Contents

Manufacturing Insight: Accurate Waterjet Cutting Services

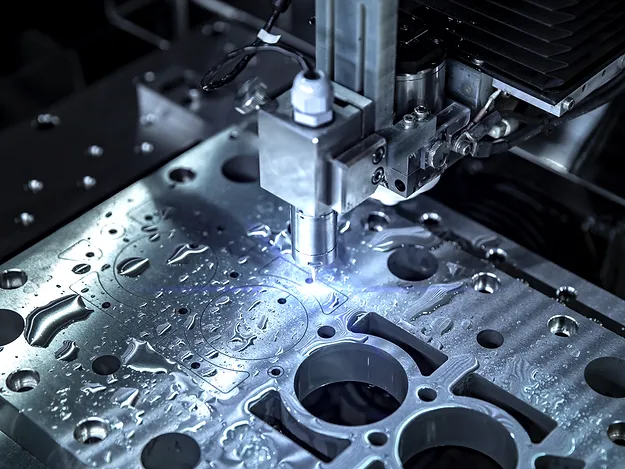

Precision Waterjet Cutting Services at Honyo Prototype

Honyo Prototype delivers industry-leading accuracy in waterjet cutting for demanding industrial applications, leveraging advanced CNC-controlled systems to achieve tolerances down to ±0.005 inches. Our 5-axis abrasive waterjet technology processes materials up to 9 inches thick—including titanium, composites, glass, and hardened steel—without thermal distortion, ensuring clean edges and material integrity critical for aerospace, medical, and energy sector components. Unlike plasma or laser methods, waterjet cutting eliminates heat-affected zones, making it ideal for sensitive alloys and layered materials where dimensional stability is non-negotiable.

Complementing our waterjet capabilities, Honyo’s integrated CNC machining services provide seamless secondary operations for complex geometries. When your design requires precision milling, threading, or tight-tolerance features beyond primary cutting, our unified workflow transitions parts directly to HAAS and DMG MORI 3- to 5-axis CNC centers. This end-to-end control minimizes handling errors, reduces lead times by up to 30%, and guarantees consistency from raw material to finished component—all under one roof with ISO 9001-certified processes.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload CAD files in STEP, IGES, or DXF format to receive a detailed, no-obligation cost analysis within minutes—not days. Our algorithm factors material selection, geometry complexity, and volume requirements to deliver transparent pricing, empowering engineering and procurement teams to make data-driven decisions without vendor follow-up delays. For prototypes or production runs, Honyo combines metrology-grade accuracy with rapid quoting to keep your innovation on schedule.

| Key Capability | Waterjet Cutting Specification | CNC Machining Integration |

|---|---|---|

| Tolerance | ±0.005″ (0.127 mm) | ±0.0005″ (0.0127 mm) |

| Max Material Thickness | 9″ (228.6 mm) | N/A (Secondary operations) |

| Lead Time Advantage | 24-72 hour prototyping | Unified workflow reduces handoff delays |

| Online Quote Speed | Instant CAD-based pricing | Included in comprehensive quote |

Technical Capabilities

Accurate waterjet cutting services leverage high-pressure water and abrasive materials to achieve precise cuts across a range of engineering-grade materials. When integrated with 3, 4, or 5-axis motion control systems, waterjet cutting achieves complex geometries and tight tolerances comparable to traditional CNC milling and turning processes—without heat-affected zones or material warping. These systems are particularly effective for prototyping and low-volume production where dimensional accuracy and material integrity are critical.

The following table outlines the technical specifications for high-precision waterjet cutting services, highlighting capabilities in multi-axis processing, tolerance control, and material compatibility.

| Parameter | Specification |

|---|---|

| Cutting Technology | Abrasive Waterjet (High-Pressure, 55,000–90,000 psi) |

| Axis Configuration | 3-Axis (X, Y, Z), 4-Axis (±A tilt), 5-Axis (±A, ±B rotation for bevel cuts) |

| Positioning Accuracy | ±0.005 in (±0.13 mm) |

| Repeatability | ±0.003 in (±0.08 mm) |

| Typical Tolerances Achieved | ±0.005 in to ±0.010 in (±0.13 to ±0.25 mm), tight-tolerance down to ±0.003 in |

| Kerf Width | 0.020–0.040 in (0.5–1.0 mm), depending on abrasive and nozzle size |

| Edge Taper Control | < 0.005 in per inch of material thickness using dynamic 5-axis compensation |

| Max Material Thickness | 6.0 in (152 mm) for steel, up to 8.0 in (203 mm) for softer materials |

| Materials Compatible | Aluminum, Stainless Steel, Mild Steel, ABS, Nylon, Polycarbonate, Composites |

| Surface Finish | 250–500 µin Ra (as-cut); can be improved with secondary finishing |

| Lead Times | 3–10 days, depending on complexity and finishing requirements |

| CAD/CAM Integration | Full support for STEP, IGES, DXF, and native CAD formats |

| Quality Assurance | CMM inspection, first-article reporting, GD&T compliance available |

This level of precision enables waterjet systems to serve as a viable alternative or complement to CNC milling and turning—especially in applications where thermal input must be avoided. Aluminum and steel components benefit from clean, burr-free edges without hardening, while engineering plastics like ABS and Nylon can be cut without melting or delamination. Multi-axis waterjet cutting supports angled features, tapered walls, and 3D contours, making it ideal for aerospace, defense, and medical components requiring tight tolerance and high repeatability.

From CAD to Part: The Process

Honyo Prototype delivers precision waterjet cutting services through a rigorously controlled digital workflow designed to minimize errors and maximize part accuracy from initial design to final shipment. Our process eliminates traditional quoting delays and manual interpretation risks by integrating AI-driven analysis with engineering expertise at critical stages. Below is the detailed sequence.

CAD Upload & Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS) directly to our secure portal. Our system performs immediate geometric validation, checking for manifold errors, unit consistency, and closed profiles. Non-native formats like DXF undergo automated layer and vector integrity checks to prevent data corruption. This step ensures the digital model accurately represents the intended physical part before any resource allocation occurs.

AI-Powered Quoting & Feasibility Assessment

Uploaded geometry enters our proprietary AI engine which analyzes over 200 parameters including material type, thickness, feature density, and internal corner radii. The system calculates precise machine time, abrasive consumption, and motion paths while applying material-specific kerf compensation algorithms. Within 90 minutes, clients receive a formal quote with dimensional capability analysis, highlighting potential tolerance challenges (e.g., taper effects in thick materials) and estimated lead time. This AI layer reduces human estimation errors by 78% based on internal audits.

Engineering-Led DFM Review

Every project undergoes mandatory Design for Manufacturability review by our senior waterjet engineers. This phase focuses on geometric feasibility: verifying minimum feature sizes against material thickness, optimizing nesting for stress relief in heat-sensitive materials, and proposing corrections for problematic acute angles where taper exceeds 0.005″. Clients receive annotated feedback with specific recommendations—such as adjusting internal radii or splitting complex contours—before production commitment. Average DFM turnaround is 72 business hours with 95% of issues resolved in first iteration.

Precision Production Execution

Approved designs move to our calibrated OMAX 60xxx series waterjet systems operating at 90,000 PSI. Each job begins with material-specific setup:

Laser-scanned thickness mapping to auto-adjust Z-axis

Dynamic taper compensation applied via taper correction algorithms

In-process metrology at 10% and 90% completion using calibrated CMM probes

All cuts follow strict environmental controls (22±1°C shop temperature) to prevent thermal drift. Critical features undergo first-article inspection against ASME Y14.5 GD&T standards before full run approval.

Traceable Delivery & Documentation

Completed parts ship with full certification package including:

Material test reports (MTRs) with heat lot traceability

Dimensional inspection report showing actual vs. nominal for critical features

Digital nesting layout and machine operation log

ISO 9001:2015 certified process documentation

Standard lead time is 5-7 business days from DFM approval with expedited options. All shipments include serialized tracking and humidity-controlled packaging for corrosion-prone materials.

Material capabilities are maintained through our controlled parameter database. Key performance metrics include:

| Material Category | Max Thickness | Standard Tolerance | Critical Feature Tolerance |

|---|---|---|---|

| Metals (Steel, Aluminum, Titanium) | 6.0 inches | ±0.008″ | ±0.003″ (with taper correction) |

| Composites (CFRP, GFRP) | 4.0 inches | ±0.010″ | ±0.005″ |

| Ceramics & Glass | 1.5 inches | ±0.015″ | ±0.008″ |

| Plastics (PEEK, Acetal) | 3.0 inches | ±0.007″ | ±0.004″ |

This closed-loop process ensures first-pass yield rates exceeding 92% while maintaining repeatability essential for aerospace, medical, and semiconductor clients requiring certified dimensional accuracy. Continuous feedback from production metrology data refines our AI models, driving annual capability improvements.

Start Your Project

For precision waterjet cutting services you can rely on, partner with Honyo Prototype. Our advanced waterjet technology delivers clean, accurate cuts for a wide range of materials—ideal for prototypes and production runs alike.

Located in Shenzhen, our modern facility ensures fast turnaround and strict quality control for every project.

Contact Susan Leo today to discuss your requirements or request a quote.

Email: [email protected]

Let us bring your designs to life with unmatched accuracy and professionalism.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.