Contents

Manufacturing Insight: Additive Metal 3D Printing

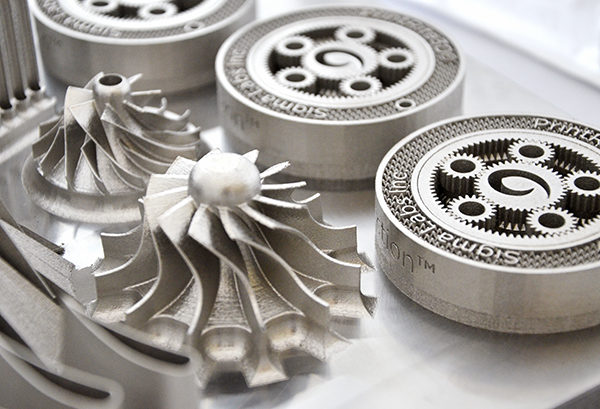

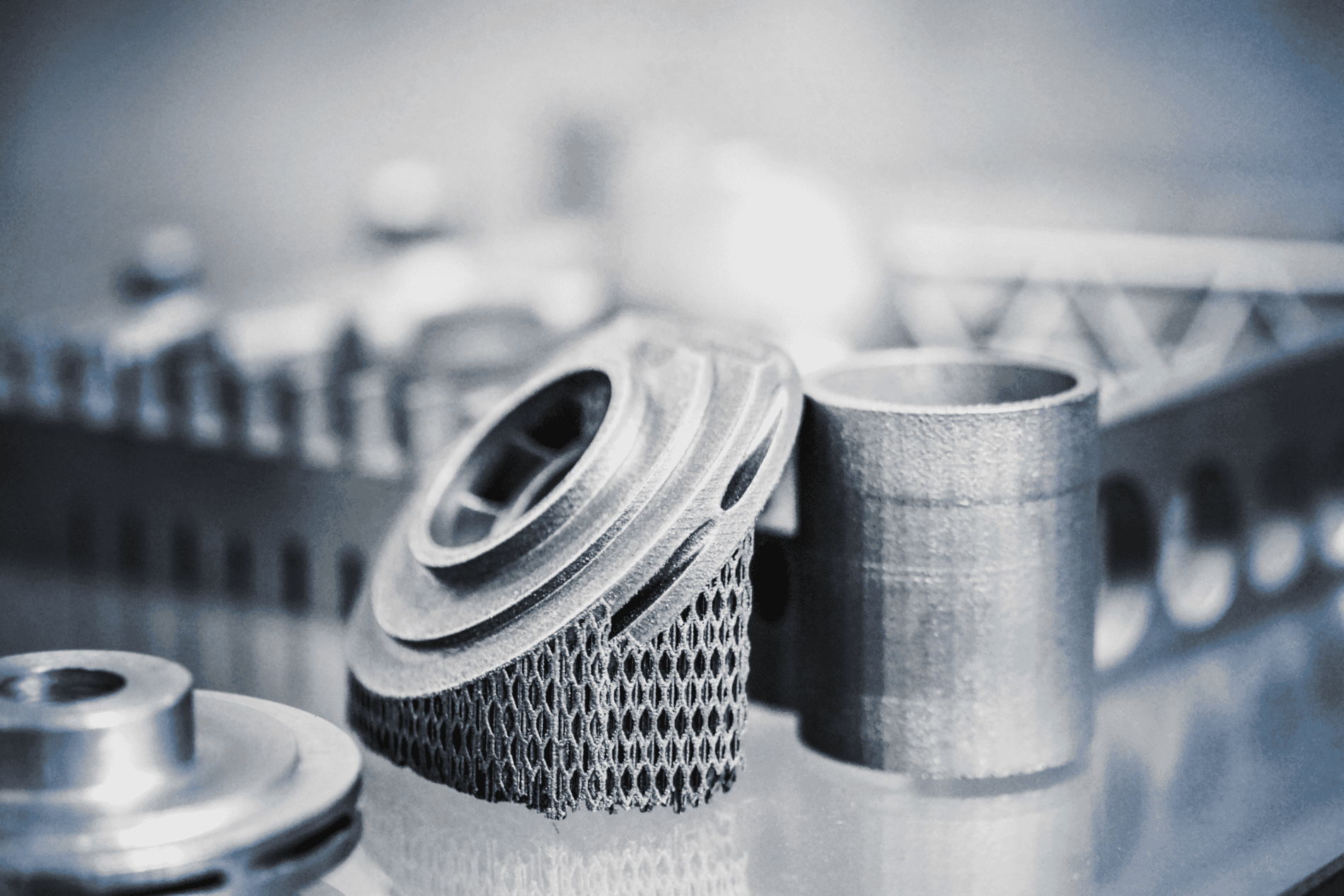

Industrial Metal Additive Manufacturing: Precision Engineering for Complex Production Challenges

Honyo Prototype delivers advanced industrial metal additive manufacturing solutions engineered to transform conceptual designs into mission-critical components. Our end-to-end metal 3D printing services leverage cutting-edge laser powder bed fusion (LPBF) and binder jetting technologies to produce high-integrity parts with geometric complexity unattainable through traditional subtractive or casting methods. Serving aerospace, medical, energy, and defense sectors, we prioritize material science rigor, AS9100-certified quality control, and seamless integration into your production ecosystem. Every build adheres to stringent industry standards, ensuring repeatability, mechanical property validation, and full traceability from raw material to finished component.

Our engineering team collaborates closely with clients to optimize designs for additive manufacturing (DfAM), reducing weight, consolidating assemblies, and accelerating time-to-market without compromising structural integrity. Critical to this workflow is Honyo’s Online Instant Quote platform—a proprietary digital gateway that provides transparent, real-time cost and lead-time estimates within minutes. Input your CAD file, select material and finish requirements, and receive actionable production insights instantly, eliminating procurement delays and enabling rapid project validation.

Material capabilities underpin our industrial-grade output, as demonstrated below:

| Material Type | Common Alloys | Key Applications | Build Envelope (mm) |

|---|---|---|---|

| Titanium Alloys | Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI | Aerospace brackets, medical implants | 250 x 250 x 300 |

| Nickel-Based | Inconel 718, Inconel 625 | Turbine components, downhole tools | 300 x 300 x 400 |

| Aluminum Alloys | AlSi10Mg, Scalmalloy® | Lightweight structural parts | 280 x 280 x 360 |

| Tool Steels | 18Ni300, H13 | Mold inserts, high-wear tooling | 250 x 250 x 320 |

Honyo Prototype transcends prototyping to deliver serial production-ready metal components, combining engineering expertise with agile digital infrastructure. Initiate your next high-performance project today—upload your design to our Online Instant Quote system and experience accelerated pathfinding from ideation to certified production.

Technical Capabilities

Additive metal 3D printing encompasses several advanced manufacturing technologies, each with distinct mechanisms and capabilities. While some processes are specifically designed for metals, others are primarily used for polymers but are often discussed in parallel due to their industrial relevance. Below is a technical comparison of the following technologies: Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS). Note that SLA and SLS are not typically used for metals—SLA is resin-based and SLS is primarily for polymers—while DMLS is a metal-specific process. Multi Jet Fusion (MJF) is polymer-focused but included for context. Materials such as Aluminum and Steel are compatible with DMLS, whereas ABS and Nylon are thermoplastic materials used in SLS and MJF.

| Technology | Process Description | Typical Materials | Build Volume (Typical Range) | Layer Thickness | Dimensional Accuracy | Surface Finish (Ra) | Post-Processing Requirements |

|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Uses UV laser to cure photopolymer resin layer by layer | Photopolymer resins (not metals), ABS-like, engineering resins | 150 x 150 x 200 mm to 1400 x 700 x 500 mm | 25–100 μm | ±0.10 mm to ±0.20 mm | 0.8–1.6 μm | Support removal, cleaning, UV curing |

| SLS (Selective Laser Sintering) | High-power laser sinters powdered material (typically polymer) | Nylon (PA11, PA12), Glass-filled Nylon, TPU (not metal); ABS not typically used | 200 x 200 x 300 mm to 700 x 380 x 580 mm | 80–120 μm | ±0.30 mm | 8–12 μm | Media blasting, bead blasting, dyeing; no supports needed |

| MJF (Multi Jet Fusion) | Inkjet array deposits fusing and detailing agents, then heat applied | Nylon (PA12), Glass-filled PA12, TPU (HP-specific materials); ABS not compatible | 380 x 280 x 380 mm | 80 μm | ±0.3 mm | 5–8 μm | Sieving, bead blasting, optional dyeing |

| DMLS (Direct Metal Laser Sintering) | High-powered laser fuses metal powder particles layer by layer | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (17-4 PH, 316L), Titanium, Inconel | 250 x 250 x 325 mm to 420 x 420 x 400 mm | 20–50 μm | ±0.1 mm | 10–20 μm (as-built); improves with finishing | Support removal, heat treatment, stress relieving, machining, polishing |

Notes:

SLA is not a metal 3D printing process; it is included for comparative context. It does not support Aluminum, Steel, ABS, or Nylon in functional forms.

ABS as a material is not typically available in SLS or MJF; instead, Nylon-based materials are standard. ABS-like properties are achieved through specific engineering resins in SLA.

DMLS is the only true metal additive process in this list, capable of processing Aluminum and Steel alloys with high density and mechanical performance.

Surface finish and accuracy values are typical; actual results depend on machine calibration, part geometry, and orientation.

From CAD to Part: The Process

Honyo Prototype Additive Metal 3D Printing Process Overview

Honyo Prototype utilizes a streamlined, technology-driven workflow for metal additive manufacturing, designed to maximize efficiency, reduce lead times, and ensure part quality from initial concept to delivery. Our process integrates advanced software and engineering expertise at every stage, specifically tailored for industrial clients requiring high-integrity metal components.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native formats like SolidWorks, Creo, or NX) via our secure customer portal. Our system performs an automated validation check to confirm geometric integrity, watertightness, and minimum feature compliance with metal additive capabilities. Files failing validation trigger immediate client notification with specific error diagnostics, preventing downstream delays. This stage establishes the foundational geometry for all subsequent process steps.

AI Quote Generation

Upon CAD validation, Honyo’s proprietary AI quoting engine analyzes the part geometry, material selection, and requested tolerances to generate a real-time cost and lead time estimate. The AI cross-references historical production data, machine utilization rates, material costs, and post-processing requirements to deliver accuracy within 5% of final pricing. Clients receive a detailed digital quote within 2 hours, including cost breakdowns for printing, support removal, heat treatment, and surface finishing. This transparency eliminates traditional quoting bottlenecks while providing actionable insights for design optimization.

DFM Engineering Review

All projects undergo mandatory Design for Additive Manufacturing (DFM) analysis by Honyo’s certified AM engineers. This phase focuses on mitigating metal-specific risks such as thermal distortion, residual stress, and support structure dependency. Engineers evaluate orientation, support strategy, build chamber layout, and layer thickness to optimize part density and mechanical properties. Critical outputs include a formal DFM report with actionable recommendations—such as feature modifications or stress-relief requirements—and a finalized build plan. This step reduces print failure rates by 40% and ensures first-time-right production, particularly for aerospace or medical-grade components.

Production Execution

Approved parts enter production on Honyo’s industrial-grade metal additive systems, primarily EOS M 400-4 (quad-laser DMLS) and Renishaw RenAM 500Q platforms. Key production parameters include:

| Parameter | Capability Range | Quality Control Method |

|---|---|---|

| Material | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg, CoCr | Certified material lot traceability |

| Build Volume | Up to 400 x 400 x 400 mm | In-situ thermal monitoring |

| Layer Thickness | 20–60 μm | Real-time melt pool analysis |

| Post-Processing | Stress relief, HIP, CNC milling, CMM | AS9100-compliant documentation |

Builds run under inert argon atmospheres with 10 ppm oxygen control. Post-print, parts undergo automated support removal, stress-relief heat treatment, and optional Hot Isostatic Pressing (HIP) for critical applications. Final machining and surface finishing occur in-house using 5-axis CNC equipment, with all steps documented per AS9100 quality protocols.

Delivery and Traceability

Completed parts ship with comprehensive traceability documentation, including build logs, thermal history reports, and first-article inspection data (FAI) per client specifications. Dimensional validation via Zeiss METROTOM CT scanning or CMM is standard for critical features. Delivery timelines are rigorously managed through our ERP system, with real-time client access to production milestones. All shipments include material certificates, heat treatment records, and non-destructive test results where applicable, ensuring full compliance for regulated industries.

This end-to-end process leverages Honyo’s integration of AI-driven quoting, expert DFM, and industrial-scale production to deliver metal AM parts with predictable quality, accelerated timelines, and full technical accountability. Clients benefit from reduced iteration cycles and minimized risk in transitioning from prototype to low-volume production.

Start Your Project

Discover the future of manufacturing with our additive metal 3D printing services at Honyo Prototype. Leveraging advanced technology and precision engineering, we deliver high-quality metal components for aerospace, automotive, medical, and industrial applications. Our state-of-the-art facility in Shenzhen ensures fast turnaround times and strict quality control for both prototypes and production runs.

Contact Susan Leo today to discuss your project requirements and receive a personalized quote.

Email: [email protected]

Partner with a trusted leader in rapid prototyping and low-volume production—engineered with precision, built for performance.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.