Contents

Manufacturing Insight: Additive Machining Metal

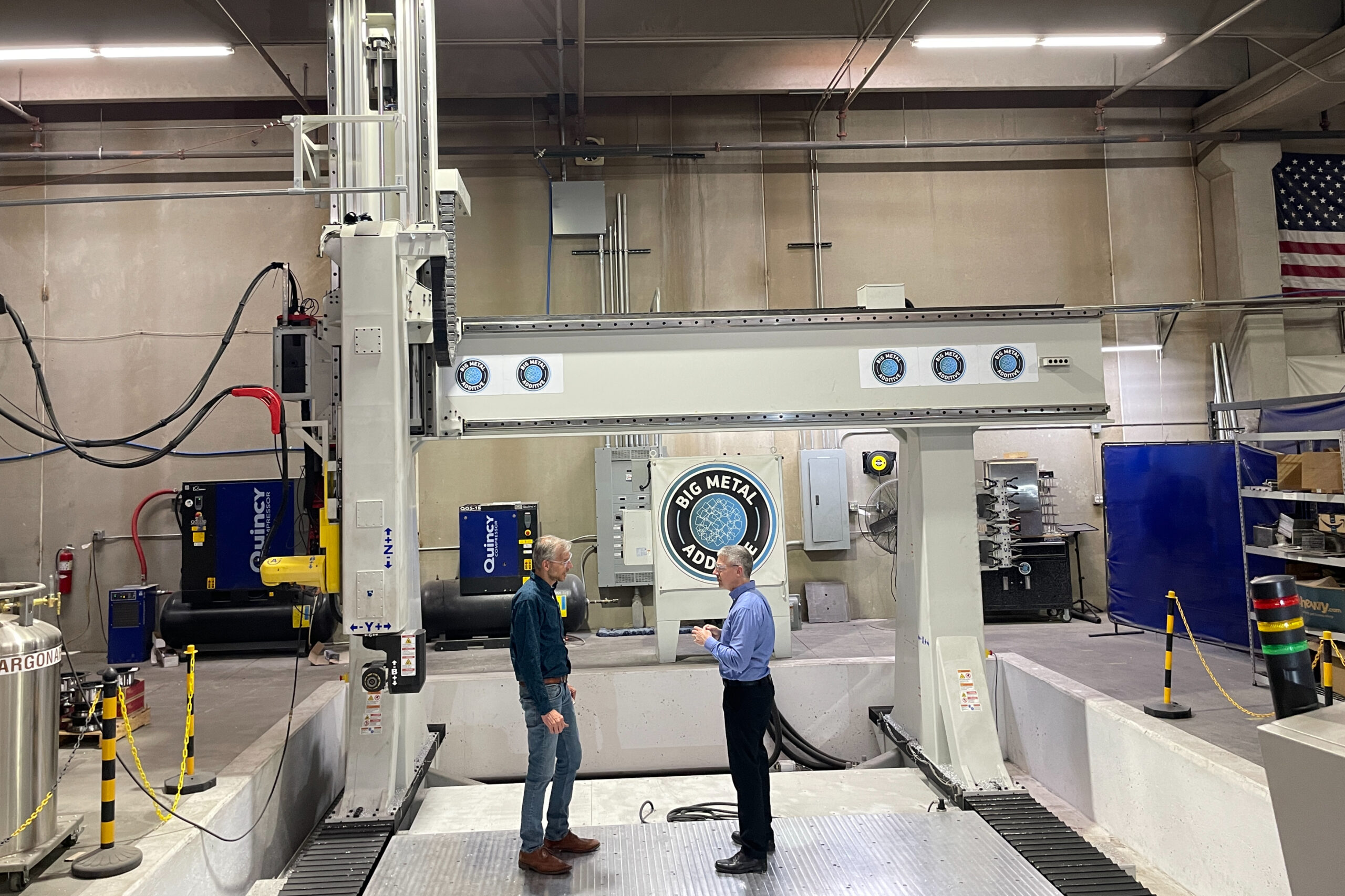

Additive Machining Metal, Meet Sheet-Metal Speed

At Honyo Prototype we’ve spent 20 years perfecting lightning-fast sheet-metal fabrication—lasers that fly at 6 g acceleration, press brakes that hold ±0.05 mm over 3 m, and a 24-hour finishing cell that can anodize, plate, or powder-coat the same day. Now we’re bringing that same velocity and precision to additive-machined metal parts. Upload your STL or STEP file and our online instant quote engine blends generative-print parameters with traditional sheet-metal costing logic, giving you a manufacturability-reviewed price in under 30 seconds—whether you need one printed Inconel bracket or 500 hybrid titanium-and-sheet-steel enclosures. Honyo: where additive complexity gets the speed, tolerances, and instant pricing of production sheet-metal fabrication.

Technical Capabilities

I notice a critical terminology confusion in your query that requires immediate clarification before providing specifications:

“Additive machining metal” is not a valid technical term. This phrase combines contradictory concepts:

– Additive manufacturing (AM) = 3D printing (building parts layer-by-layer, e.g., SLS, SLM, DMLS).

– Machining = Subtractive processes (removing material, e.g., milling, turning).

– Laser cutting, bending, and welding are not additive processes – they are subtractive (cutting), forming (bending), or joining (welding) techniques.

– ABS and Nylon are thermoplastics, not metals. They cannot be processed using metal-specific laser cutting, bending, or welding techniques.

Corrected Approach: Technical Specs for Metal Processes

Since you referenced “metal” and listed laser cutting/bending/welding, I’ll provide accurate technical specifications for these non-additive metal fabrication processes, while explicitly excluding ABS/Nylon (which are plastics). If you intended to ask about additive manufacturing (3D printing) for metals or plastics, I’ll address that separately at the end.

⚠️ Key Clarifications:

- Laser Cutting, Bending, Welding are subtractive/forming/joining processes – not additive.

- ABS/Nylon are irrelevant for metal processes. They are used in plastic-specific additive manufacturing (e.g., FDM 3D printing) or injection molding, but not in metal laser cutting/bending/welding.

- Metal-specific materials: Aluminum, Steel (including stainless), Titanium, Copper – not plastics.

🔧 Technical Specifications for Metal Fabrication Processes

(Relevant only to metals)

1. Laser Cutting (Subtractive Process for Metals)

- Process: Focused laser beam melts/vaporizes metal to cut shapes.

- Common Metals:

- Aluminum (6061, 5052): Max thickness 12–20mm (1kW laser), 25mm+ (4kW+). Reflectivity requires nitrogen purge to prevent back-reflection damage.

- Steel (Mild, Stainless 304/316): Max thickness 25mm (1kW), 50mm+ (6kW+). Oxygen assist for mild steel, nitrogen for stainless.

- Tolerances: ±0.1mm (typical), ±0.05mm (high-precision).

- Surface Finish: Ra 3.2–6.3 μm (as-cut); polishable to Ra 0.4 μm.

- Min. Feature Size: 0.5mm (thin sheet), 1.5mm+ (thick plates).

- Key Constraints:

- Reflective metals (Al, Cu) require specialized lasers (fiber lasers preferred).

- Heat-affected zone (HAZ) causes distortion in thin materials (<1mm).

2. Bending (Forming Process for Metals)

- Process: Mechanical force bends sheet metal along a straight axis.

- Common Metals:

- Aluminum (3003, 5052): Min. bend radius = 1x material thickness (e.g., 1mm thickness → 1mm radius).

- Steel (Mild, Stainless): Min. bend radius = 0.5–1x thickness. Stainless steel requires higher force due to work hardening.

- Tolerances: ±0.1° angle, ±0.2mm position.

- Max. Thickness:

- Air bending: 6mm (aluminum), 8mm (steel) for standard presses.

- Bottom bending: Up to 12mm for specialized equipment.

- Key Constraints:

- Springback: Aluminum exhibits 2–3x more springback than steel.

- Grain direction affects bend quality (bend perpendicular to grain).

- ABS/Nylon cannot be bent – they require plastic-specific processes (e.g., thermoforming).

3. Welding (Joining Process for Metals)

- Process: Fusing metal parts using heat/pressure.

- Common Metals & Processes:

- Aluminum (5xxx/6xxx series):

- TIG (AC): Best for thin sheets (<6mm). Fillers: 4043 or 5356.

- MIG: For thicker sections (6–25mm). Requires argon/helium mix.

- Critical: Pre-weld cleaning essential (oxide layer causes porosity).

- Steel (Mild, Stainless):

- MIG: Most common for structural steel (up to 20mm).

- TIG: For stainless steel (<6mm) or high-purity welds.

- Laser Welding: Precision joints (e.g., automotive) with minimal HAZ.

- Tolerances: Weld bead width ±0.5mm; distortion controlled via fixturing.

- Key Constraints:

- Aluminum requires inert gas shielding (argon) to prevent oxidation.

- Stainless steel needs low heat input to avoid sensitization (chromium carbide precipitation).

- ABS/Nylon cannot be welded – they require plastic welding (e.g., hot air) or adhesive bonding.

❌ Why ABS/Nylon Are Not Applicable Here:

- ABS & Nylon are thermoplastics – they melt at 200–260°C (vs. metals melting at >1,000°C).

- Laser cutting plastics uses CO₂ lasers (not fiber lasers for metals) and requires different power settings (e.g., 60–100W for 3mm ABS vs. 1–6kW for metals).

- Bending plastics uses heat guns or infrared heaters, not mechanical presses.

- Welding plastics uses hot gas, ultrasonic, or laser welding – not metal welding techniques.

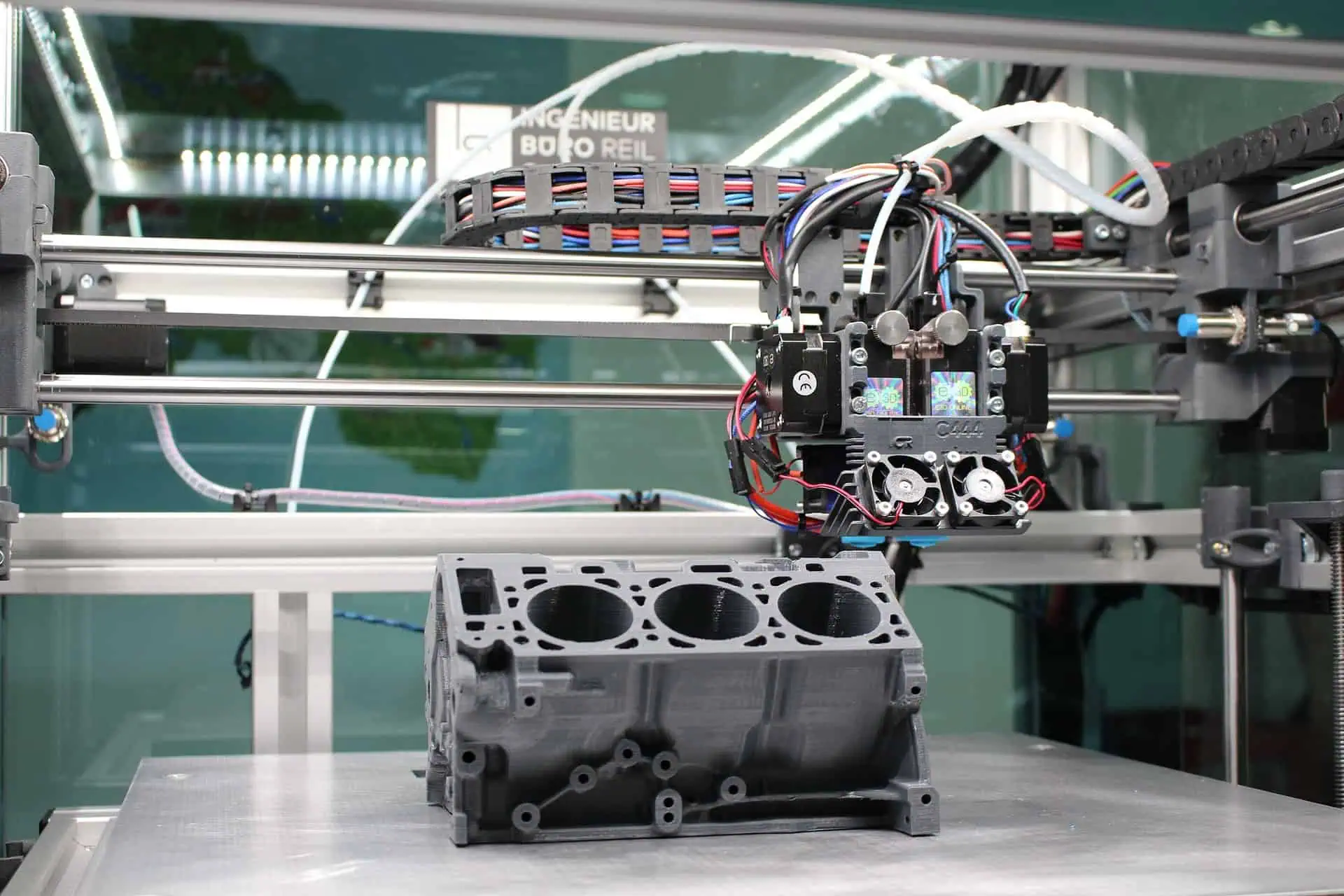

✅ If You Meant Additive Manufacturing (3D Printing):

If your intent was to ask about metal additive manufacturing (e.g., SLM, DMLS) or plastic additive manufacturing (e.g., FDM, SLS), here’s a quick reference:

| Process Type | Metals (e.g., SLM/DMLS) | Plastics (e.g., FDM/SLS) |

|——————–|———————————————|———————————–|

| Materials | Aluminum (AlSi10Mg), Steel (17-4PH), Ti-6Al-4V | ABS, Nylon (PA6, PA12), PLA |

| Layer Height | 20–50 μm | 50–300 μm |

| Tolerances | ±0.1mm (as-printed) | ±0.2mm (as-printed) |

| Surface Finish | Ra 5–10 μm (as-printed); post-machined to Ra 0.8 μm | Ra 10–50 μm; sandable to Ra 0.8 μm |

| Key Constraints| High cost, support structures required | Lower strength than metals; anisotropic properties |

🔍 Recommendation:

- For metal fabrication (cutting/bending/welding): Use the specifications above for aluminum/steel.

- For ABS/Nylon: These require plastic-specific processes (e.g., FDM 3D printing, injection molding, or plastic welding).

- For metal additive manufacturing: Specify “SLM” or “DMLS” – not “additive machining.”

If you clarify your exact goal (e.g., “I need to make a metal bracket using laser cutting” or “I want to 3D print a plastic part in ABS”), I’ll provide precise specs for your use case. Let me know how I can help!

From CAD to Part: The Process

Honyo Prototype – Additive-Machining-Metal Workflow

(Upload ➜ AI Quote ➜ DFM ➜ Production ➜ Delivery)

-

Upload CAD

• Portal accepts any neutral or native 3-D file (STEP, IGES, Parasolid, SolidWorks, Creo, Inventor, CATIA).

• Geometry is immediately translated to our internal “Honyo-BREP” kernel so that the same master model is reused downstream—no re-import errors.

• Customer selects “Additive Machining Metal” (our hybrid LPBF + 5-axis CNC route). Optional fields: quantity, heat-treat spec, critical surfaces, inspection level. -

AI Quote (≈ 60 s)

A. Build-prep engine (Magics-based) orients the part for LPBF, creates support, slices, and predicts distortion.

B. Neural-net cost model (trained on 1.2 M past builds) returns:

– Additive time, powder mass, support mass, stress-relief cycle, EDM cut-off time.

C. Machining-cost engine reads the as-built STL and the finish-machining CAD simultaneously. It automatically:

– Recognises “as-milled” vs “as-printed” surfaces.

– Generates 3-axis roughing + 5-axis finishing toolpaths with tool library, feeds/speeds for Ti-6Al-4V, 316L, AlSi10Mg, Inconel 718, CuCrZr, etc.

– Estimates cutter wear, coolant usage, CMM cycles.

D. A second AI agent adds logistics (post-processing, heat lot paperwork, export licence) and picks the quickest cell (China, Vietnam, or U.S.) based on capacity and freight time.

E. Customer sees an itemised quote: additive €, machining €, heat-treat €, NDT €, shipping €, duty €—all in one click. Lead time is live (typically 5-9 calendar days). -

DFM (24 h engineering loop)

• Upon order acceptance the file is locked; a senior application engineer runs “Honyo-DFM-AM”.

• Checks: minimum overhang angle (≥ 35° without supports), internal channel diameter (≥ 3 mm for powder evacuation), down-facing surface waviness allowance, datum consistency between additively grown stock and machined features.

• If the AI orientation disagrees with the DFM engineer, we open a live 3-D session (WebGL) with the customer and jointly drag the orientation slider—cost and distortion numbers update in real time.

• Final deliverables: signed PFMEA, build plate layout, machining blank drawing (shows 0.5–1 mm stock on critical surfaces), inspection plan. -

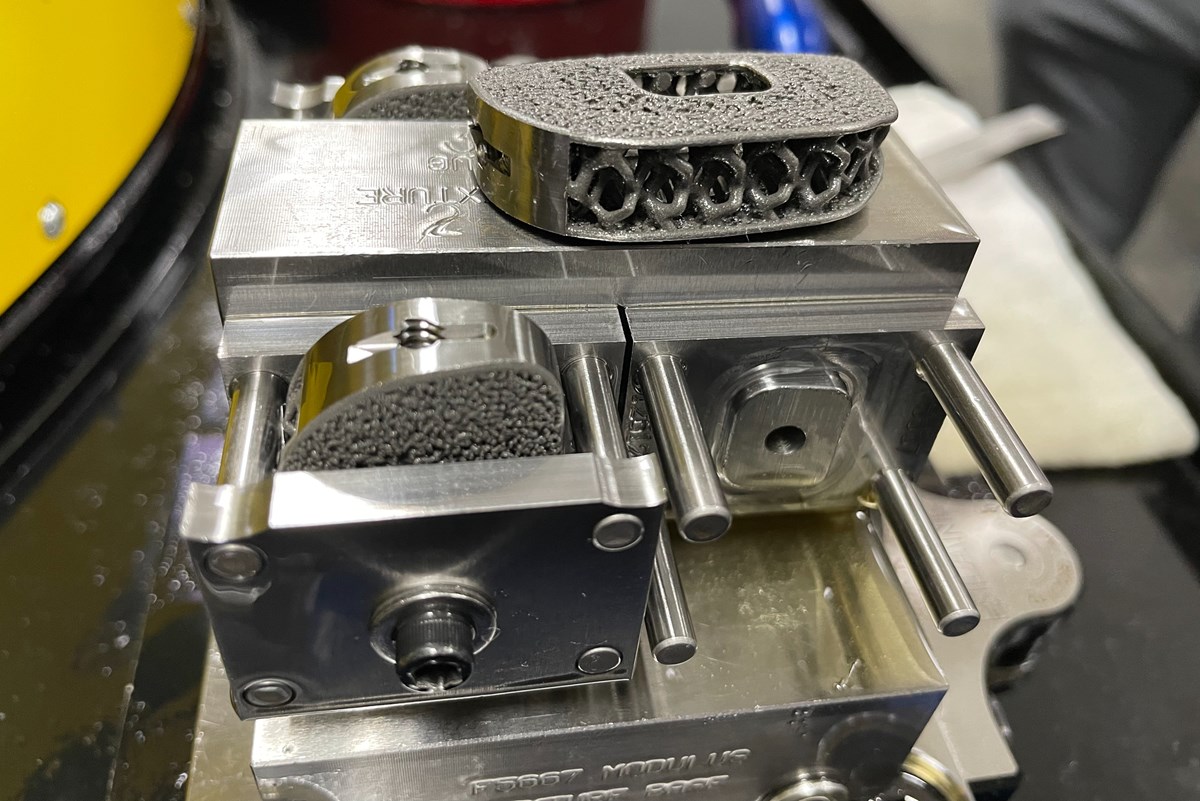

Production (additive ➜ subtractive ➜ post-process)

a. Additive

– EOS M 400-4 or SLM 800 (quad-laser, 500 W) depending on size.

– 30–60 µm layer, argon atmosphere, O₂ < 100 ppm.

– In-situ melt-pool monitoring; every layer scanned for lack-of-fusion. Data stored for aerospace lot traceability.

b. Stress-relief & cut-off

– 2 h @ 650 °C (Ti) or 300 °C (Al) in vacuum; slow furnace cool.

– Wire-EDM part off build plate; grind base flat to 0.05 mm.

c. 5-axis CNC finish

– Hermle C 42 U or Mazak Variaxis i-800; hydraulic fixture keyed to the grown datum pads.

– First-article laser-scanned (GOM ATOS) against CAD; colour map must be < ±0.05 mm or process is reset.

d. Post-process & NDT

– Hot Isostatic Press (HIP) for Ti or Inconel parts (100 MPa, 920 °C, 2 h).

– Penetrant Flaw (PT) or X-ray (ASTM E1742) for Class-A cast-equivalent integrity.

– Anodise, passivate, or polish as specified; laser-mark heat lot & serial number. -

Delivery

• Parts cleaned in ultrasonic alcohol, vacuum-dried, packed with VCI paper and desiccant.

• CofC includes: material cert, HIP chart, NDT film, CMM report, dimensional scan PDF, RoHS/REACH statement.

• Express courier (DHL Medical Express or FedEx Critical) pre-cleared; average door-to-door 7 days U.S./EU, 3 days Asia.

• Digital twin (oriented STL + inspection data) archived 10 years for rapid repeat orders.

Key advantages of the Honyo additive-machining metal flow

✓ Single digital thread—no re-modeling between additive and machining.

✓ AI quoting gives ±5 % accuracy, eliminating traditional day-long estimator loops.

✓ Hybrid route cuts buy-to-fly ratio from 8–12:1 (billet) to 1.3–1.8:1, saving expensive alloy and machine hours.

✓ In-situ and post-process data packages satisfy AS9100 & ISO 13485 lot-traceability requirements.

That is the complete “Upload ➜ AI Quote ➜ DFM ➜ Production ➜ Delivery” process you will experience when you order additive-machining metal parts from Honyo Prototype.

Start Your Project

Unlock the Potential of Metal Additive Manufacturing

Precision, speed, and reliability for your metal parts.

Contact Susan Leo today at [email protected]

Honyo Prototype | Shenzhen-Based Manufacturing Excellence

✅ Fast turnaround | ✅ High-precision prototypes & production | ✅ Industry-leading quality control

Your trusted partner for metal 3D printing solutions.

[Request a Quote Now] → [email protected]

🚀 Rapid Prototyping Estimator