiting for estimates or manual approvals.

AI-powered DFM (Design for Manufacturability) analysis flags potential issues before production begins, saving time, cost, and material waste.

Cloud-based collaboration tools connect your team with our engineers 24/7—seamlessly refining designs, tracking progress, and accelerating innovation.

At Honyo Prototype, we don’t just manufacture parts—we engineer solutions that turn your vision into reality, faster and with unmatched precision.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Precision Engineering at the Micron Level

3/4/5-Axis CNC Machining: Master complex geometries and intricate features with multi-axis precision for aerospace, medical, and robotics applications

Tight Tolerances (±0.01mm): Deliver functional prototypes and end-use parts that consistently meet the strictest specifications

Advanced Tooling & Fixturing: Minimize setup time and maximize accuracy for high-value components requiring micron-level consistency

Scalable Production for Every Stage

1 to 10,000+ Parts: Seamlessly transition from prototype to full-scale production without retooling or quality compromises

No Minimum Order Quantities (MOQs): Ideal for hardware startups iterating rapidly or testing new designs with zero financial risk

Flexible Scheduling: Dynamically adjust production volumes to match your project’s evolving needs

ISO-Certified Quality Assurance

ISO 9001 Certified Processes: Rigorous quality control at every stage of manufacturing, from raw material inspection to final delivery

100% In-Process Inspection: CMM and optical measurement systems ensure dimensional accuracy for critical features

Full Traceability: Complete digital documentation for compliance, audits, and continuous improvement

Digital-First Manufacturing Experience

Instant Online Quoting: Get accurate, transparent quotes in under 60 seconds via our AI-powered platform—no more waiting for manual estimates

AI-Optimized Design Feedback: Real-time DFM (Design for Manufacturability) analysis to prevent errors and optimize toolpaths before production starts

Industry-Leading Turnaround: Prototypes delivered in 3-5 days, production orders in 1-2 weeks with expedited options for critical projects

Materials & Surface Finishes

Material Options & Finishes: Precision Engineered for Your Vision

At Honyo Prototype, material selection isn’t just about compatibility—it’s about maximizing CNC machining’s precision advantages to deliver parts that meet exact functional and aesthetic demands. Our 3/4/5-axis capabilities ensure tight tolerances (+/- 0.01mm) across diverse materials, while strategic surface finishes enhance durability, conductivity, and visual appeal. Here’s how to align your design with CNC’s strengths:

Why Material Selection Matters for CNC Precision

Choosing the right material isn’t just about cost—it’s about leveraging CNC’s repeatability and accuracy to eliminate post-processing errors. Whether prototyping or producing end-use parts, our AI-driven platform analyzes your design specs to recommend materials that:

Maintain dimensional stability during high-speed machining

Resist deformation under tight-tolerance constraints

Optimize toolpath efficiency for cost-effective production

Precision-Ready Materials for Every Application

Aluminum 6061:

Why it excels: Exceptional machinability, corrosion resistance, and lightweight strength. Ideal for structural prototypes and aerospace components where CNC’s 5-axis precision ensures complex geometries without warping.

CNC advantage: Achieves +/- 0.01mm tolerances consistently, even in thin-walled designs.

Aluminum 7075:

Why it excels: High-strength aerospace-grade alloy for load-bearing parts. CNC’s rigid tooling and thermal management prevent micro-cracking during high-speed milling.

CNC advantage: Perfect for medical devices or drone frames requiring ultra-precise stress points.

Stainless Steel 304/316:

Why it excels: 304 for general corrosion resistance (food/medical); 316 for marine/chemical environments. CNC’s multi-axis capabilities handle intricate threads and micro-channels without distortion.

CNC advantage: Maintains surface finish integrity for sterile or high-wear applications.

Brass:

Why it excels: Electrical conductivity and machinability for connectors, valves, and decorative elements. CNC minimizes burrs and achieves fine surface details in a single setup.

CNC advantage: Ideal for parts requiring both precision and aesthetic polish.

PEEK (Polyether Ether Ketone):

Why it excels: High-temp, chemical-resistant polymer for aerospace, medical implants, and EV components. CNC’s controlled cutting prevents thermal degradation during machining.

CNC advantage: Delivers +/- 0.01mm tolerances for critical sealing surfaces and micro-fluidic channels.

Surface Finishes That Enhance Performance & Aesthetics

Anodizing (Type II/III):

For aluminum only. Enhances corrosion resistance and wear properties while allowing color customization. CNC’s smooth base surface ensures even dye absorption—critical for optical or consumer electronics.

Precision Polishing:

For metals/plastics. Achieves mirror-like finishes (Ra < 0.1μm) for optical components or medical devices. CNC’s vibration-free machining provides the ideal substrate for flawless polishing.

Powder Coating & Painting:

For complex geometries. CNC’s dimensional accuracy ensures uniform coating thickness, eliminating drips or uneven coverage. Ideal for automotive or industrial enclosures.

Bead Blasting:

For matte finishes. Creates consistent texture on stainless steel or aluminum parts—perfect for ergonomic grips or architectural elements.

Streamline Your Process with Honyo’s Smart Platform

Online Instant Quote:

Upload your CAD in seconds—our AI analyzes material compatibility, tolerances, and finishes to deliver a cost-optimized quote in <60 seconds. No manual back-and-forth.

AI-Powered Material Recommendations:

Get real-time suggestions based on your part’s function, environment, and performance needs. Our algorithms cross-reference 10,000+ historical projects to eliminate guesswork.

Fast Turnaround Guaranteed:

From quote to delivery in as little as 3 days. Our automated workflow and 24/7 machining capacity ensure your prototypes or production runs stay on schedule—without compromising precision.

“Precision isn’t just a specification—it’s the foundation of innovation. At Honyo, we engineer materials and finishes to turn your vision into reality, faster and smarter.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload CAD File – Instantly Ready for Production

Submit your design in any standard format (STEP, STP, STL, IGES, DWG) via our secure, cloud-based platform.

Real-time validation checks compatibility with our precision CNC capabilities (3/4/5-axis machining, ±0.01mm tolerances), eliminating guesswork before production begins.

No manual delays—your file is automatically optimized for manufacturability, reducing redesign cycles by up to 40%.

2. AI-Powered Instant Quote – Transparent Pricing in Seconds

Our proprietary AI engine analyzes geometry, materials, and tolerances to generate a competitive quote within 10 seconds—no waiting, no hidden fees.

See live cost breakdowns for materials, machining time, and surface finishes. Adjust parameters instantly to optimize cost without compromising quality.

Innovation highlight: AI-driven cost simulations predict savings for high-volume runs, helping startups scale efficiently.

3. Collaborative DFM Analysis – Optimize Before Production

Our engineering team reviews your design with AI-driven insights, suggesting improvements for manufacturability, cost efficiency, and performance.

Receive actionable feedback via the platform—modify designs in real-time, then re-quote instantly. No back-and-forth emails; all communication tracked in one place.

Solution-oriented benefit: Prevent costly errors early, ensuring your part meets functional requirements for prototypes or end-use applications.

4. Precision Production & Fast Delivery – On Time, Every Time

Once approved, your part enters our automated workflow: high-speed CNC machining with ±0.01mm precision, followed by ISO 9001-certified quality checks.

Track production progress in real-time with our digital dashboard. Standard lead times: 3–5 days for prototypes, 7–10 days for production runs—delivered globally with full traceability.

Why startups choose us: From design to delivery, we cut traditional lead times by 50% while maintaining aerospace-grade accuracy.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Engineering, Simplified

AI-Powered Instant Quoting

Upload your CAD file for real-time pricing, design-for-manufacturability feedback, and instant cost optimization—eliminating weeks of back-and-forth.

Fast Turnaround Guaranteed

Prototypes delivered in 3–5 days, production parts in 7–10 days—all while maintaining ±0.01mm tolerances across 3/4/5-axis CNC machining.

Founder-Driven Expertise

Susan Leo and our Shenzhen-based engineering team provide end-to-end support—from design refinement to final inspection—ensuring your parts meet functional and aesthetic requirements.

Ready to accelerate innovation?

📩 [email protected] | 📞 +86 139 2843 8620

📍 Explore our Shenzhen & Dongguan state-of-the-art facilities

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.